Method and system for preparing polymer polyol

A polyol and polymer technology, applied in chemical instruments and methods, mixers, chemical/physical processes, etc., can solve the problems of increasing labor intensity and energy consumption of workers, shorten the cooling time of materials, reduce labor intensity, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

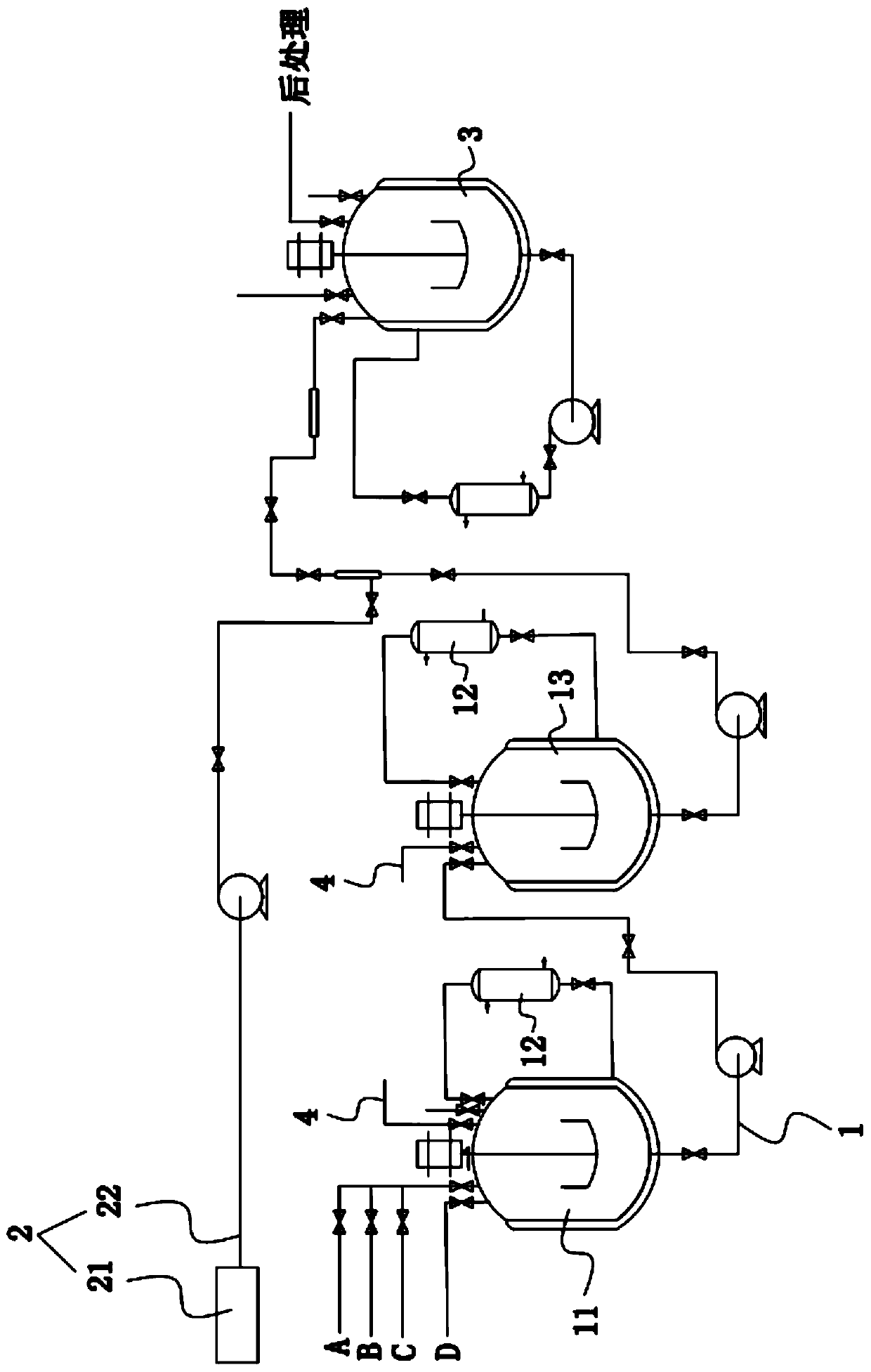

[0042] This example relates to a system for preparing polymer polyols.

[0043] Specifically, such as figure 1 As shown, the system for preparing polymer polyols includes a first feed unit 1 , a second feed unit 2 and a reactor 3 . The first feed unit 1 and the second feed unit 2 are arranged side by side, and the reactor 3 is connected to both the first feed unit 1 and the second feed unit 2 .

[0044] Wherein, the first feeding unit 1 is used for mixing the first material and delivering the first material to the reactor 3 , and the second feeding unit 2 is used for delivering the second material to the reactor 3 . Specifically, the first material is raw materials other than the basic polyether, usually including vinyl monomer A, chain transfer agent B, dispersant C and initiator D, and the second material is the basic polyether.

[0045] Optionally, in this embodiment, the first feeding unit 1 includes a batching tank 11 , a cooling system 12 and a dropping tank 13 . Amon...

Embodiment 2

[0055] This embodiment relates to a method for preparing polymer polyols, which is applied to the system provided in Example 1, and specifically includes the following steps:

[0056] S1. Vinyl monomer (acrylonitrile 1.05kg and styrene 2.45kg), chain transfer agent isopropanol 2.20kg, dispersant 1.30kg and initiator dimethyl azobisisobutyrate 0.20kg at 14 ℃ according to Proportional mixing to obtain the first material;

[0057] S2. Simultaneously transport 7.20kg of the first material and 30.00kg of the basic polyether to the reactor for polymerization.

[0058] Tested according to the GB / T12008.7 standard, the viscosity of the polymer polyol is 850mPa.s, the solid content is 10.05%, and the particle size distribution of the product is wide and uniform.

[0059] It takes 15 hours to produce 37.20kg of polymer polyol, and the batching frequency is once. After calculation, the energy consumption is 6.84 yuan / kg.

Embodiment 3

[0061] This embodiment relates to a method for preparing polymer polyols, which is applied to the system provided in Example 1, and specifically includes the following steps:

[0062] S1. Vinyl monomer (acrylonitrile 5.32kg and styrene 12.42kg), chain transfer agent isopropanol 2.66kg, dispersant 1.46kg and initiator dimethyl azobisisobutyrate 0.14kg at 14°C Proportional mixing to obtain the first material;

[0063] S2. Transport 22.00kg of the first material and 20.00kg of the basic polyether to the reactor for polymerization at the same time.

[0064] Tested according to the GB / T12008.7 standard, the viscosity of the polymer polyol is 3680mPa.s, the solid content is 45.08%, and the particle size of the product is evenly distributed.

[0065] It takes 17 hours to produce 42.00kg of polymer polyol, and the batching frequency is 2 times. After calculation, the energy consumption is 6.92 yuan / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com