Stamping process of double-folded-edge back plate structure

A double edge folding and back plate technology is applied in the field of stamping technology, which can solve the problems of increased cost and easy scraping of foreign objects, and achieves the effect of solving energy consumption and production cost, and processing reasonable and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

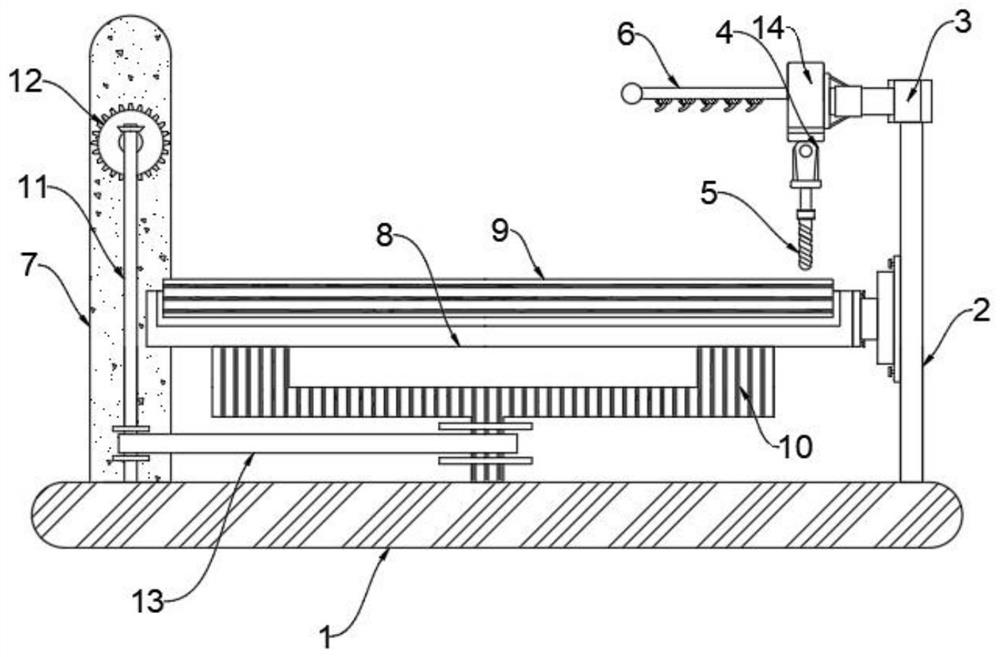

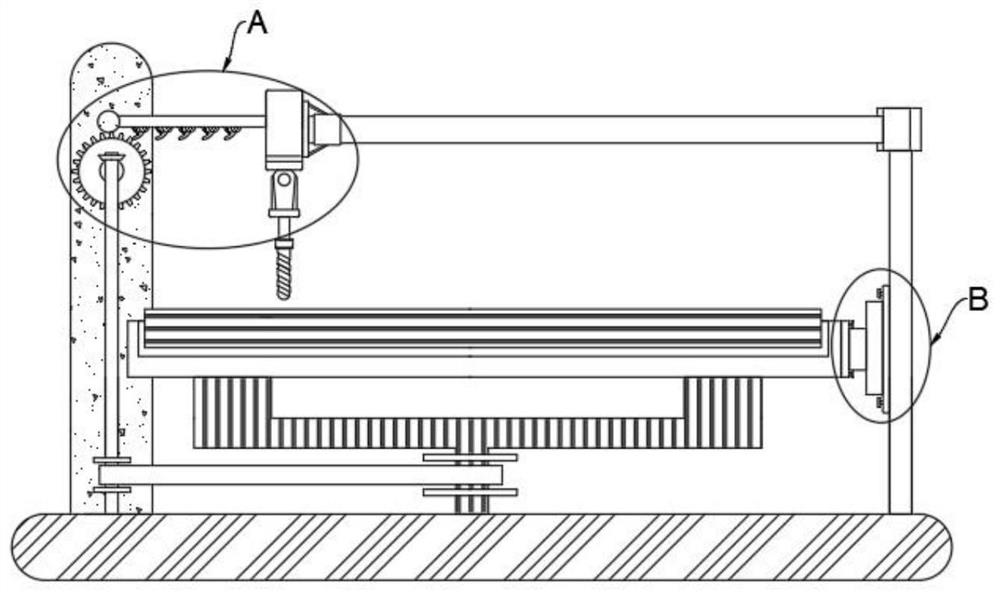

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

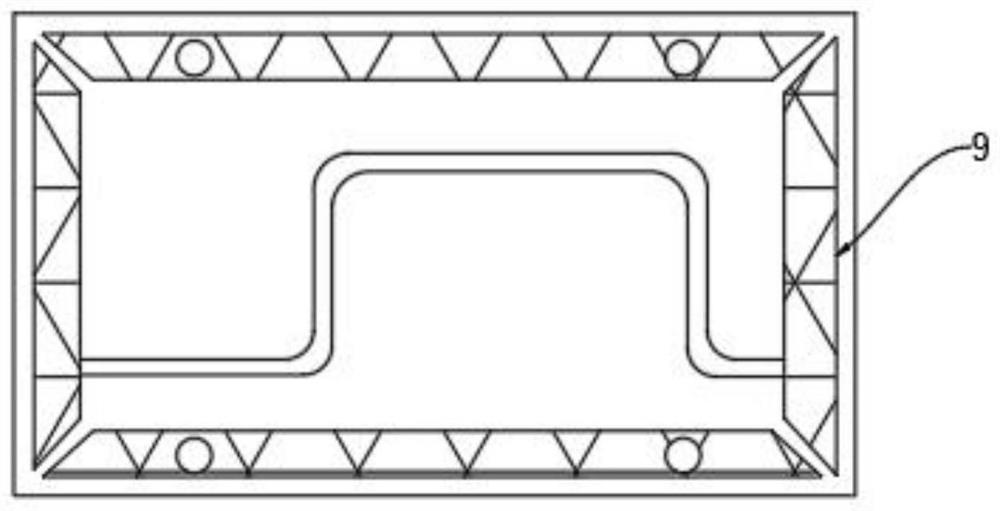

[0023] refer to Figure 1-5 , a stamping process of a double-folded backboard structure, comprising the following steps: S1, embossing, embossing in the middle area of the backboard forming to form a convex hull structure, and simultaneously drawing holes on the backboard around the surroundings, One circle is a semicircular drawing bead; S2, plane shaping, partial trimming, use a cutting device to cut part of the edge of the backboard; S3, trimming, punching, use a cutting device to trim the backboard Cut the outer dimensions of the backplane, and then use the punching device to punch holes around the screw holes on the backplane; S4, bend, form and position the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com