Process for preparing low-temperature phase barium metaborate monocrystalline film through magnetron sputtering

A technology based on barium metaborate and single crystal thin film, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., and can solve the problems of growth period as long as 1 to 3 months, low mechanical strength, group velocity mismatch, etc. Achieve good economic benefits and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

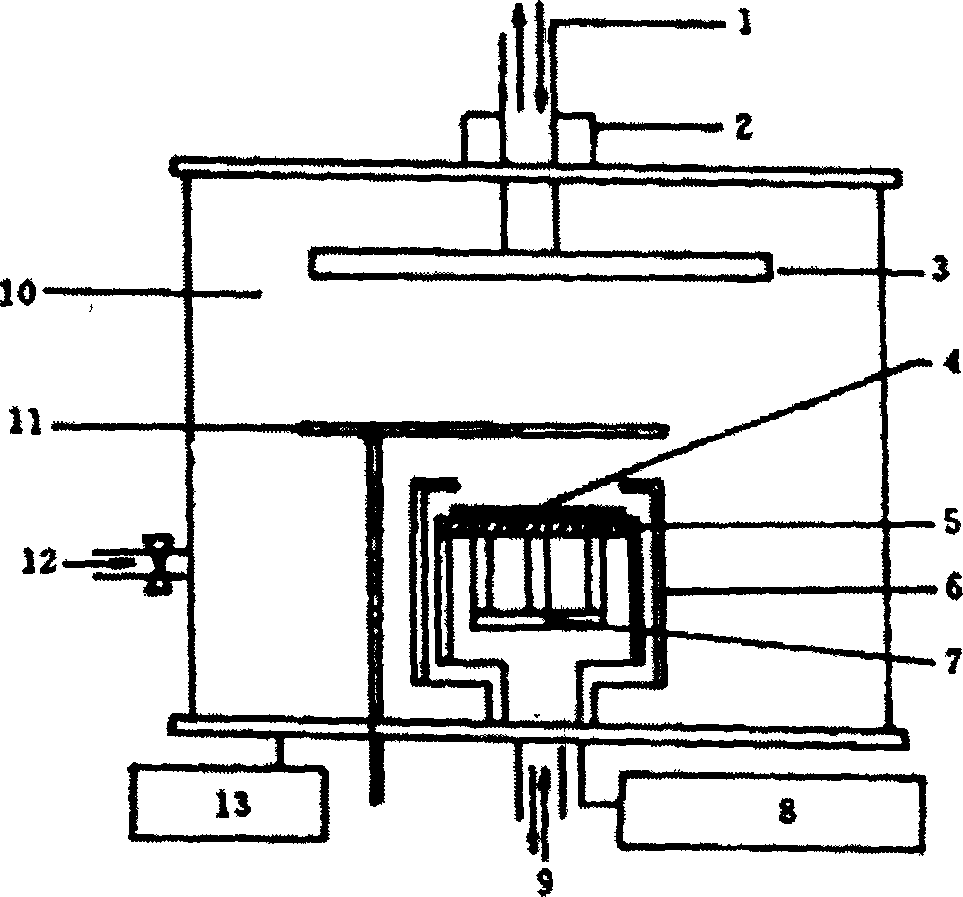

Method used

Image

Examples

Embodiment 1

[0017] Preparation of β-BBO film on α-BBO single crystal substrate: use β-BBO ceramics as the target material, the target diameter is 85mm, the thickness is 3mm, and the polished and cleaned α-BBO single crystal substrate is sent into RF magnetron sputtering device, the substrate is a double-sided polished α-BBO single wafer, and the substrate temperature is room temperature. The indoor vacuum degree of the radio frequency magnetron sputtering device is 3×10 -4 Pa, the power used is 500W, and the RF sputtering time is 2 hours;

[0018] Then put the β-BBO / α-BBO sample obtained in the above step into an annealing furnace, raise the temperature to 600°C, keep the temperature constant for 3 hours, the heating rate is 10°C / h, and the cooling rate is 10°C / h.

[0019] The X-ray diffraction and twin crystal rocking curve analysis of the prepared β-BBO / α-BBO samples showed that the β-BBO film grown on the (001)α-BBO substrate had a highly preferred orientation in the c-axis direction...

Embodiment 2

[0021] Preparation of β-BBO thin film on α-BBO single crystal substrate: use β-BBO single crystal as target material, target diameter is 85mm, thickness 3mm, polished and cleaned α-BBO single crystal substrate Send it into a radio frequency magnetron sputtering device, the substrate is a double-sided polished α-BBO single wafer, and the substrate temperature is room temperature. The indoor vacuum degree of the radio frequency magnetron sputtering device is 3×10 -4 Pa, the power used is 500W, and the time is 2 hours.

[0022] Then put the β-BBO / α-BBO sample obtained in the above step into an annealing furnace, raise the temperature to 700°C, keep the temperature constant for 3 hours, the heating rate is 30°C / h, and the cooling rate is 30°C / h.

[0023] The X-ray diffraction and twin crystal rocking curve analysis of the prepared β-BBO / α-BBO samples showed that the β-BBO film grown on the (001)α-BBO substrate had a highly preferred orientation in the c-axis direction, Twin cry...

Embodiment 3

[0025] Preparation of β-BBO thin film on α-BBO single crystal substrate: use β-BBO single crystal as target material, target diameter is 85mm, thickness 3mm, polished and cleaned α-BBO single crystal substrate Send it into a radio frequency magnetron sputtering device, the substrate is a double-sided polished α-BBO single wafer, and the substrate temperature is room temperature. The indoor vacuum degree of the radio frequency magnetron sputtering device is 2×10 -4 Pa, the power used is 500W, and the time is 2 hours.

[0026] Then put the β-BBO / α-BBO sample obtained in the above step into an annealing furnace, raise the temperature to 500°C, keep the temperature constant for 10h, the heating rate is 100°C / h, and the cooling rate is 100°C / h.

[0027] The prepared β-BBO / α-BBO samples were tested, and the results showed that β-BBO films were formed on (001)α-BBO substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com