Flexible polypropylene cable sheath material

A technology of cable sheath material and polypropylene, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc. It can solve problems such as stress whitening, limited expansion and application, and insufficient softness of cable materials, so as to increase weight, Good flexibility, the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

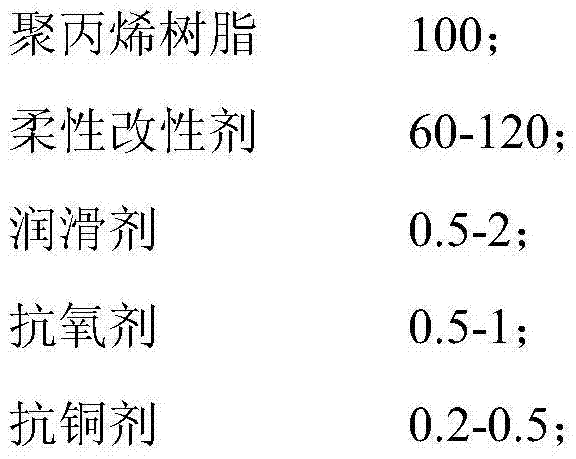

[0020] A kind of flexible polypropylene cable sheath material is prepared, comprising the following components:

[0021]

[0022] Select the raw materials according to the stated components and proportions, mix the accurately weighed resin and additives fully in a high-speed mixer, and then extrude them in a feeding extrusion granulation mixing type twin-screw extrusion granulator. For granulation, the extrusion process temperature is set as follows: feeding section 160°C, mixing section 190°C, extrusion granulation section 200°C, head part 210°C; after granulation, dry to obtain cable sheathing material.

[0023] The properties of the prepared cable materials are shown in Table 1.

Embodiment 2

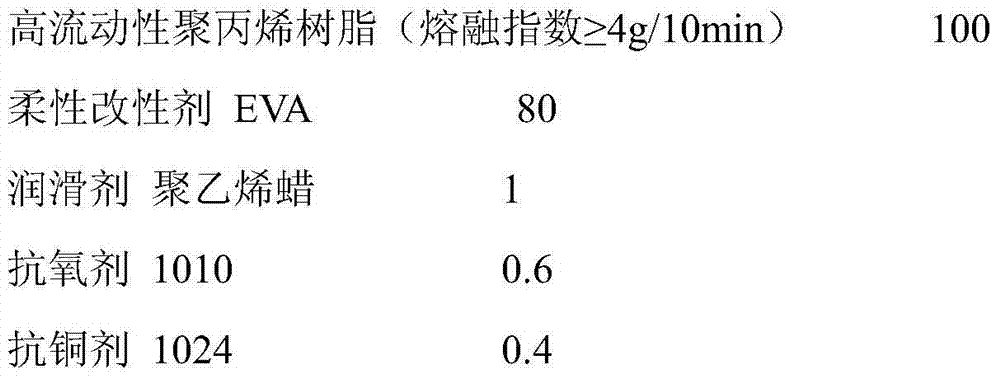

[0025] In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0026]

[0027] Processes such as mixing and extrusion granulation are the same as in Example 1. The properties of the prepared cable materials are shown in Table 1. Example 3

Embodiment 3

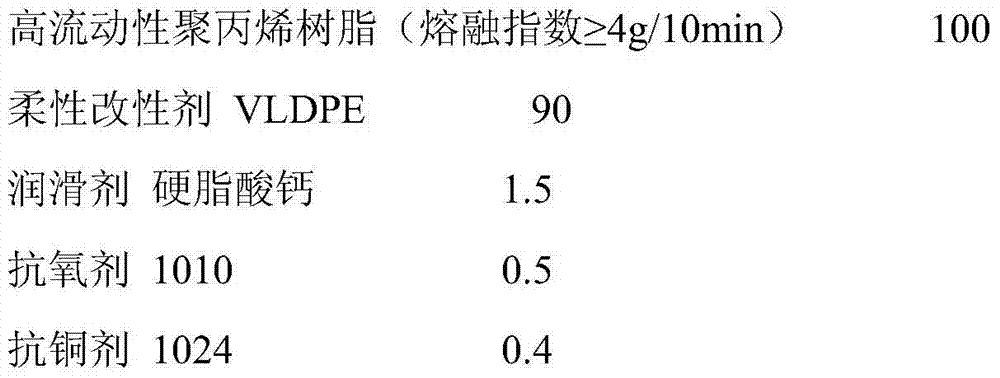

[0028] In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com