Self-cleaning dust collection filter screen for spinning

A filter and self-cleaning technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of filter mesh clogging, suction, wind rotor blade idling, falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

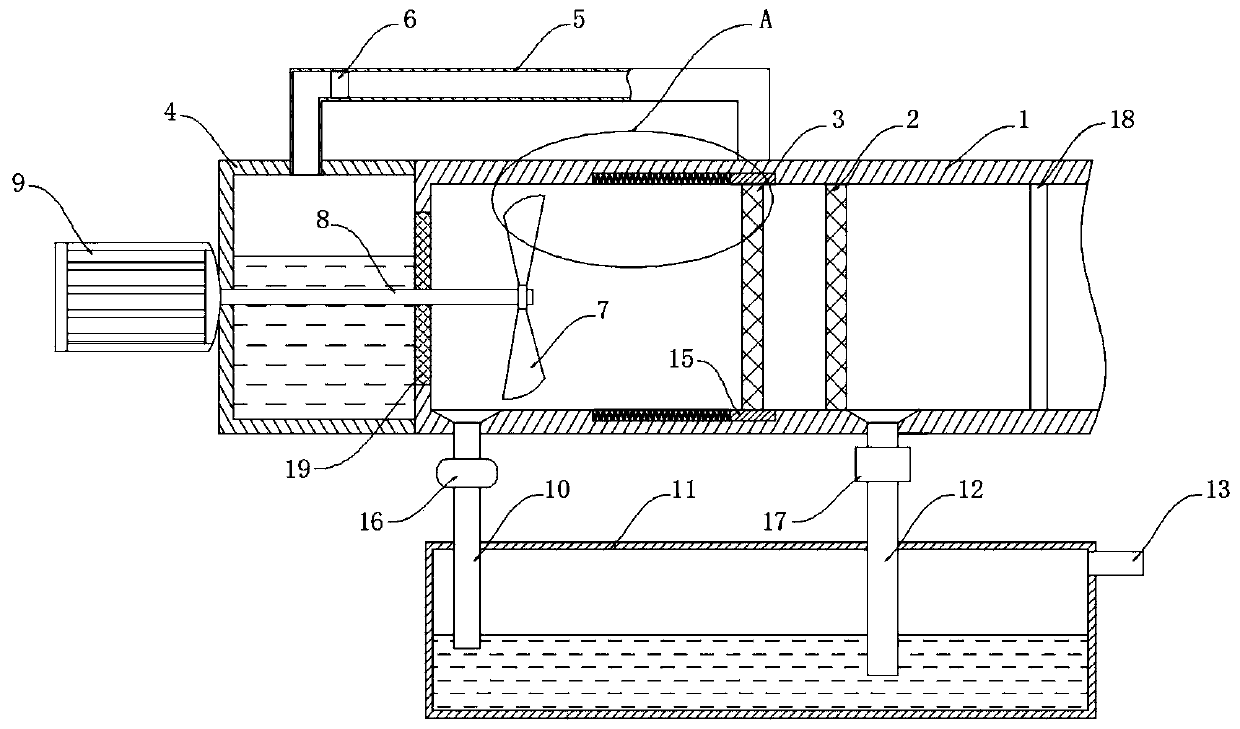

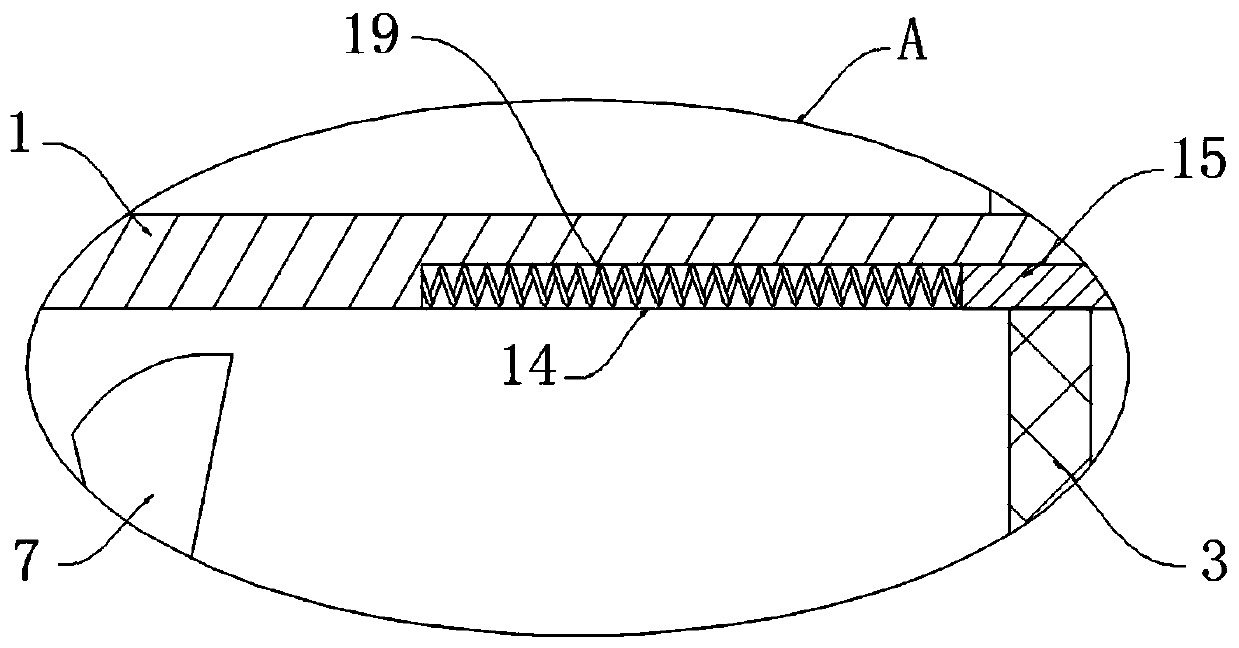

[0022] refer to Figure 1-2 , a self-cleaning dust suction filter screen for textiles, comprising a dust suction pipe 1, a first filter screen 2 and a second filter screen 3 are respectively arranged in the dust suction pipe 1, the first filter screen 2 and the inner wall of the dust suction pipe 1 Sealed and fixed connection, the second filter screen 3 is connected with a sliding device, the dust suction pipe 1 is provided with a wind wheel 7, the wind wheel 7 adopts the blade structure of a centrifugal fan, so that the rotation of the wind wheel 7 will be close to the first filter screen 2 One side of the wind turbine creates a low pressure, so that the external dust enters the dust suction pipe 1 under pressure, the wind wheel 7 is fixedly connected with a rotating shaft 8, the rotating shaft 8 runs through the bottom of the dust suction pipe 1, and one side of the dust suction pipe 1 is fixedly connected There is a liquid tank 4, and the liquid tank 4 and the dust suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com