Method for processing feeding gear gauge

A processing method and the technology of poking teeth, which are applied in the field of processing gauges for poking teeth, to achieve the effect of improving launch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

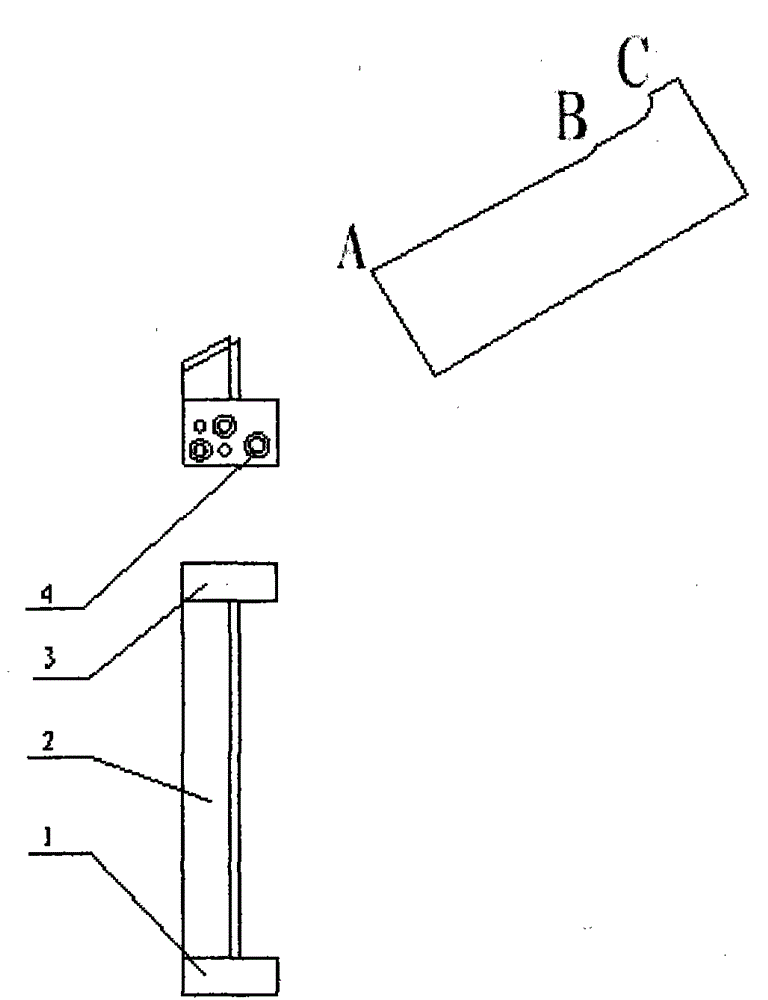

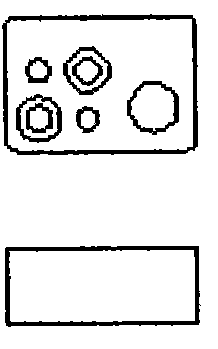

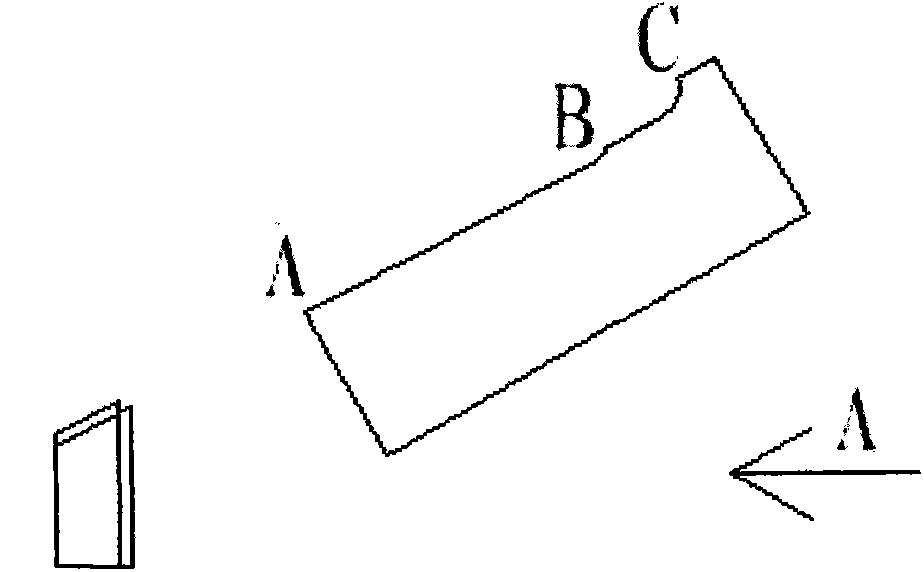

[0048] refer to Figure 1 to Figure 9 A processing method for a gauge for poking teeth is shown, comprising a gauge body for poking teeth, the body of the gauge for poking teeth is composed of a first workpiece, a second workpiece, a third workpiece and a fourth workpiece, the The processing of the first workpiece, the second workpiece, the third workpiece and the fourth workpiece comprises the following steps:

[0049] (1) The first workpiece and the third workpiece:

[0050] Cutting material: the material uses high carbon tool steel T10;

[0051] High-speed milling: milling hexagonal, guaranteed size 35×25×14;

[0052] Flat grinding: grinding each surface and a set of diagonal reference planes;

[0053] Boring: Boring φ9 for grinding, boring bottom hole for assembly hole;

[0054] Fitter: drill assembly pin hole 2-φ4, countersunk hole 2-φ4.5 / φ8;

[0055] Quenching: Quenching according to the drawings;

[0056] Flat grinding: grinding all sides;

[0057] Inner hole gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com