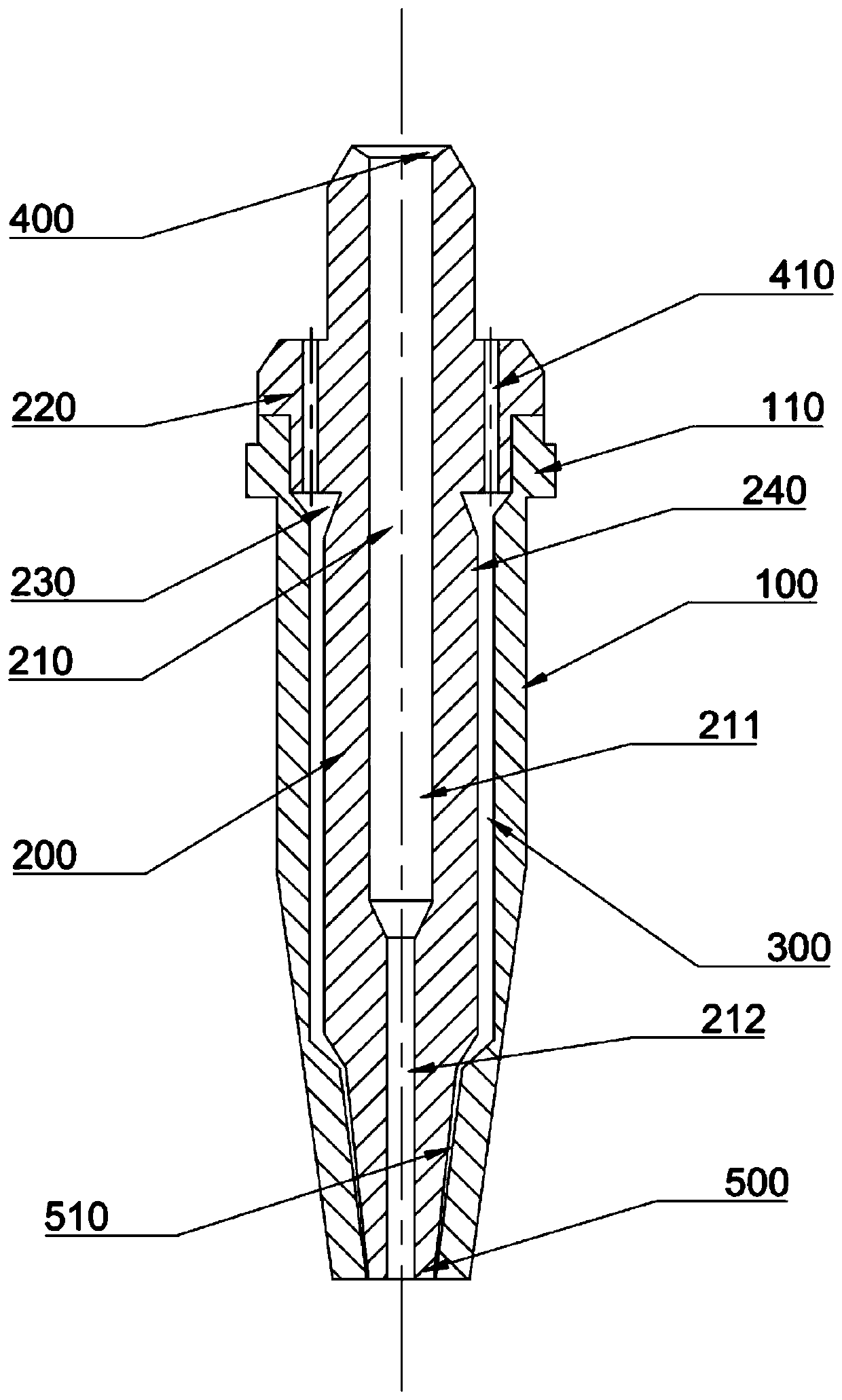

Acetylene cutting nozzle and production process thereof

A production process and technology of cutting nozzles, applied in the field of acetylene cutting nozzles and its production technology, can solve the problems of cutting nozzle processing difficulties, insufficient mixing, small volume of mixed gas chamber, etc., and achieve easy promotion, sufficient gas mixing, and overcome processing difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a production process of an acetylene cutting nozzle, including the following steps:

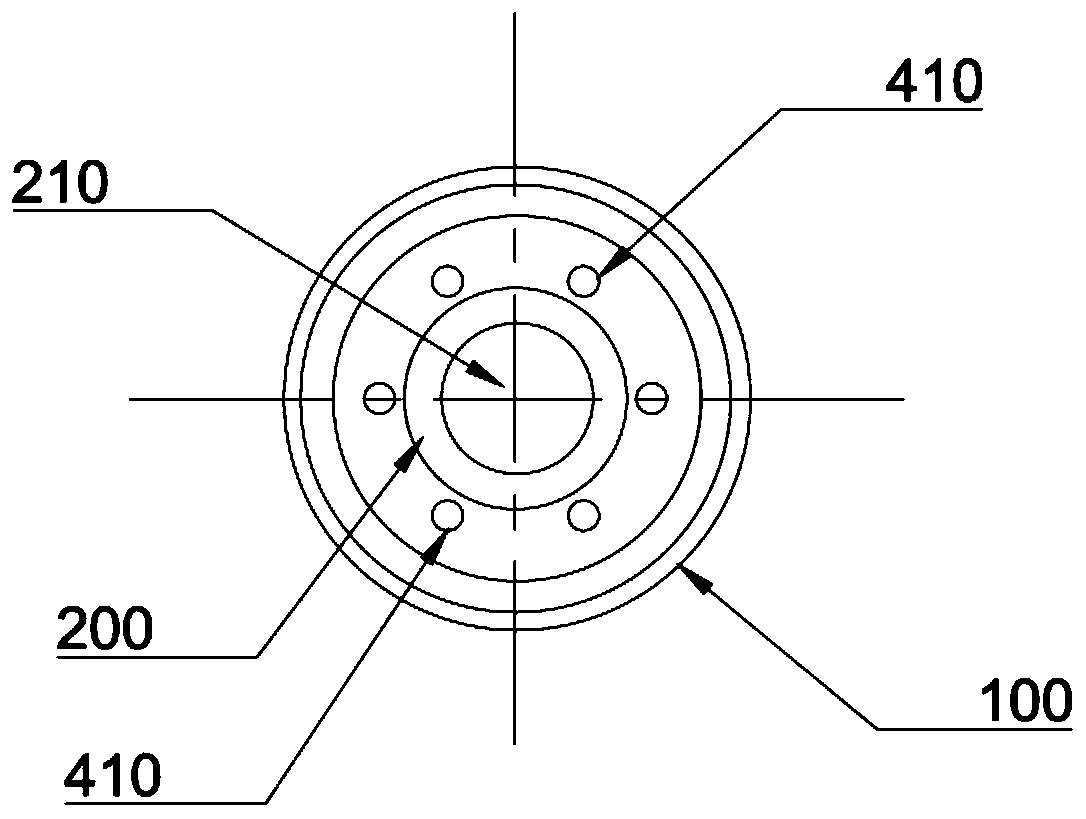

[0053] (1) Using copper rods as raw materials, according to the set external dimensions and shapes, the raw materials are made into outer nozzle preforms and inner nozzle preforms using a cold heading machine. The outer nozzle preforms are cold forged to form a connecting platform, and the outer nozzle The preform is cold-headed to form a sleeve structure with a connecting groove;

[0054] (2) Further processing the inner nozzle preform, punch the center of the inner nozzle preform to obtain an oxygen flow mechanism, punch out the air inlet holes evenly at the air inlet end of the inner nozzle, and cut air grooves inward along the outer wall of the inner nozzle Connect with the air inlet;

[0055] (3) Sleeve the processed inner nozzle preform into the outer nozzle preform, the connecting table is embedded in the connecting groove, and the connecting table is punched ...

Embodiment 2

[0060] This embodiment provides a production process of an acetylene cutting nozzle, including the following steps:

[0061] (1) Using copper rods as raw materials, according to the set external dimensions and shapes, the raw materials are made into outer nozzle preforms and inner nozzle preforms using a cold heading machine. The outer nozzle preforms are cold forged to form a connecting platform, and the outer nozzle The preform is cold-headed to form a sleeve structure with a connecting groove;

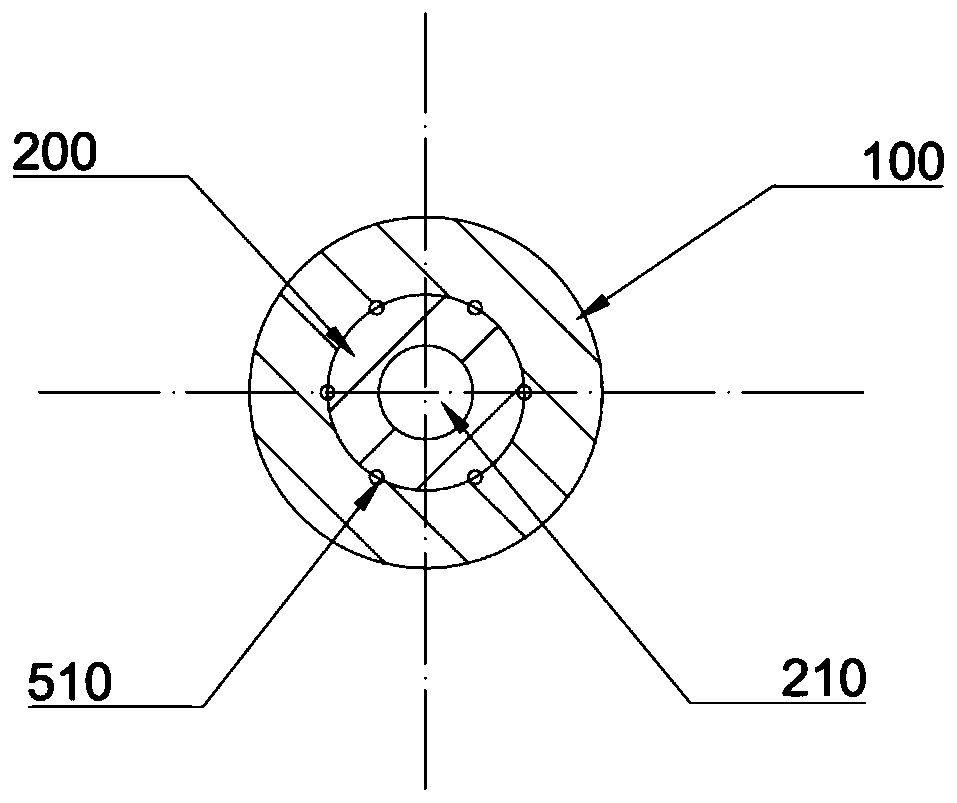

[0062] (2) Further processing the inner nozzle preform, punch the center of the inner nozzle preform to obtain an oxygen flow mechanism, and evenly punch 6 air inlet holes through the connecting table at the air inlet end of the inner nozzle, and place them on the lower edge of the connecting table. Cut the air groove inward along the outer wall of the inner nozzle to communicate with the air inlet hole, and mill out 6 long grooves uniformly in the circumferential direction along the out...

Embodiment 3

[0068] This embodiment provides a production process of an acetylene cutting nozzle, including the following steps:

[0069] (1) Using copper rods as raw materials, according to the set external dimensions and shapes, the raw materials are made into outer nozzle preforms and inner nozzle preforms using a cold heading machine. The outer nozzle preforms are cold forged to form a connecting platform, and the outer nozzle The preform is cold-headed to form a sleeve structure with a connecting groove. At the outlet end of the outer nozzle preform, 6 long grooves are milled circumferentially along the inner wall of the preform, and the diameter of the long groove is larger than that of the set fire hole;

[0070] (2) Further processing the inner nozzle preform, punch the center of the inner nozzle preform to obtain an oxygen flow mechanism, punch out the air inlet holes evenly at the air inlet end of the inner nozzle, and cut air grooves inward along the outer wall of the inner nozzle Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com