Scratch-resistant PVC film and preparation method thereof

A scratch-resistant and scratch-resistant technology, applied in the field of polyvinyl chloride, can solve the problems of uneven performance of PVC film and cannot meet the scratch-resistant requirements of writing boards, and achieve the effect of reducing residues, reducing dosage, and overcoming processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

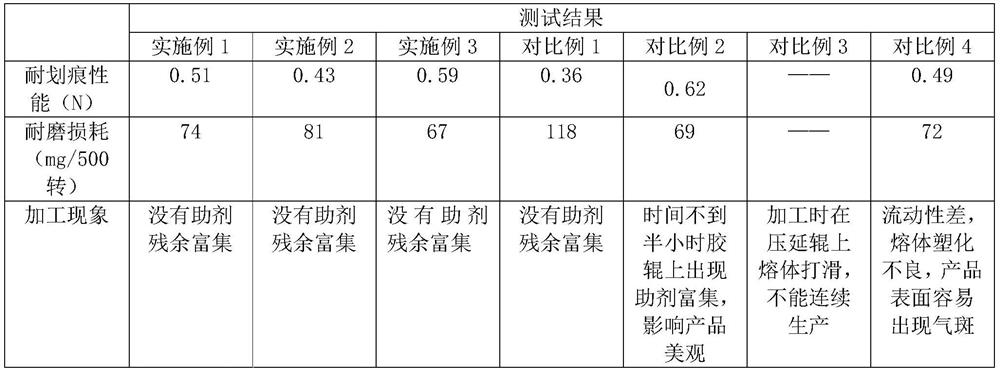

Examples

Embodiment 1

[0033] A scratch-resistant PVC film, comprising the following raw materials in parts by weight:

[0034] 100 parts of PVC powder, 5 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol ester, 0.6 parts of styrene-acrylic resin, 5 parts of diisononyl phthalate, wear-resistant agent 1.3 parts, 3.5 parts of barium zinc stabilizer, 5 parts of MBS, 0.2 parts of fatty acid ester, 0.3 parts of calcium stearoyl lactylate and 1.5 parts of acrylate additives; the wear-resistant agent model is Yuchuan Materials Co., Ltd., Shunde District, Foshan City The anti-wear agent VS-5350 produced by the company.

Embodiment 2

[0036] A scratch-resistant PVC film, comprising the following raw materials in parts by weight:

[0037] 100 parts of PVC powder, 4 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol ester, 0.2 parts of styrene-acrylic resin, 15 parts of dioctyl terephthalate, 1.5 parts of wear-resistant agent 2 parts, 2 parts of organotin, 2 parts of nitrile rubber, 0.1 part of fatty acid ester, 0.1 part of calcium stearoyl lactylate, and 0.8 part of acrylate additives; the wear-resistant agent model is Dow Corning DC-51.

Embodiment 3

[0039] A scratch-resistant PVC film, comprising the following raw materials in parts by weight:

[0040]100 parts of PVC powder, 7 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol ester, 1 part of styrene-acrylic resin, 10 parts of epoxy soybean oil, 2 parts of anti-wear agent, calcium 4 parts of zinc stabilizer, 10 parts of SEBS, 0.5 part of fatty acid ester, 0.5 part of sodium stearoyl lactylate and 2.5 parts of acrylate additives;

[0041] Wherein the wear-resistant agent is a product produced by Dongguan Hongfu Chemical Co., Ltd., and the model is wear-resistant agent T-85.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com