High voltage LED (light-emitting diode) chip and manufacturing methods thereof

A technology of LED chips and manufacturing methods, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of heat dissipation, unreliable chip interconnection, etc., and achieves convenient electrode interconnection, low manufacturing cost, and solution Effects of production cost issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the following descriptions are only to illustrate the principles of the present invention, rather than limiting the present invention and the descriptions of the following specific embodiments.

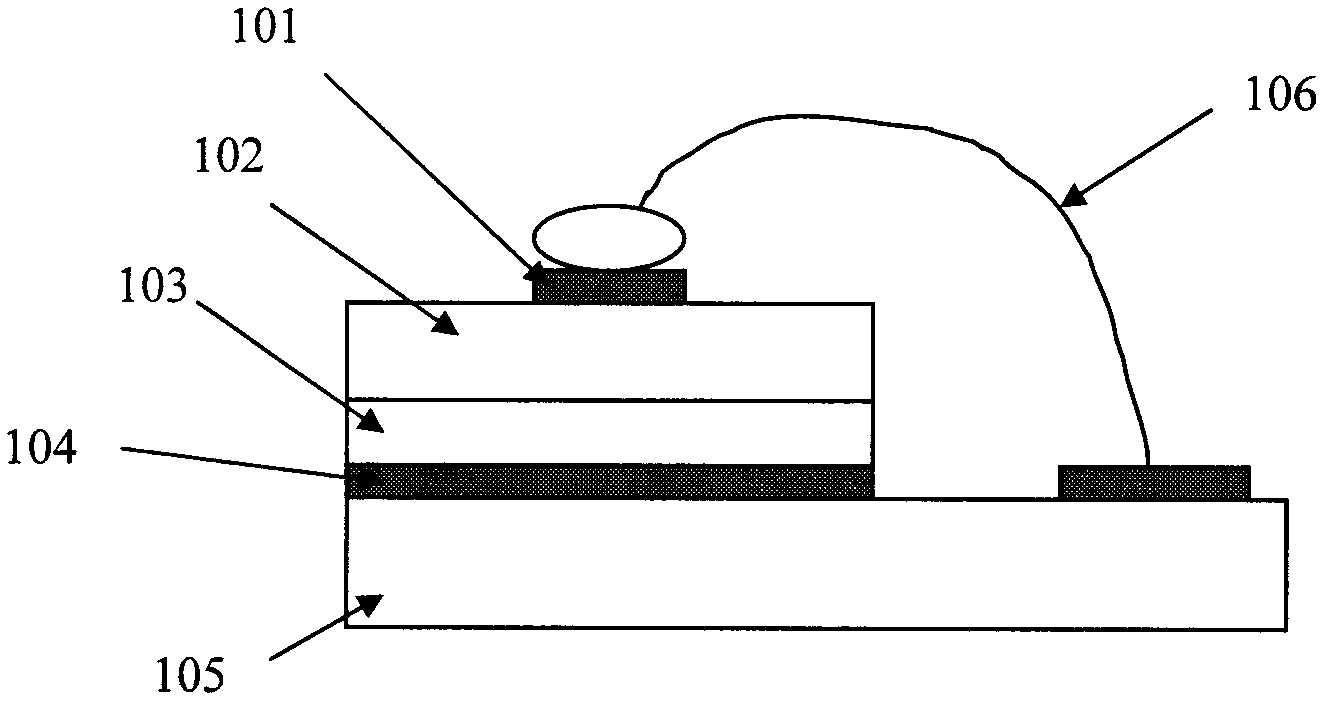

[0022] figure 1 Disclosed is a previous vertical structure LED chip. The LED chips containing the n-type semiconductor layer 102 and the p-type semiconductor layer 103 are respectively plated with a conductive electrode 101 and a reflective electrode 104, and then the reflective electrode 104 is bonded on the carrier substrate 105, and the conductive electrode 101 is bonded to the carrier substrate by putting gold wires 106 on it. connected to the other electrode.

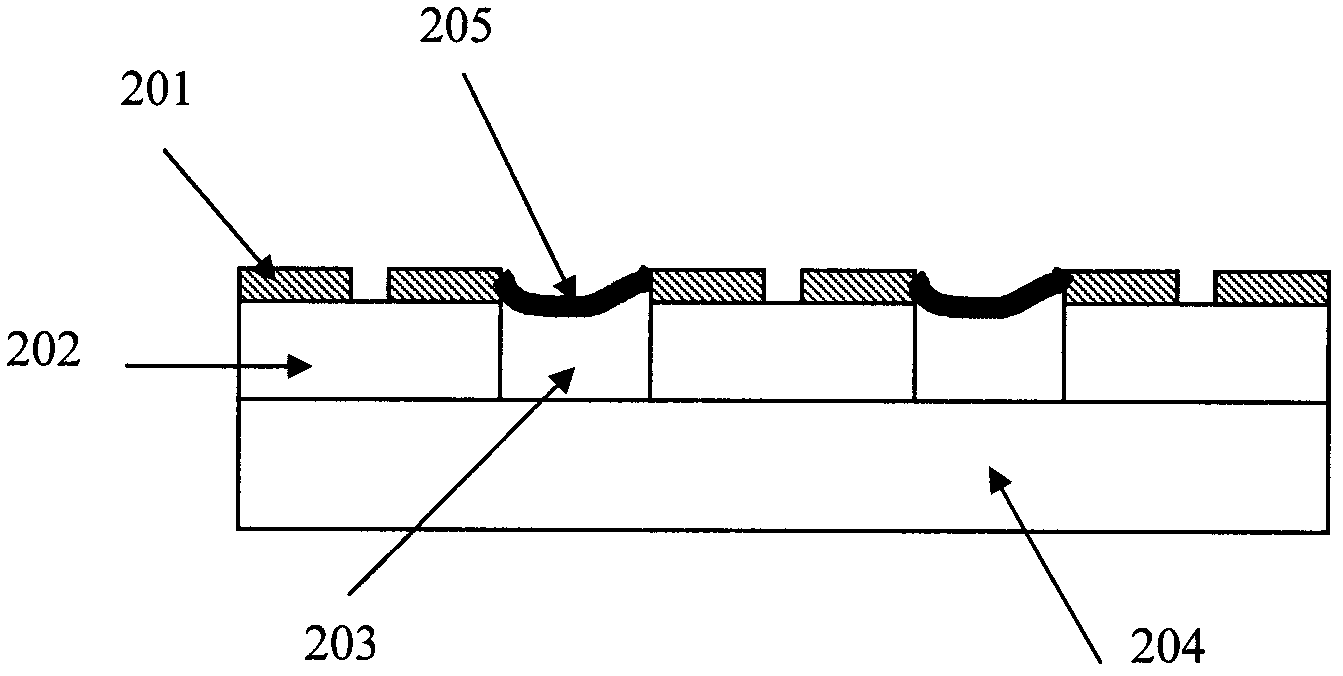

[0023] figure 2 Disclosed are prior high voltage LED chips. Firstly, an LED epitaxial layer is grown on the substrate 204, and then the LED unit chips 202 are isolated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com