Toughened intermetallic compound, preparation method of toughened intermetallic compound and apparatus

An intermetallic compound and toughening technology, which is applied in the field of toughened intermetallic compound and its preparation, can solve the problems of low material utilization rate, poor forming process, and poor feasibility of performance design, so as to improve material utilization rate and reduce Development cost, effect of ensuring internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Attached below figure 1 And embodiment further illustrate the present invention.

[0048] Preparation:

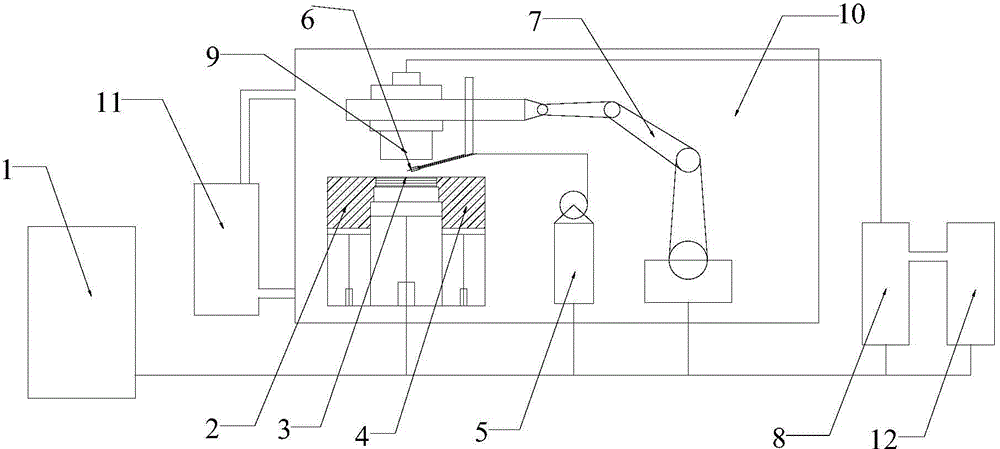

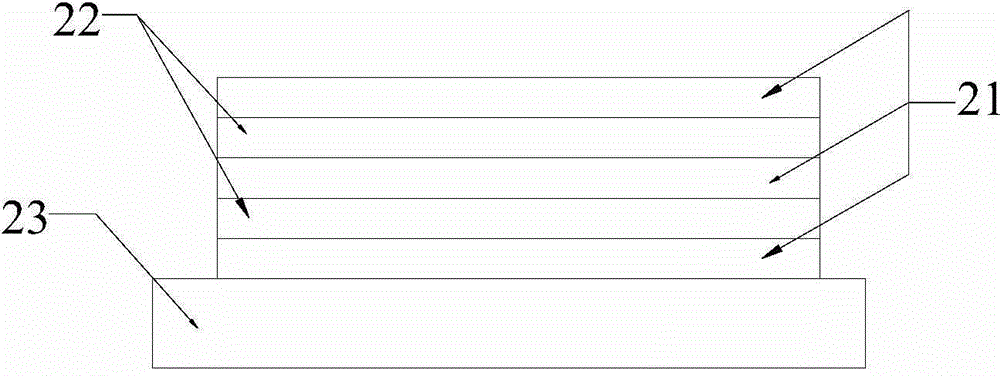

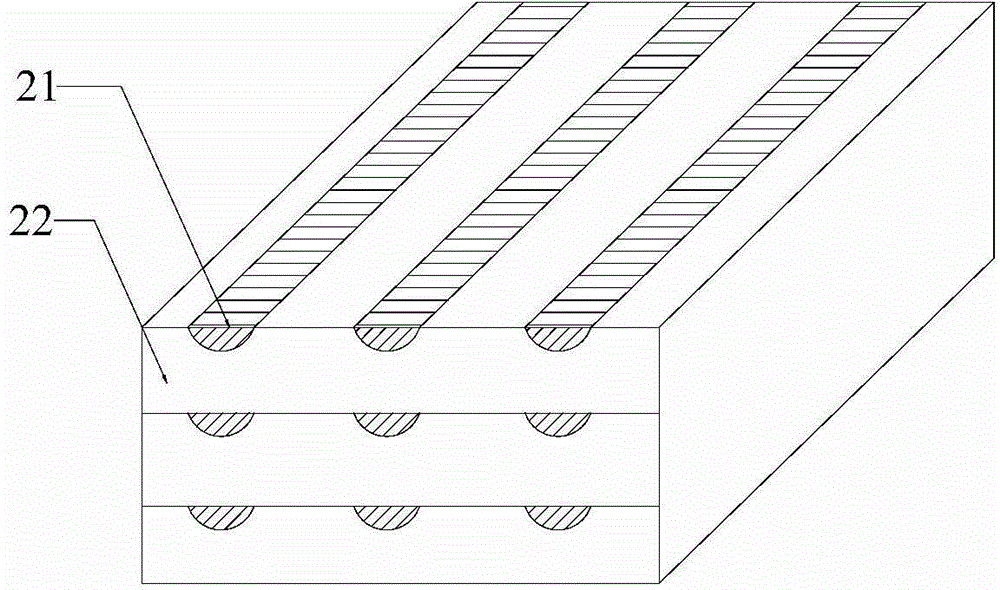

[0049] First put the γ-TiAl intermetallic compound powder into the powder bed supply cylinder 2, put the metal Nb (or refractory metal such as Mo) wire with a diameter of 0.01 into the wire feeder 5 and send it to the wire feeder nozzle 6; fix The substrate 23 is connected to the forming platform 3, and the laser scanning vibrating mirror 9 is connected to the multi-axis linkage arm 7 through the fixed connection flange of the processing head / manipulator; the inert gas chamber 10 is filled with argon.

[0050] Then, start the forming platform 3, water cooling system 12, atmosphere control and dust removal system 11, wire feeder 5, laser generator 8, laser scanning vibrating mirror 9, multi-axis linkage arm 7, etc. through the industrial computer 1;

[0051] Requirements for working conditions before preparation: the oxygen content in the inert gas chamber 10 is les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com