Mobile phone front shell, machining method thereof, mobile phone and machine tool

A processing method and technology of processing machine tools, which are applied in metal processing, telephone structure, and other household appliances, etc., can solve the problems that mass production cannot be realized, and pillars are easily broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

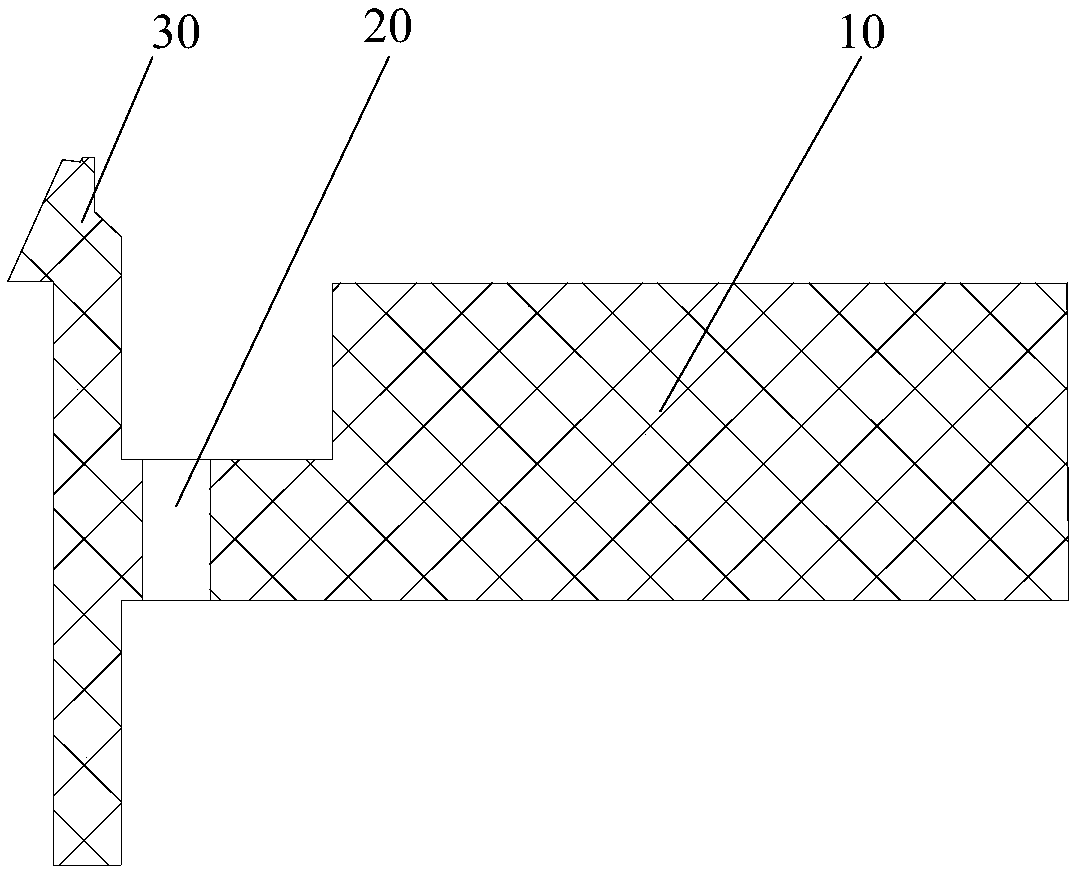

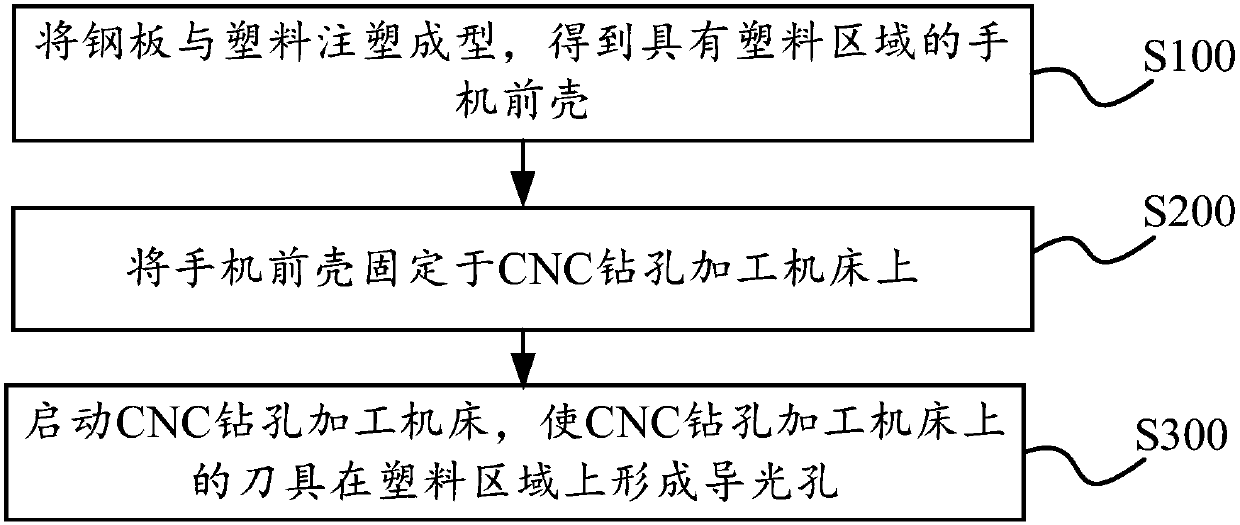

[0058] A method for processing the front case of a mobile phone. The front case 10 of the mobile phone has a light guide hole 20. The processing method includes: injecting a steel plate and plastic to obtain the front case 10 of the mobile phone with a plastic area; fixing the front case 10 of the mobile phone to a CNC drill. On the hole processing machine tool; start the CNC drilling machine tool, so that the cutter 30 on the CNC drilling machine tool forms the light guide hole 20 on the plastic area, the rotating speed of the CNC drilling machine tool is 160000r / min, and the blade on the tool 30 passes through It is processed by CNC, the blade length is 0.9 mm, and the diameter of the light guide hole 20 is 0.15 mm. Preferably, the working pressure of the CNC drilling machine is 1100 MPa.

Embodiment 2

[0060] A method for processing the front case of a mobile phone. The front case 10 of the mobile phone has a light guide hole 20. The processing method includes: injecting a steel plate and plastic to obtain the front case 10 of the mobile phone with a plastic area; fixing the front case 10 of the mobile phone to a CNC drill. On the hole processing machine tool; start the CNC drilling machine tool, so that the cutter 30 on the CNC drilling machine tool forms the light guide hole 20 on the plastic area, the rotating speed of the CNC drilling machine tool is 150000r / min, and the blade on the tool 30 passes through It is processed by CNC, the blade length is 0.85 mm, and the diameter of the light guide hole 20 is 0.1 mm. Preferably, the working pressure of the CNC drilling machine tool is 1200 MPa.

Embodiment 3

[0062] A method for processing the front case of a mobile phone. The front case 10 of the mobile phone has a light guide hole 20. The processing method includes: injecting a steel plate and plastic to obtain the front case 10 of the mobile phone with a plastic area; fixing the front case 10 of the mobile phone to a CNC drill. On the hole processing machine tool; start the CNC drilling machine tool, so that the cutter 30 on the CNC drilling machine tool forms the light guide hole 20 on the plastic area, the rotating speed of the CNC drilling machine tool is 170000r / min, and the blade on the tool 30 passes through It is processed by CNC, the blade length is 0.9 mm, the diameter of the light guide hole 20 is 0.17 mm, and the working pressure of the CNC drilling machine tool is 1000 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com