Coal processing method and system

A processing method and gas technology, which can be used in hydrotreating process, chemical instruments and methods, petroleum industry, etc., can solve problems such as difficult processing, and achieve the effects of high added value, reduced storage and transportation investment, and concentrated product types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

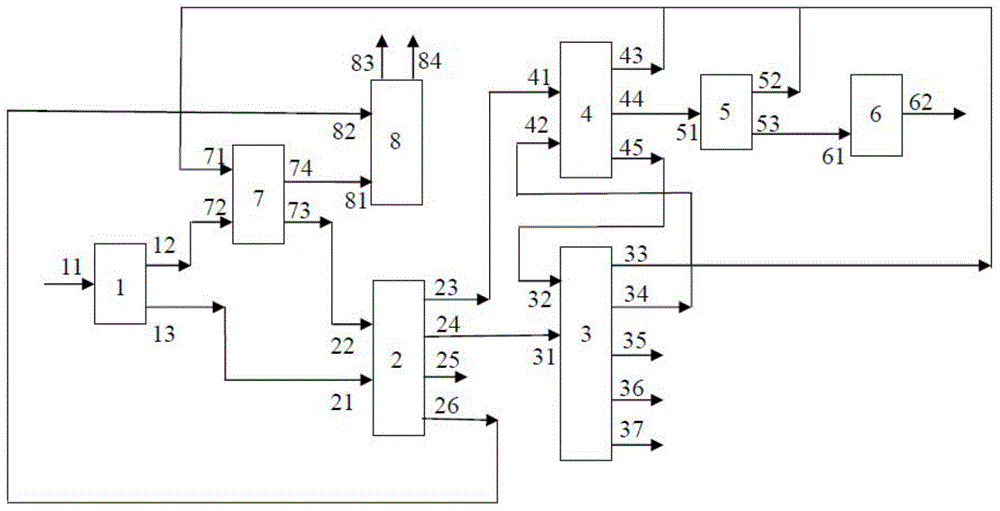

Method used

Image

Examples

preparation example Construction

[0056] (5) Preparation of propane dehydrogenation and polypropylene: the propane obtained in step (4) is subjected to propane dehydrogenation and preparation of polypropylene to obtain polypropylene and hydrogen products;

[0057] (6) The hydrogen product obtained in step (3) and / or step (4) and / or step (5) is purified by pressure swing adsorption (PSA) as hydrogen required for hydrocracking in step (2) ; and the hydrogen production process comprising at least pressure swing adsorption (PSA) is used to produce hydrogen from coal dry distillation or coal gasification in step (1) as a raw material, and the hydrogen obtained is used as hydrogenation in step (2) Hydrogen for cracking;

[0058] (7) using the coal dry distillation or coal gasification in step (1) to obtain the impurities containing sulfur and nitrogen obtained after producing hydrogen as a raw material, and obtain sulfur and liquid ammonia products through the sulfur recovery unit; and the step (2) The impurities c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com