Fuel pump

a technology of fuel pump and jet pump, which is applied in the direction of machines/engines, filtration separation, separation processes, etc., can solve the problems of reducing the discharge amount of the pump device, the vapor generated within the fuel suction filter may not be discharged to an outside of the filter, and the device may decrease the discharge amount, so as to reduce the fuel suction force, reduce the amount of the pump discharge amount of the jet pump, and reduce the effect of the pump discharge amoun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

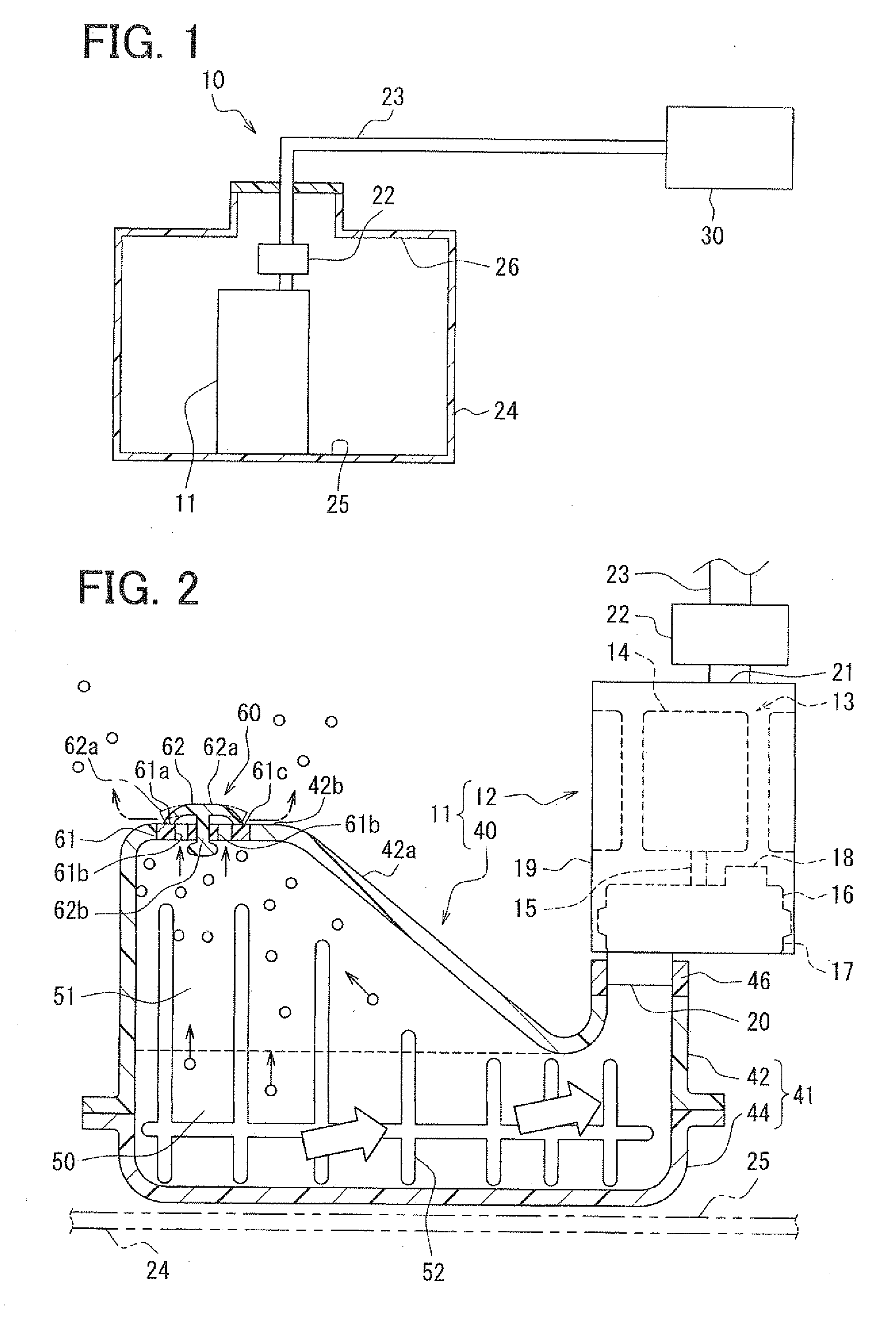

[0064]A first embodiment of the present invention will be explained with reference to the drawings. FIG. 1 is a schematic view showing a fuel supply system 10 incorporating a fuel supply device 11 according to the first embodiment of the present invention.

[0065]In the fuel supply system 10, fuel in a fuel tank 24 is supplied to an engine 30 outside of the fuel tank. The fuel supply system 10 according to the present embodiment is a so-called return fuel supply system, in which surplus fuel which will not be consumed by the engine 30 is treated in an inside of the fuel tank 24 so that the surplus fuel may not be return from the engine 30. The fuel supply system 10 is composed of the fuel supply device 11, a pressure regulating device 22 and a fuel supply pipe 23, and so on.

[0066]The fuel supply device 11 and the pressure regulating device 22 will be explained with reference to FIG. 2. FIG. 2 shows a cross sectional view of the fuel supply device 11. The fuel supply device 11, the pre...

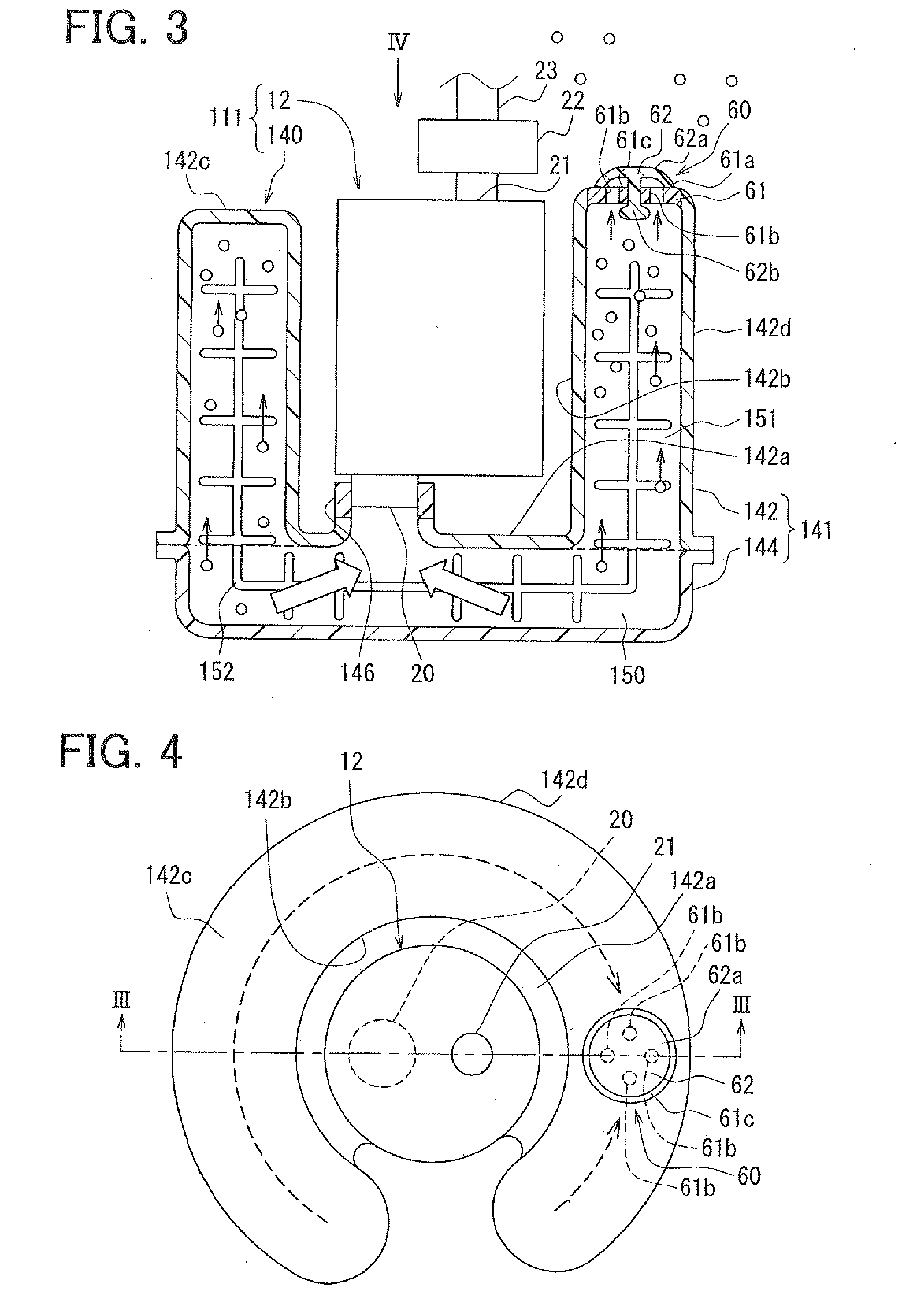

second embodiment

Modification of Second Embodiment

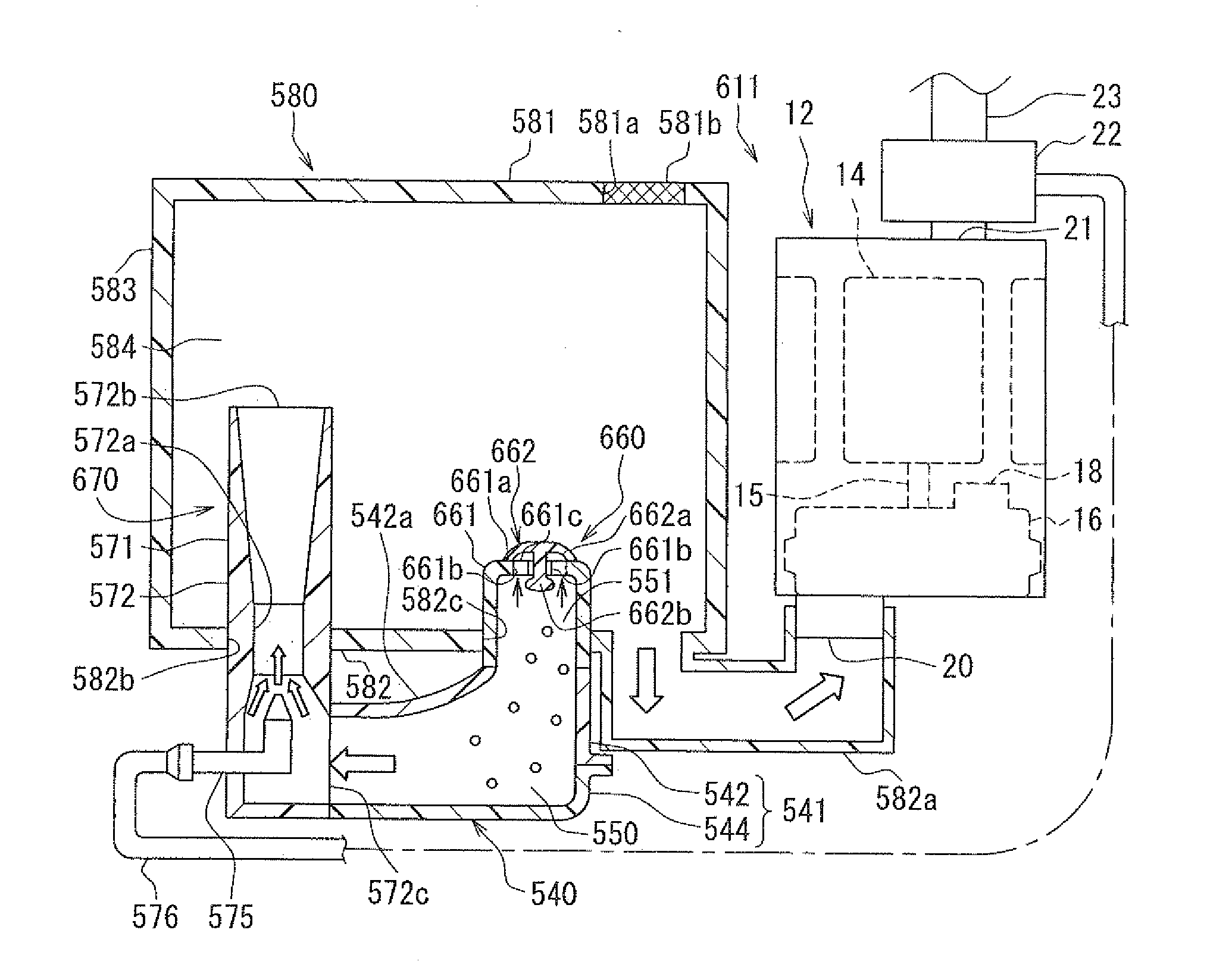

[0120]A modification of the second embodiment will be explained with reference to the drawing. A position for the valve device 60 in the modification is different from the second embodiment. The electric pump 12, the pressure regulating device 22 and the fuel supply pipe 23 are identical to the first embodiment. FIG. 5 is a schematic enlarged cross sectional view showing a filter device 240 of a fuel supply device 211 according to the modification of the second embodiment. The other parts and / or portions, except for a valve device 160 forming a part of the filter device 240, are the same to the second embodiment.

[0121]According to the modification, the valve device 160 is provided at the outer cylindrical wall portion 142d of the first element 142, more exactly, at a portion of the radial side wall portion thereof. Like the valve device 60 of the first embodiment, the valve device 160 of the modification also allows the vapors to flow out from the va...

third embodiment

Modification of Third Embodiment

[0138]A modification of the third embodiment will be explained with reference to the drawing. A filter device 440 of the modification is different from the filter device 340 of the third embodiment in that an auxiliary jet pump 470 is provided between the tank portion 340b and the filter portion 340a. The auxiliary jet pump 470 subsidizes fuel supply into the tank portion 340b. The electric pump 12, the pressure regulating device 22 and the fuel supply pipe 23 in this modification are also identical to the first embodiment. FIG. 7 is a schematic cross sectional view showing a fuel supply device 411 according to the modification of the third embodiment. The auxiliary jet pump 470 will be mainly explained.

[0139]The auxiliary jet pump 470 generates fuel suction force and discharges the fuel (sucked from the first fuel passage 350a) into the second fuel passage 350b, in order to subsidize the fuel supply into the tank portion 340b. The auxiliary jet pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suction force | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com