Heavy oil processing method and system

A heavy oil and heavy oil cracking technology, applied in the petroleum industry, hydrotreating process, chemical instruments and methods, etc., can solve the problems of high investment and operating costs, high operating pressure, low coke utilization efficiency and benefits, etc., and achieve economic benefits. Better, less expensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

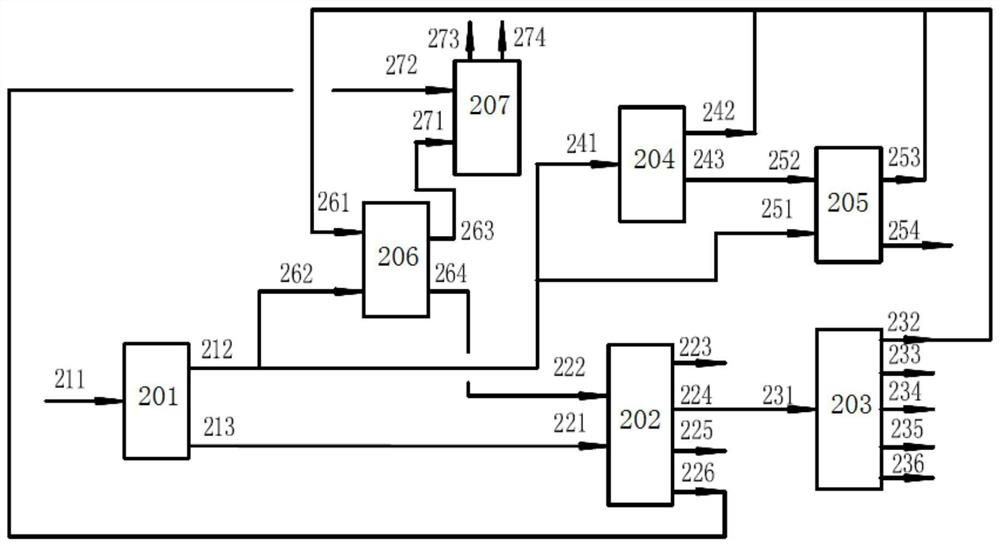

[0087] like figure 1 The heavy oil processing system shown includes:

[0088] Heavy oil cracking and gasification unit 201, pyrolysis oil hydrocracking unit 202, aromatics complex unit 203, methanol synthesis unit 204, ethanol synthesis unit 205, hydrogen production unit 206 including at least pressure swing adsorption equipment, sulfur recovery unit 207;

[0089] The heavy oil cracking and gasification device 201 includes a heavy oil inlet 211, a cracked gas outlet 212, and a cracked oil outlet 213;

[0090] The pyrolysis oil hydrocracking unit 202 includes a cracking oil hydrocracking unit raw material inlet 221, a cracking oil hydrocracking unit hydrogen inlet 222, a light naphtha outlet 223, a heavy naphtha outlet 224, a diesel outlet 225, and a pyrolysis oil hydrocracking unit. Device impurity outlet 226,

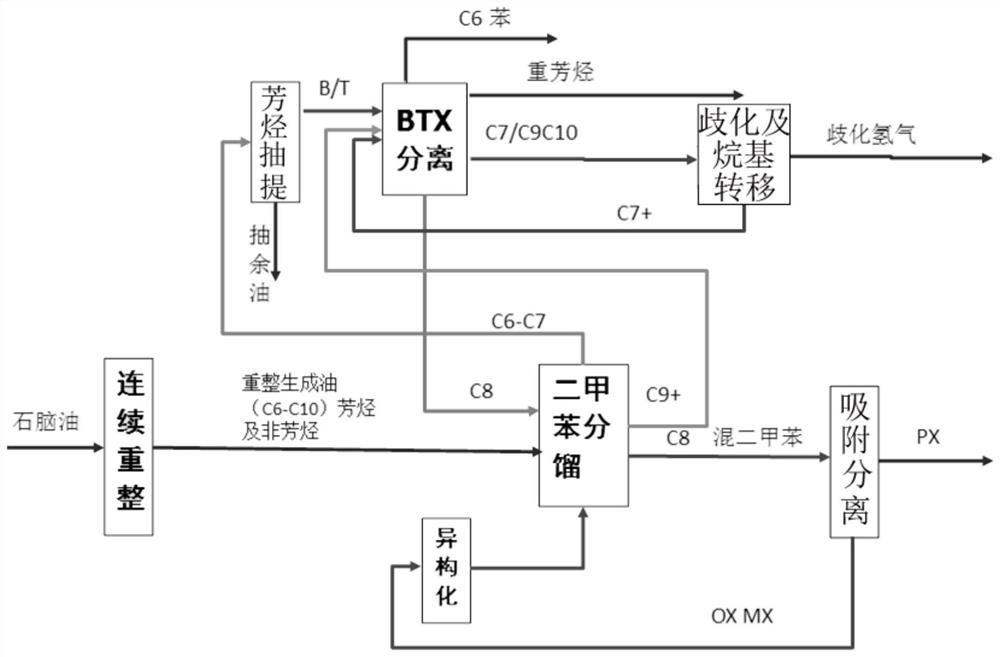

[0091] The aromatics complex 203 includes an aromatics complex raw material inlet 231 , an aromatics complex hydrogen outlet 232 , a by-product outlet 233 , a benze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com