Patents

Literature

36results about How to "Increase the serving size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green extraction process for artemisinin

The invention discloses a green extraction process for artemisinin, and relates to the field of drug production. The process comprises the following steps: (1) drying of raw materials, that is, putting the raw materials into drying equipment for drying; (2) primary processing of artemisinin, that is, putting the dried raw materials into an extraction tank, adding petroleum ether, heating the extraction tank, carrying out countercurrent extraction, allowing the extract to flow out from the extraction tank, standing the extract to obtain a supernatant, allowing the supernatant to pass through asilica gel column, eluting the silica gel column with petroleum ether, collecting artemisinin fractions, putting the artemisinin fractions into a concentrating tank for concentration until crystals are precipitated, putting the obtained concentrate into a crystallizing tank for crystallization, carrying out filtering to obtain crystals, and drying the crystals so as to obtain crude products of artemisinin; (3) refining of artemisinin, that is, dissolving the crude products of artemisinin in an alcohol precipitating tank with ethanol, wherein the ethanol with a concentration of 93 to 95% is 65to 75 times the amount of the crude products, standing the solution, taking the supernatant of the solution for secondary filter, concentrating the filtrate in the concentrating tank, standing the concentrate for crystallization, carrying out filtering to obtain crystals, and drying the crystals under vacuum so as to obtain refined products of artemisinin.

Owner:GUANGXI XIANCAOTANG PHARMA

Extraction technology of artemisinin

The invention relates to an extraction technology of artemisinin, and belongs to the technical field of natural plant extraction. The extraction technology comprises the following steps: (1) drying raw materials: putting the raw materials in a drying facility to dry the raw materials; (2) primary preparation of artemisinin: putting the dried raw materials in an extraction tank, adding petroleum ether into the extraction tank, heating, carrying out reflux extraction, discharging the liquid extract from the extraction tank after the reflux extraction, allowing the liquid extract to stand still for a while, collecting the supernate, making the supernate go through a silica gel column, then washing the silica gel column by petroleum ether, collecting the fractions containing artemisinin, transferring the fractions to a condensing tank, condensing the fractions, transferring the condensed liquid to a crystallization tank when the liquid in the condensing tank start to crystallize, carrying out crystallization in the crystallization tank, filtering to obtain the crystals, and drying the crystals so as to obtain crude artemisinin; (3) artemisinin refinement: placing the crude artemisinin in an alcohol-precipitation tank, dissolving the crude artemisinin by ethanol with a concentration of 85-95%, wherein the volume of the ethanol is 60 to 70 times of that of the crude artemisinin, allowing the solution to stand still for a while, collecting the supernate, subjecting the supernate to fine filtration, transferring the filtrate to a condensing tank, condensing the filtrate, allowing the condensed filtrate to stand still so as to carry out crystallization, filtering to obtain the crystals, and finally drying the crystals in vacuum so as to obtain refined artemisinin.

Owner:QINGDAO ZHONGREN ZHIYE BIOTECH

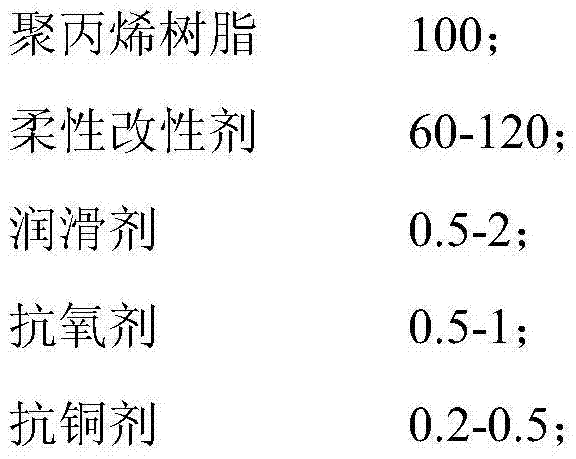

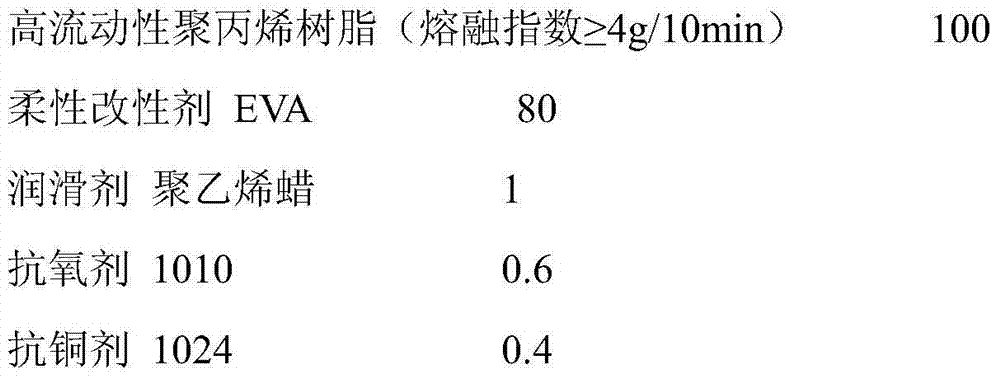

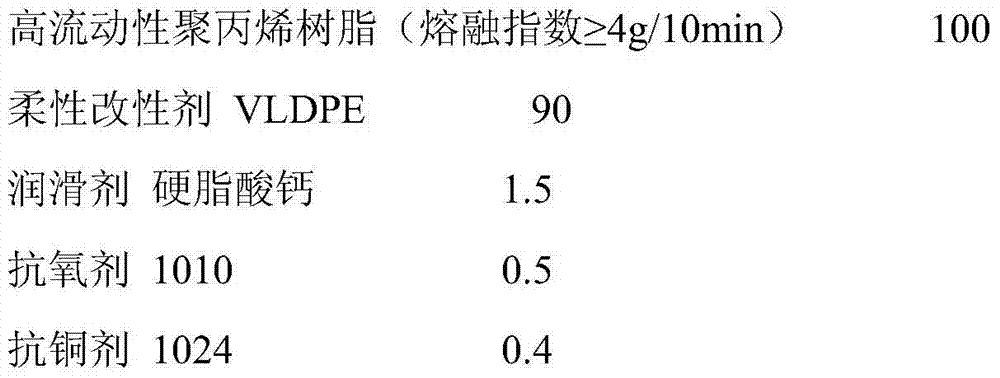

Flexible polypropylene cable sheath material

InactiveCN104744807AGood flexibilityImproves stress whiteningPlastic/resin/waxes insulatorsEngineeringCopper

The invention relates to a flexible polypropylene cable sheath material. The material comprises the following components by weight: 100 parts of polypropylene resin, 60 to 120 parts of a flexible modifier, 0.5 to 2 parts of a lubricant, 0.5 to 1 part of an anti-oxidant and 0.2 to 0.5 part of an anti-copper agent. The flexible polypropylene cable sheath material has good low temperature resistance and flexibility and can effectively improve original stress whitening of a polypropylene cable material and enhance low temperature resistance of the polypropylene cable material.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

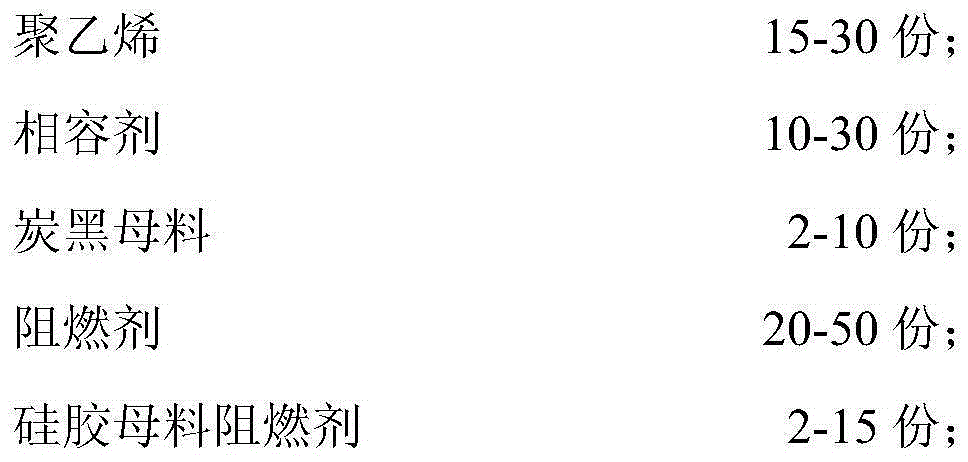

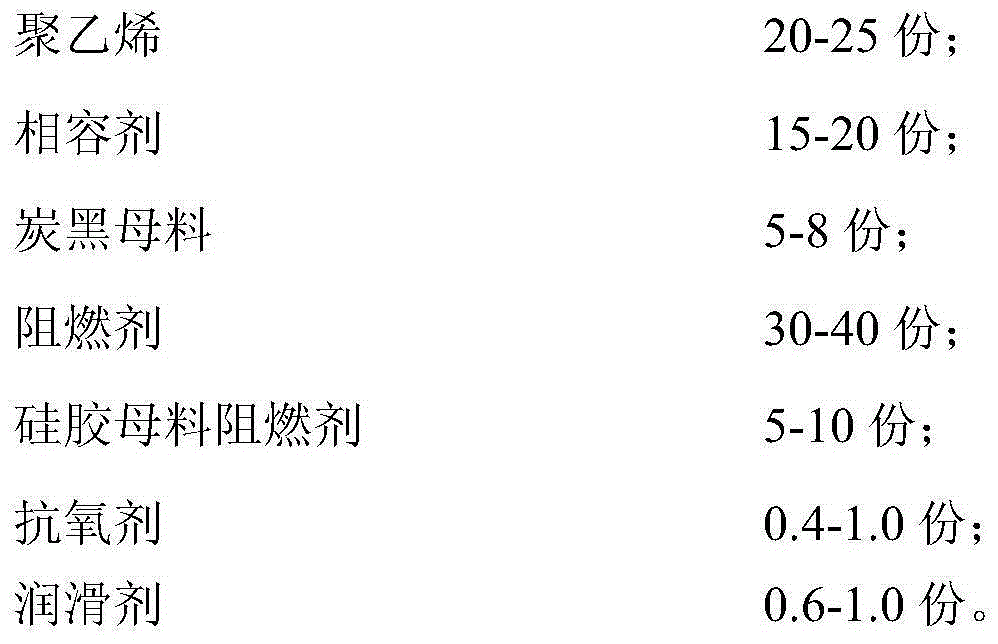

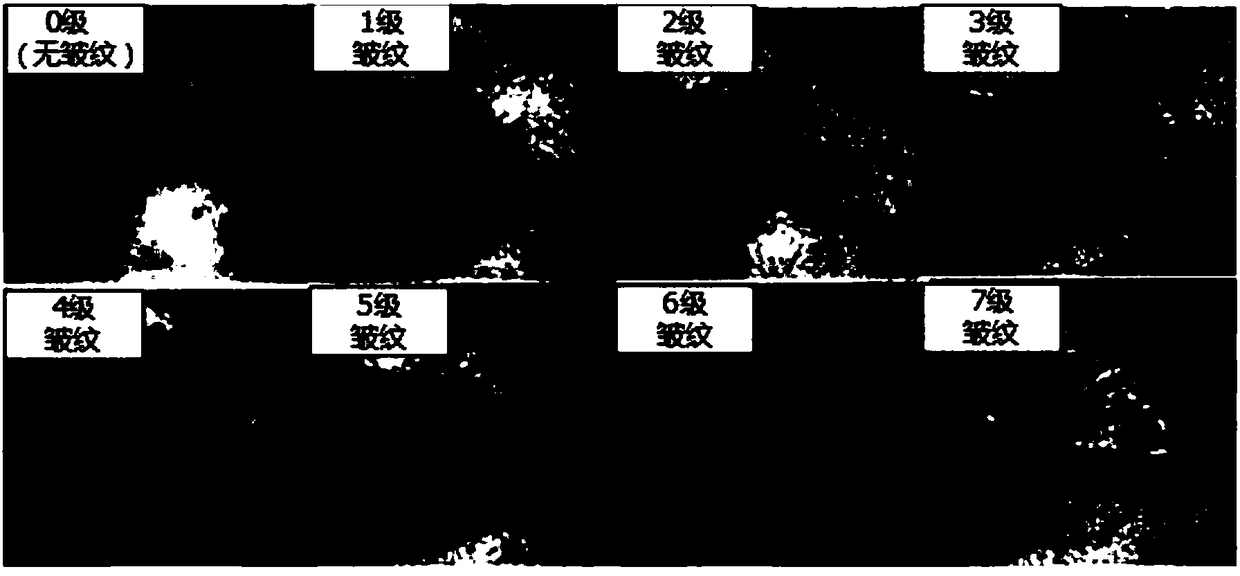

Low-cost anti-cracking flame-retardant polyethylene cable material and preparation method thereof

The invention provides a low-cost anti-cracking flame-retardant polyethylene cable material, which comprises the following components by weight: 15-30 parts of polyethylene resin; 10-30 parts of a compatilizer; 2-10 parts of carbon black masterbatch; 20-50 parts of a flame retardant; 2-15 parts of a silica gel masterbatch flame retardant; 0.2-2.0 parts of an antioxidant; and 0.2-2.0 parts of a lubricant. The invention further provides a preparation method of the low-cost anti-cracking flame-retardant polyethylene cable material. The low-cost anti-cracking flame-retardant polyethylene cable material provided by the invention has the advantages of low cost, n halogen, lead or other heavy metals, and good mechanical properties, processability, cracking resistance and flame retardance, also the prepared cable has smooth surface, thus being suitable for medium and low voltage, ultrahigh pressure of various specifications.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

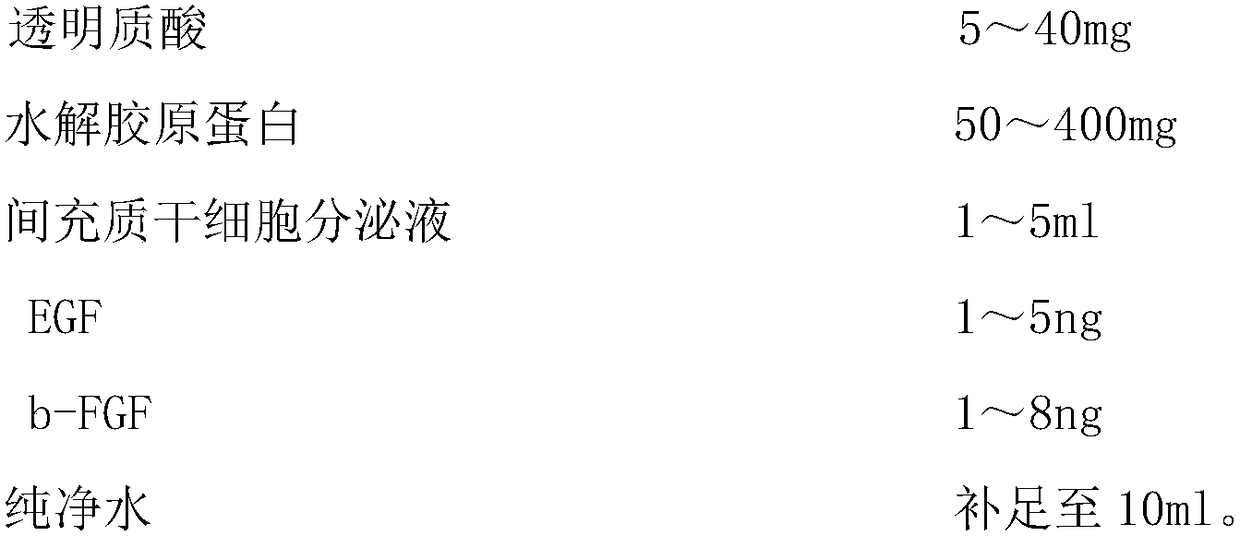

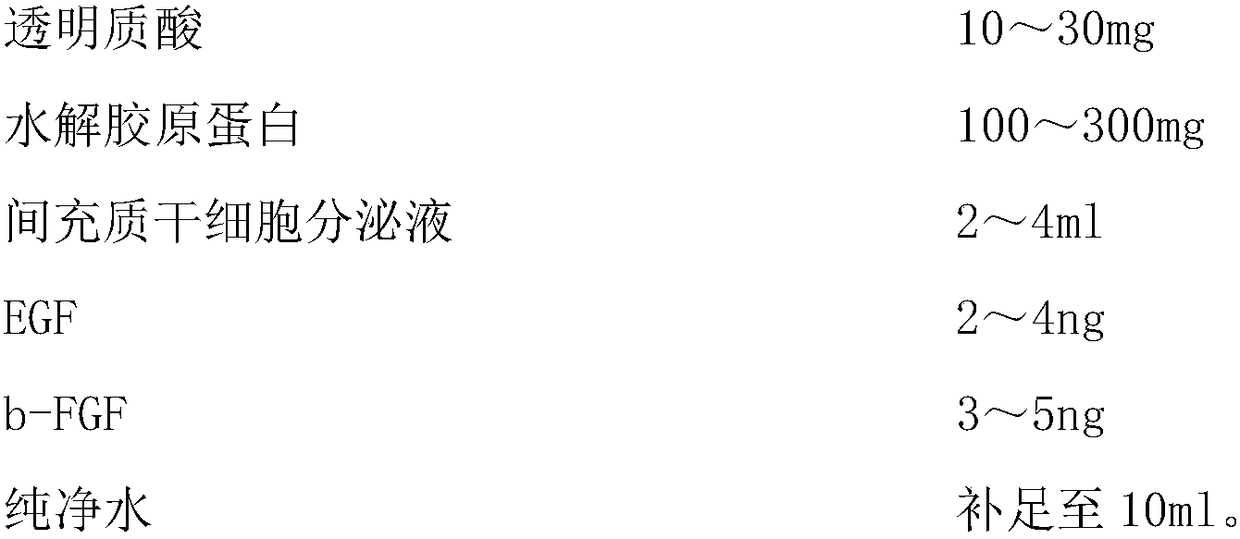

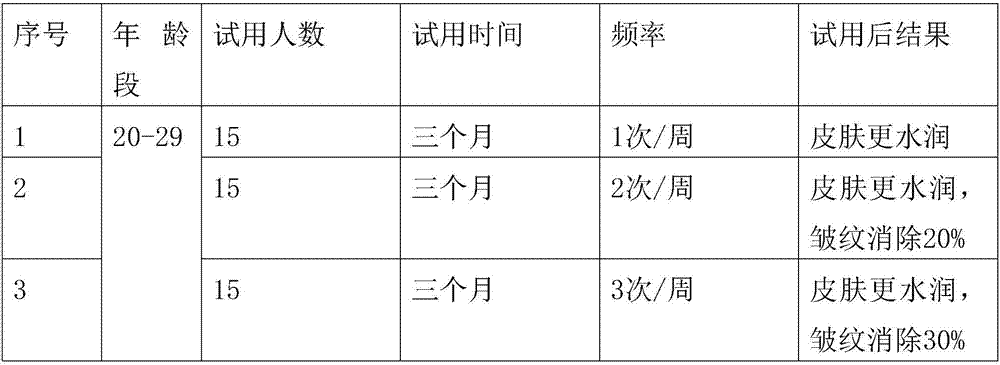

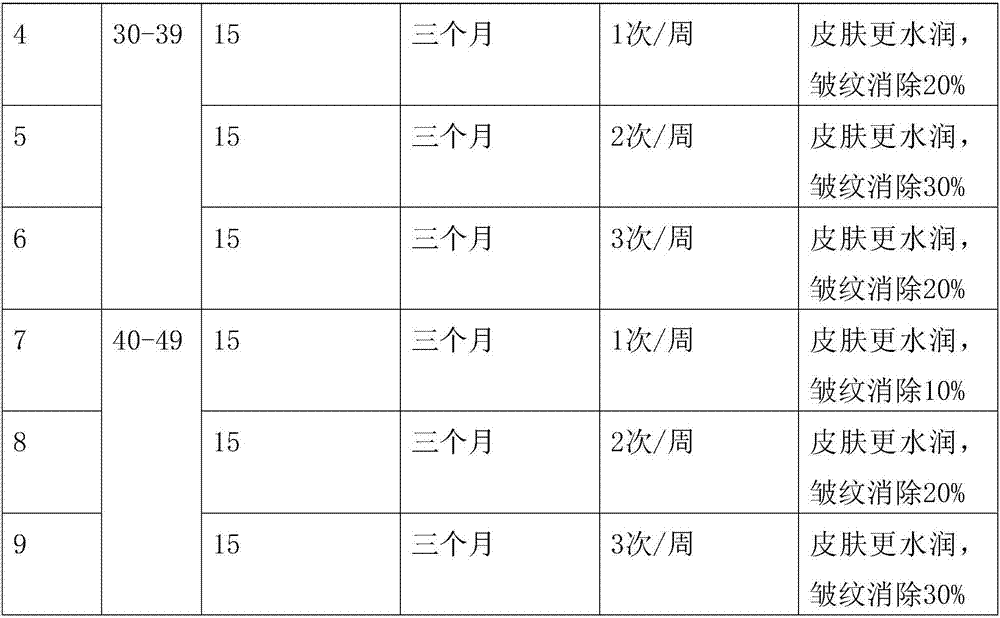

Skin anti-ageing composition

InactiveCN109125246AEnergeticEfficient regenerationCosmetic preparationsToilet preparationsWrinkle skinAdditive ingredient

The invention relates to a skin anti-ageing composition, in particular to a skin care product containing kinds of biological factors, and belongs to the fields of cosmetics and biotechnologies. Every10 ml of composition is composed of, by content, 5-40 mg of transparent hyaluronic acid, 50-400 mg of hydrolyzed collagen, 1-5 ml of mesenchymal stem cell secretion, 1-5 ng of EGF, 1-8 ng of b-FGF1 and 10 ml of sufficiently-supplemented purified water. The skin anti-ageing composition has the advantages that a formula is safe and effective, there are no allergic substances and preservative, ageingresistance and wrinkle removal are effective, the premature ageing of the skin is improved greatly, meanwhile, it is avoided that nutrition excess makes the skin burdened, and new skin problems appear, and the skin anti-ageing composition is particularly suitable for allergic skin.

Owner:灏灵赛奥(天津)生物科技有限公司

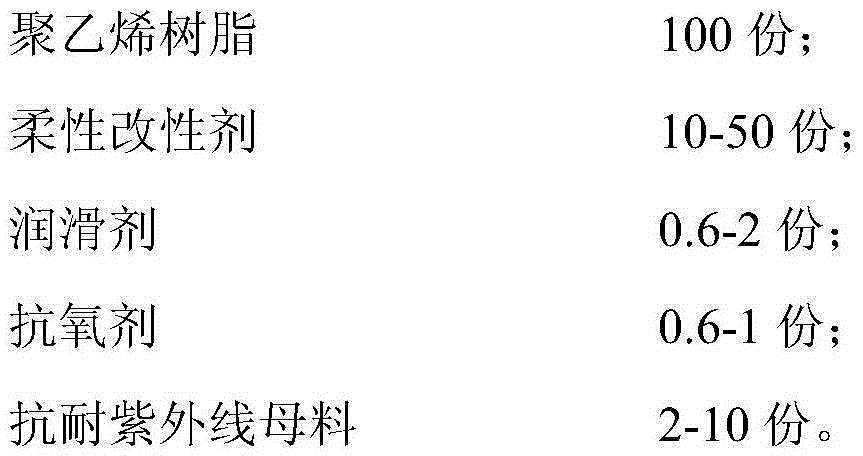

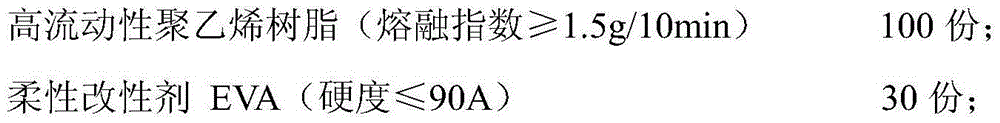

Soft polyethylene cable sheath material and preparation method thereof

ActiveCN105778206AGood flexibilityImprove brittlenessPlastic/resin/waxes insulatorsInsulated cablesMasterbatchAntioxidant

The invention provides a soft polyethylene cable sheath material. The material comprises the components of, by weight, 100 parts of polyethylene resin, 10-50 parts of a flexibility modifier, 0.6-2 parts of a lubricant, 0.6-1 part of an antioxidant, and 2-10 parts of a UV-resistant masterbatch. The invention further provides a preparation method of the soft polyethylene cable sheath material. The soft polyethylene cable sheath material provided by the invention has good flexibility. Original characteristics of brittleness and bending difficulty of a polyethylene cable material can be effectively ameliorated, such that the application range of polyethylene cable material can be effectively expanded. Therefore, market value of the polyethylene cable material can be improved.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Processing method for preparing lactic acid honey

The invention discloses a processing method for preparing lactic acid honey. The method comprises the following steps of: preparing lactic acid bacteria strain solution, disinfected liquefied honey and sterile water respectively, and mixing the three to prepare fermentation mother liquor A and fermentation mother liquor B, wherein the liquor A contains 20 to 25 percent of disinfected liquefied honey and the liquor B contains 5 to 25 percent of disinfected liquefied honey. After the fermentation of the fermentation mother liquor, the liquor B is lactic acid honeydew health-care beverage of a second terminal product. The liquor A is processed with honey increment, secondary fermentation, sterilization, concentration and the like to obtain transparent liquid colloidal lactic acid honey health-care food of a first terminal product. Through fermentation of lactic acid, sugar in the honey is transformed into the lactic acid, trace nutritional components are preserved, and multiple new nutritional substances such as enzyme, oligosaccharide, polysaccharide, complex carbohydrate and the like are produced at the same time. The method produces good biological preservative effect by using the bacteriostatic effect of the lactic acid, and does not need to add any preservative.

Owner:才玉山

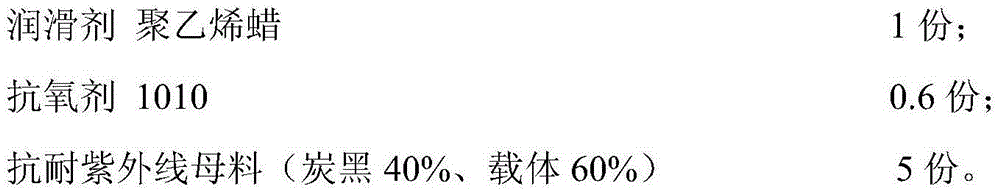

Ultrasonic atomization pyrolytic deposition device and method for preparing thin film by using device

ActiveCN108385089AHigh-quality and uniform growth processHigh-quality uniform processChemical vapor deposition coatingTemperature controlGas phase

The invention relates to an ultrasonic atomization pyrolytic deposition device and a method for preparing a thin film by using the device. The device comprises a gas phase growing agent producing chamber and a pyrolytic deposition thin film growing chamber. The gas phase growing agent producing chamber comprises an atomizing box, an atomizing bottle, an ultrasonic atomization oscillator, a carriergas inflow pipe and a carrier gas outflow pipe; the carrier gas inflow pipe and the carrier gas outflow pipe are adjustable relative to each other at the pipe opening position in the atomizing bottlein the height direction; the ultrasonic atomization oscillator is fixed in the atomizing box; and the atomizing bottle is placed on the ultrasonic atomization oscillator. The pyrolytic deposition thin film growing chamber comprises a conical growing bin and a temperature control heating device; and a thin film growing substrate is arranged at the bottom of a bin cavity of the conical growing bin,and a rectifying device is arranged at the position, close to the top, in the bin cavity. Due to the device and the method, the transparent and uniform thickness thin film can be made, a growing source for use is low in price, the process is simple, and the preparing period is short.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES +1

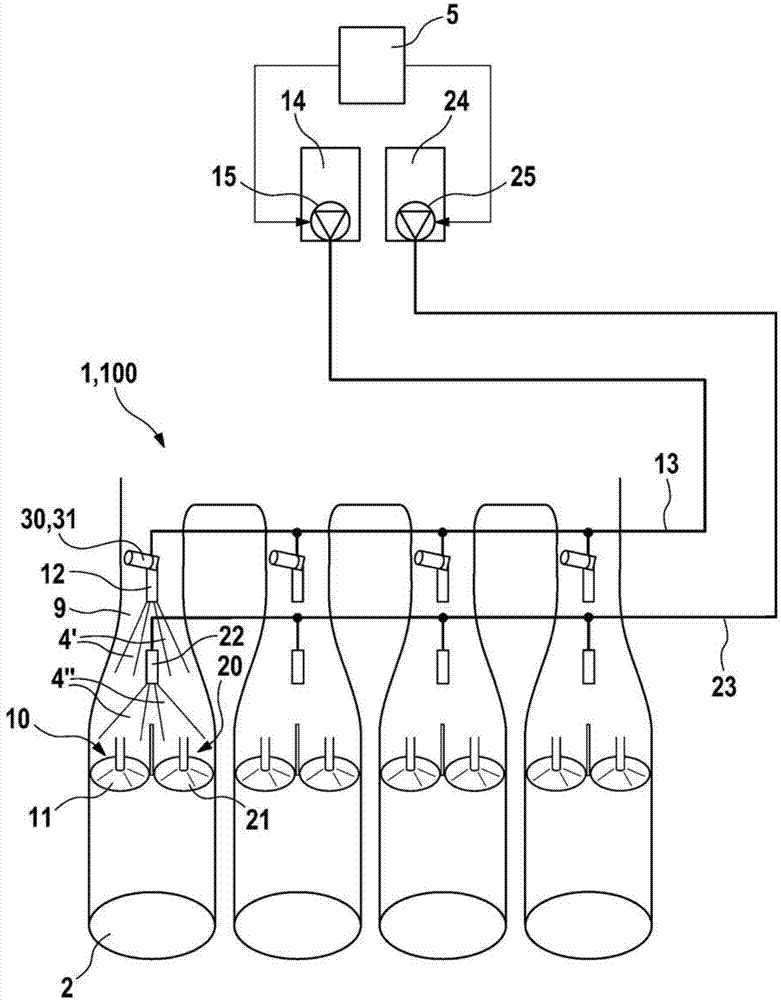

Injection device, internal combustion engine, and method for operating an internal combustion engine

InactiveCN103717858AEmission reductionBurn fullyElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

Owner:ROBERT BOSCH GMBH

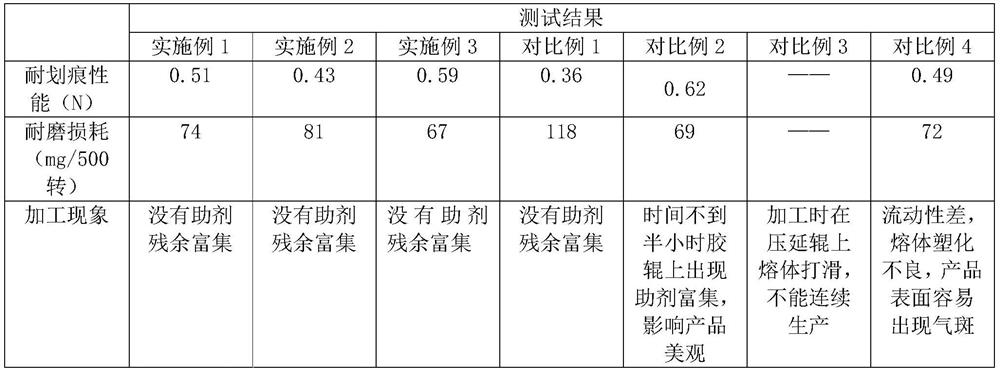

Scratch-resistant PVC film and preparation method thereof

ActiveCN112143135AOvercome processing difficultiesReduce dosageWriting boardsPolymer chemistryPlasticizer

The invention relates to the field of polyvinyl chloride, particularly to a scratch-resistant PVC film and a preparation method thereof. The PVC film is prepared from the following raw materials in parts by weight: 100 parts of PVC powder, 2-8 parts of a scratch-resistant modifier, 0.2-1.0 part of a slipping processing aid, 5-15 parts of a plasticizer, 0.8-2 part of a wear-resistant agent, 2-4 parts of a stabilizer, 2-10 parts of an impact modifier, 0.1-0.5 part of an external lubricant, 0.1-0.5 part of a lubricant and 0.8-2.5 parts of an aid. According to the invention, by adding the wear-resistant agent, the scratch-resistant effect is achieved, the precipitation of the rubber flower roller is reduced, and the processing technology difficulty caused by adding the wear-resistant agent inthe prior art is overcome.

Owner:GUANGDONG TIANAN NEW MATERIAL

High-purity hyaluronic acid luster-effect skin-renewing essence

ActiveCN107468629ANourishingGood moisturizing effectCosmetic preparationsToilet preparationsJojoba oilGlycerol

The invention discloses high-purity hyaluronic acid luster-effect skin-renewing essence. The high-purity hyaluronic acid luster-effect and skin-renewing essence is prepared from the following raw materials in parts by weight: 0.1 to 1 part of carbomer, 1 to 10 parts of glycerol, 1 to 10 parts of propylene glycol, 1 to 10 parts of jojoba oil, 0.1 to 1 part of triethanolamine, 0.1 to 5 parts of vitamin E, 0.05 to 1 part of sodium hyaluronate, 0.1 to 1 part of Germaben-II, 0.1 to 3 parts of polydimethylsiloxane, 0.1 to 1 part of allantoin, 1 to 10 parts of an aloe extracting solution, 8 to 15 parts of an earthworm extracting solution, 0.05 to 0.5 part of a flavoring agent and 10 to 100 parts of pure water. The essence disclosed by the invention has remarkable moisture-keeping, nourishing and anti-oxidization effects.

Owner:HUBEI MULAN TONGDA TECH

Meltblown composite non-woven anti-wrinkle mask containing plant fiber and preparation method of meltblown composite non-woven anti-wrinkle mask

InactiveCN107334722ARich in nutrientsImprove wrinkle resistanceCosmetic preparationsToilet preparationsBody shapePolyester

The invention discloses a melt-blown composite plant fiber non-woven fabric anti-wrinkle mask and a preparation method thereof, which is prepared from the following components according to the mass percentage: 40-60 parts of natural plant fiber, 20-50 parts of polyester, chitosan 15-35 parts of fiber, the preparation method is: mixing natural plant fiber, polyester, and chitosan fiber together to prepare mixed raw material; using a screw extruder to melt the mixed raw material into a melt; The fibers are formed by fine flow cooling, drafting and shaping; the fibers are passed through the diffusion air duct, so that the fibers are evenly adsorbed on the web-forming conveyor belt, forming a continuous mesh fiber layer; the continuous mesh fiber layer is prepared by using a hot rolling mill. Non-woven fabric; soak the prepared non-woven fabric in silk protein solution; apply the nutrient solution on the non-woven fabric, and then attach plastic films with the same shape as the mask cloth on both sides of the non-woven fabric, seal Just pack it. The invention has the advantages of obvious skin care effect, good anti-wrinkle effect and the like.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

Plant essence facial care solution and preparation method thereof

InactiveCN110151662AImprove nutrient metabolismIncrease elasticityCosmetic preparationsToilet preparationsChemical synthesisWax

The invention discloses a plant essence facial care solution and a preparation method thereof. The solution is prepared from, by weight, 5-10 parts of a peach kernel extracting solution, 5-10 parts ofa wax gourd seed extracting solution, 6-15 parts of honey, 3-6 parts of a green tea extracting solution, 2-4 parts of a cactus extracting solution, 0.2-1 part of rose essential oil, 0.5-1 part of macromolecule hyaluronic acid powder and 15-30 parts of a tremella leaching agent. Various plant raw materials are adopted for extraction, the raw materials are medicinal and edible dual-purpose plants basically, the ingredients are adjuvant, the assistant and guide compatibility principle is adopted, the ingredients supplement each other, no other additive or chemical synthesis medicine is added, the safety is ensured, the solution can be used for a long time, the preparation method is simple, the effects are various, skin can be conditioned slowly, the solution has the functions of whitening, water supplementing, repairing and the like, and the using requirement is met.

Owner:中山市智辉科技服务有限公司

Medicated bag for conditioning and treating hypertension, and preparation method thereof

InactiveCN103479870AImprove myocardial functionEnhance physical fitnessFood preparationCardiovascular disorderSalvia miltiorrhizaMedicine

The invention provides a medicated bag for conditioning and treating hypertension, and a preparation method thereof. The medicated bag comprises the following drug substances in parts by weight according to the formula: 1-4 parts of radix ophiopogonis, 1-5 parts of membranous milkvetch roots, 2-10 parts of notoginseng, 2-10 parts of radix salviae miltiorrhizae, 2-8 parts of hawthorn fruit, 2-7 parts of boxthorn roots, 2-8 parts of cassia seeds, 2-10 parts of radix panacis quinquefoli, and 3-15 parts of fern root powder. The medicated tea can improve symptoms of patients with hypertension, has an obvious conditioning effect on various syndromes of hypertension, provides a reliable conditioning effect on patients who want to have safe diet therapies, can fill up domestic medicated food components, and improves functions of the medicated bag in the market.

Owner:廖昕琳

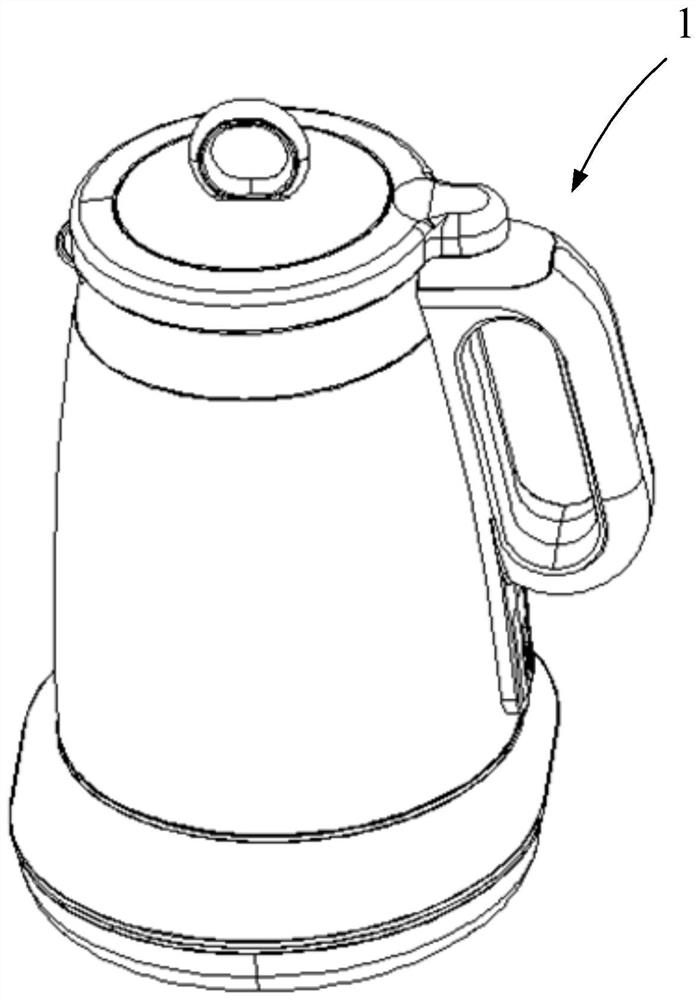

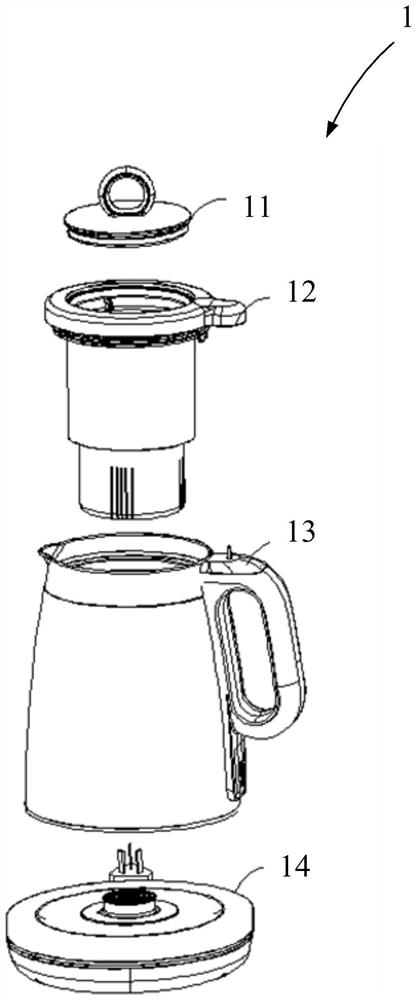

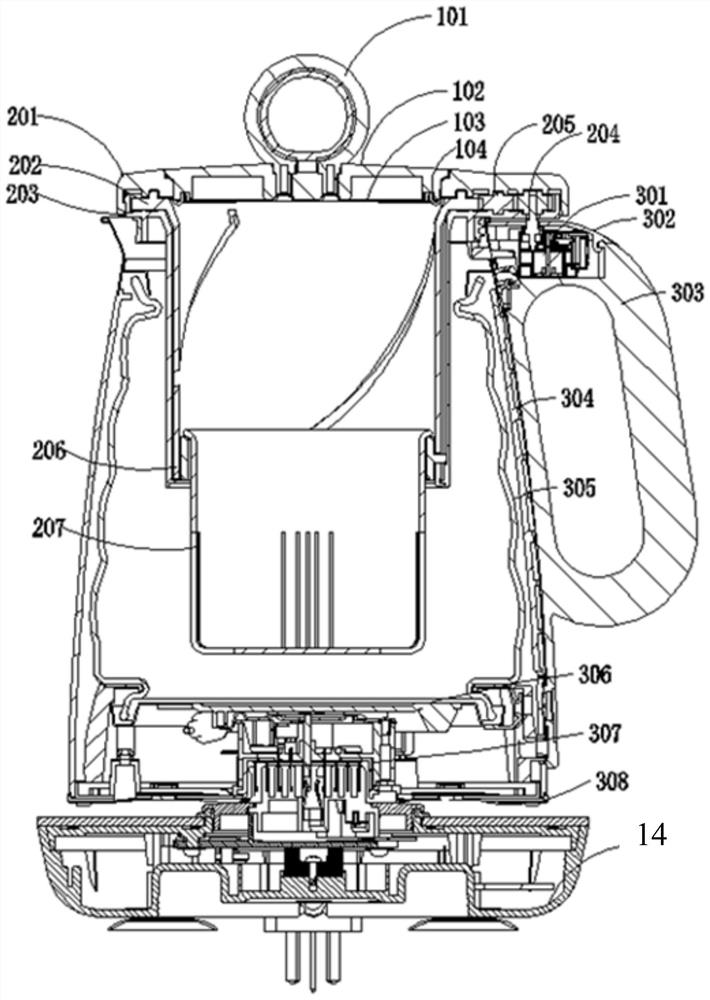

Brewing method and device of tea making container and tea making container

ActiveCN112826320AConcentration meetsIncrease concentrationBeverage vesselsProcess engineeringTea leaf

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

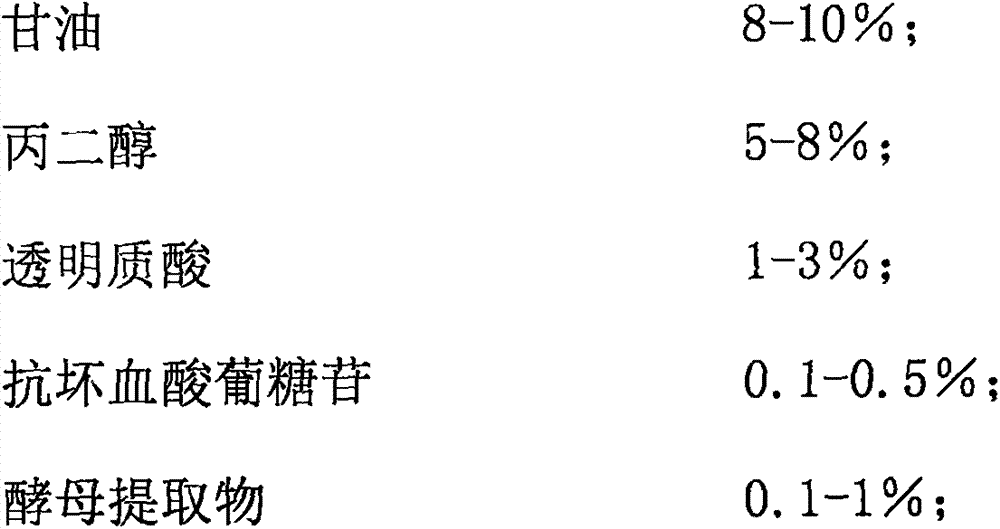

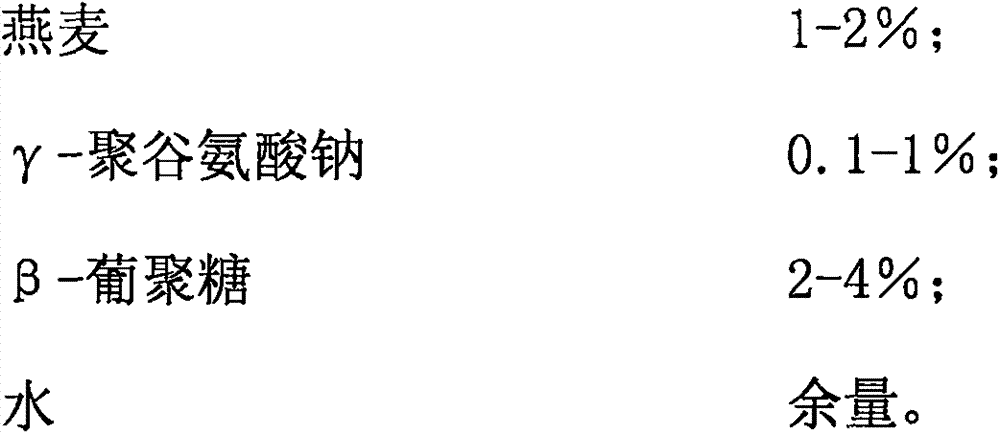

Cosmetic for rejuvenating skin and preserving moisture

InactiveCN107456409AImprove nutrient metabolismEasy nutrition metabolismCosmetic preparationsToilet preparationsGlycerolPropanediol

The invention discloses a cosmetic for rejuvenating skin and preserving moisture. The cosmetic consists of the following components in percentage by mass: 8-10% of glycerol, 5-8% of propanediol, 1-3% of hyaluronic acid, 0.1-0.5% of ascorbyl glucoside, 0.1-1% of a yeast extract, 1-2% of oat, 0.1-1% of [gamma]-sodium polyglutamate, 2-4% of [beta]-glucan and the balance of water. The cosmetic provided by the invention, by virtue of the low-molecular-weight hyaluronic acid and the ascorbyl glucoside which are mixed, can retain human body moisture and prevent water loss of a human body, and moisture retention and moisture preserving are synchronously implemented; with the use of the [beta]-glucan, a thin film is formed on the surface of the skin, so that a good wetting feeling of the skin is generated by the user; the damaged skin can be recovered to a state of being smooth, soft and bright; and the cosmetic has functions of rejuvenating skin and preserving moisture.

Owner:广州子弘生物科技有限公司

Green extraction process for artemisinin

ActiveCN102219790BReduce manufacturing costReduce contentOrganic chemistryAlcohol ethylPharmaceutical drug

The green artemisinin extraction process of the present invention relates to the field of pharmaceutical production, and the extraction process includes the following steps: (1) raw material drying treatment: putting the raw material into drying equipment for drying treatment; (2) initial preparation of artemisinin: Put the dried raw material into the extraction tank, add petroleum ether, heat countercurrent extraction, release the countercurrent extraction solution from the extraction tank, let the countercurrent extraction solution stand still, take the supernatant and let it pass through the silica gel column, and then elute with petroleum ether Silica gel column, collect artemisinin-containing fractions and concentrate them in a concentration tank. When crystals are precipitated in the concentration tank, put the concentrated solution in a crystallization tank for crystallization, filter out the crystals, and dry the crystals to obtain crude artemisinin; (3) Refining of artemisinin: Put the crude artemisinin in an alcohol precipitation tank, dissolve it with 65-75 times 93-95% ethanol and let it stand still, take the supernatant and filter it finely, put the filtrate in a concentration tank to concentrate and let it stand still Place crystals, filter out the crystals, and vacuum dry the crystals to obtain fine artemisinin.

Owner:GUANGXI XIANCAOTANG PHARMA

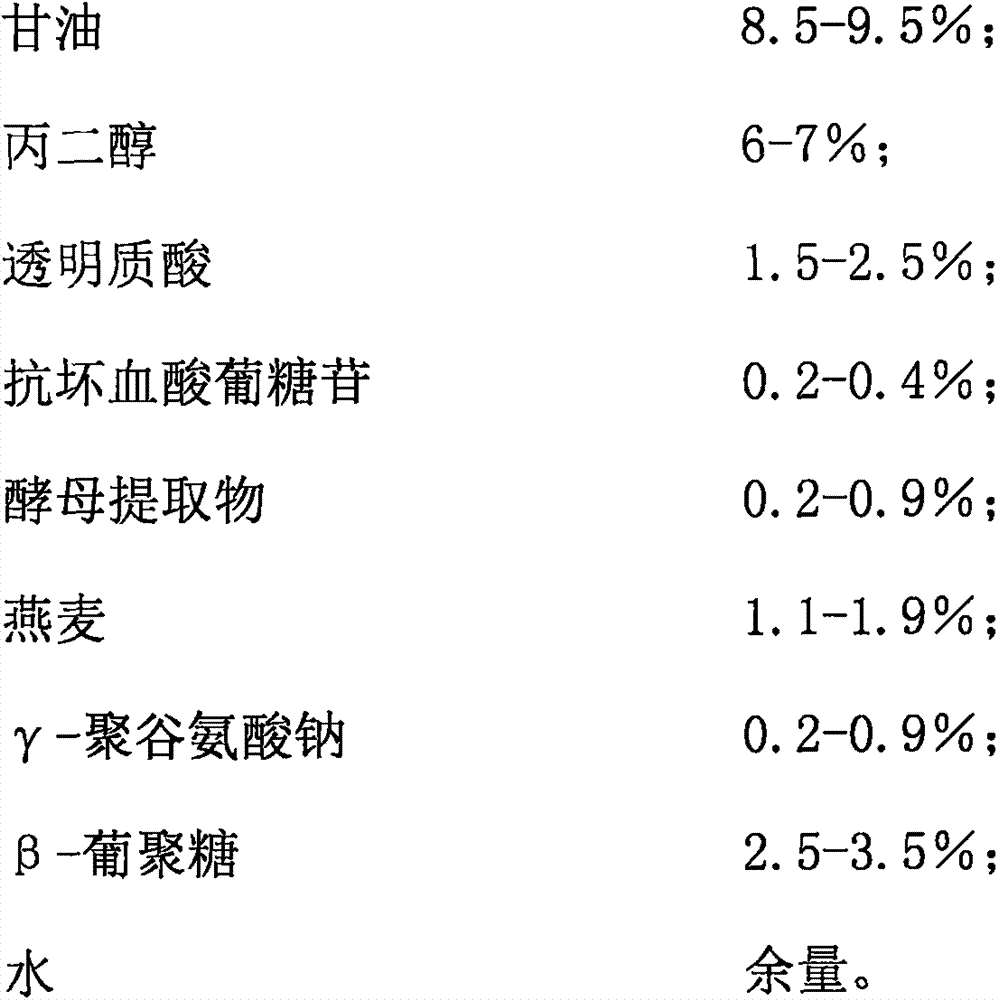

Polyethylene insulating material for high-speed extrusion, and preparation method thereof

ActiveCN106543515AIncrease productivityGood extrusion processing performancePlastic/resin/waxes insulatorsPortion sizePolymer science

The present invention belongs to the technical field of electric cable materials, and more particularly relates to a polyethylene insulating material for high-speed extrusion, and a preparation method thereof. The polyethylene insulating material comprises the following components by weight: 100 parts of a polyethylene resin, 12-35 parts of a high-speed extrusion accelerator, 0.5-2.5 parts of a lubricant, 0.3-0.8 part of an antioxidant, and 1-3 parts of a weathering resistant masterbatch. The present invention further provides a preparation method of the polyethylene insulating material. According to the present invention, the polyethylene insulating material has excellent extrusion processing performance, especially can ensure the smooth and delicate surface during the high-speed extrusion, and can effectively improve the electric cable production efficiency under the premise of the ensuring of the product quality, such that the application range of the polyethylene insulating material can be effectively expanded, the use of the imported electric cable material can be reduced, the cost can be saved, and the competitive power in the market can be improved.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

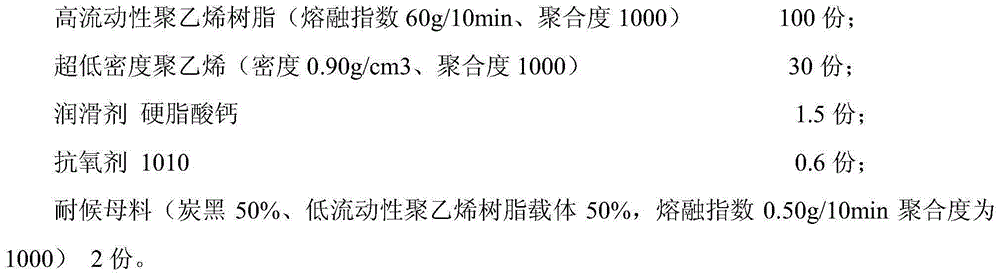

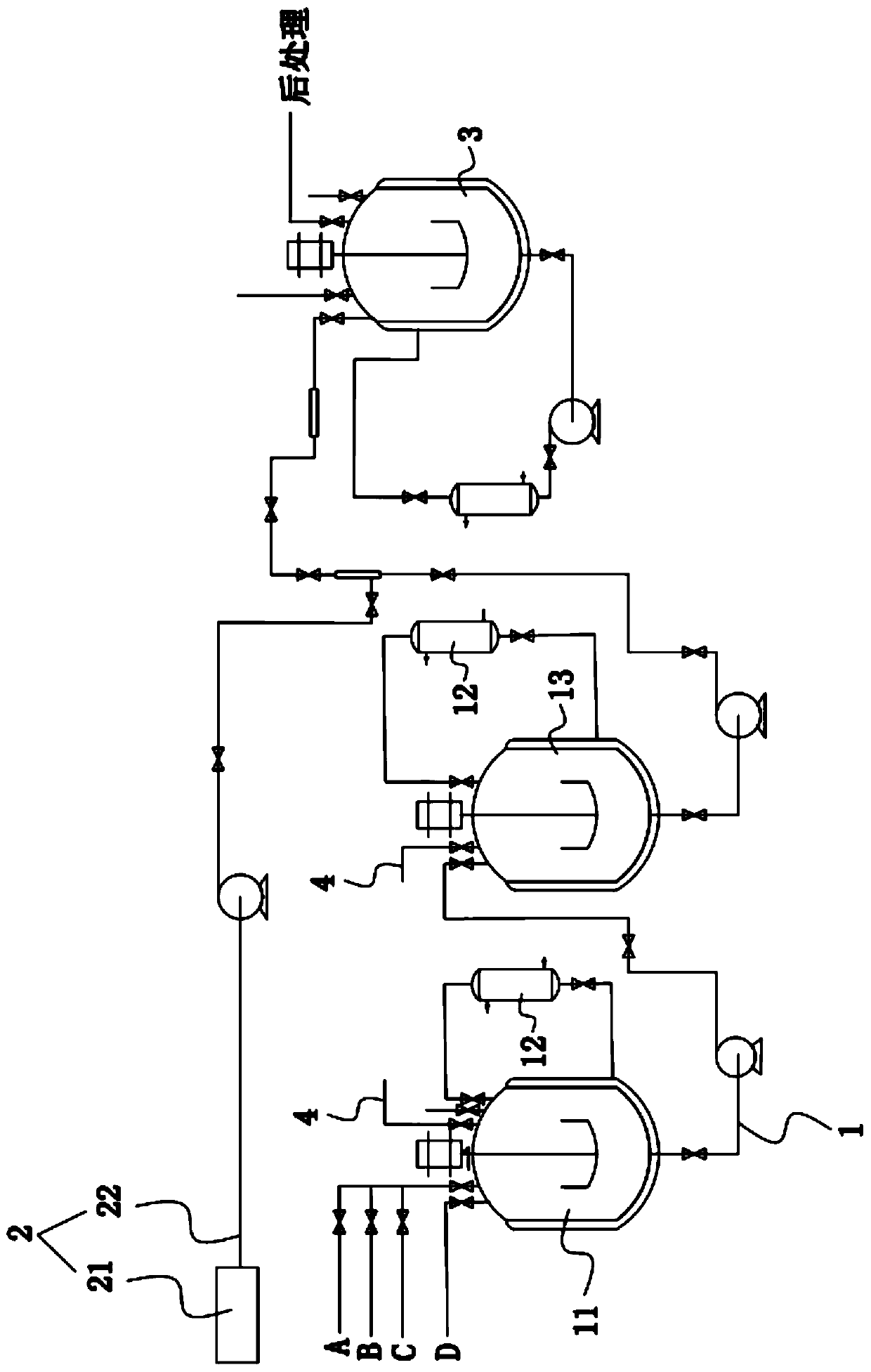

Method and system for preparing polymer polyol

PendingCN111499810ALess impuritiesImprove qualityTransportation and packagingMixer accessoriesPolymer sciencePolyol

The invention relates to the technical field of chemical production, in particular to a method and a system for preparing polymer polyol. The method for preparing the polymer polyol comprises the following steps: uniformly mixing the raw materials except the basic polyether, and then mixing with the basic polyether to carry out polymerization reaction. The raw materials except the basic polyetherare uniformly mixed and then mixed with the basic polyether, so that on one hand, the material cooling time can be shortened, the production period is shortened, the production efficiency is improved,and on the other hand, the batching frequency and the labor intensity of workers can be reduced; and the self-polymerization reaction of the raw materials except the basic polyether can be prevented,so that impurities in the polymer polyol can be reduced, the quality of the polymer polyol can be improved, a pipeline can be prevented from being blocked by a product produced by a self-polymerization reaction, and meanwhile, the situation that a part of raw materials volatilize due to the fact that the temperature of the basic polyether is higher than the boiling point of the raw materials except the basic polyether can be avoided.

Owner:上海抚佳精细化工有限公司 +1

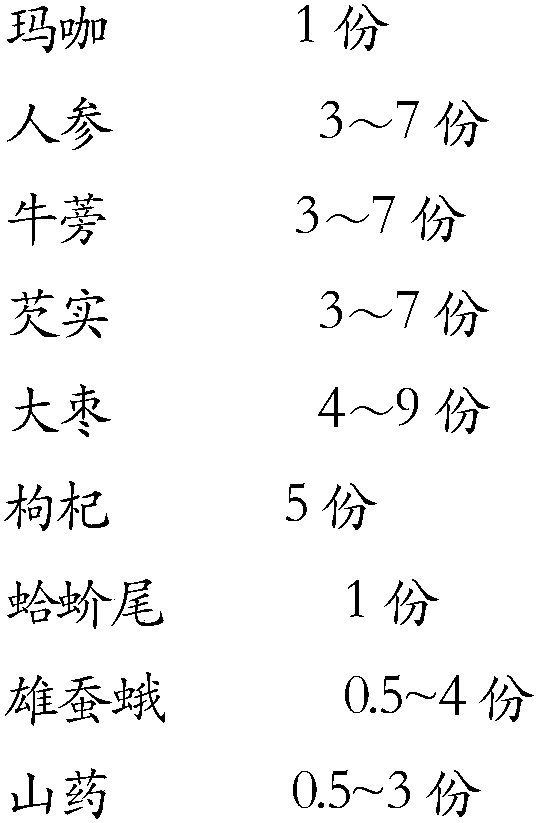

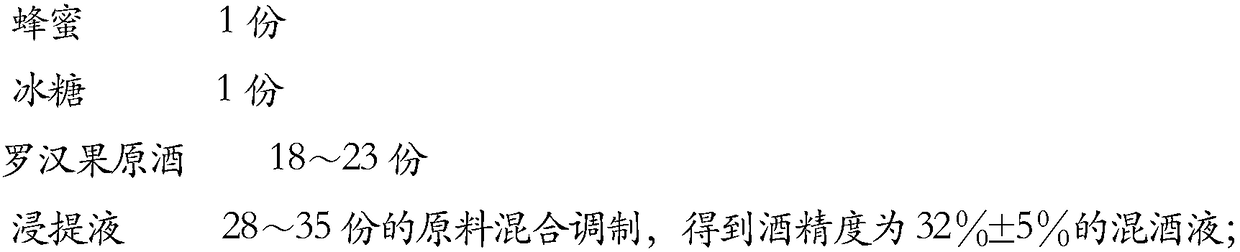

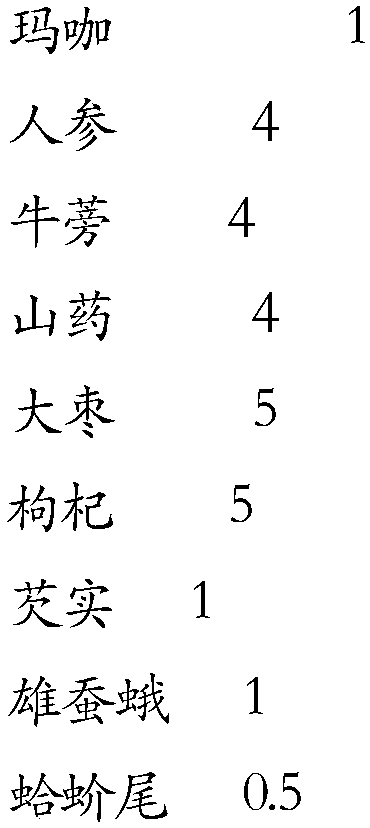

Preparation method of fructus momordicae health wine

InactiveCN108220093AUnique tasteUnique fragranceAnthropod material medical ingredientsDigestive systemForest yamMedicine

The invention discloses a preparation method of fructus momordicae health wine. The preparation method comprises the following steps: preparing fructus momordicae raw liquid; mixing the raw liquid andleaching liquid of maca, ginseng, burdock, medlar, jujubes, gecko tails, male silkworm moths and yam; mixing the mixed raw liquid, honey and crystal sugar, filtering, clarifying and aging to obtain the health wine. The health wine prepared by the preparation method disclosed by the invention has good liver-protecting and kidney-tonifying effects.

Owner:泸州施可富大曲酒厂有限责任公司

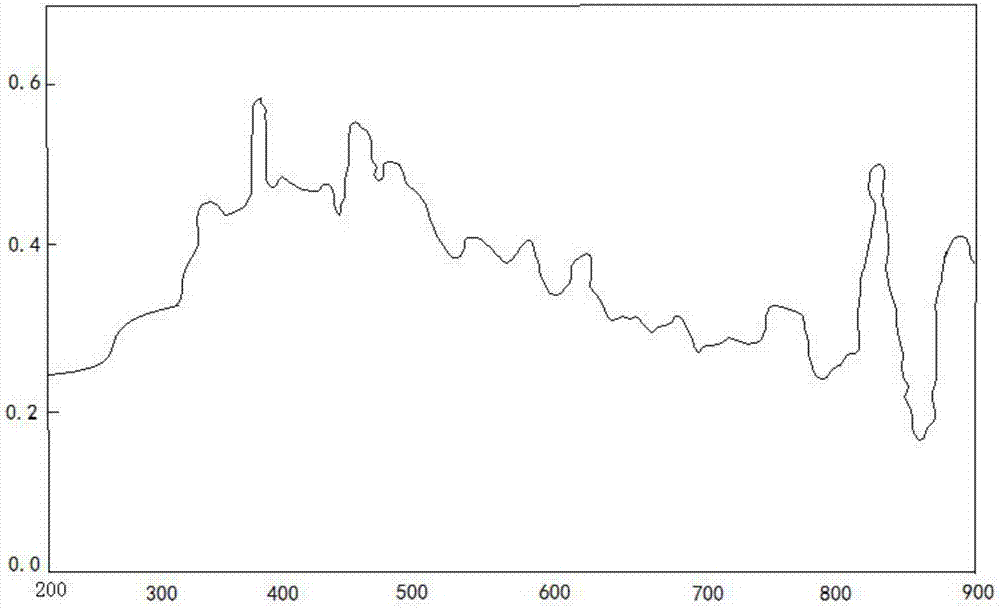

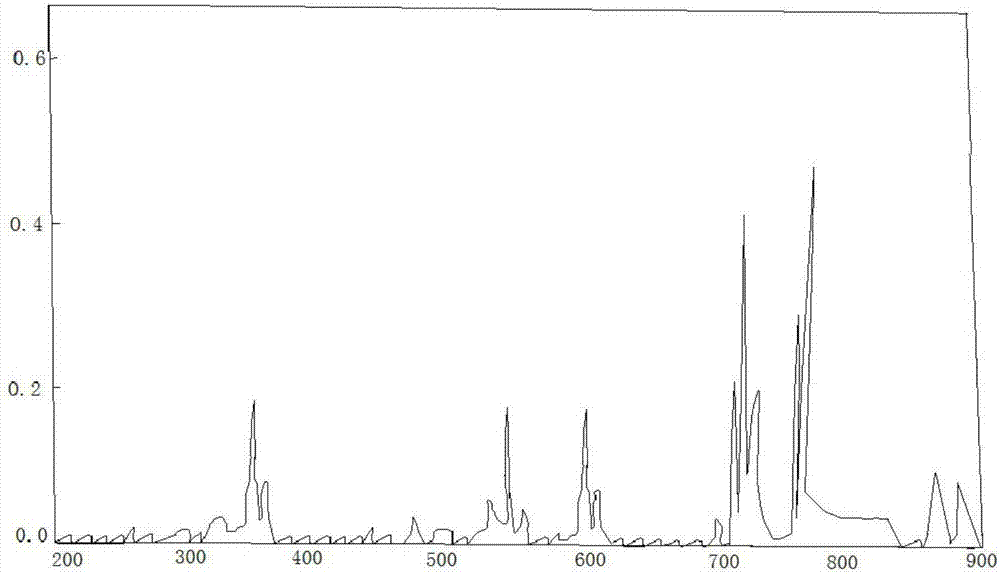

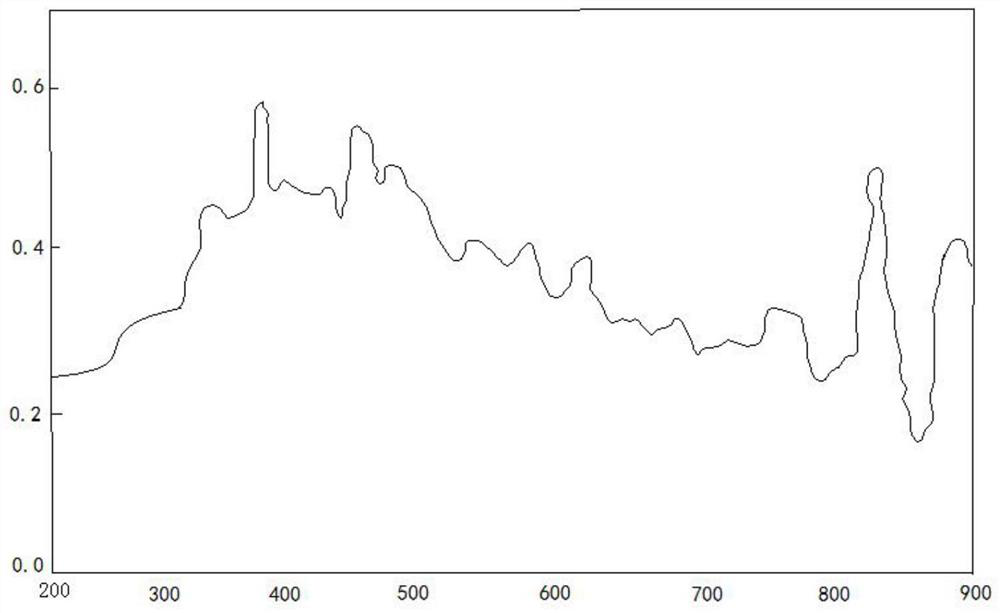

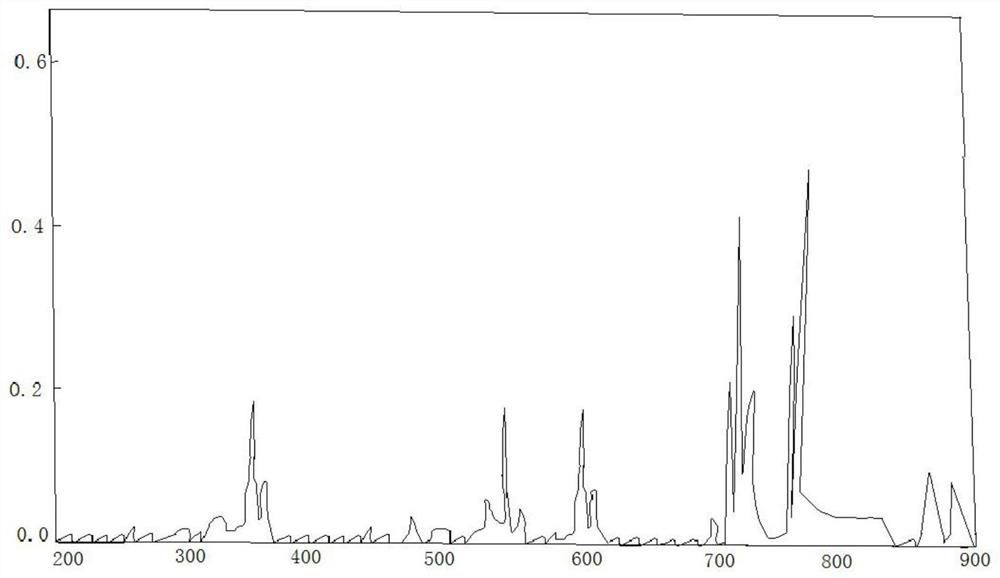

Spectral body capable of improving laser photoelectric conversion efficiency and optical quality

InactiveCN107171168AImprove conversion efficiencyReduce Thermal LensingLaser detailsHigh power lasersWavelength

The invention discloses a spectral body capable of improving laser photoelectric conversion efficiency and optical quality. The spectral body refers to a spectrum isolation plate, which is arranged between a xenon lamp and a crystal, and is made of cerium-doped quartz glass. One surface of the spectrum isolation plate is plated with a total-reflection film for isolating infrared light with a wavelength from 0.87 to 1.2 mu m. The other surface of the spectrum isolation plate is plated with a layer of an optical substance used for absorbing light with a wavelength from 0.6 to 0.7 mu m and capable of converting the light into light with a wavelength from 0.8 to 0.9 mu m. The spectral body adopts a spectrum conversion method according to absorption features of the YAG laser crystal, increases the component of spectra useful for the laser crystal, isolates the component of harmful bands, improves the efficiency of laser photoelectric conversion and improves the optical quality of laser output. Through the two conversions, the laser efficiency can be increased by 40% or more, the thermal lens effect of the crystal is reduced, the beam quality is significantly improved, and the effect is remarkable for forming high-power laser devices.

Owner:秦树军

Health-care tea capable of preventing and treating stroke

The invention discloses health-care tea capable of preventing and treating stroke, and relates to the technical field of health-care products. The health-care tea capable of preventing and treating stroke consists of the following raw materials in parts by weight of 65-80 parts by weight of Guangxi sweet tea, 4-6 parts by weight of American ginseng, 7-9 parts by weight of radix astragali, 16-18 parts by weight of radix salviae miltiorrhizae, 16-18 parts by weight of pseudo-ginseng, 16-18 parts by weight of radix puerariae and 7-9 parts by weight of haws. The health-care tea disclosed by the invention is prepared from traditional Chinese medicines and the Guangxi sweet tea, and the sweet tea is a natural non-toxic high-sugariness low-calorie sweet plant having good health-care functions inthe world at present, is a saccharide substitute which is widely searched by developed countries in the world, is sweet in taste and also has tea fragrance, so that the health-care tea disclosed by the invention is excellent in mouth feel, safe and free from side effects, and can replace Western medicines to prevent and treat the stroke.

Owner:李华丽

Spectrum body capable of improving laser photoelectric conversion efficiency and optical quality

InactiveCN111653927AImprove conversion efficiencyReduce Thermal LensingLaser detailsHigh power lasersMaterials science

The invention discloses a spectrum isolation sheet capable of improving laser photoelectric conversion efficiency and optical quality. The spectrum isolation sheet is arranged between a xenon lamp anda crystal, and the spectrum isolation sheet is made of cerium-doped quartz glass. And one surface of the spectrum isolation sheet is plated with a total reflection film for isolating near-infrared light from 0.87 mu m to 1.2 mu m. And the other surface of the spectrum isolation sheet is coated with a layer of light substance which is used for absorbing light of 0.6-0.7 mu m and can be converted into light of 0.8-0.9 mu m. According to the absorption characteristics of the YAG laser crystal, the spectrum conversion mode is adopted, the part of useful spectrum of the laser crystal is increased,the part of harmful wave bands is isolated, the laser photoelectric conversion efficiency is improved, and the laser output optical quality is improved. Through the two times of conversion, the laserefficiency can be improved by more than 40%, the thermal lens effect of the crystal is reduced, the light beam quality is greatly improved, and the effect is very obvious especially for a high-powerlaser.

Owner:秦树军

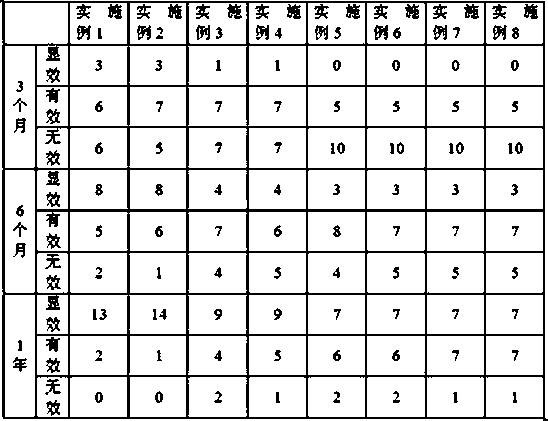

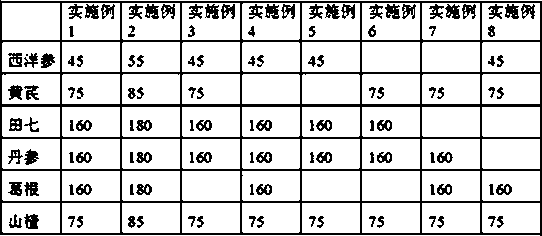

Medicine for preventing and treating apoplexy

InactiveCN107789409AIncrease vitalityPromote growthCardiovascular disorderPlant ingredientsWestern medicineSide effect

The invention discloses a medicine for preventing and treating apoplexy, and relates to the technical field of medicines. The medicine for preventing and treating the apoplexy is prepared from the following raw materials in parts by weight: 45 to 55 parts of American ginseng, 75 to 85 parts of radix astragali, 160 to 180 parts of radix salviae miltiorrhizae, 160 to 180 parts of radix notoginseng,160 to 180 parts of radix puerariae and 75 to 85 parts of fructus crataegi. The medicine can replace a western medicine for preventing and treating the apoplexy; thereby solving the problems that themedicine for preventing and treating the apoplexy at the present has certain biotoxicity and dependency and causes large side effects.

Owner:李华丽

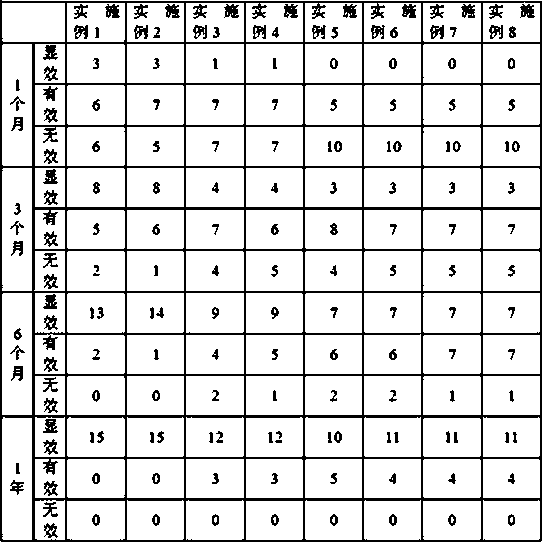

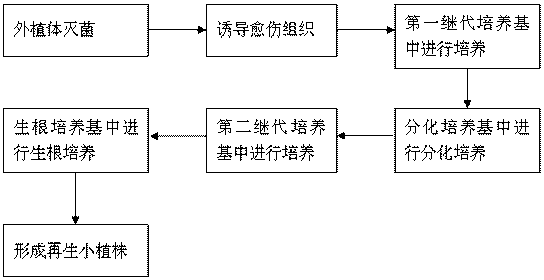

Method for Tissue Culture Regeneration of Mature Bromegrass Seeds

InactiveCN104137774BA large amountIncrease vitalityPlant tissue cultureHorticulture methodsBudGenetic engineering

The invention discloses a method for tissue culture and regeneration of mature seeds of awnless brome. The mature seeds of awnless brome are used as explants, and the surface is first sterilized, and then the sterilized seeds of awnless brome are transferred to cultured in the callus induction medium; the induced callus was transferred to the first subculture medium for the first subculture, and then transferred to the differentiation medium for culture; the adventitious buds obtained from the differentiation culture were inserted into the second The second subculture was carried out in the subculture medium, and after differentiation and emergence, the seedlings were inserted into the rooting medium to induce rooting. In this method, mature brome seeds are used as explants, and callus is induced, differentiated and rooted by adding different concentrations of auxin and cytokinin in the medium, so as to establish its complete tissue culture regeneration system. Wheat provides the basis for genetic improvement through genetic engineering.

Owner:GRASSLAND RES INST OF CHINESE ACAD OF AGRI SCI

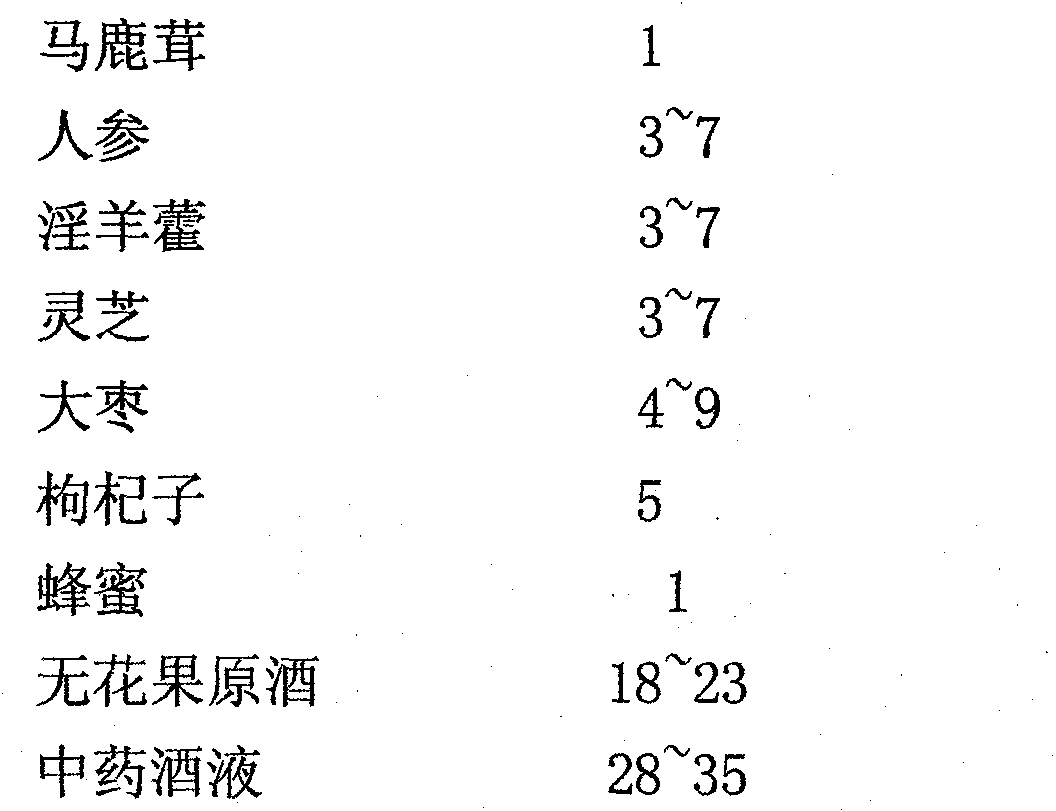

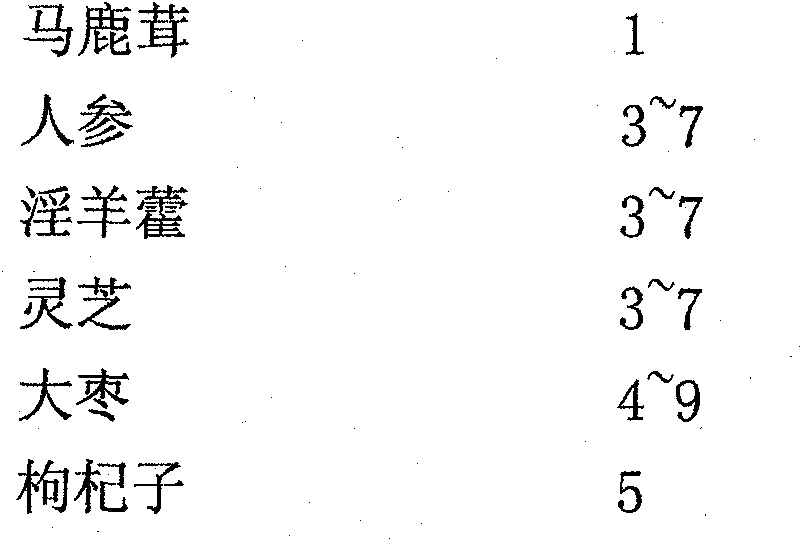

Fig health care wine and preparation method thereof

ActiveCN102465073BUnique tasteUnique fragranceAlcoholic beverage preparationBlood pressureAllium sativum

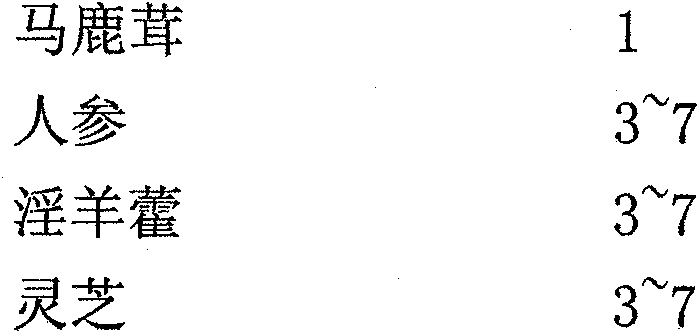

The invention relates to health care wine and a preparation method thereof, and especially to fig health care wine and a preparation method thereof. The preparation method comprises the following steps: 1, preparing fig bulk wine; 2, preparing traditional Chinese medicinal liquor liquid, wherein, traditional Chinese medicinal components comprise cervus elaphus linnaeus, ginseng, epimeddium, lucid ganoderma, Chinese date and wolfberry; 3, preparing the fig health care wine which comprises honey, the fig bulk wine and the traditional Chinese medicinal liquor liquid. According to the invention, a composition of fig, Chinese date, wolfberry, cervus elaphus linnaeus, ginseng, epimeddium, lucid ganoderma, honey and the like is utilized, and the composition has the characteristics of cancer resistance, virus resistance and improvement of human immunity; in addition, fig contains considerable selenium, the content of selenium in fig is 400 times of the content of selenium in garlic, and selenium is an immunopotentiator, can remove free radicals and protect cell membranes from being oxidized and has a regulating effect on blood vessels of the heart and the brain, blood sugar and blood pressure.

Owner:威海紫光优健科技股份有限公司

Processing method for preparing lactic acid honey

The invention discloses a processing method for preparing lactic acid honey. The method comprises the following steps of: preparing lactic acid bacteria strain solution, disinfected liquefied honey and sterile water respectively, and mixing the three to prepare fermentation mother liquor A and fermentation mother liquor B, wherein the liquor A contains 20 to 25 percent of disinfected liquefied honey and the liquor B contains 5 to 25 percent of disinfected liquefied honey. After the fermentation of the fermentation mother liquor, the liquor B is lactic acid honeydew health-care beverage of a second terminal product. The liquor A is processed with honey increment, secondary fermentation, sterilization, concentration and the like to obtain transparent liquid colloidal lactic acid honey health-care food of a first terminal product. Through fermentation of lactic acid, sugar in the honey is transformed into the lactic acid, trace nutritional components are preserved, and multiple new nutritional substances such as enzyme, oligosaccharide, polysaccharide, complex carbohydrate and the like are produced at the same time. The method produces good biological preservative effect by using the bacteriostatic effect of the lactic acid, and does not need to add any preservative.

Owner:才玉山

Soft polyethylene track cable sheath material and preparation method thereof

InactiveCN108715662AGood flexibilityImprove brittlenessPlastic/resin/waxes insulatorsLow-density polyethyleneSodium Bentonite

The invention discloses a soft polyethylene track cable sheath material and a preparation method thereof. The soft polyethylene track cable sheath material comprises, by weight, 40-50 parts of low-density polyethylene, 50-60 parts of PVC resin, 20-25 parts of soft modifying agents, 10-12 parts of aluminum silicate, 10-12 parts of stannic oxide, 10-15 parts of light calcium carbonate, 8-10 parts ofxylene, 5-7 parts of diatomite, 5-7 parts of bentonite, 2-4 parts of lubricants, 3-8 parts of thermal stabilizing agents, 3-8 parts of halogen-free flame retardants, 1-3 parts of antioxidants and 1-3parts of plasticizers. The prepared sheath material has the advantages that the sheath material has high flexibility, original brittleness and low bendability of polyethylene cable materials can be improved effectively, flexibility and bendability of the cable materials can be improved, construction is facilitated, the application range of the polyethylene cable materials can be widened effectively, and market share can be increased.

Owner:ANHUI YILI CABLE

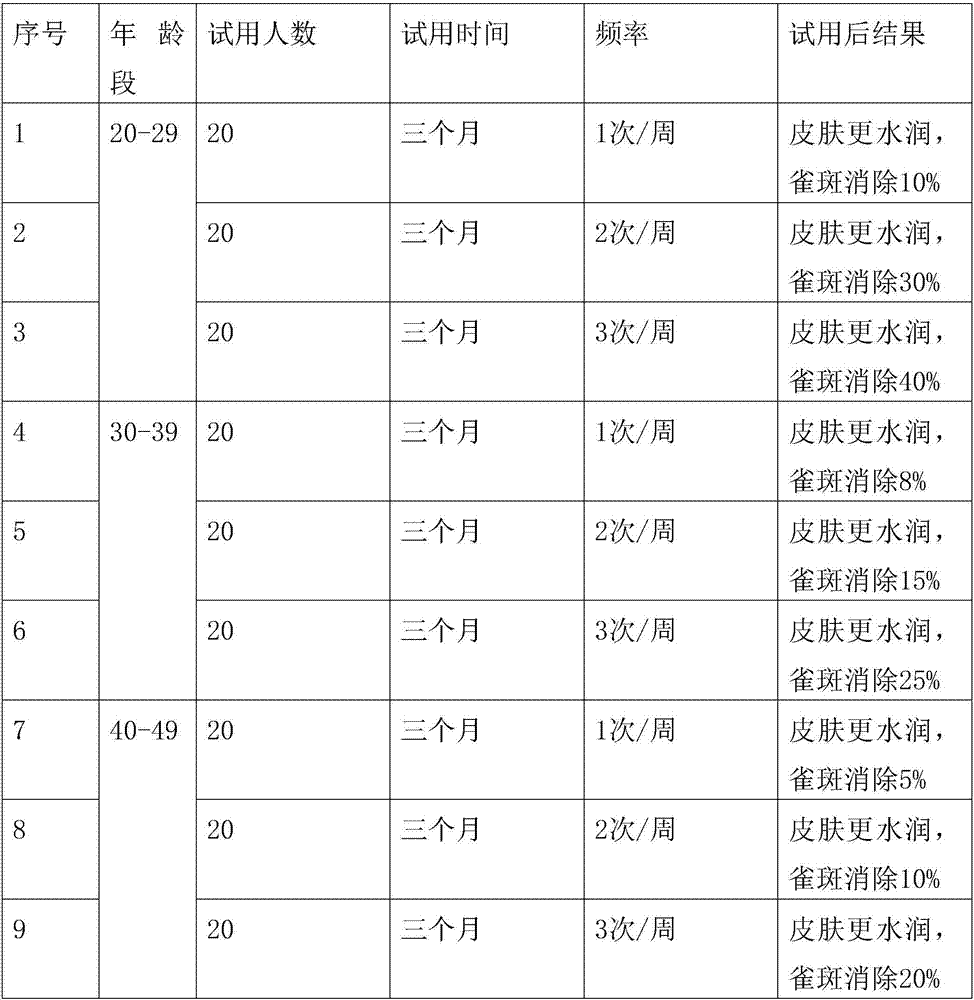

Melt-blowing compound plant fiber non-woven freckle removal mask and preparation method thereof

InactiveCN107362125ARich in anti-freckle ingredientsGood skin careCosmetic preparationsToilet preparationsAdditive ingredientNutrient solution

The invention discloses a melt-blown composite plant fiber non-woven freckle removing mask and a preparation method thereof, which is prepared from the following components according to mass percentage: 30-50 parts of plant fiber, 10-30 parts of polyamide fiber, chitosan 15-35 parts of sugar fiber, the preparation method is: plant fiber, polyamide fiber, chitosan fiber are mixed together, then join in the screw extruder, melt into melt by screw extruder; The spinneret hole of the spinning die is extruded, and the fine flow of the melt is cooled and drafted through the drafting air channel to form fibers; the prepared fibers are passed through the diffusion air channel to make the fibers evenly adsorbed on the web-forming conveyor belt, A continuous mesh fiber layer is prepared; the prepared continuous mesh fiber layer is processed into a non-woven fabric by a hot rolling mill; the processed non-woven fabric is soaked in the silk protein liquid; the nutrient solution is evenly coated on the On non-woven fabric, sealed packaging. The invention has the advantages of better skin care effect, obvious freckle removal effect and the like.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

High Purity Hyaluronic Acid Radiance Revitalizing Essence

ActiveCN107468629BNourishingGood moisturizing effectCosmetic preparationsToilet preparationsGlycerolJojoba oil

Owner:HUBEI MULAN TONGDA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com