Polyethylene insulating material for high-speed extrusion, and preparation method thereof

A polyethylene insulating material, high-speed extrusion technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of corporate profit impact, cable extrusion surface effect is not very ideal, etc., to improve production efficiency , smooth and delicate surface, the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

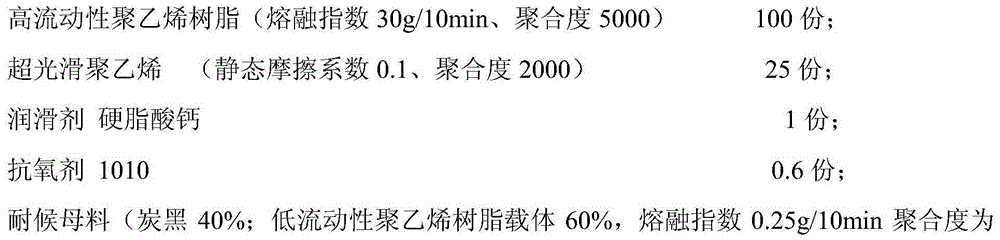

[0053] In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0054]

[0055]

[0056] Select the raw materials for each component according to the stated ratio, mix the accurately weighed resin and additives fully in a high-speed mixer, and then extrude them in a feeding extrusion granulation mixing type twin-screw extrusion granulator. For granulation, the extrusion temperature of the twin-screw extruder is 145-205°C, and the temperature of the twin-screw extruder is set as: 145-155°C in the feeding section, 160-185°C in the mixing section, extruding The temperature of the granulation section is 185-195°C, and the head part is 195-205°C. Drying after granulation, the drying temperature is 60-95° C., and the drying time is 1-3 hours, and the pellets for cables are obtained. The composition and weight ratio of the raw material components are shown in Table 1.

Embodiment 2

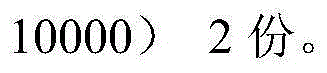

[0058] In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0059]

[0060] Select raw materials for each component according to the stated ratio, fully mix the accurately weighed resin and additives in a high-speed mixer at a speed of 500-1000 rpm, the mixing temperature of the high-speed mixer is 50°C, and the mixing time is 15 minutes . Extrude and granulate in a feed extrusion granulation mixing type twin-screw extrusion granulator, the extrusion temperature of the twin-screw extruder is 155-200 ° C, the temperature setting of the twin-screw extruder It is: 155°C in the feeding section, 180°C in the mixing section, 190°C in the extrusion granulation section, and 200°C in the head part. Drying after granulation, the drying temperature is 80° C., and the drying time is 2 hours, to obtain granules for cables. The composition and weight ratio of the raw material components are shown in Table 1.

Embodiment 3

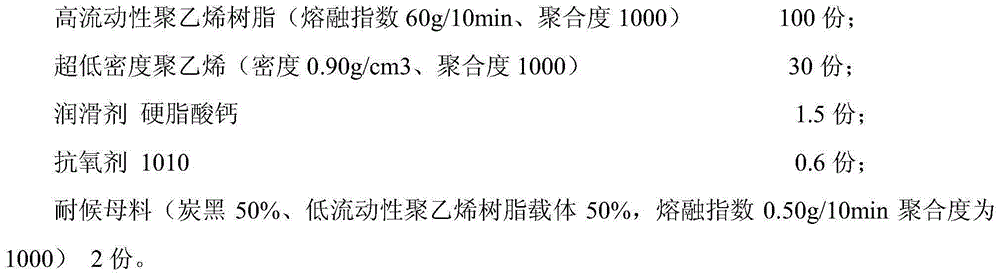

[0062] In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0063]

[0064] Processes such as mixing and extrusion granulation are the same as in Example 1. The composition and weight ratio of the raw material components are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com