Waste aluminum product pressing device

A technology of aluminum products and pressing plates, which is applied in the field of aluminum products, can solve the problems of affecting pressing efficiency, poor cleaning effect, and poor stability, and achieve the effects of simple pressing process, good practicability, and improved pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

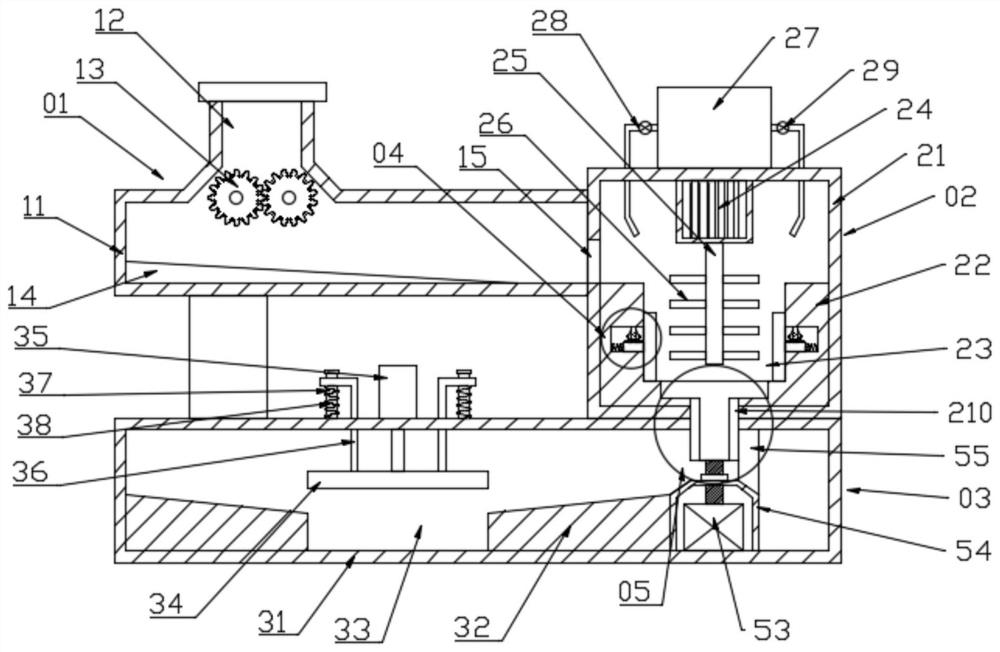

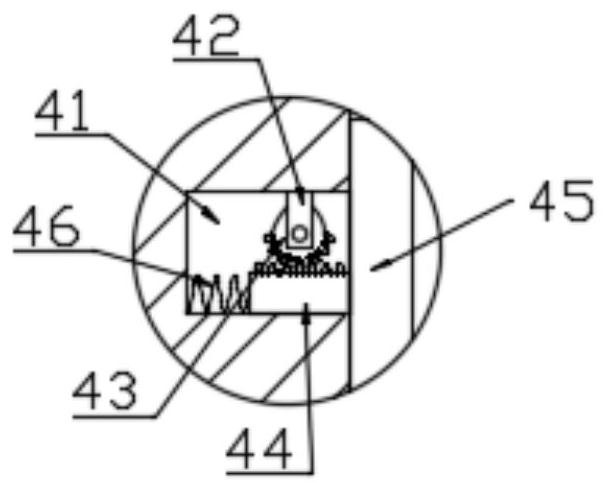

[0023] see Figure 1~4 , in an embodiment of the present invention, a platen device for waste aluminum products includes a feed assembly 01, a cleaning assembly 02, and a platen assembly 03, wherein the feed assembly 01 is used for entering and crushing waste aluminum products, and the cleaning assembly 02 is used for For the cleaning of waste aluminum products, the pressing plate assembly 03 is used to press the waste aluminum products, which is very simple; the feeding assembly 01 and the cleaning assembly 02 are connected through the discharge port 15, and the cleaning assembly 02 and the pressing plate assembly 03 Through the communication of the feeding channel 210, the waste aluminum products in the feeding assembly 01 can be transferred in the cleaning assembly 02 and the pressing plate assembly 03, which has very good practicability; in addition, the cleaning assembly 02 is equipped with a pushing assembly 04. The cleaning effect of waste aluminum products can be impro...

Embodiment 2

[0031] A connecting frame 36 is fixed above the pressing plate 34, and the connecting frame 36 runs through the pressing box 31 and is slidably connected with the guide bar 37 fixed on the top of the pressing box 31, and is connected by a spring 38 between the guiding bar 37 and the pressing box 31, thereby improving the The stability of the platen 34 during movement.

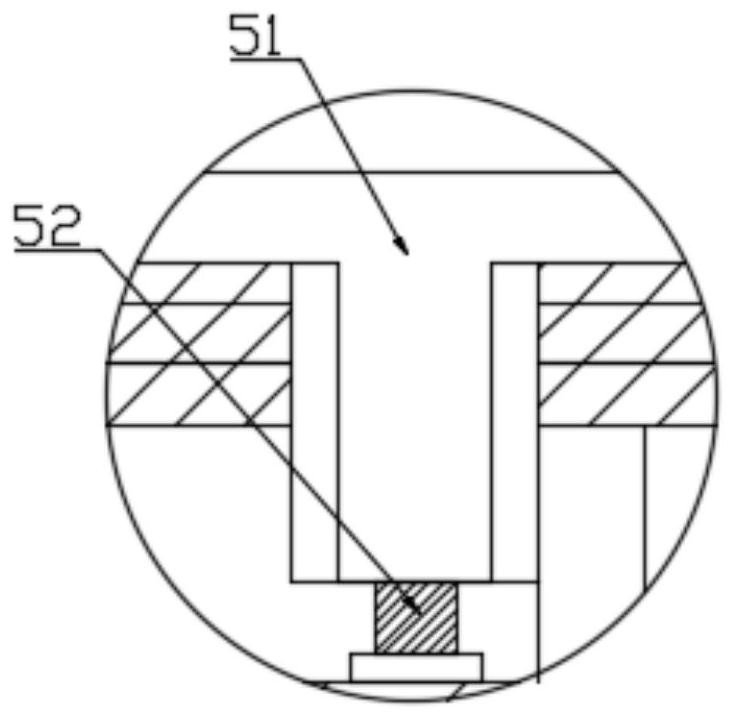

[0032]The working principle of the present invention is: the waste and old aluminum alloy enters the feed box 11 through the feed port 12, enters the cleaning cavity 23 in the cleaning box 21 after being pulverized by the crushing gear 13, and is stirred and cleaned by the stirring rod 26. During the cleaning process, the waste aluminum alloy at the edge is pushed to the middle position by the pusher assembly 04, and then the second motor 53 drives the threaded rod 52 to rotate, and then drives the stopper 51 to move upward, so that the waste aluminum alloy in the cleaning chamber 23 Enter the pressing plate as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com