Preparation method of yttrium aluminum garnet crystal film doped with metal ions

A technology of yttrium aluminum garnet and metal ions, which is applied in the field of preparation of yttrium aluminum garnet crystal thin films, can solve the problems of complex process, poor uniformity and compatibility, low conversion efficiency, etc., and achieves cost reduction, huge market application prospect, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

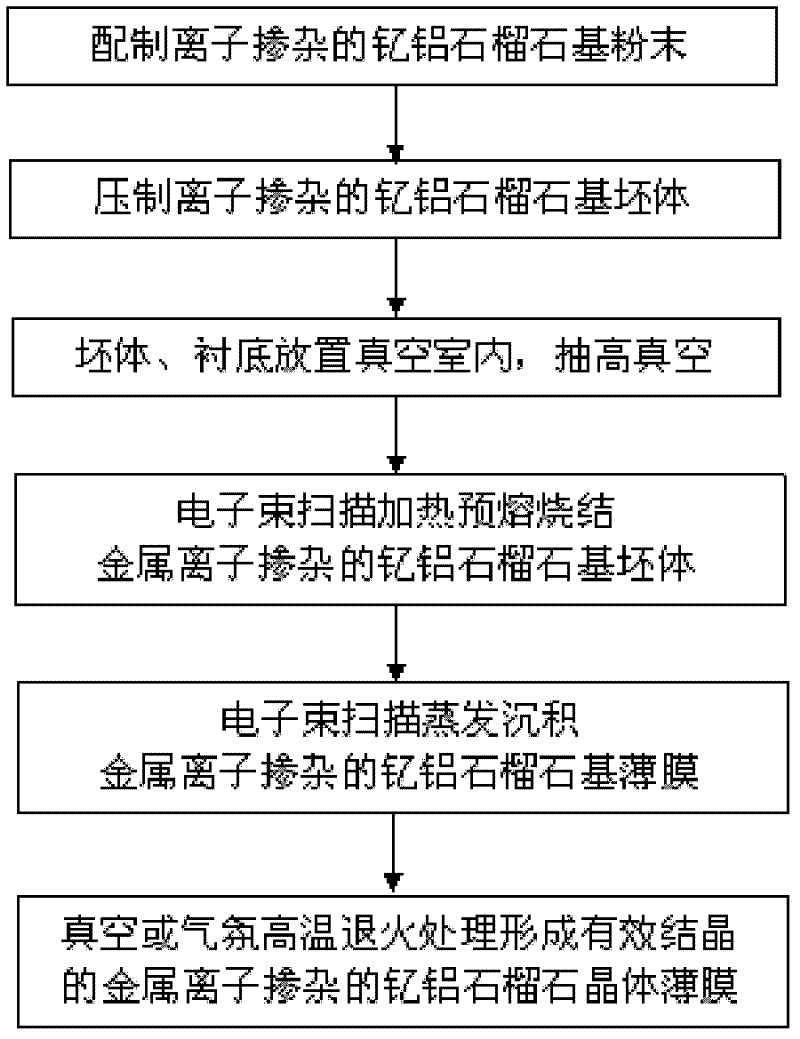

Method used

Image

Examples

Embodiment 1

[0039] The specific process of Nd-doped yttrium aluminum garnet (Nd:YAG) crystal thin film is as follows:

[0040] (1) Select high-purity Y 2 o 3 , Al 2 o 3 ,Nd 2 o 3 Material, Nd-doped yttrium aluminum garnet (Nd:Y 3 Al 5 o 12 ) powder, the doping concentration of Nd ions is 2at%, and the neodymium-doped yttrium aluminum garnet powder is pressed into a green body for electron beam evaporation deposition coating;

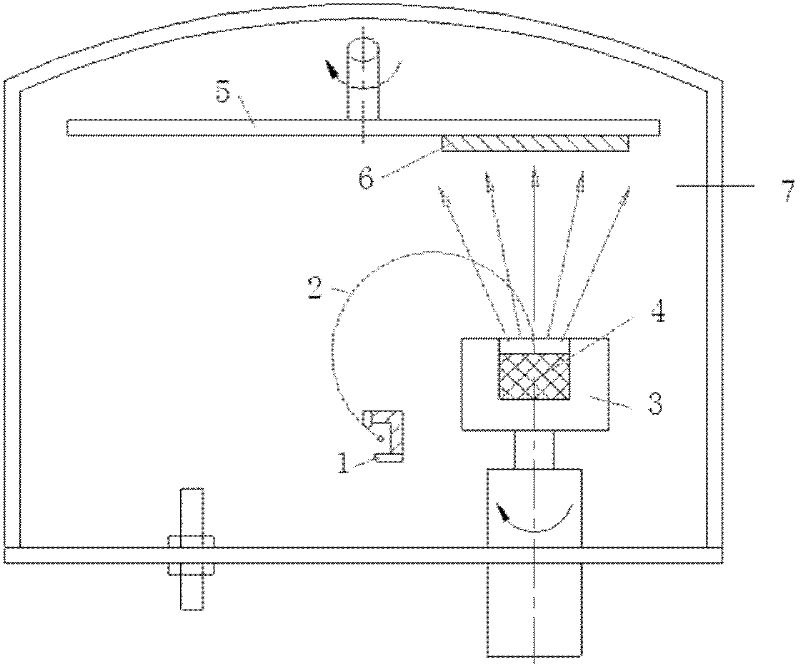

[0041] (2) Place the neodymium-doped yttrium aluminum garnet body in the crucible of the electron beam evaporation deposition device. The substrate material is a single-sided polished, (100)-oriented P-type single crystal Si wafer. Before preparation, use acetone, ethanol and Perform ultrasonic cleaning on the substrate with deionized water, place the cleaned substrate on the workpiece rack directly above the crucible, and adjust the distance between the substrate and the crucible to be 55 cm;

[0042] (3) Evacuate the vacuum chamber of the electron beam ev...

Embodiment 2

[0049] The formula and process flow are the same as those in Example 1, except that the annealing treatment in step (6) is annealing treatment at 900° C. for 1 hour.

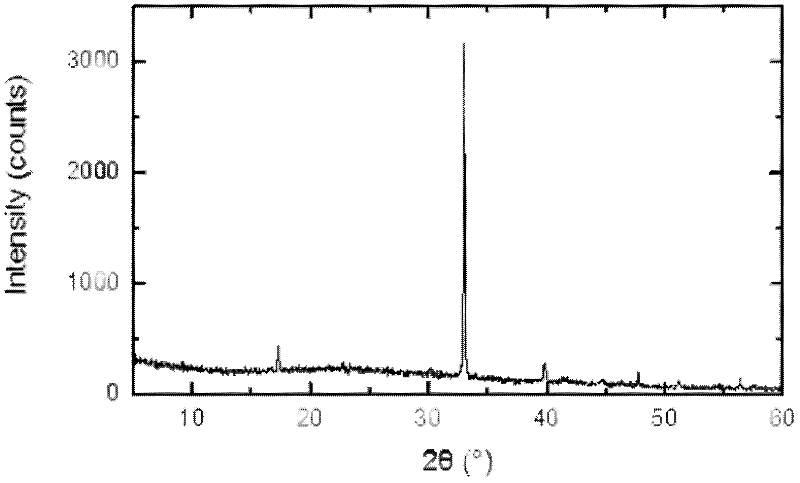

[0050] The XRD spectrum of the neodymium-doped yttrium aluminum garnet (Nd:YAG) crystal film prepared in embodiment 2 is shown in Figure 5 ,From Figure 5 It can be seen that the crystal phase of the thin film is pure YAG phase, and the Nd 3+ Into the YAG lattice, no impurity phase appears.

Embodiment 3

[0052] The recipe and process flow are the same as those in Example 1, except that the used substrate is Nd:YAG single crystal. The Nd-doped yttrium aluminum garnet (Nd:YAG) crystal film is also prepared, and because the film and the substrate are homogeneous materials, the influence of lattice mismatch is reduced, and the film surface is smoother.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com