Method and device for 3D printing of thermosetting material or photosensitive material

A 3D printing, photosensitive material technology, applied in the field of thermosetting material or photosensitive material 3D printing and device, can solve the problem of limiting the application of thermosetting resin, avoid thermal degradation risk and loss, improve performance, and obvious economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, a method and device for 3D printing of thermosetting materials are provided. The raw material used in this embodiment is a thermosetting material, so that the thermosetting resin has a certain fluidity in the nozzle of the 3D printer, and then the resin on the working platform is cured with a laser. The present invention uses thermosetting plastics as raw materials to carry out 3D printing, which can promote the deep development of 3D printing technology, so that thermosetting plastics can be applied to more products.

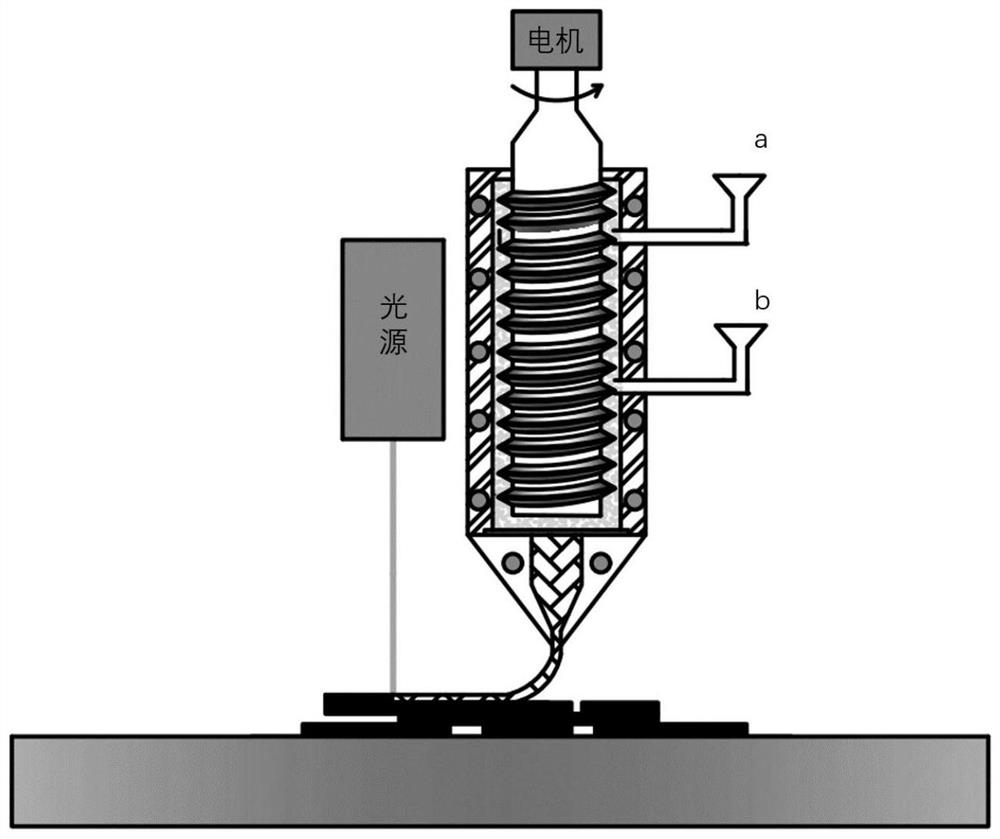

[0030] The thermosetting resin 3D printing device of this embodiment implements the method of thermosetting resin 3D printing of the present invention, including a feeding system, a 3D printer nozzle, a temperature control device, a laser device and a workbench, and the resin is passed through a delivery pipeline and a computer control valve. The feeding system enters the nozzle of the printer, and the temperature is controlled by the...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, especially in that:

[0034] In this example, see figure 1, the resin used is bisphenol A epoxy resin E51, and the curing agent is dicyandiamide. The epoxy resin and dicyandiamide are transported from the feed port to the barrel for mixing according to a certain ratio, the screw temperature is set at 55-60°C, and the extrusion rate is set at 0.2m / s, so that E51 has a flow in the screw nozzle. properties, and the dicyandiamide curing epoxy resin condition is 150 ~ 170 ℃, so the resin will not solidify at the nozzle and block the nozzle. As the raw materials are continuously conveyed to the barrel, the resin is also continuously extruded and accumulated on the workbench, and solidified and formed under laser heating to obtain epoxy resin 3D printed products. The tensile strength of the obtained 3D printed products can reach Up to 100MPa.

[0035] At present, the most commonly used printing material in the tradition...

Embodiment 3

[0037] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0038] In this example, see figure 1 , the resin used is bisphenol A type epoxy resin E20, and the curing agent is phthalic anhydride. A certain ratio of epoxy resin and phthalic anhydride is transported from the feed port to the barrel for mixing, the screw temperature is set at 40-60°C, and the extrusion speed is set at 0.1m / s, so that E20 has a Fluidity, and the melting point of phthalic anhydride is 128 ° C, so the resin will not solidify at the nozzle and block the nozzle. As the raw materials are continuously conveyed to the barrel, the resin is also continuously extruded and accumulated on the workbench. It is cured and formed under laser heating to obtain epoxy resin 3D printed products with a tensile strength of up to 80MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com