Ultrasonic detection device and data processing method for bolt joint surface

A bolt joint surface and data processing technology, which is applied to measurement devices, uses ultrasonic/sonic/infrasonic waves, and uses sonic/ultrasonic/infrasonic waves to analyze solids, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

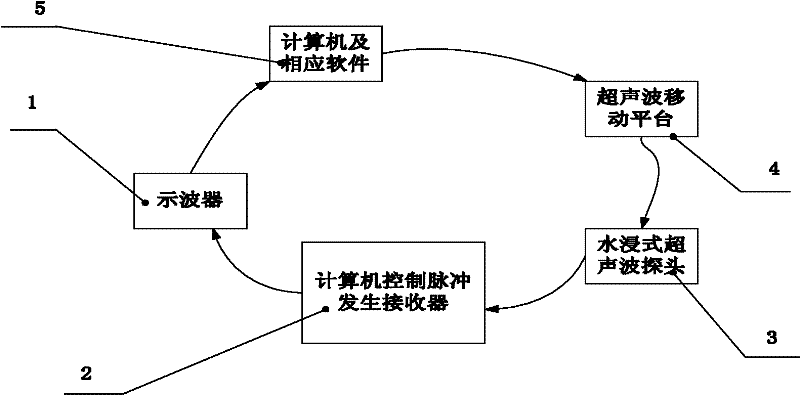

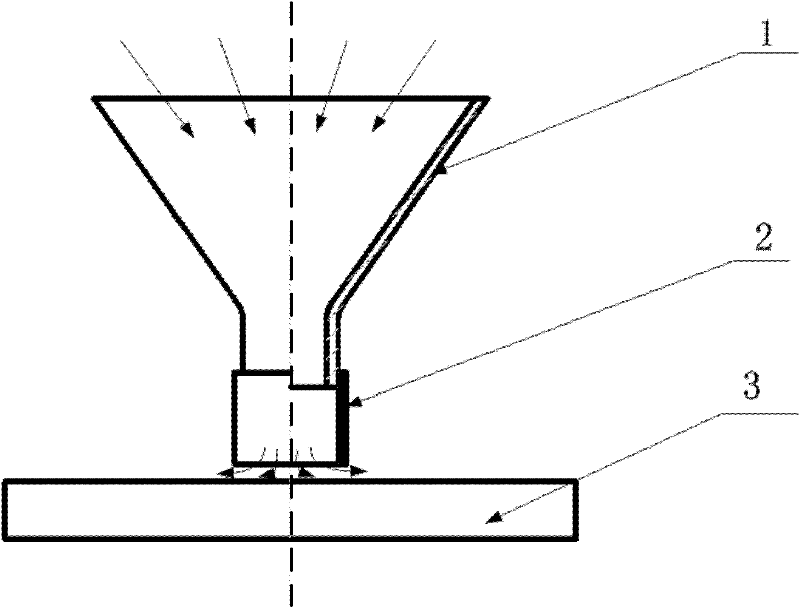

[0035] Ultrasonic detection bolt joint surface device:

[0036] figure 1 In the figure 4 is the mobile platform; in the figure 2 is the ultrasonic pulse receiving transmitter, 3 is the ultrasonic transducer, 2 and 3 form the ultrasonic transmitting and receiving device; in the figure 1 and 5 are data acquisition and processing device. The ultrasonic transducer shown in Figure 3 is installed on the mobile platform and connected to 2 pulse transmitter receivers through data lines; Figure 1 is an oscilloscope, which is connected to 2 through data lines; Figure 5 is a computer, which is connected to the oscilloscope through a network cable , using the software labview to realize data collection and storage.

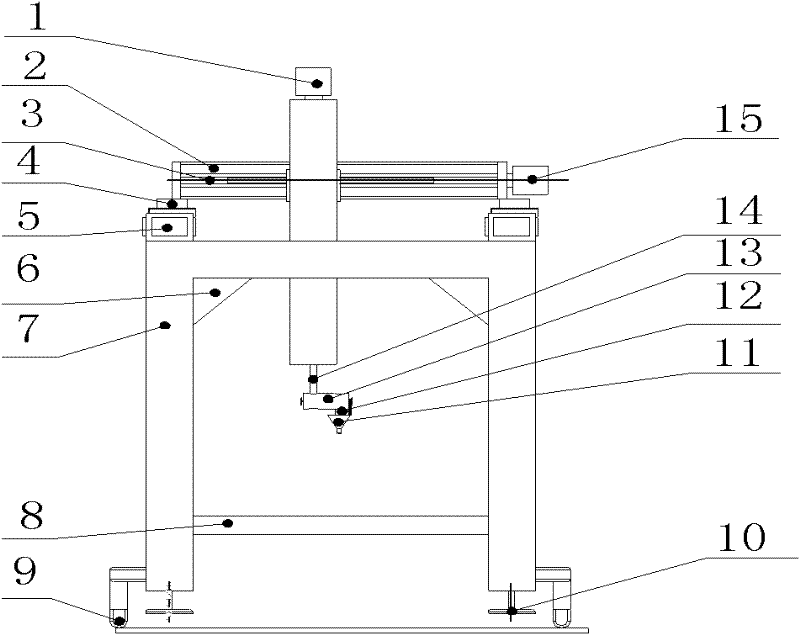

[0037] figure 2 It is a mobile platform, and the mobile translation platform of the ultrasonic measurement joint surface mainly consists of a mobile bracket and a micro-motion measuring device. The mobile bracket mainly includes a moving wheel 9, a leveling nut 10 and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com