Manufacturing method for cylinder body of offshore wind power large-diameter thin-wall suction cylinder

A manufacturing method and suction cylinder technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of unsatisfactory diameter, easy deformation of the cylinder body, and difficult manufacturing, so as to improve the level of wind power manufacturing and optimize the manufacturing process , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

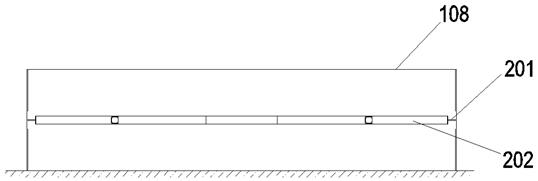

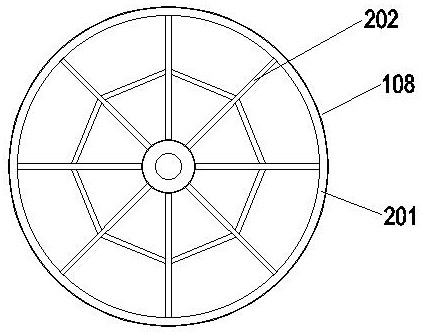

[0052] The diameter of the suction cylinder in this embodiment reaches 12000mm, the plate thickness is 35-50mm, and the height reaches 22000mm.

[0053] Specifically adopt the following manufacturing scheme: comprise the following steps:

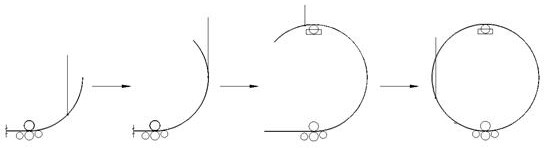

[0054] S1. Divide the cylinder into 8 segments, each segment from the top to the bottom of the cylinder 10 is the first segment 101, the second segment 102, the third segment 103, the fourth segment 104, The fifth segment 105, the sixth segment 106, the seventh segment 107, and the eighth segment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com