Elongate vacuum system for coating one or both sides of a flat substrate

A vacuum system and substrate technology, applied in vacuum evaporation coating, coating, sputtering coating, etc., can solve problems such as eddy current generation, vacuum pump performance value decline, and adverse effects on the discharge process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

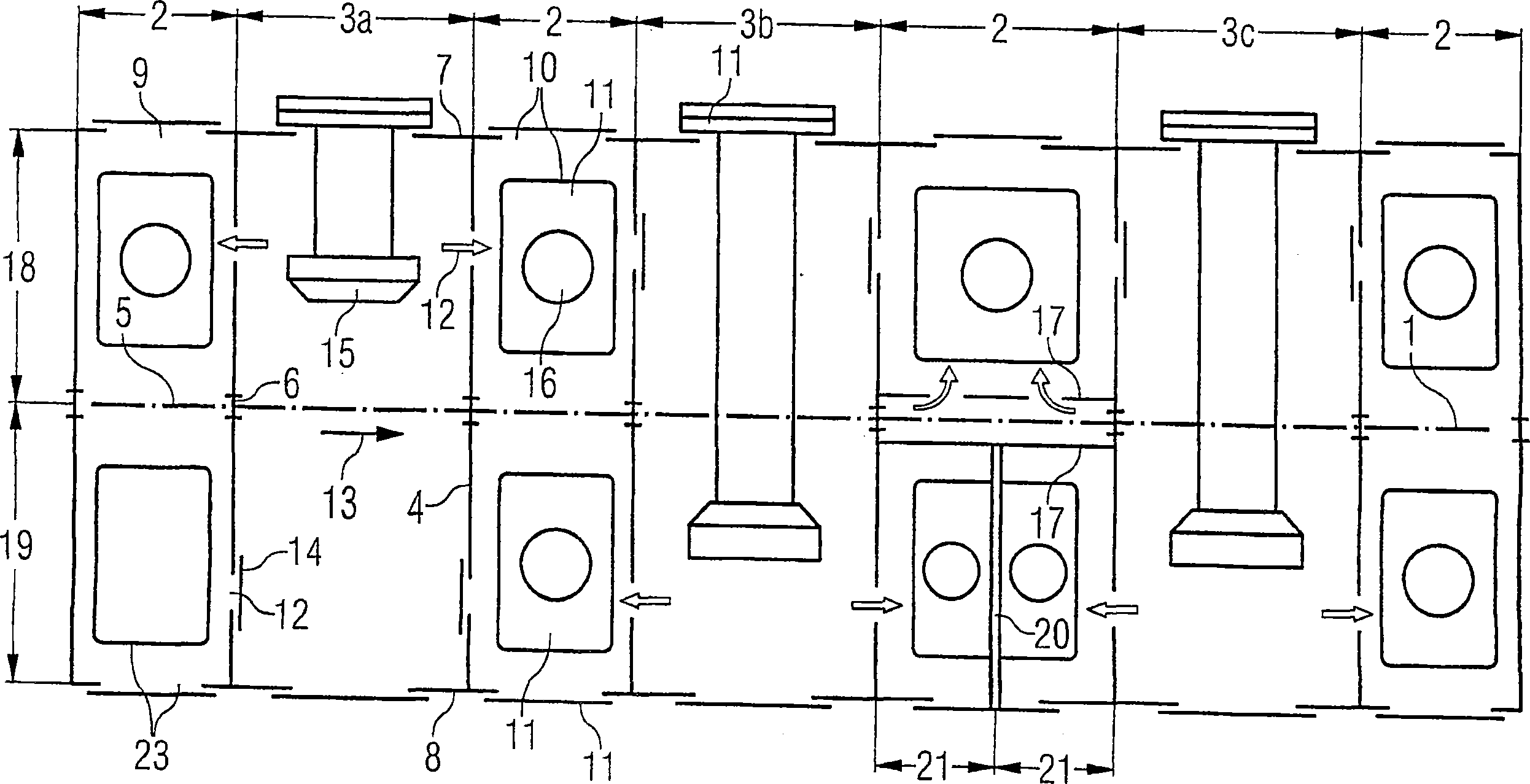

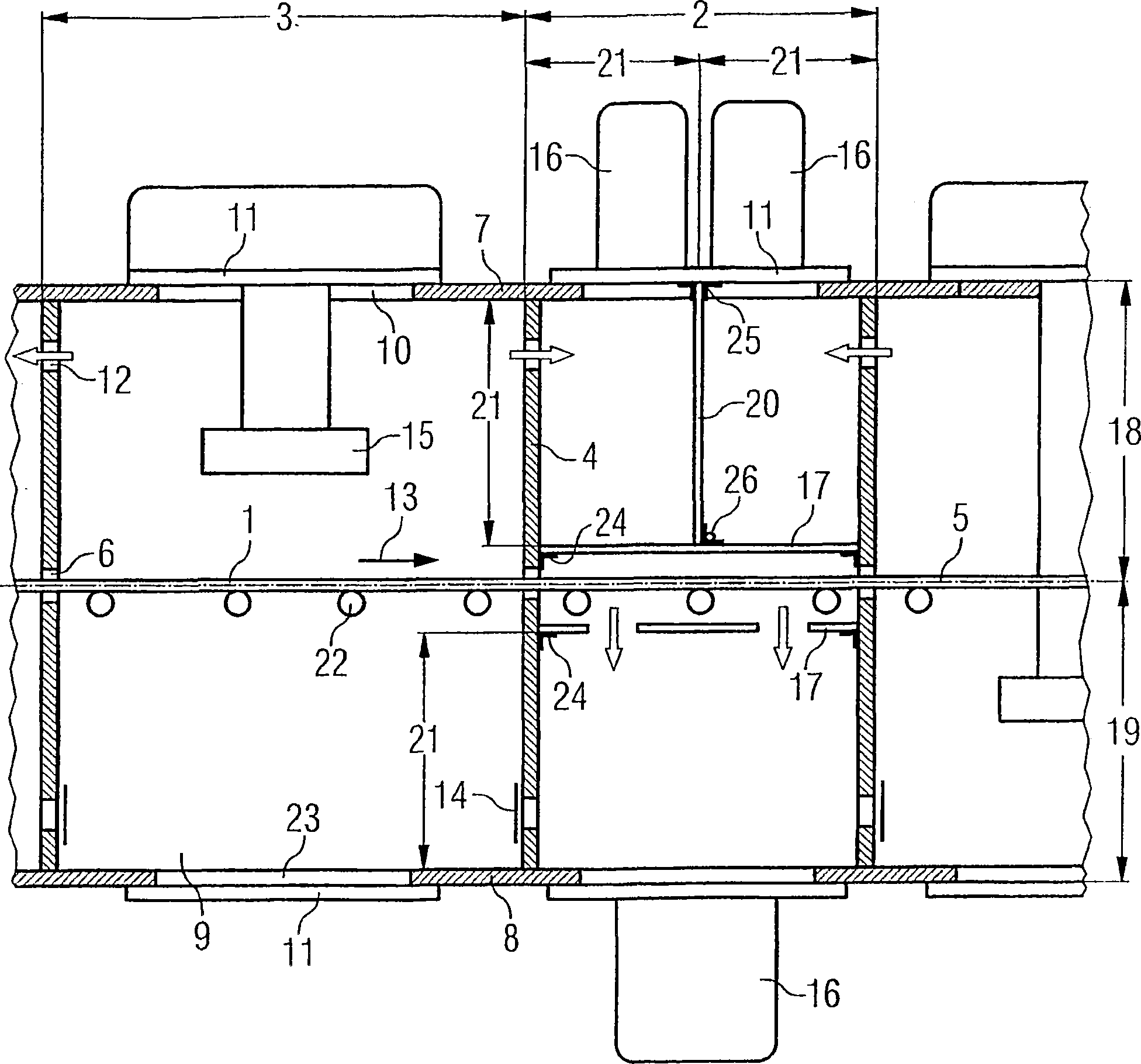

[0067] figure 1 The extended vacuum system shown in is used for double-sided coating of a flat substrate 1 during one cycle through the system. The vacuum system consists of four evacuation compartments 2 and three coating compartments 3 which are separated from each other by a partition wall 4 . The substrate 1 is conveyed through the coating system by means of a conveying system not shown in the conveying platform 5, whereby access to and from the coating system and from one compartment to the next is achieved by a gate 6 located in the compartment inside the partition wall 4.

[0068] In this embodiment, all partial compartments in the upper outer wall 7 and the lower outer wall 8 have upper and lower openings 10, 23 which can be tightly closed by covers 11 of the same size. The evacuated compartment 3 also comprises a vacuum connection 16 in the cover 11a which closes the openings in the lateral outer walls 9, whereby, in this embodiment, these lateral covers 11a exhibit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com