A method for preparing corrosion samples of welded joints of metal composite plates

A metal composite plate and welded joint technology, which is applied in the preparation, sampling, and instrumentation of test samples, can solve problems such as the inability to ensure the density of the isolation layer and the corrosion sample, and the isolation of one surface is not allowed, so as to overcome the problem of processing Difficulty, the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

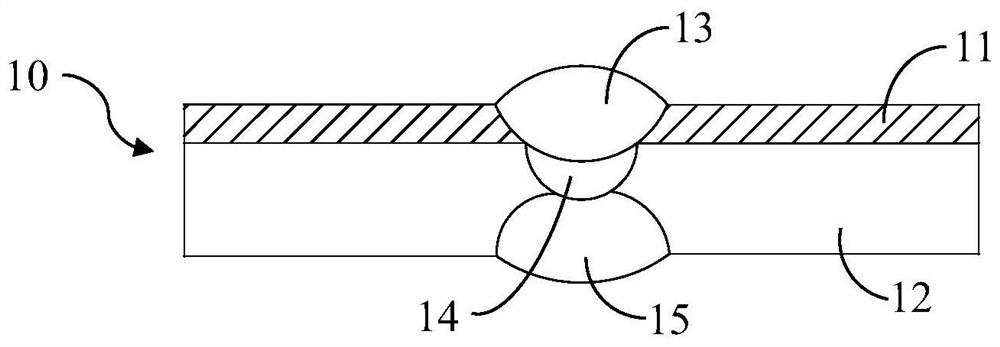

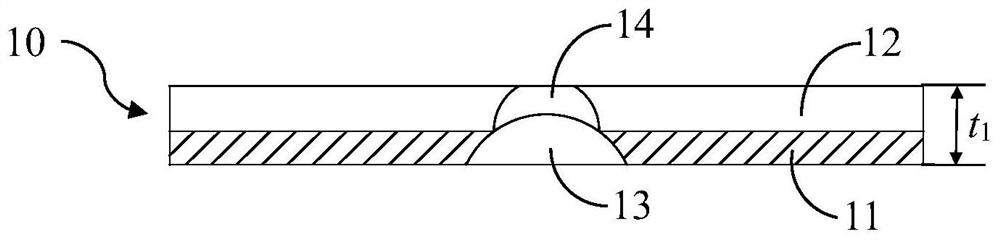

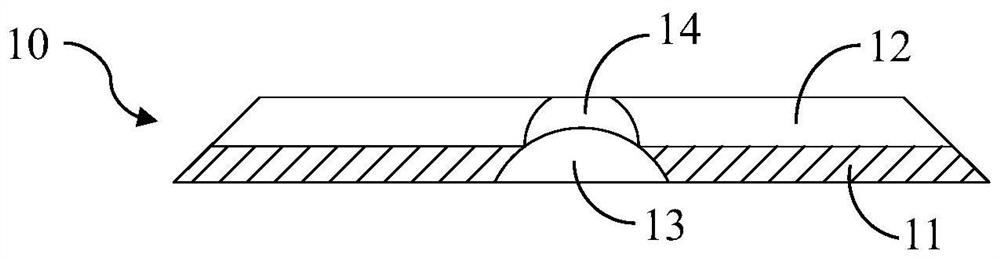

[0030] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

[0031] The metal composite plate includes a cladding layer and a base layer, and the preparation method of the welded joint corrosion sample of the metal clad plate of the present invention is to prepare a welded joint corrosion sample with only cladding components, see Figure 1 to Figure 6 , the preparation method of metal clad plate welded joint corrosion sample of the present invention comprises:

[0032] Step 1, select a metal composite plate blank sample 10 with welded joints.

[0033] Due to the deviation of the welding process, different metal composite panels have different welding deformations, and the cladding of the metal composite panels is generally thin, with a thickness between 1 and 3 mm. Once the deformation of the welding test panel is too large, the standard will not be obtained. Corrosion samples, therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com