TWT impregnated Ba-W cathode and its preparation method

A barium tungsten cathode and traveling wave tube technology, applied in the field of traveling wave tubes, can solve the problems of increasing cost and affecting widespread use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

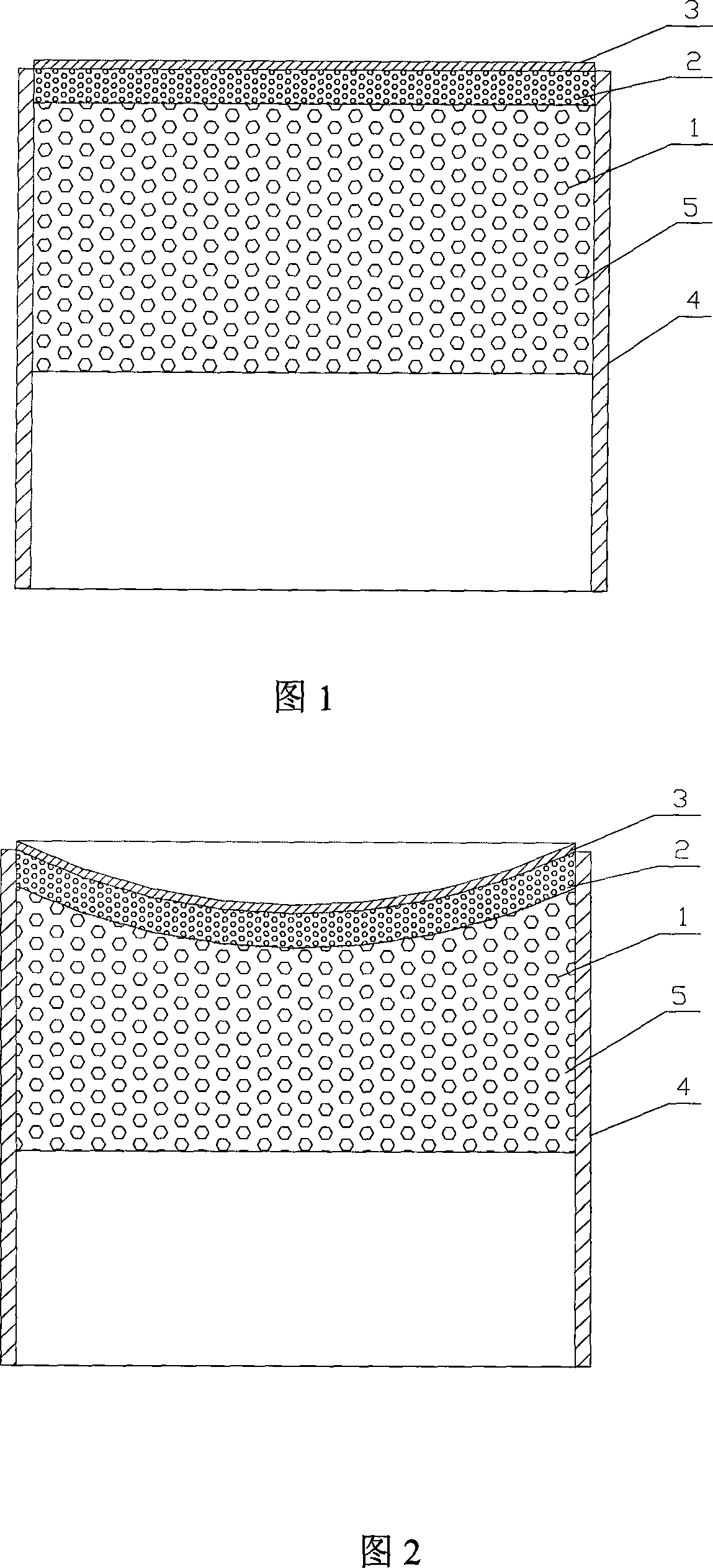

[0020] Below in conjunction with Fig. 1, Fig. 2, the present invention is described in detail, a kind of traveling wave tube impregnated coated barium tungsten cathode, comprises cathode cylinder 4, the sponge body of the cathode that is positioned at cathode cylinder 4, the sponge body of described cathode is made of The tungsten sponge body 1 and the tungsten-rhenium sponge body 2 are press-fitted and connected, and the surface of the tungsten-rhenium sponge body 2 is provided with a precious metal film 3 . The tungsten sponge 1 has a pore size of 30±2%, and a thickness of 1.2±0.3mm; the tungsten-rhenium sponge 2 has a pore size of 25±2%, a weight ratio of tungsten and rhenium of 1:1, and a thickness of 0.4mm. ±0.1 mm; the noble metal film 3 is a rhenium film with a film thickness of 0.6-0.8 microns. The cathode salt 5 impregnated in the sponge body of the cathode is aluminate BaO: CaO: Al 2 o 3 The molar ratio is 2.4:0.6:1. The cathode surface can be planar or spherical....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com