Composite material casing containing inward-flanging windows, forming die and forming method

A composite material and inner flanging technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low weight and high structural efficiency, achieve light weight, improve structural efficiency, and ensure the effect of resisting internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

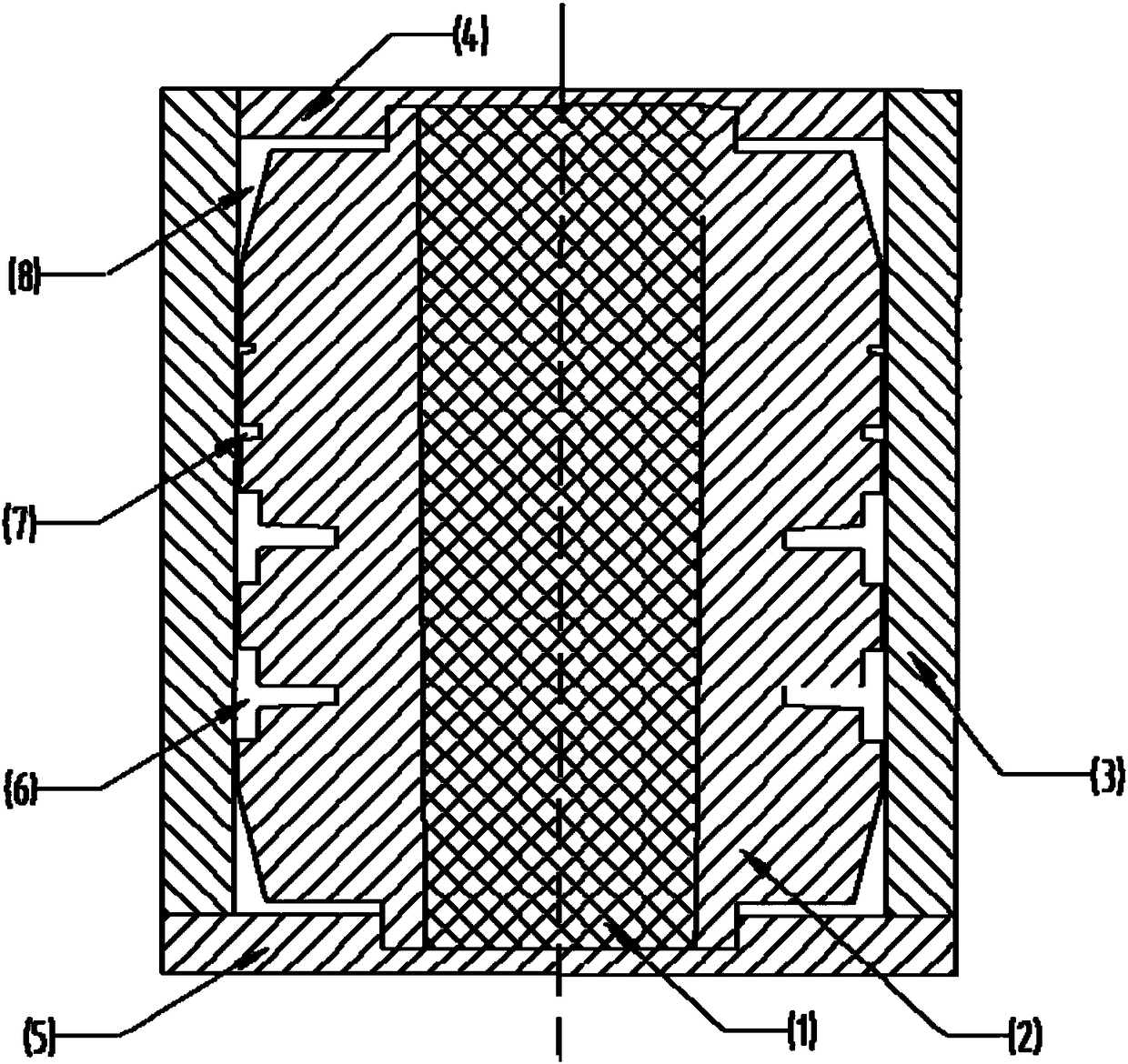

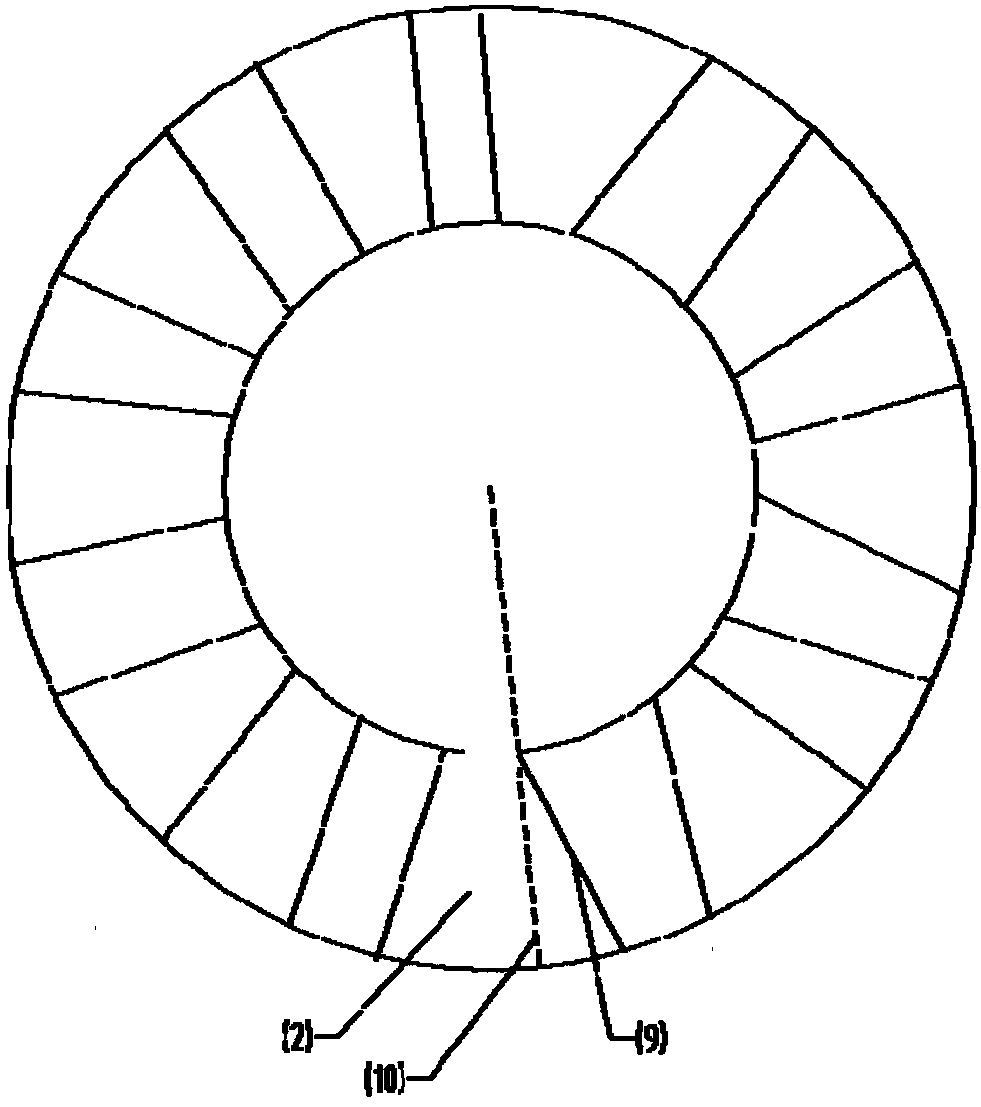

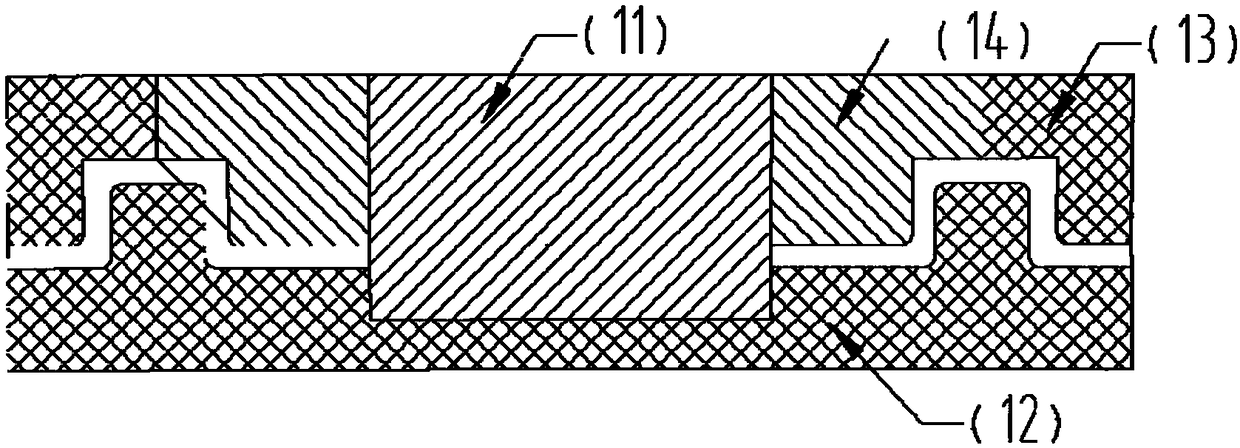

[0046] Such as figure 1 As shown, the rib-skin structure composite shell forming mold with inner flanged windows includes a core mold 1, a male film 2, an outer female mold 3, an upper pressure ring 4 and a lower pressure ring 5. The male mold 2 is composed of a plurality of split units, the inner surface of each split unit is fixedly connected with the mandrel 1, and the split line 10 of two adjacent split units intersects with the radius 9 of the mandrel where it is located, as figure 2 shown. The split unit forms an outward pressure during the thermal expansion process to ensure that pressure is applied to the window, ribs, skin, and thickening areas of variable thickness to ensure the internal quality of the product. Consistent with the shape of the composite material component to be produced, the molding die described in the present invention can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com