Mold roller for film pressing machine for producing glitter films and film pressing machine

A mold roller and film press technology, which is applied to home appliances, other home appliances, applications, etc., can solve the problems of complicated printing operations, easy powder drop of glitter powder, and single pressing pattern, so as to achieve simple pressing process and high production efficiency. The method is simple and the pattern effect is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

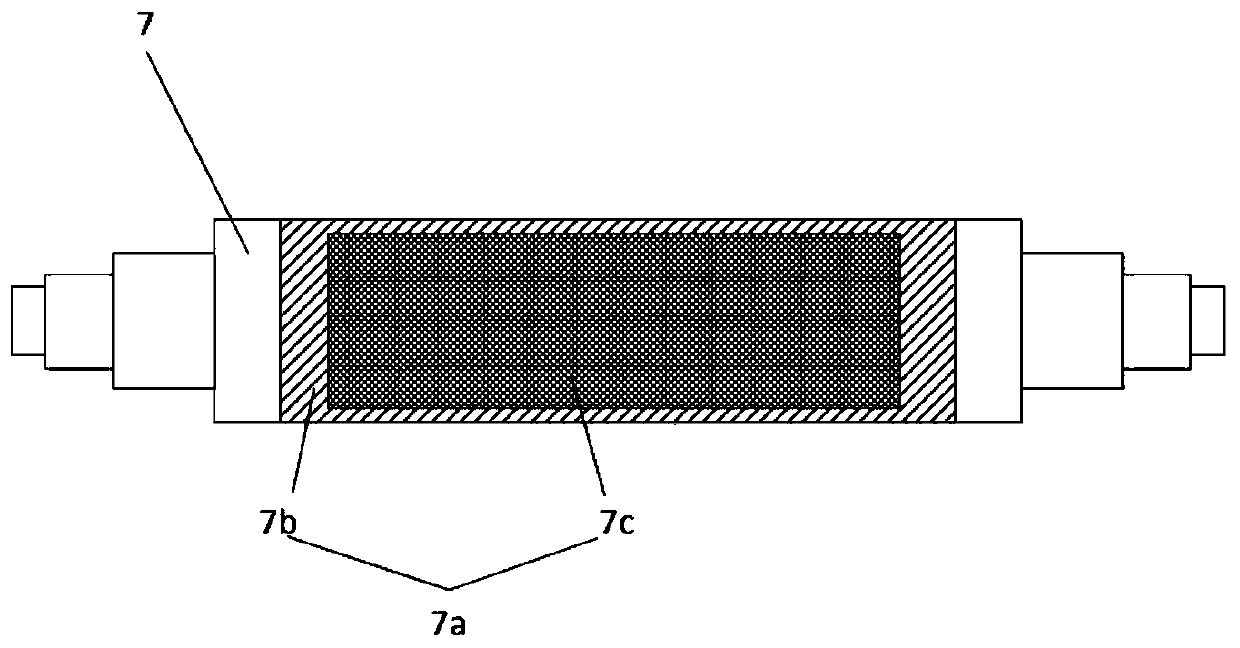

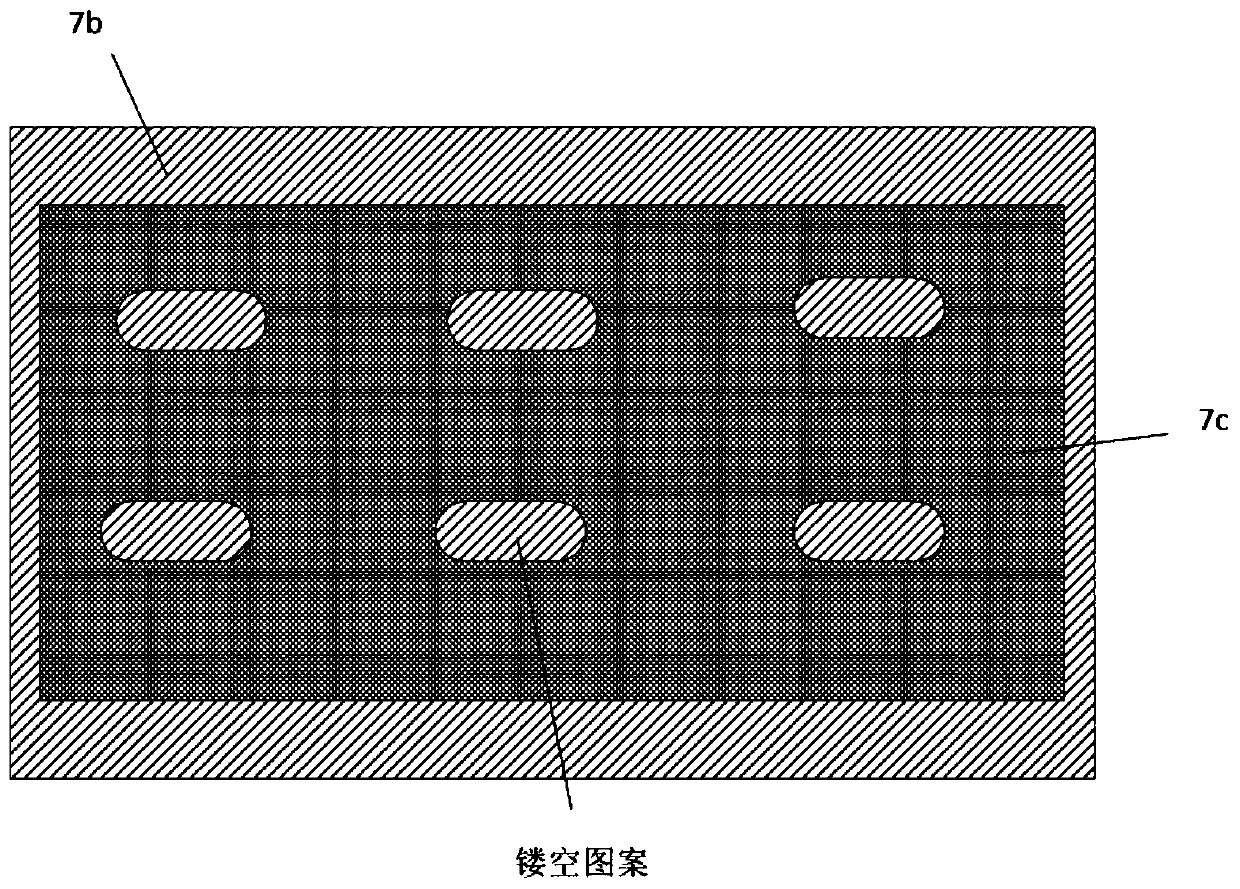

[0055] The mold roll template used in this embodiment is as figure 2 As shown, the template is: a layer of PVC film or PET film is used as the substrate 7b, and the glitter powder coating 7c is fixed on the PVC film or PET film. The glitter powder adopts aluminum foil hexagonal gold glitter powder, and The glitter powder coating is engraved with a hollow pattern, so that the glitter film prepared by hot pressing presents the effect of a hollow pattern. The membrane press used in this embodiment is as Figure 4 As shown, the film press includes a first unwinding roll 4, a second unwinding roll 5, a third unwinding roll 3, a thermal roll 9 and a first rubber roll 10 that are axially parallel and attached to each other, and The mold roll 7 is axially parallel to the second rubber roll 8, the first winding roll 2 and the second winding roll 1 that are attached to each other;

[0056] The first unwinding roller is used for winding the first layer of film, the second unwinding ro...

Embodiment 2

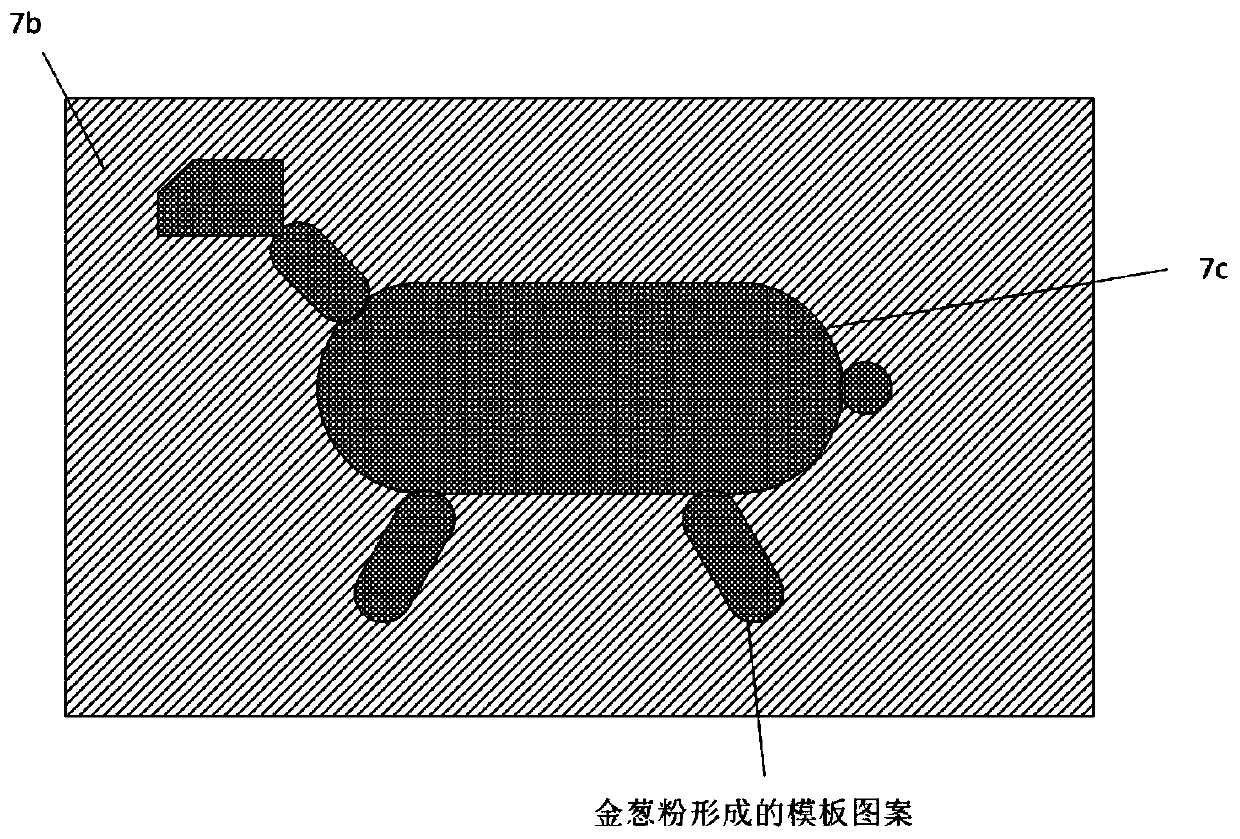

[0062] The mold roll template used in this embodiment is as Figure 4 As shown, the template is: a layer of cardboard is used as the substrate 7b, and the glitter powder coating 7c is fixed on the cardboard. The glitter powder uses PET square laser glitter powder, and the required pattern is drawn using the glitter powder. Make the glitter powder coating be the stencil pattern layer. Thus, the glitter film prepared by hot pressing shows a drawing pattern with a laser effect. The membrane press used in this embodiment is as Figure 5 As shown, the film press includes a first unwinding roll 4, a second unwinding roll 5, a third unwinding roll 3, a thermal roll 9 and a first rubber roll 10 that are axially parallel and attached to each other, and The mold roll 7 is axially parallel to the second rubber roll 8, the first winding roll 2 and the second winding roll 1 that are attached to each other;

[0063] The first unwinding roller is used for winding the first layer of film, ...

Embodiment 3

[0069] In this example, on the basis of Example 1, the substrate is replaced with cotton cloth, and a glitter film is prepared by hot pressing. The film press used in this example and other preparation processes are the same as in Example 1, and the effect of the glitter film prepared by hot pressing is equivalent to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com