Method for preparing film system with secondary electron emission function

A secondary electron emission and functional technology, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of short life of electron multipliers, short service life, and failure to solve the life of cesium atomic clocks, etc. Achieve the effects of good compactness, high secondary electron emission rate and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

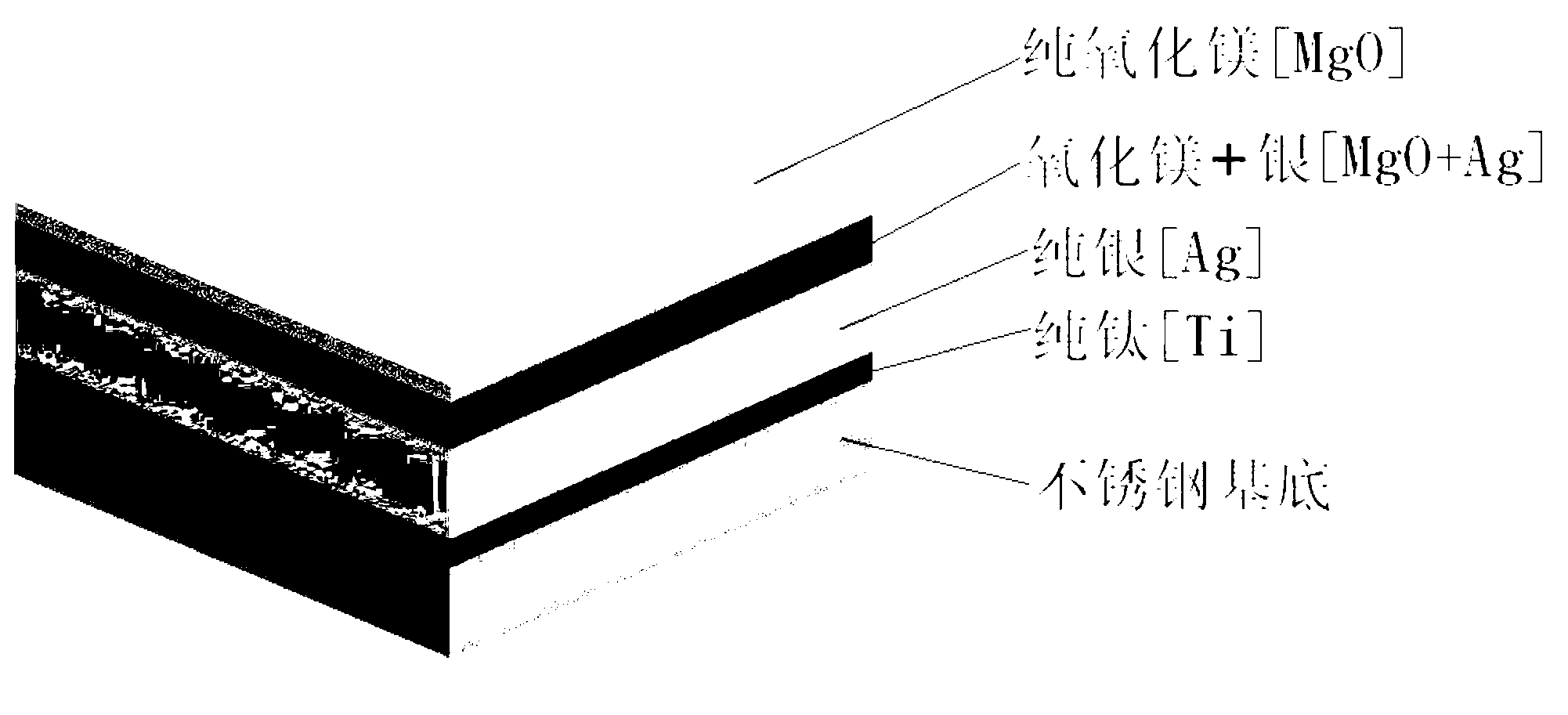

[0025] A method for preparing a film system with a secondary electron emission function, the steps of the method are as follows:

[0026] (1) Clean the vacuum chamber: open the vacuum chamber, place the aluminum film that protects the target from pollution directly above the target, remove the film layer that falls off in the vacuum chamber and the pollutants in the air, and then use degreasing gauze dipped in absolute ethanol Wipe clean the inner wall of the vacuum chamber; there are three kinds of target materials, namely metal titanium target, metal silver target, and ceramic magnesium oxide target; the purity of the target material is above 99.99%;

[0027] (2) Clean the substrate: put the No. 304 stainless steel substrate into a clean container, rinse it with deionized water, and then ultrasonically clean the No. 304 stainless steel substrate with analytical pure acetone and analytical pure alcohol for 15 minutes, and then use analytical Rinse with pure anhydrous ethanol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com