Processing Technology of 5083-o Aluminum Alloy Door

A processing technology, aluminum alloy technology, applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problem of low processing success rate, achieve the effect of simple tooling, reduce requirements, and reduce part deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

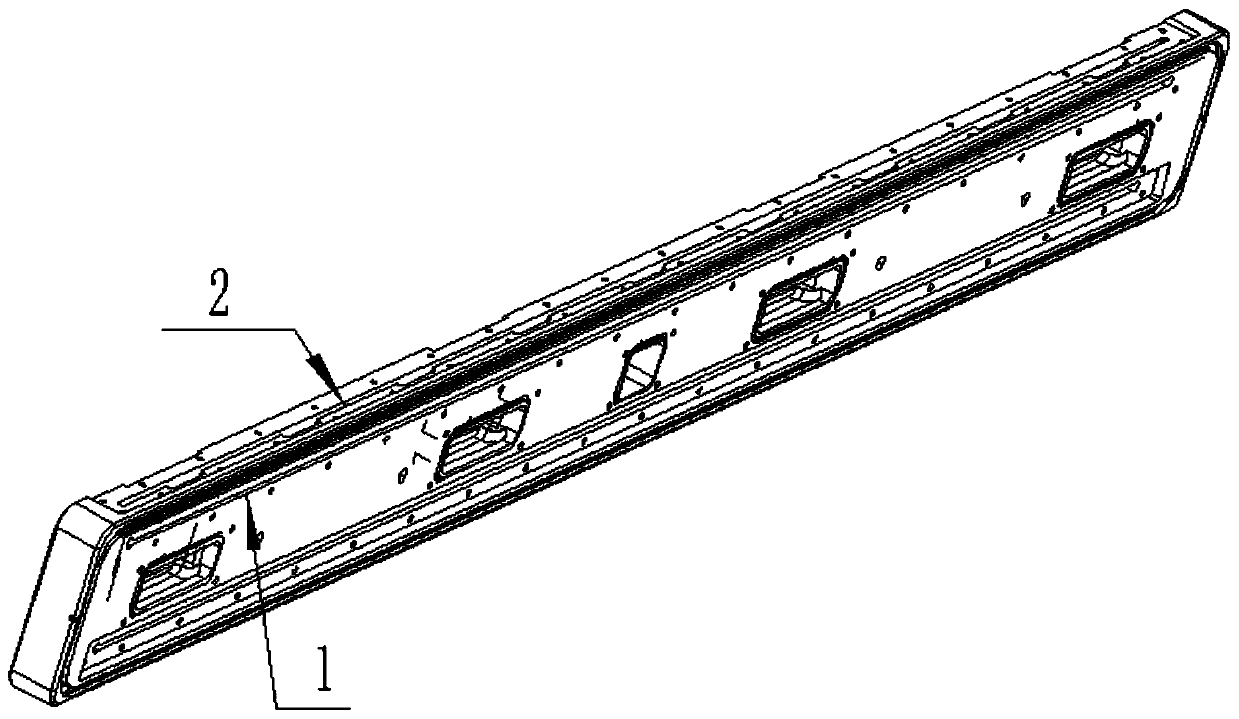

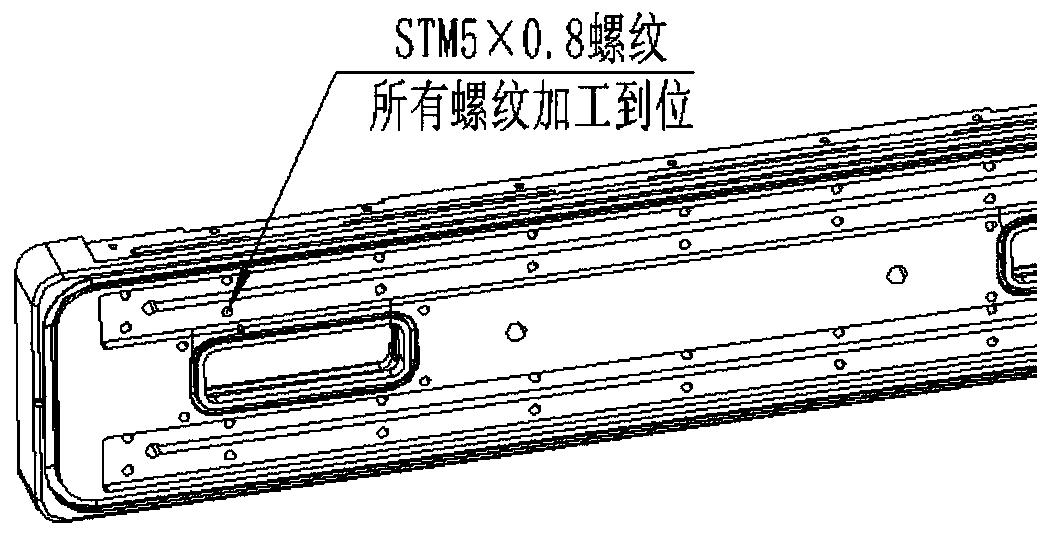

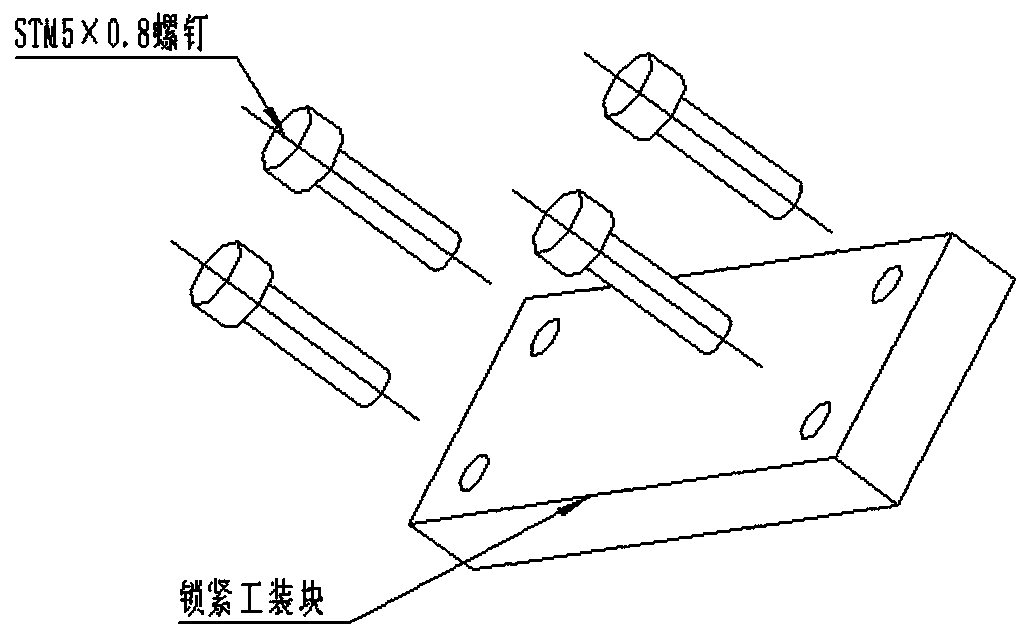

[0039] A real picture of 5083-O aluminum alloy door figure 1 As shown, the width 5±0.2mm of the front groove 1 position and the width 5±0.2mm of the side deep groove 2 are completely penetrated. If there is no effective process plan during processing, the tool will tremble directly during the processing of the part, and the part will be scrapped. Before processing the deep groove on the side, figure 2 The front groove in the partially enlarged picture is processed to the required size, and the STM5X0.8 threads on both sides of the front groove are processed for use. Made in advance image 3 The matching screw STM5X8 and the matching locking tooling block for conversion as shown. press Figure 4 As shown, use STM5X8 screws to tighten each tooling block on the machined STM5X8 threads on the front face, evenly distribute and lock, effectively support, fix, and process parts. During the machining process, aluminum chips will flow out from the gap with the cutting fluid. The parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com