Cutting device for steel plate

A cutting device and steel plate technology, which is applied in the field of machinery, can solve the problems of poor processing environment, low degree of automation, and large area occupied by processing equipment, and achieve the effects of avoiding twisting or messy, high degree of automation, and ensuring the unloading angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

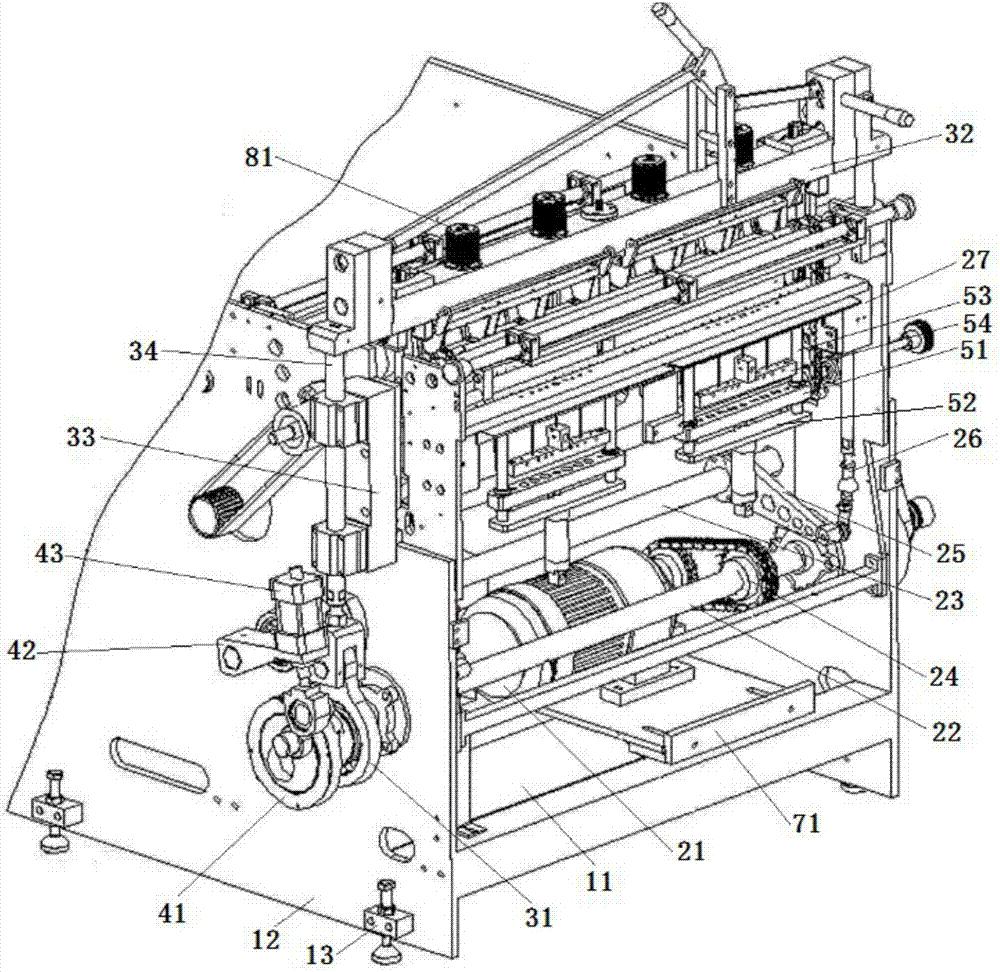

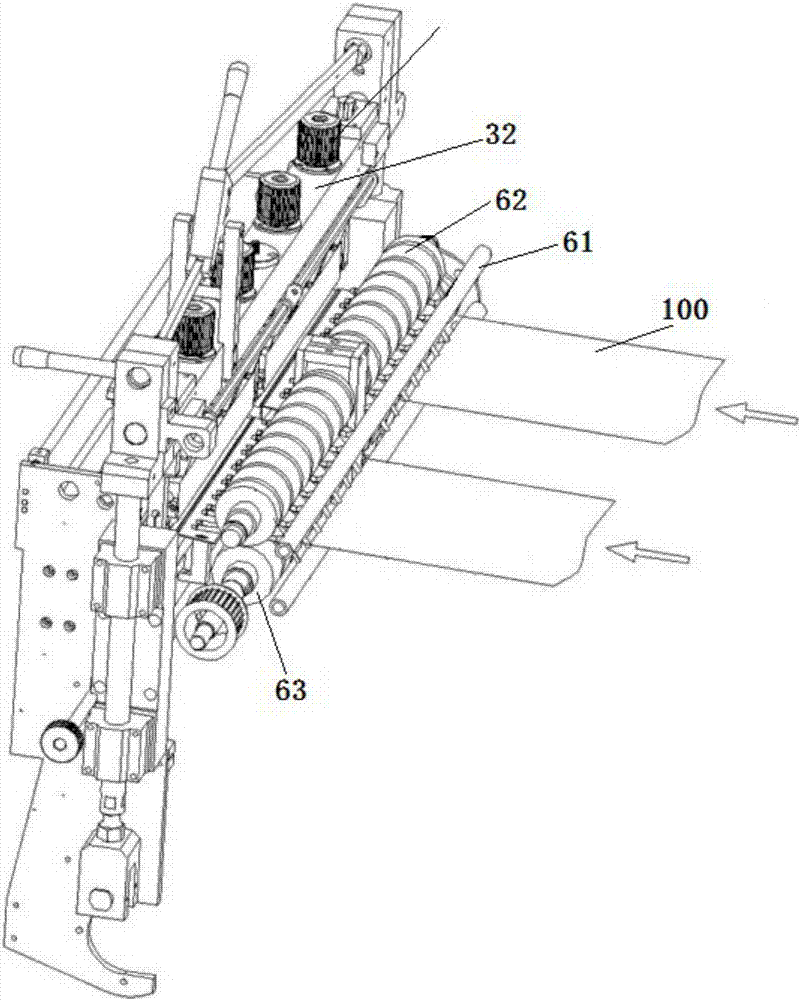

[0019] see figure 1 with figure 2 A steel plate cutting device according to the present invention includes a frame and a cutting mechanism. The frame includes a base 11 and side plates 12 respectively arranged on both sides of the base 11 . The base 11 is provided with a driving motor 21, a driving main shaft 22 and a driving sub-shaft 23 are erected between the two side plates 12, a driving wheel 24 is fixedly set on the driving main shaft 22, and the driving motor 21 is connected to the driving wheel 24 through a transmission belt. . The driving spindle 22 is erected on the side plate 12 and its two ends respectively protrude from the side plate 12 . Cams 31 and eccentric wheels 41 are respectively provided on the two protruding ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com