Patents

Literature

68results about How to "Avoid angular deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

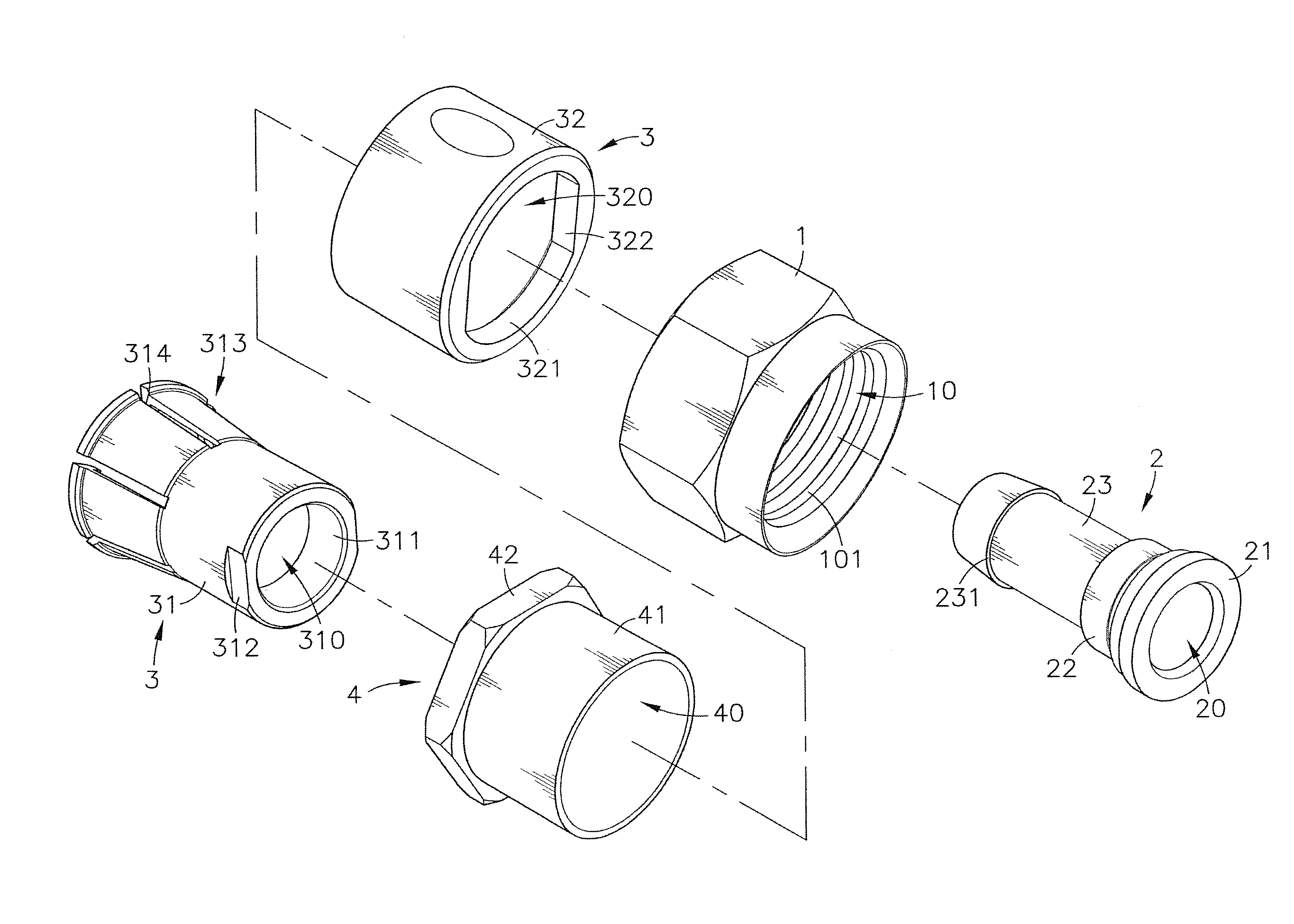

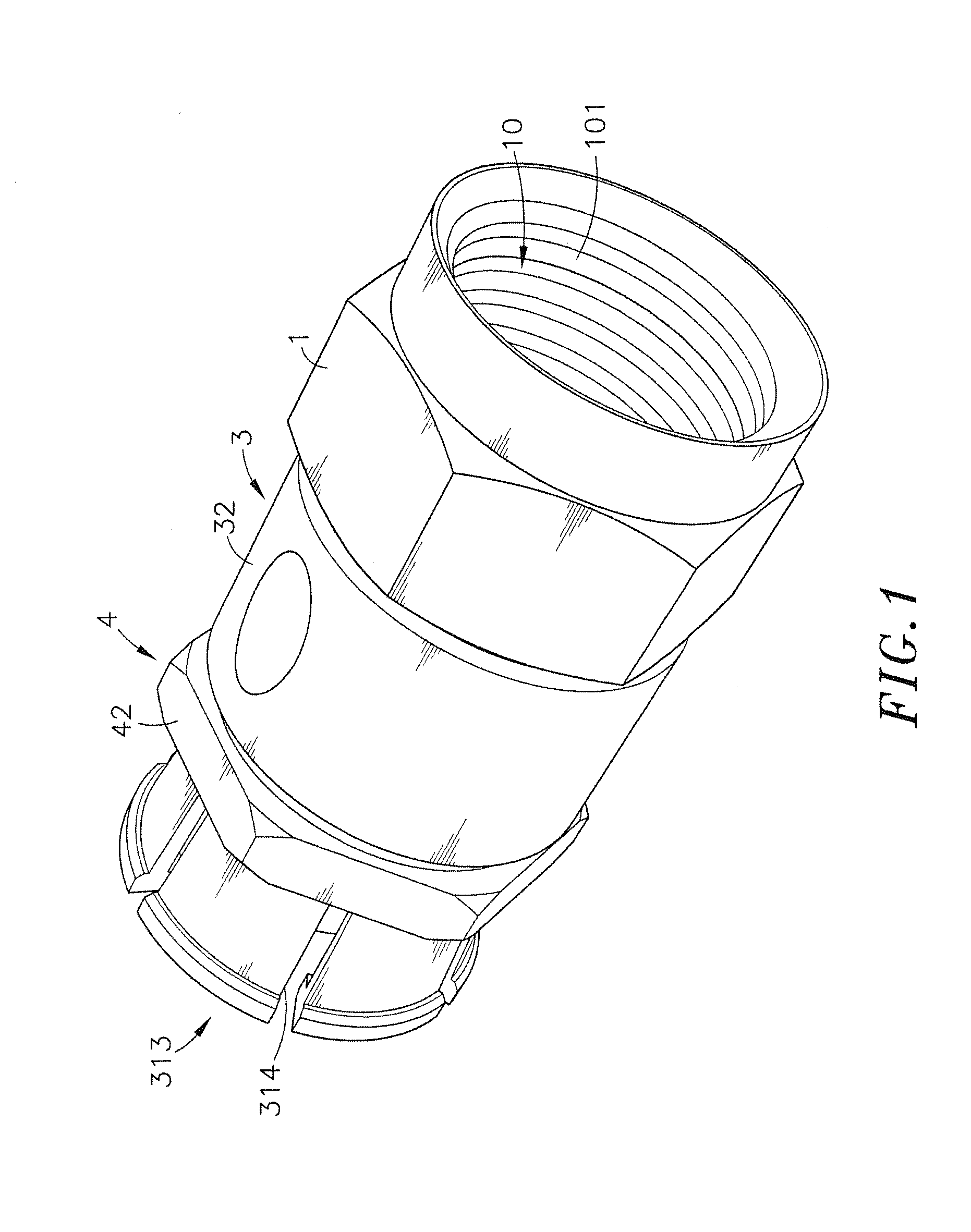

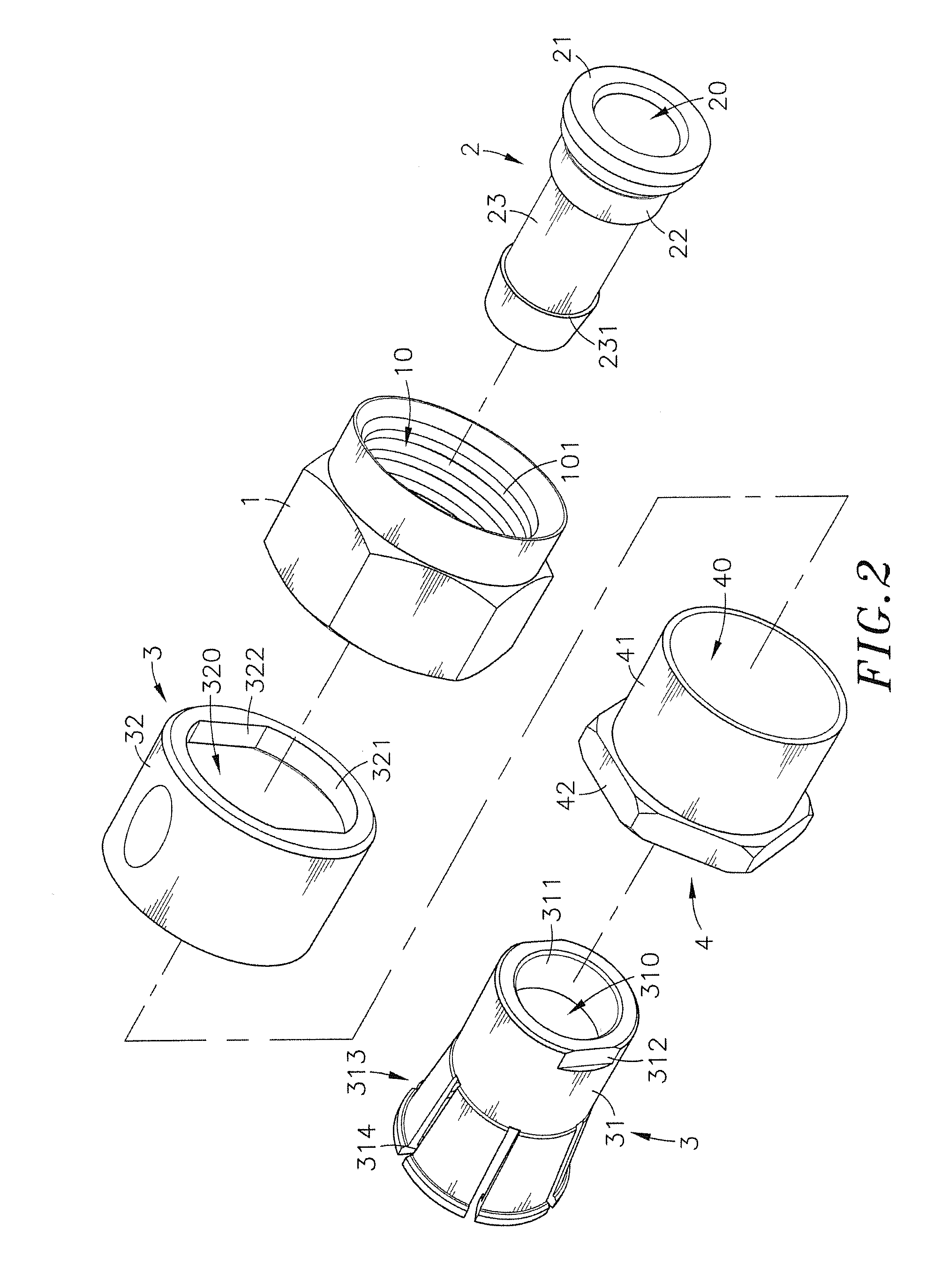

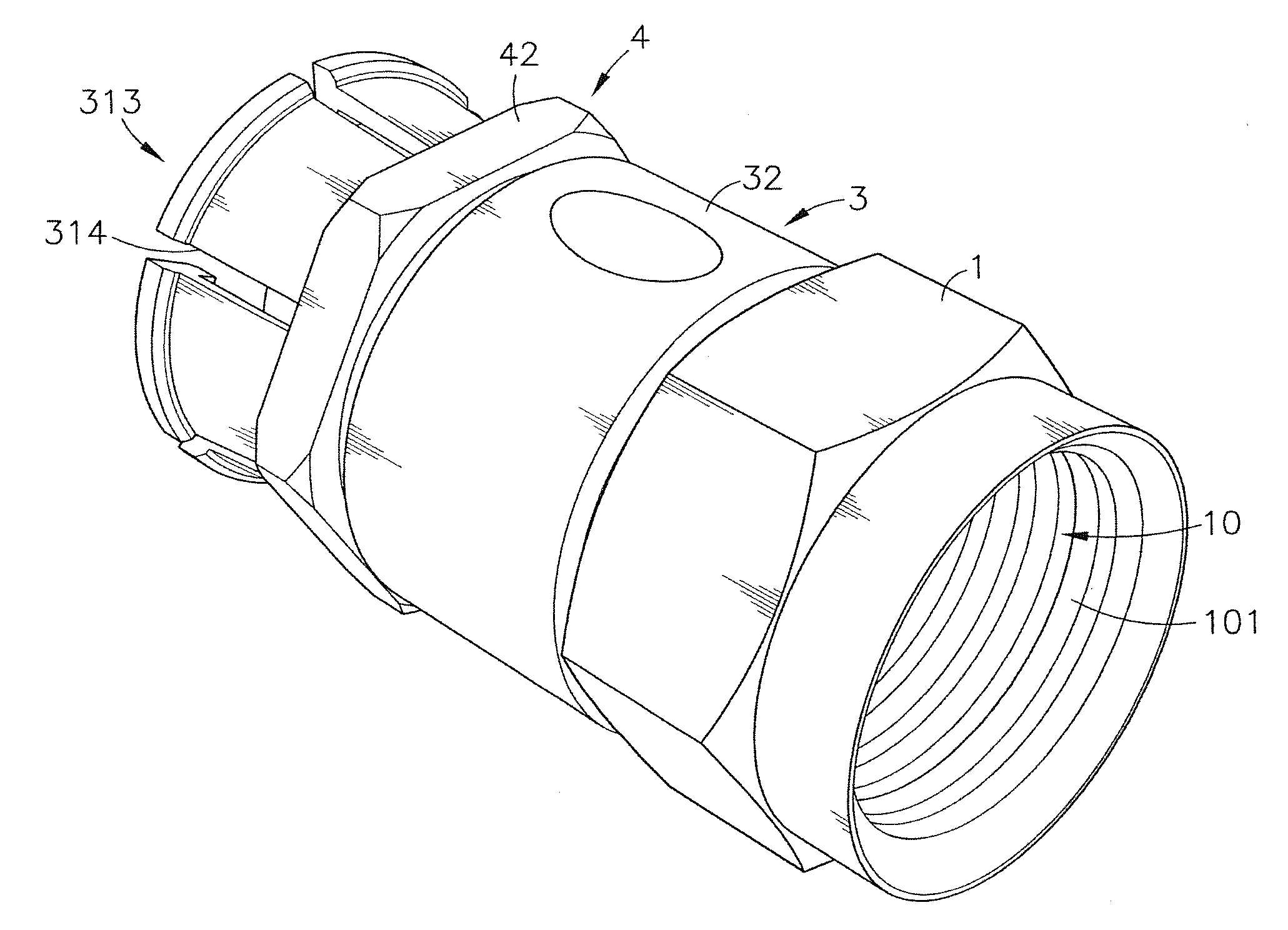

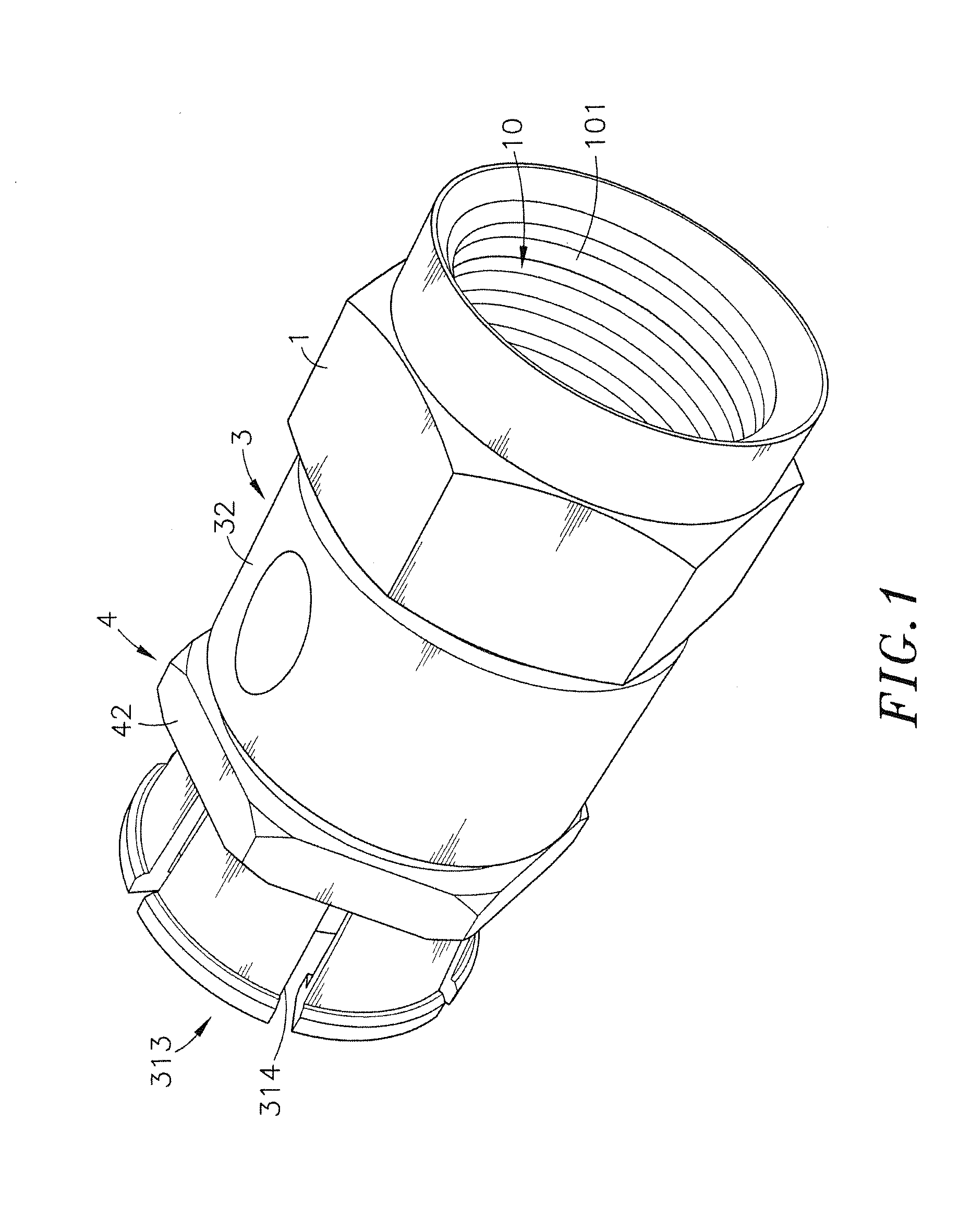

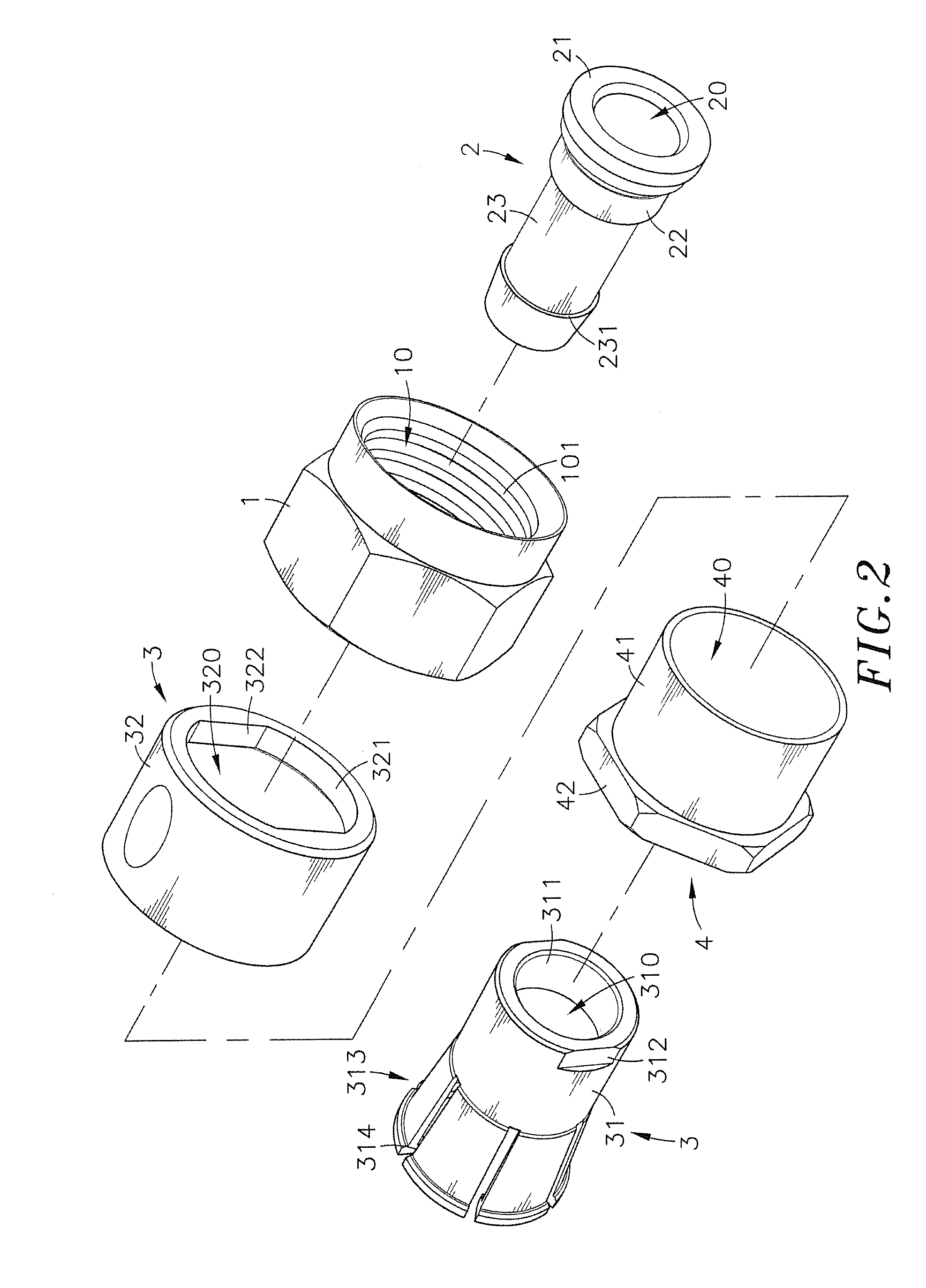

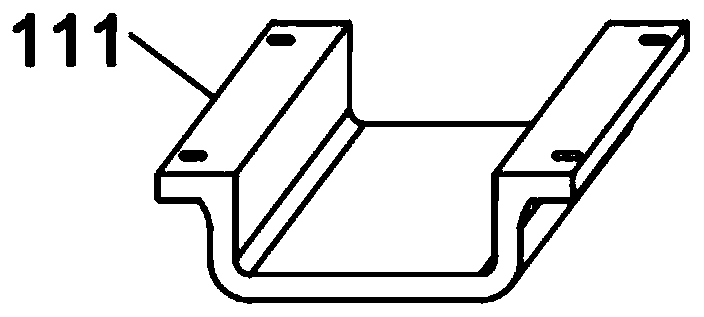

Electrical signal connector

InactiveUS8944846B2Avoid angular deviationQuick installationElectrically conductive connectionsTwo-part coupling devicesMating connectionCoaxial cable

An electrical signal connector for connecting a coaxial cable to a mating connector is disclosed to include a locknut, a metal central tube inserted through the locknut and defining a stop flange at one end, a barbed retaining portion at an opposite end, a locating groove around the periphery between the stop flange and barbed retaining portion and an annular bearing surface portion extending around the periphery between the stop flange and the locating groove, a chuck unit including a collar, which is press-fitted onto the annular bearing surface portion of the metal central tube and having longitudinal clamping strips suspending around the barbed retaining portion of the metal central tube, and a constraint shell surrounding the collar, and an actuation sleeve mounted within the constraint shell around the collar and manually axially movable relative to the chuck unit between two positions to compress or release the longitudinal clamping strips.

Owner:LEE CHUNG YU

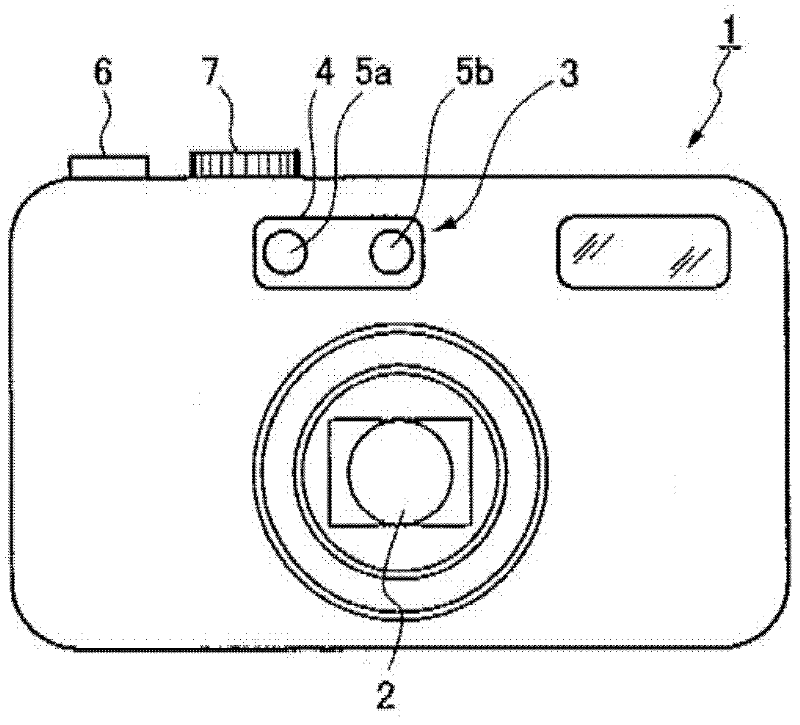

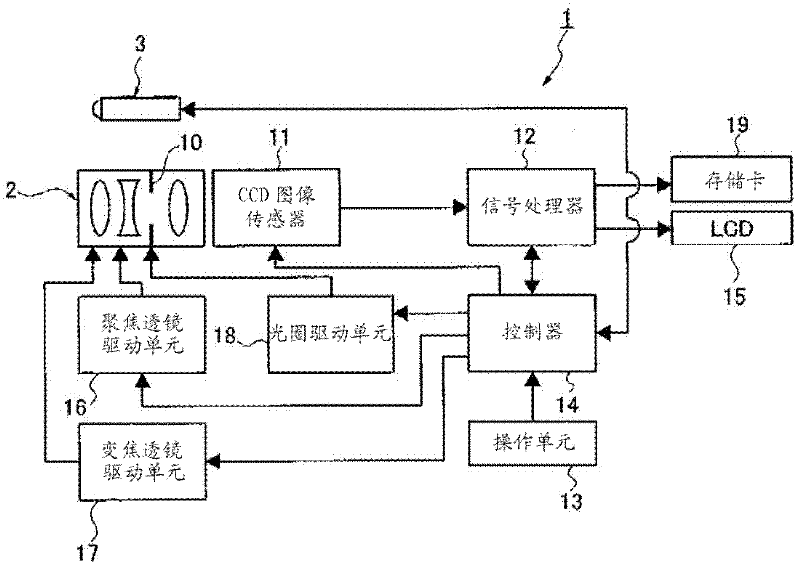

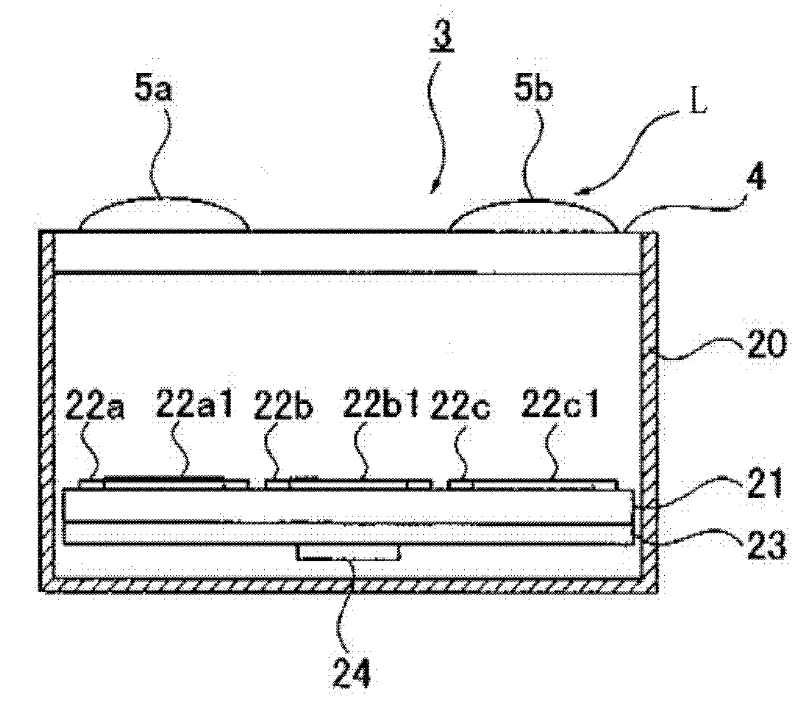

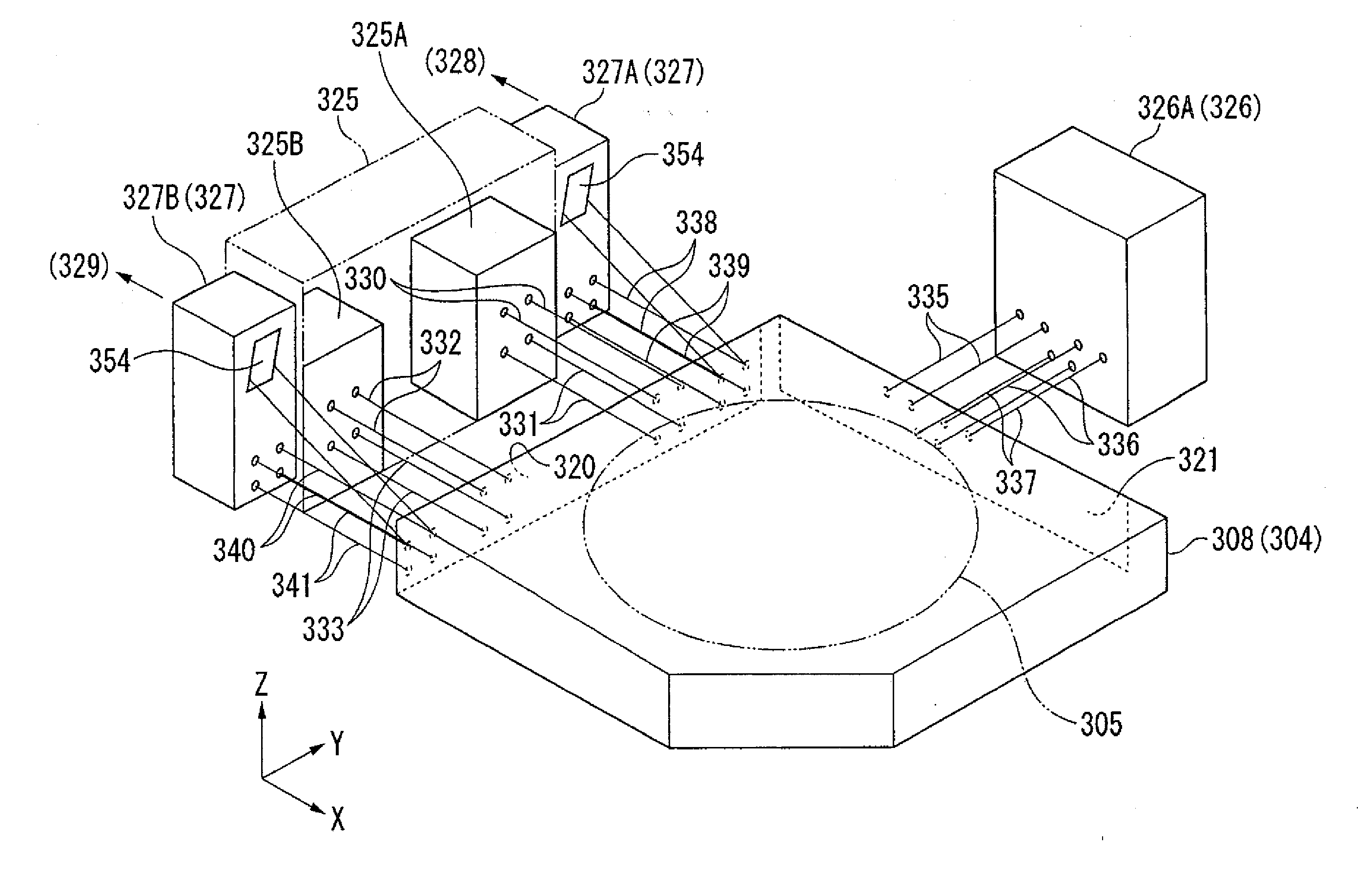

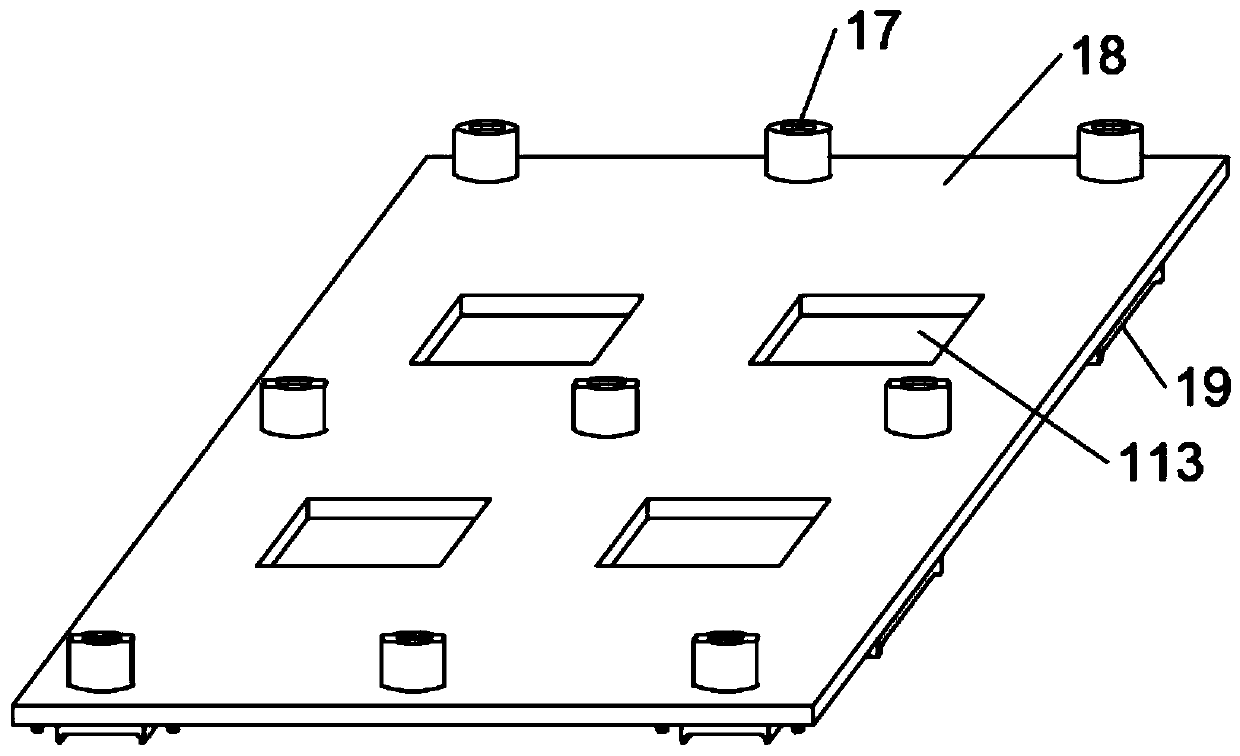

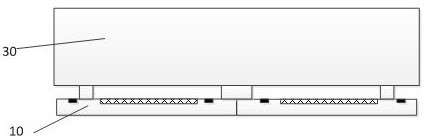

Range-finding device and imaging apparatus

InactiveCN102300054AAvoid angular deviationTelevision system detailsOptical rangefindersComputer visionImaging equipment

A range-finding device includes a plurality of image pickup units disposed at a predetermined interval with each other, a lens unit to form subject images of a subject on the plurality of image pickup units, the image pickup units on which the subject image is formed outputting signals of the subject image, and a distance calculation unit to calculate a distance to the subject based on the signals output from the image pickup units. The plurality of image pickup units are formed on a single substrate. The subject image is formed through the lens unit on at least two image pickup units of the plurality of image pickup units. The distance calculation unit calculates a distance to the subject based on the signals output from the at least two image pickup units on each of which the subject image is formed.

Owner:RICOH KK

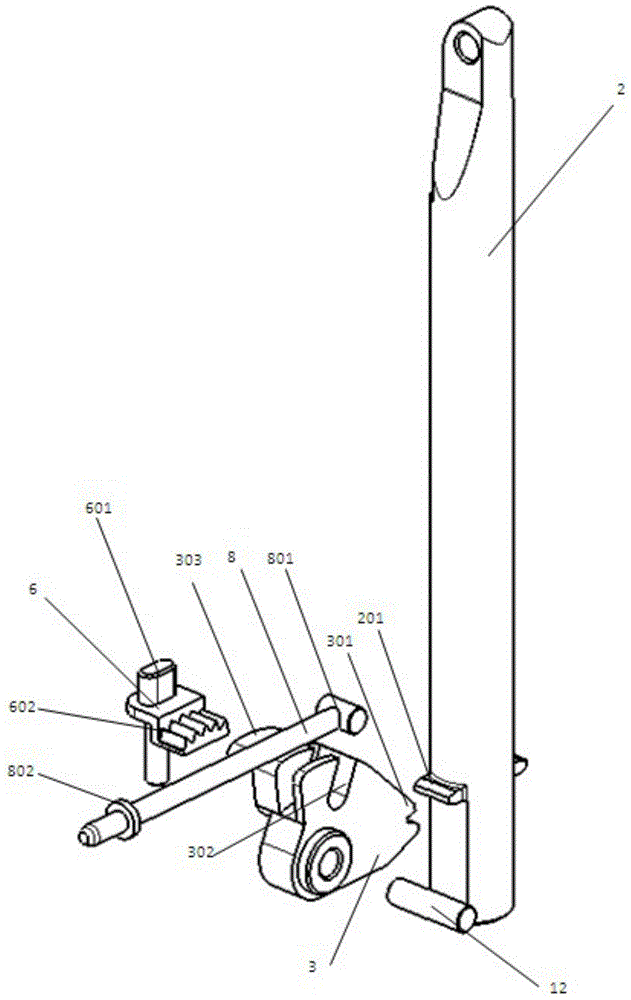

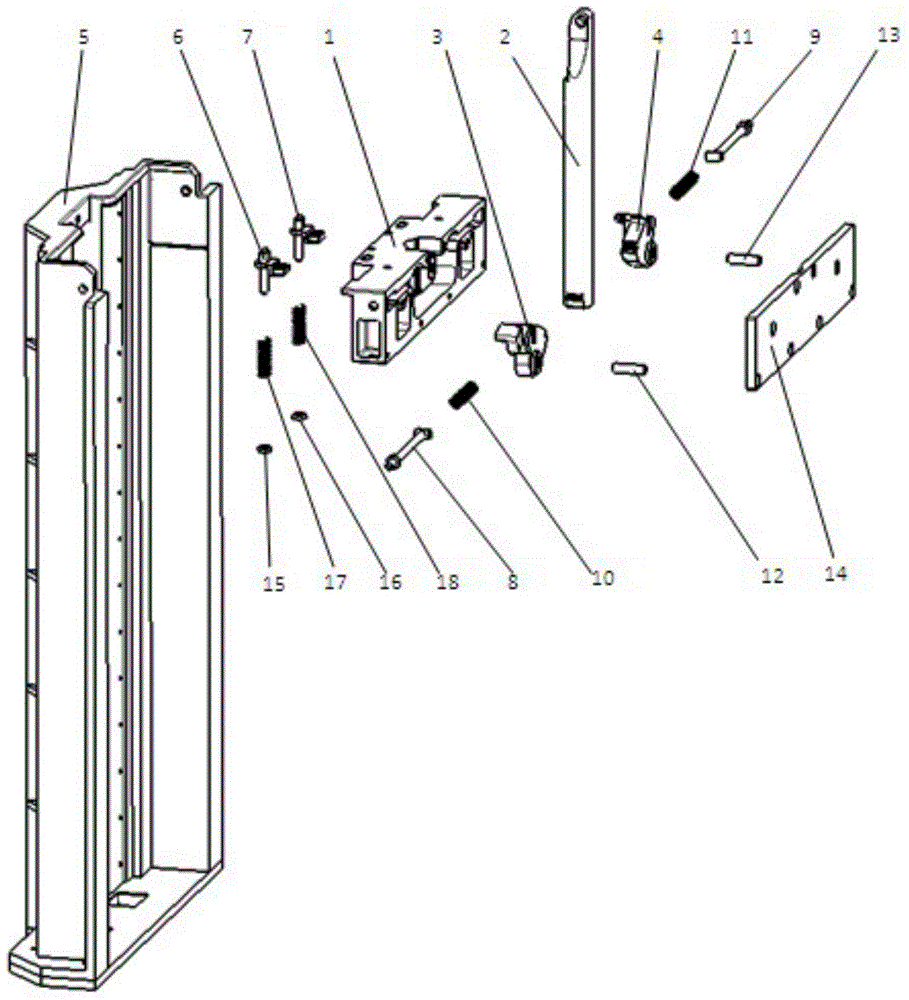

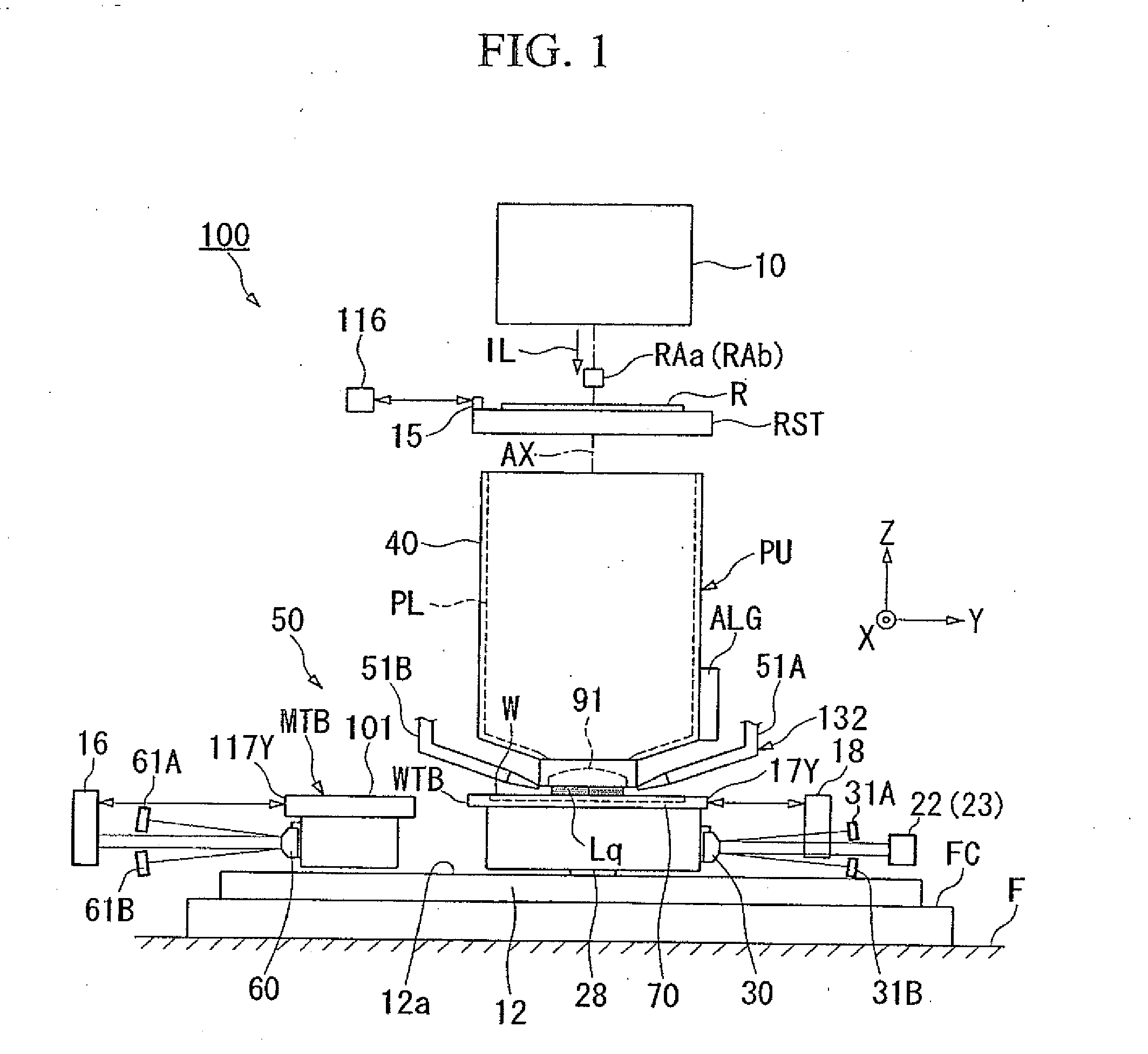

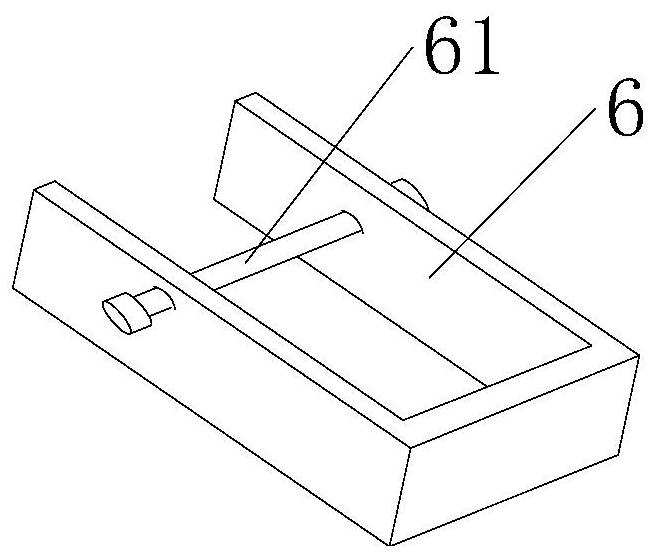

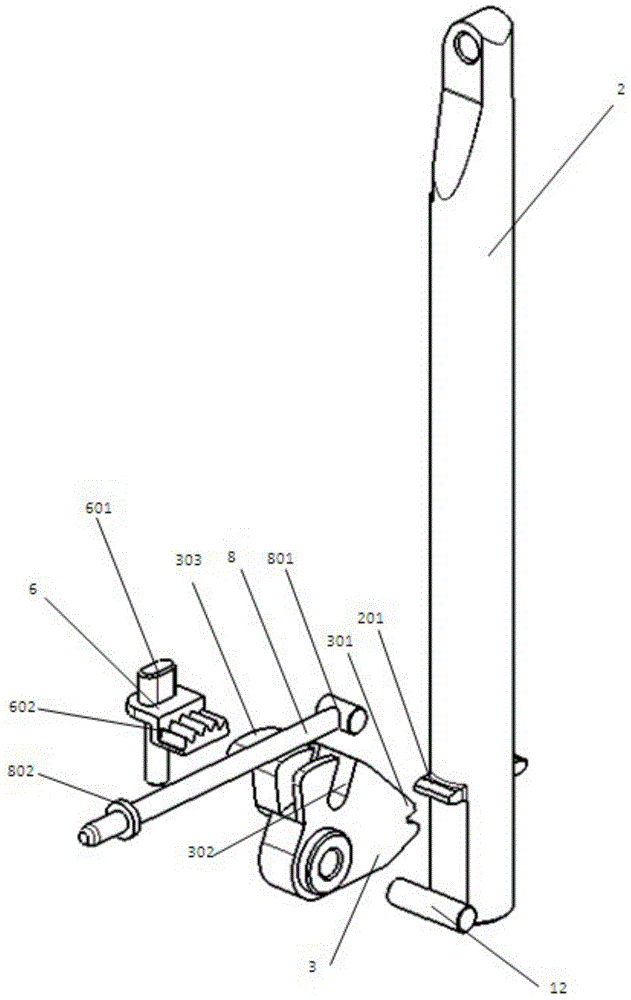

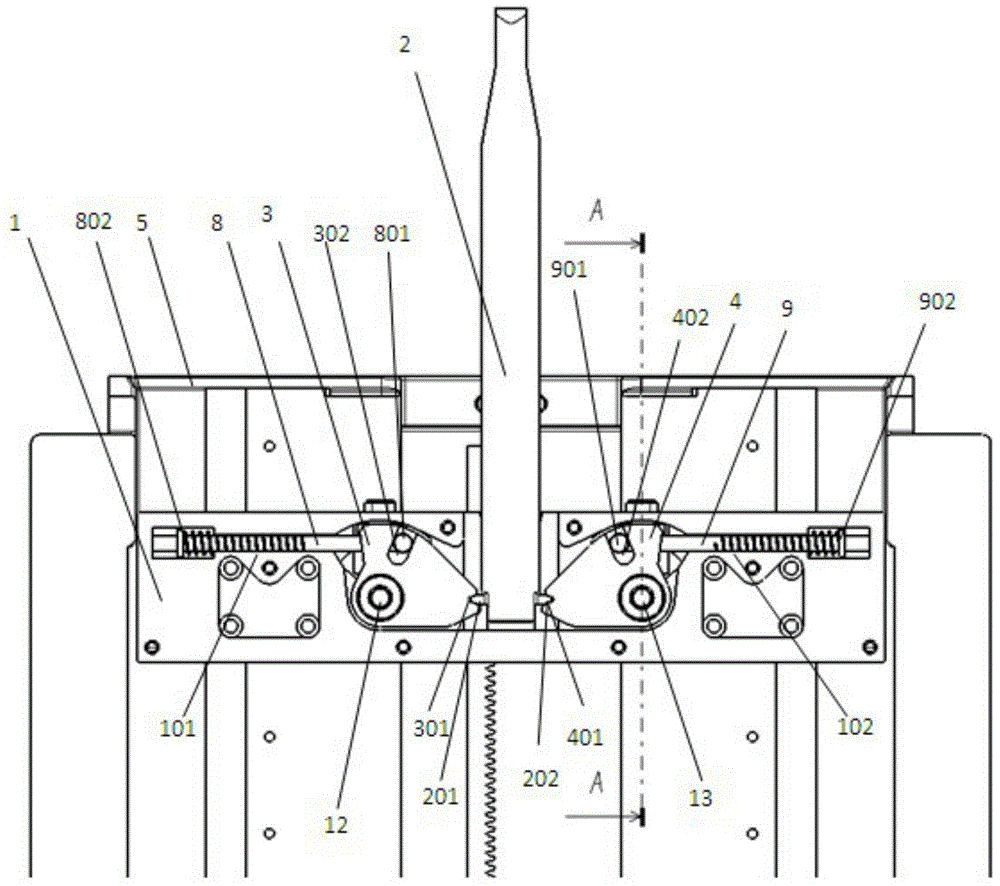

Lock mechanism for controlling action sequences and vehicle-mounted tablet personal computer support frame comprising lock mechanism for controlling action sequences

InactiveCN103557416AControl motion sequenceOvercome the Risk of MisoperationStands/trestlesVehicle componentsLocking mechanismMedial axis

The invention provides a lock mechanism for controlling action sequences and a vehicle-mounted tablet personal computer support frame comprising the lock mechanism for controlling action sequences. The lock mechanism comprises a base, a lifting table, fish head wheels, a spring bolt, a top rod and a middle shaft, wherein the base is provided with a first-stage guide rail in vertical extending, the lifting table can move along the first-stage guide rail, the fish head wheels are symmetrically arranged on the lifting table at the left side and the right side, and the middle shaft is arranged in the center position of the lifting table and is matched with the fish head wheels. The lock mechanism has the advantages that the action sequences can be effectively controlled, the defect of risk of misoperation of mechanical parts is overcome, meanwhile, the structure is simple, the operation force is small, the noise is low, and the service life is long. The vehicle-mounted tablet personal computer support frame has the advantages that the integral operation is convenient, through the coil spring assistance, damping and friction hinge mechanisms are matched, the operation comfort is realized, the actions are smooth and coherent, the opening and the closing can be respectively completed within five seconds, a tablet personal computer can be in the most comfortable use position and angle, after the use completion, the tablet personal computer can be hidden into an interior trimming surface along with a support frame, and the appearance of the interior trimming is not influenced.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

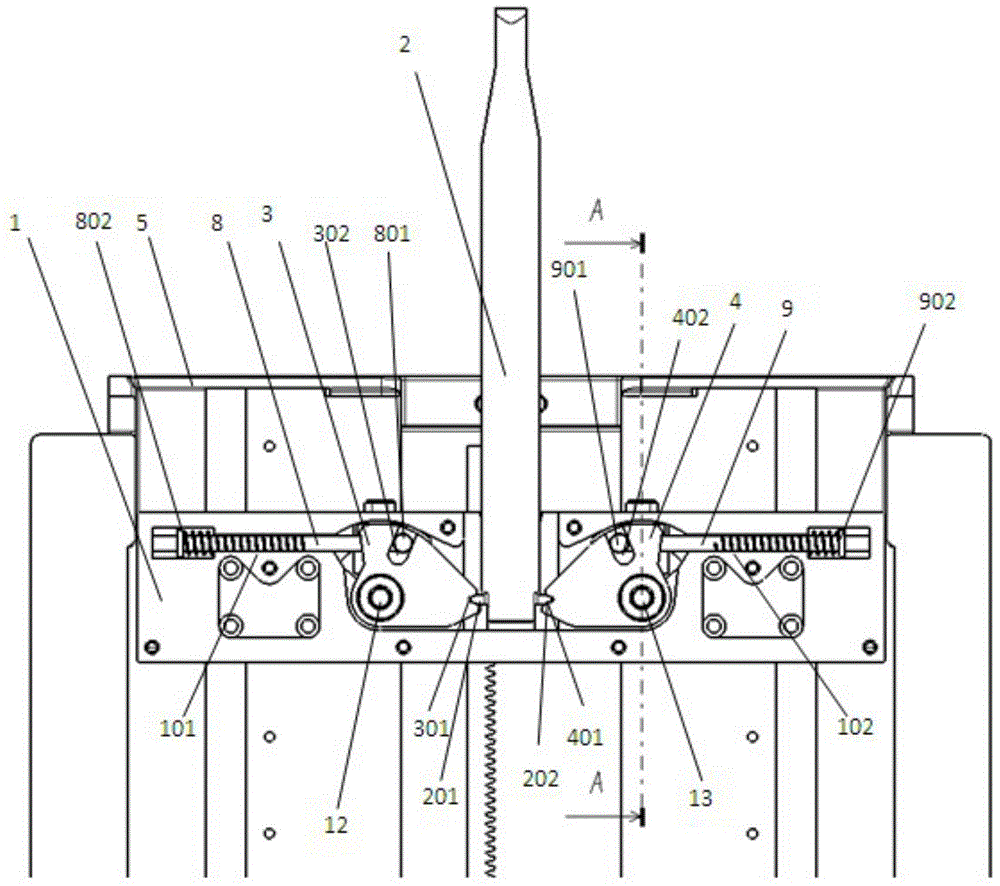

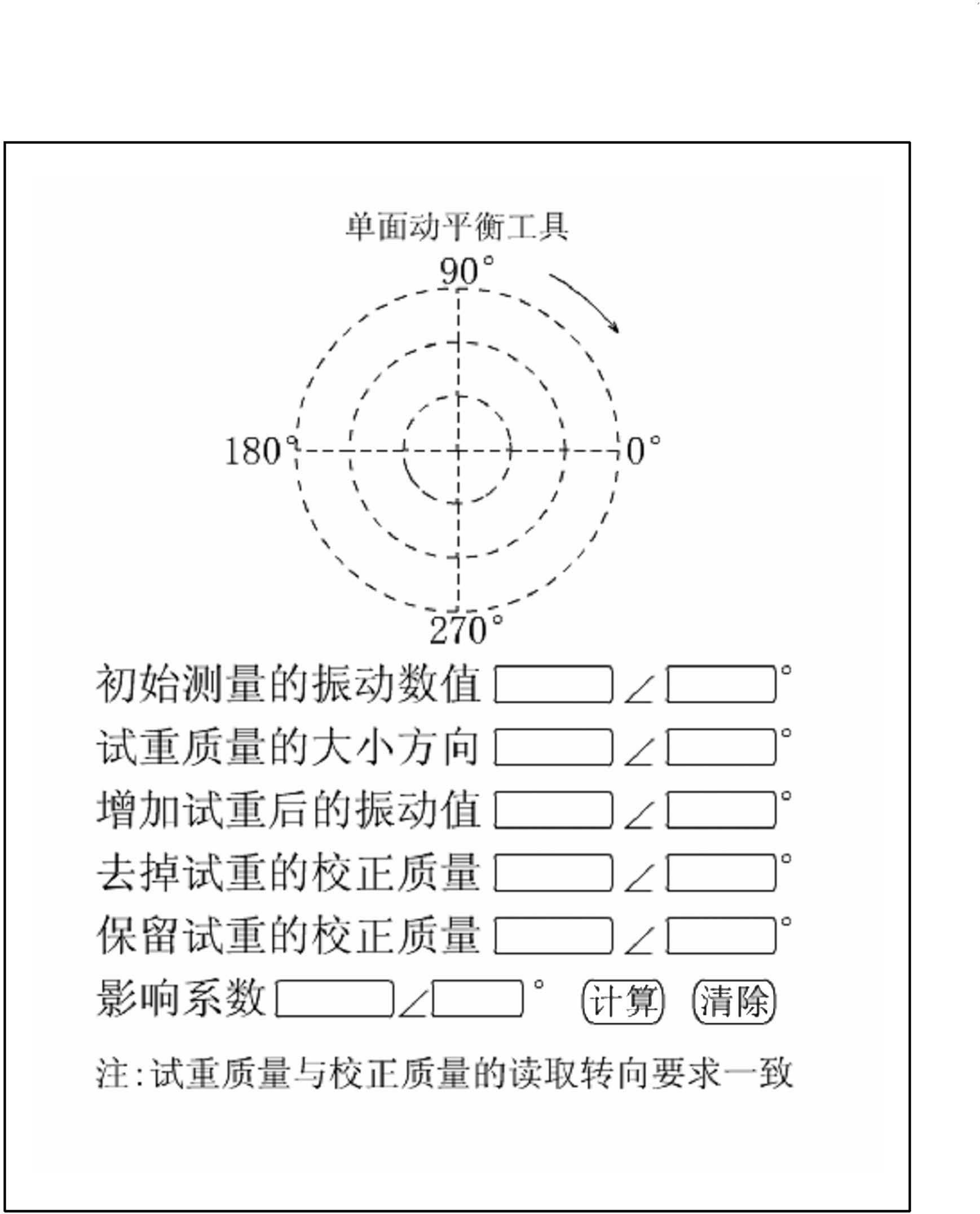

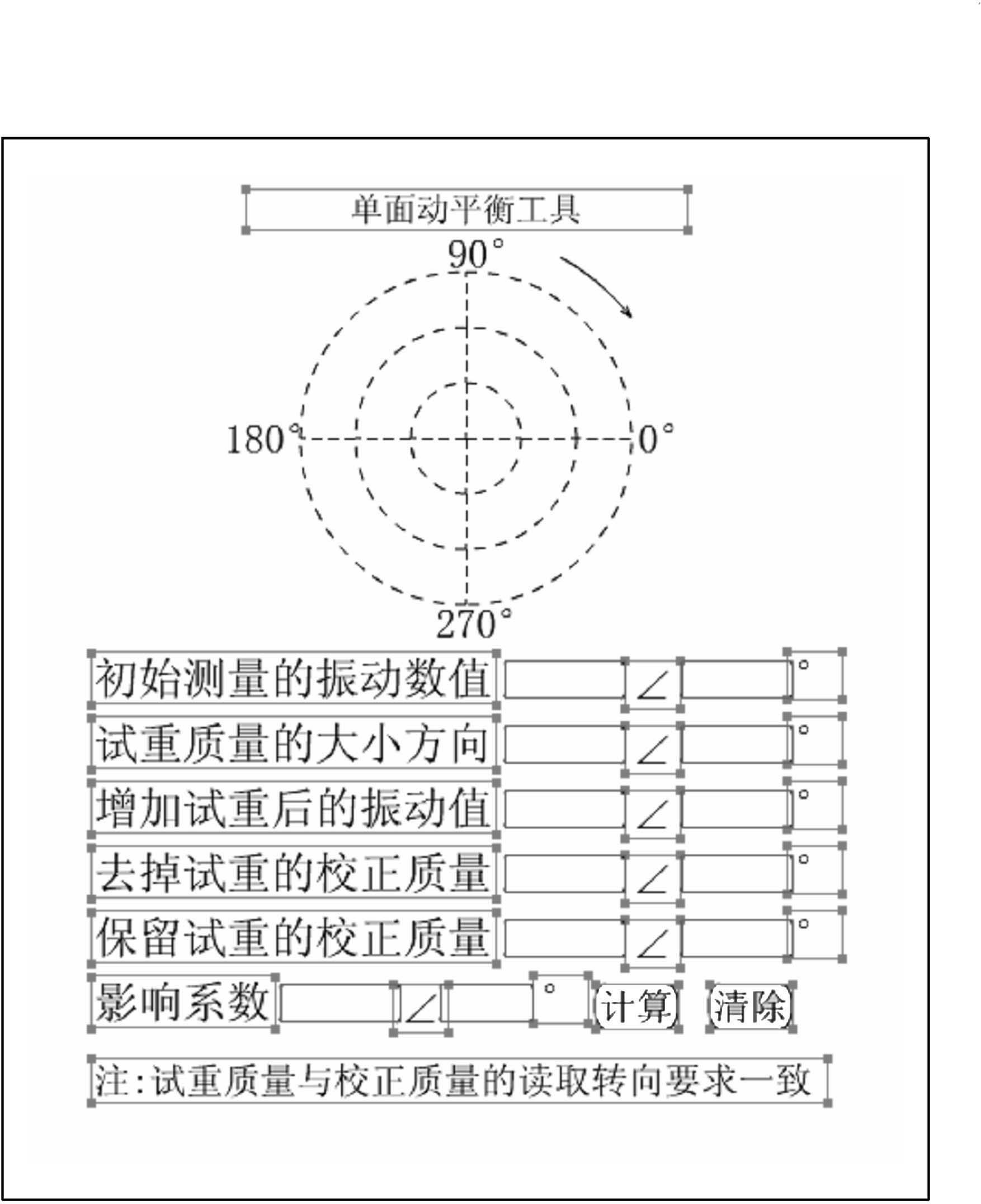

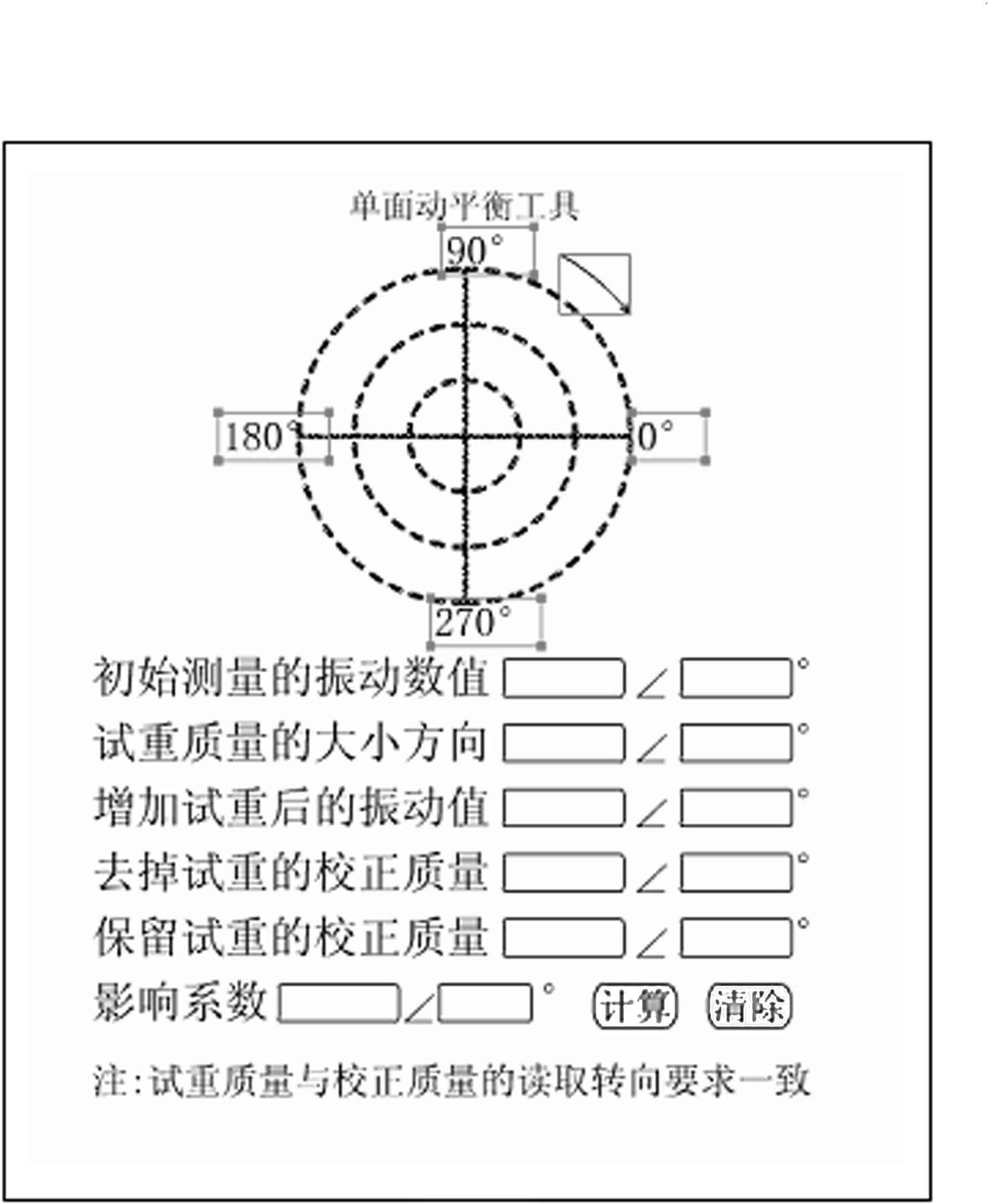

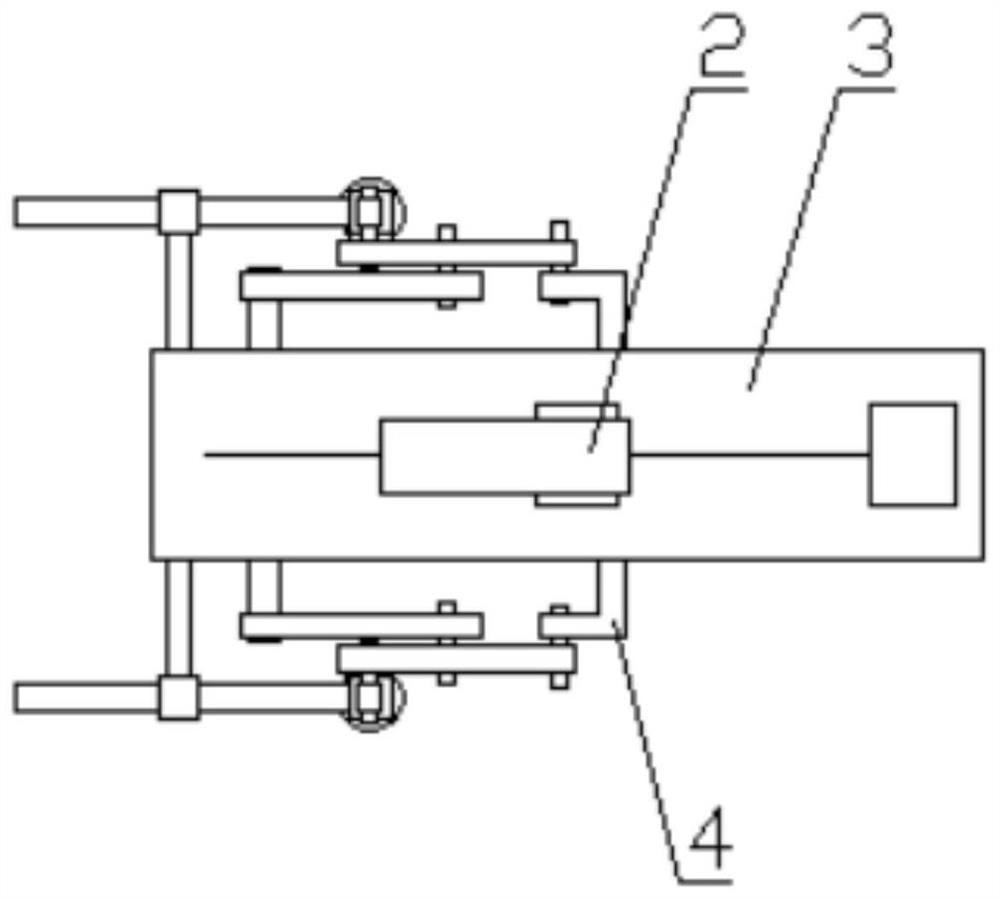

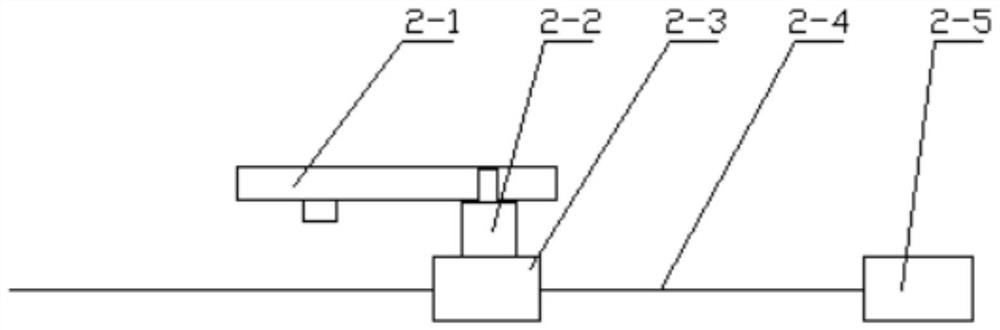

Single-side dynamic balance tool

InactiveCN102494846ASolve the problem of unbalanced vibration exceeding the standardDifferent computing powerStatic/dynamic balance measurementGraphicsDynamic balance

The invention discloses a single-side dynamic balance tool comprising two parts, namely a vibration collector and a mobile phone / computer. The mobile phone / computer is provided with a tool module which comprises a text module, an image module, input modules, an output module and a button module. The application steps are as follows: firstly, collecting the dynamic balance data of a rotating machine with exceeding vibration; secondly, selecting and running the tool in the mobile phone / computer loaded with the single-side dynamic balance tool; thirdly, inputting the dynamic balance data in the input modules in sequence; and fourthly, selecting and clicking the button module for calculating, displaying two set of solutions of correction mass without trial mass and correction mass with trial mass, as well as two key information elements, namely an influence coefficient value and the vibration vector relational graph on the output module. The single-side dynamic balance tool is convenient and rapid, displays the result instantly, and simplifies and visualizes the complicated process intuitively.

Owner:马杰

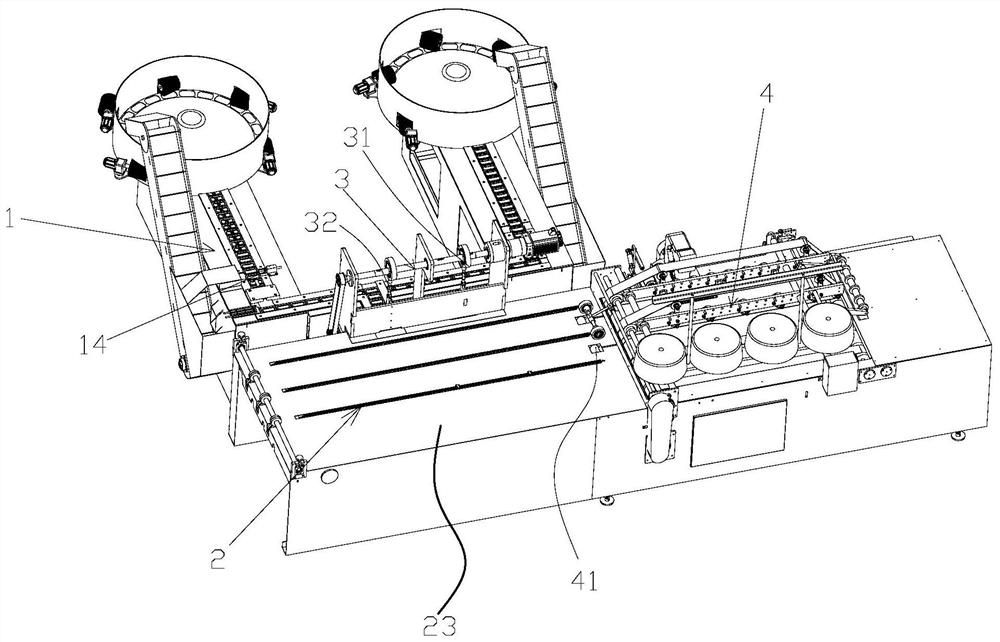

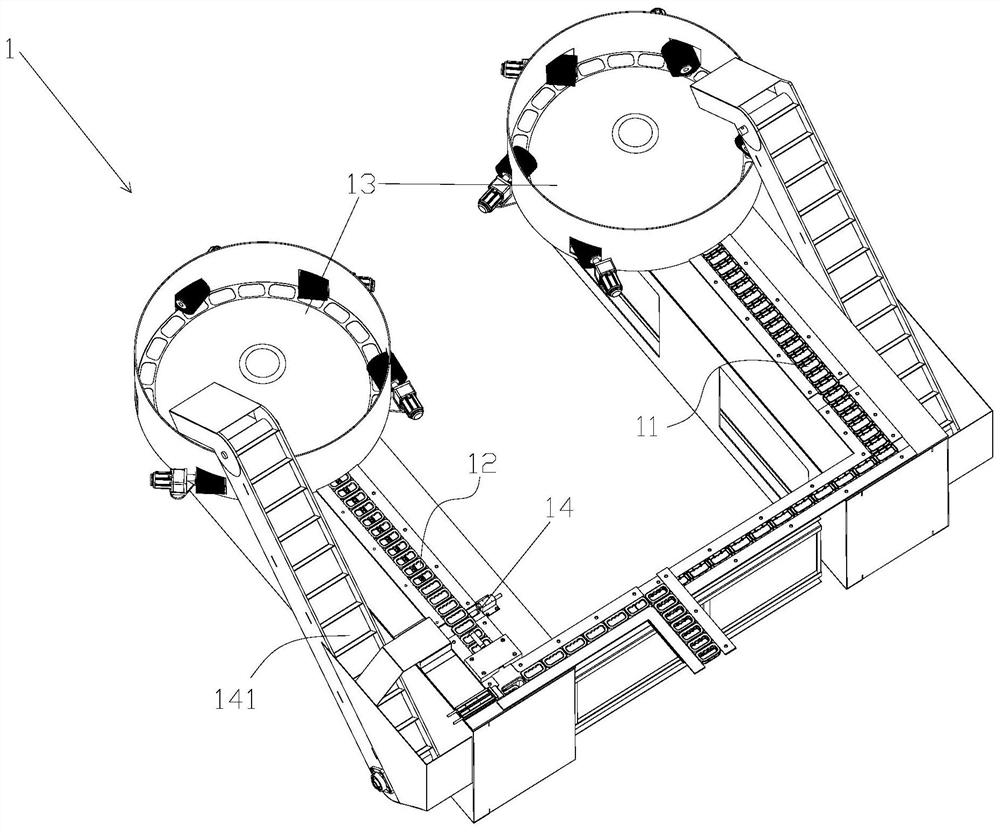

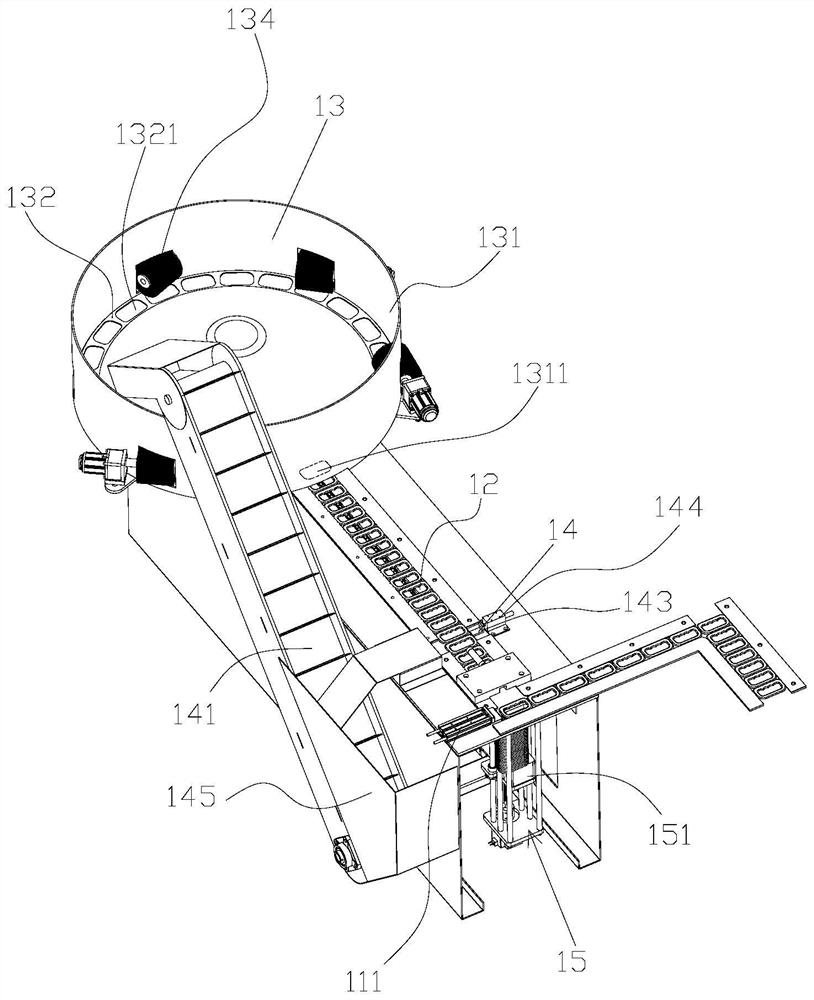

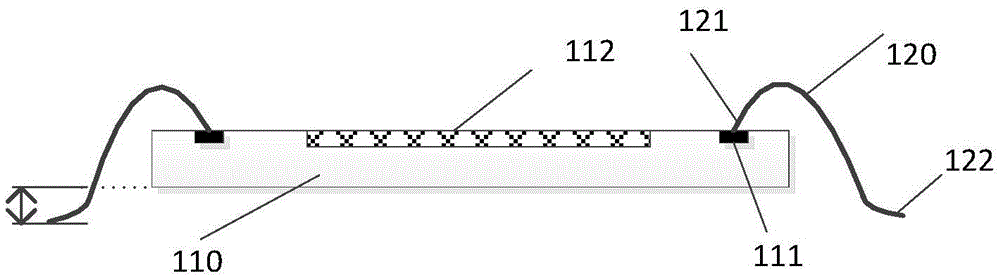

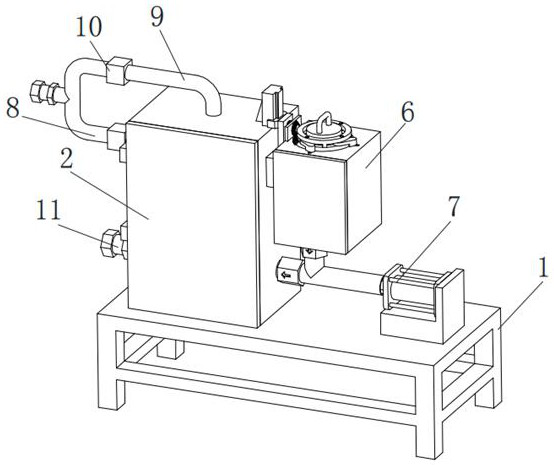

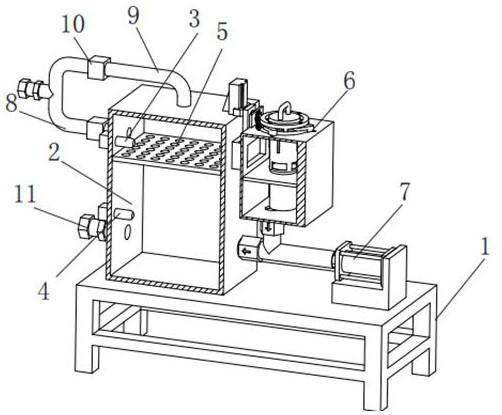

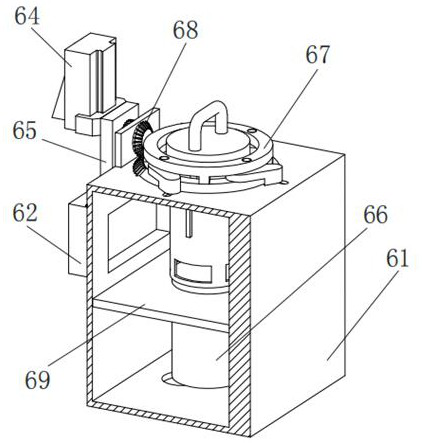

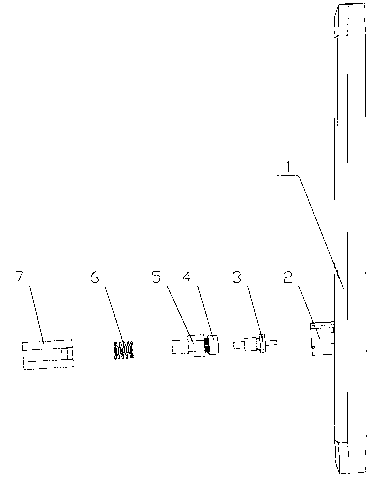

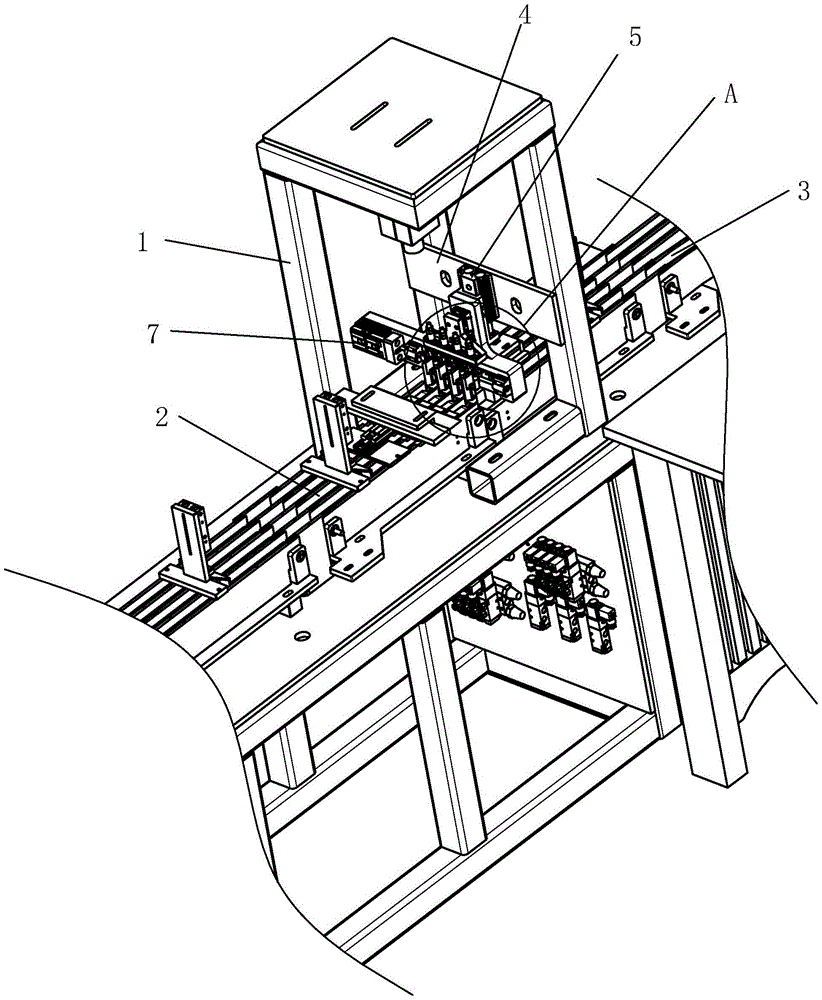

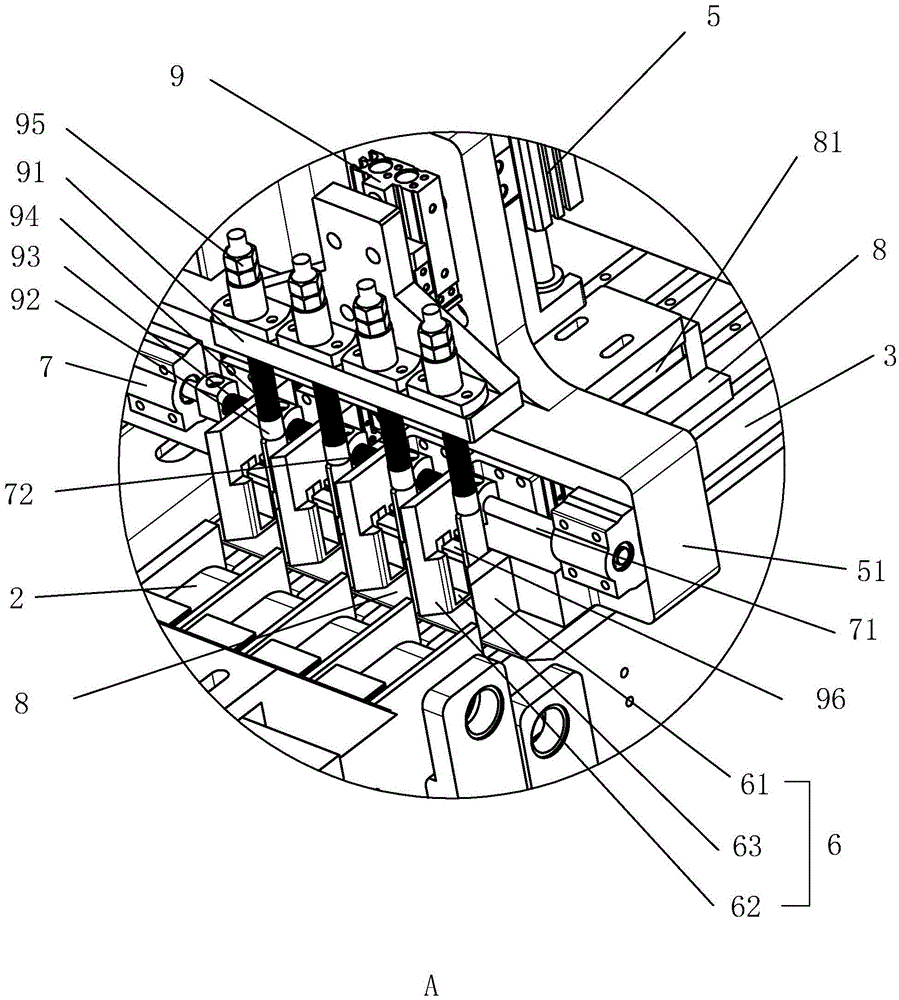

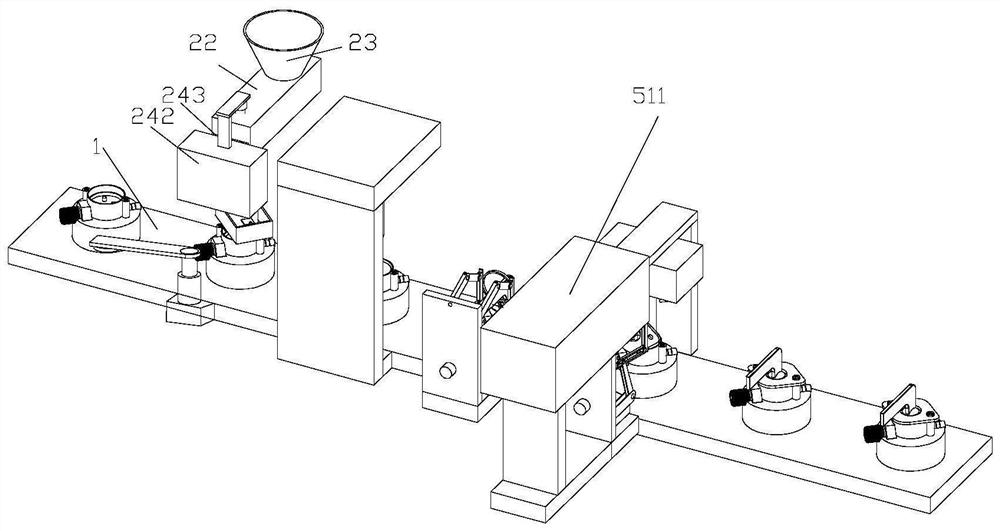

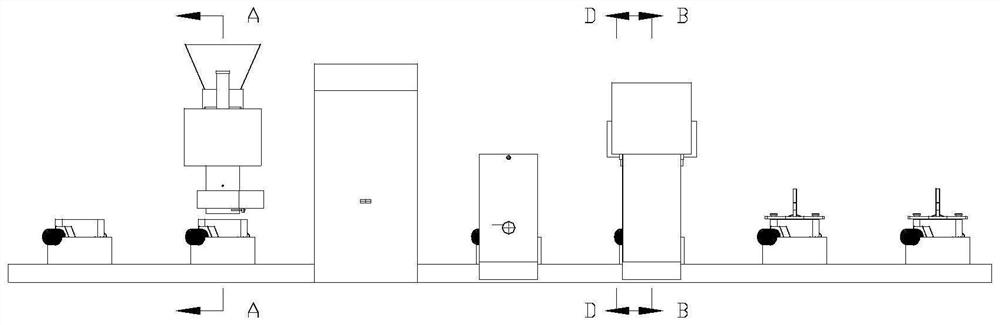

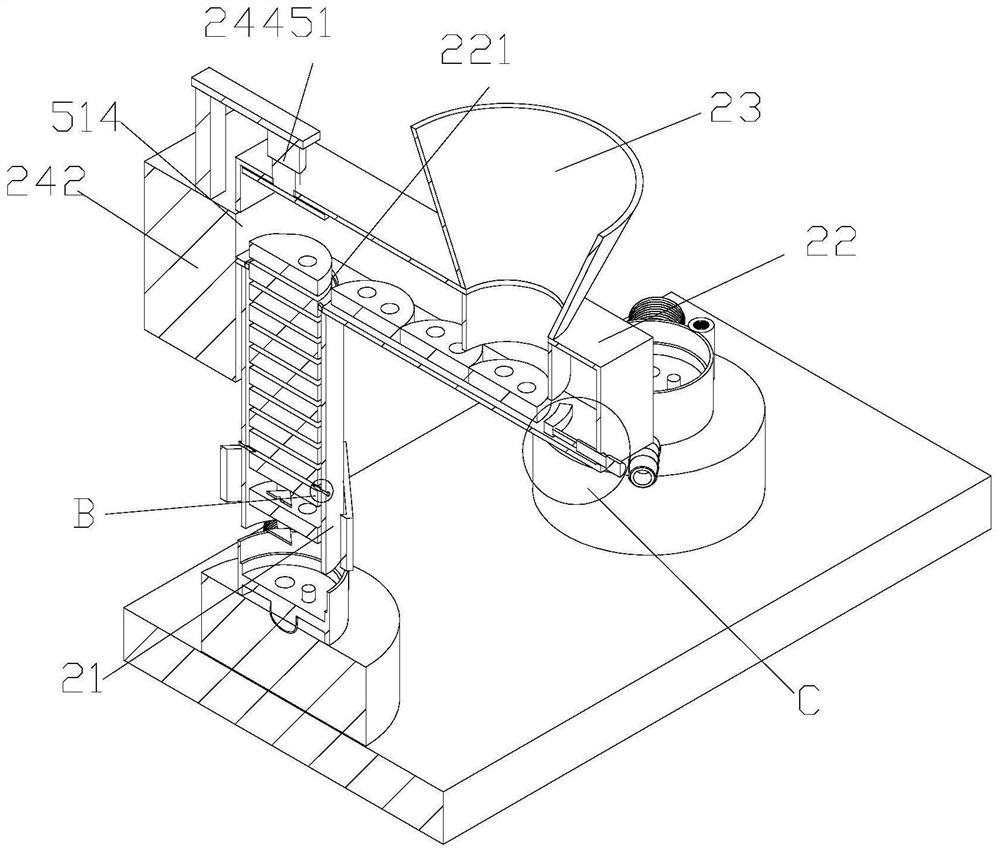

Automatic hand buckle buckling and pressing equipment

PendingCN112009028AAffect normal deliveryNormal delivery does not produceBag making operationsPaper-makingStructural engineeringIndustrial engineering

The invention discloses automatic hand buckle buckling and pressing equipment. The automatic hand buckle buckling and pressing equipment comprises a frame, wherein a hand buckle feeding device, a woven bag feeding device and a stamping device are arranged on the frame; the stamping device is provided with a stamping station and a pressing and buckling station; a primary buckle feeding track and asecondary buckle feeding track are respectively arranged on the upper end surface and the lower end surface of a woven bag, corresponding to the pressing and buckling station, of the hand buckle feeding device; the primary buckle feeding track and the secondary buckle feeding track are respectively provided with filling mechanisms for feeding primary buckles into the primary buckle feeding track and feeding secondary buckles into the secondary buckle feeding track; and sorting mechanisms used for distinguishing and sorting the front faces and the back faces of the primary buckles and the frontfaces and the back faces of the secondary buckles are arranged on track paths of the primary buckle feeding track and the secondary buckle feeding track respectively. The automatic hand buckle buckling and pressing equipment provided by the invention can perform automatic production, improves the production efficiency and is used for automatic processing and assembling of woven bag punching and automatic buckling of hand buckles.

Owner:WENZHOU KEWANG MACHINERY

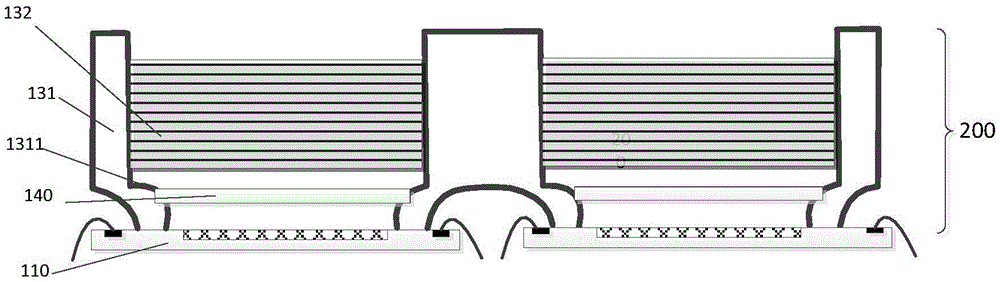

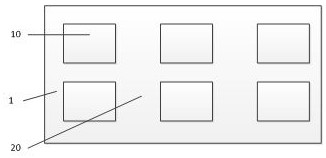

Multi-camera module and assembling method therefor

PendingCN105633108AGuaranteed Optical PerformanceQuality improvementSemiconductor/solid-state device detailsSolid-state devicesMulti cameraEngineering

The invention provides an assembling method for a multi-camera module. The assembling method comprises the steps of providing multiple image sensor chips with suspending metal wires, wherein the first end of each metal wire is arranged on a bonding pad of each image sensor chip in a bonding manner, while the second end of each metal wire is suspended on each image sensor chip; providing a lens cone framework, wherein the lens cone framework adopts an integral structure and is suitable for assembling multiple groups of lens modules and the multiple image sensor chips; and assembling the multiple image sensor chips and the lens cone framework into standard components, and assembling the standard components and circuit boards into the multi-camera module through the second ends of the metal wires.

Owner:GALAXYCORE SHANGHAI

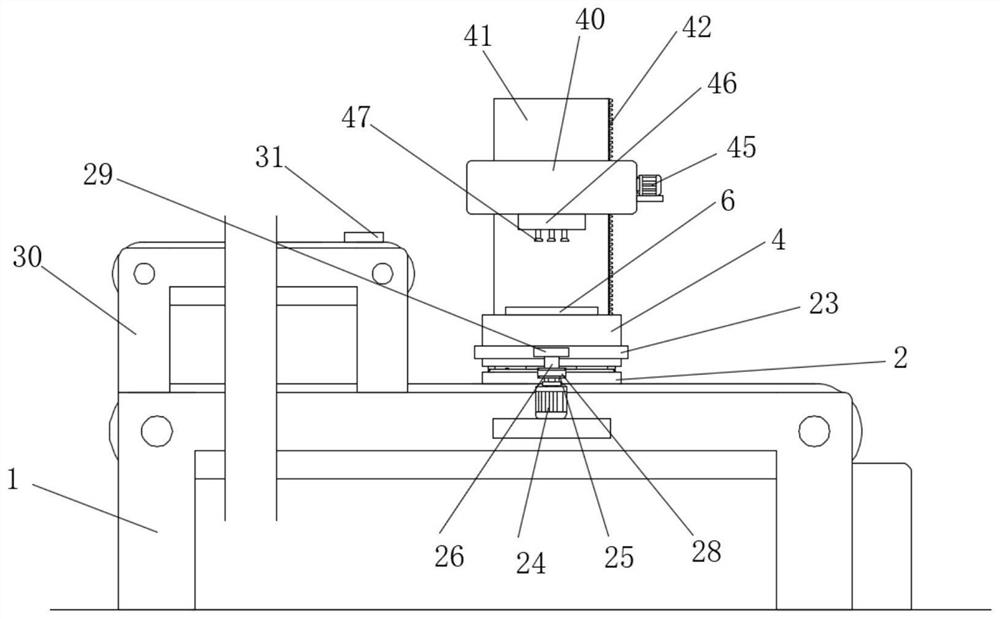

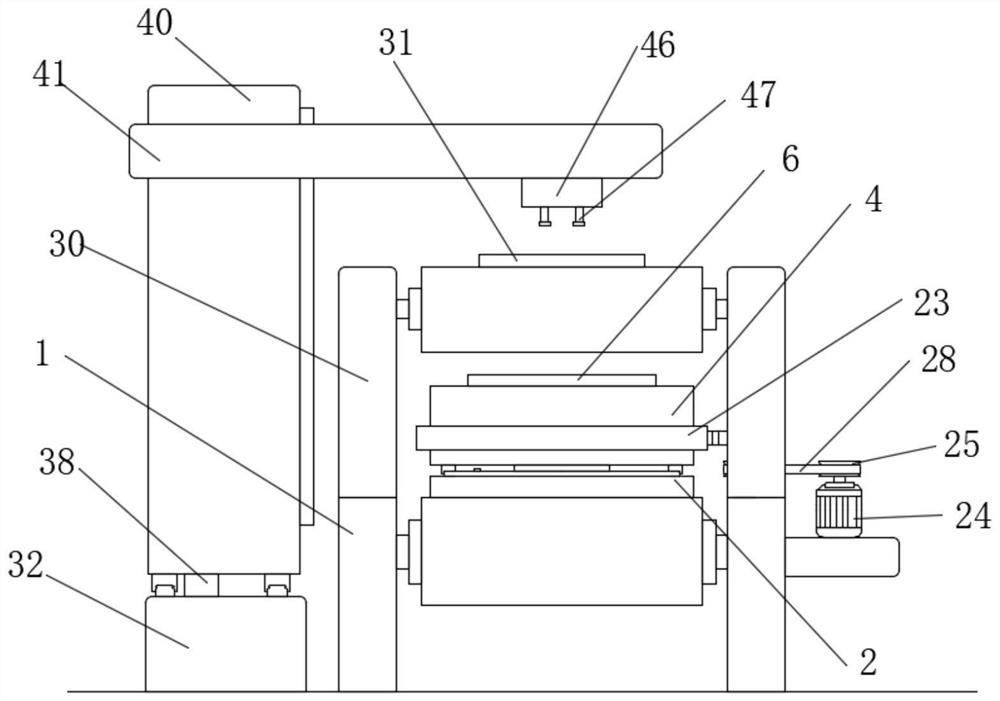

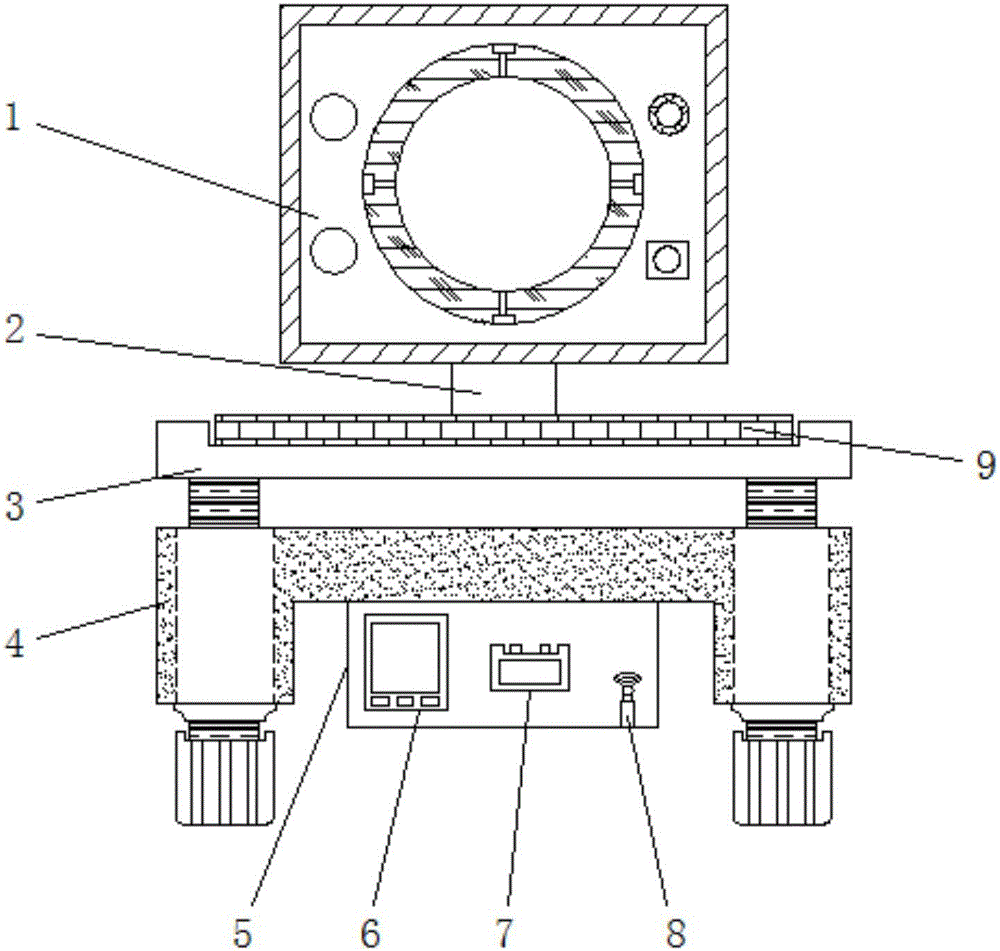

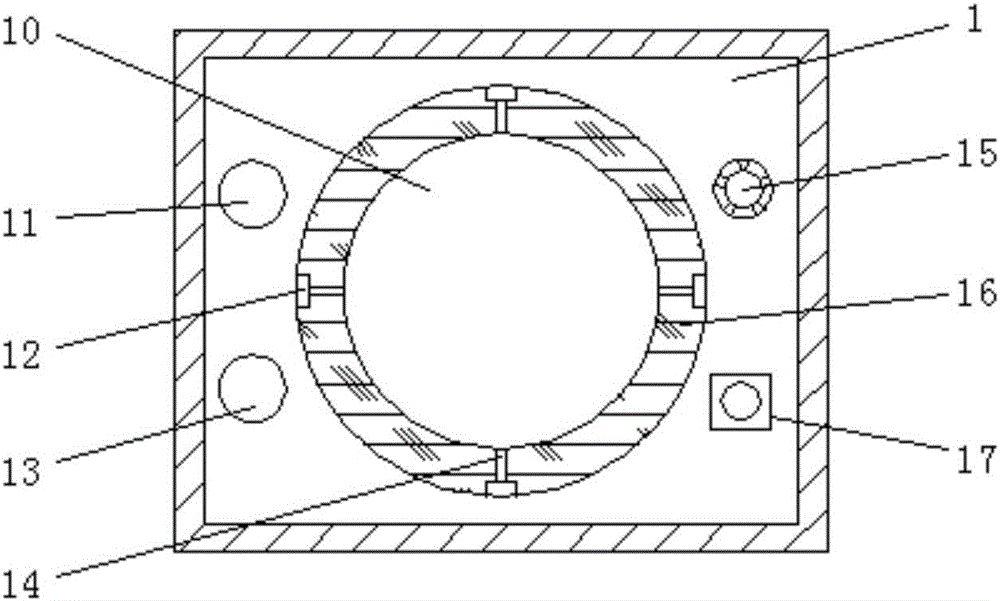

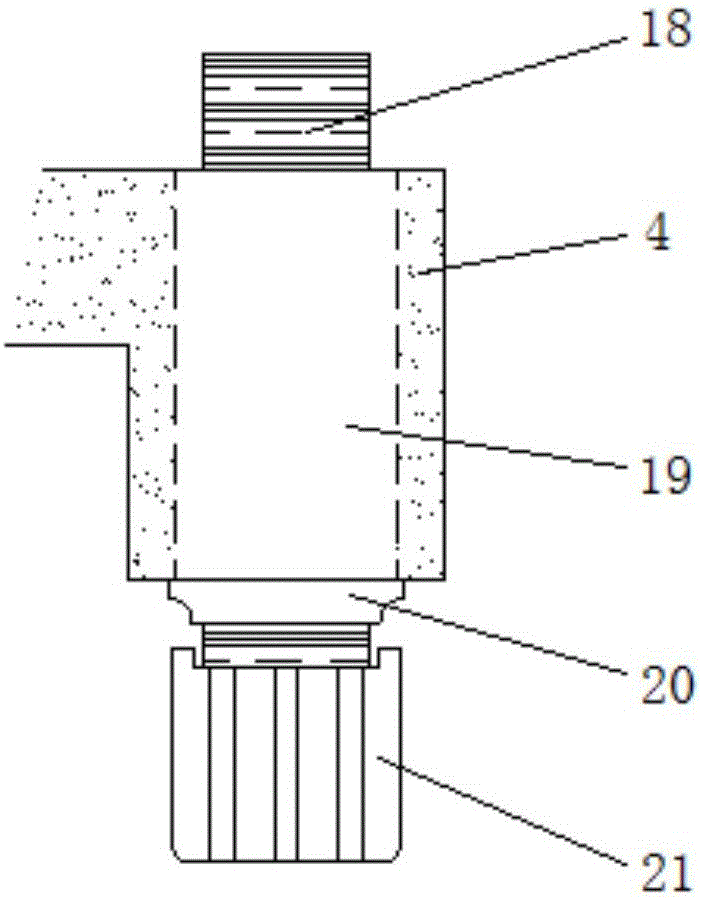

Automatic assembly system and assembly process for electric power instrument production

ActiveCN112719842AAffect assembly accuracyCalibration angleMetal working apparatusPositioning apparatusAssembly systemsMechanical engineering

The invention belongs to the technical field of electric power meter production, particularly relates to automatic assembly system and assembly process for electric power meter production. The automatic assembly system comprises a first conveying belt, wherein a bottom plate is fixedly connected to the top of the first conveying belt, a rotating shaft is rotatably connected to the top of the bottom plate, the top of the rotating shaft is fixedly connected with a clamping table, the bottom of the clamping table is slidably connected with the top of the bottom plate, and the inner walls of the two sides of the clamping table are fixedly connected with placement plates. According to the automatic assembly system, the operation is convenient, a plurality of arc-shaped clamping blocks can slide towards the middle so as to clamp a meter by starting a first driving motor, the meter is prevented from shaking in the assembling process; and a rotating motor is started to drive a outer gear ring and a clamping table to rotate at the same time, the effect of calibrating a dial plate and the meter is achieved, the angle deviation generated by manual calibration is avoided, the assembling efficiency can be improved, and the precision deviation generated in the assembling process can be reduced.

Owner:QINGDAO HIGH TECH COMM

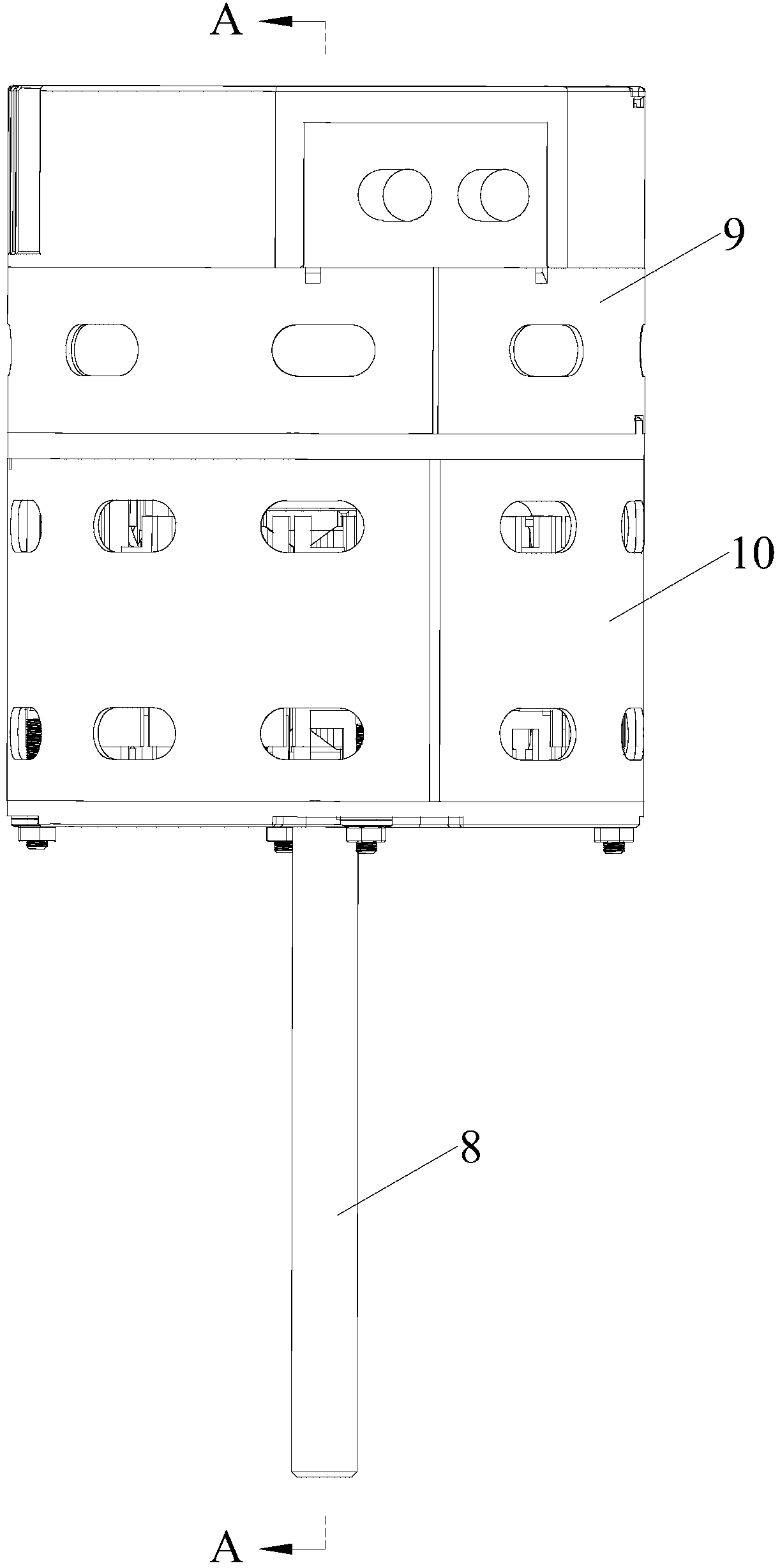

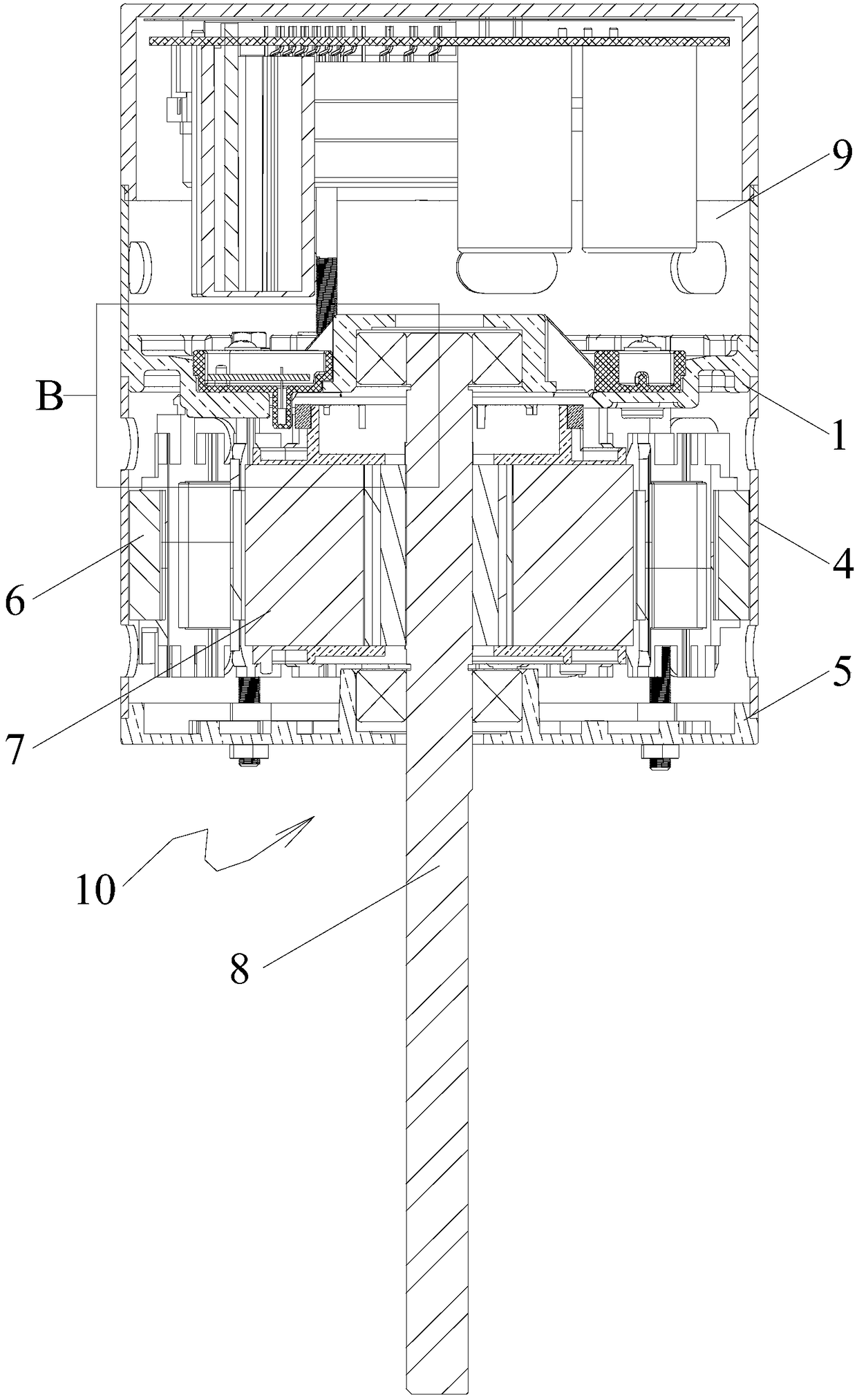

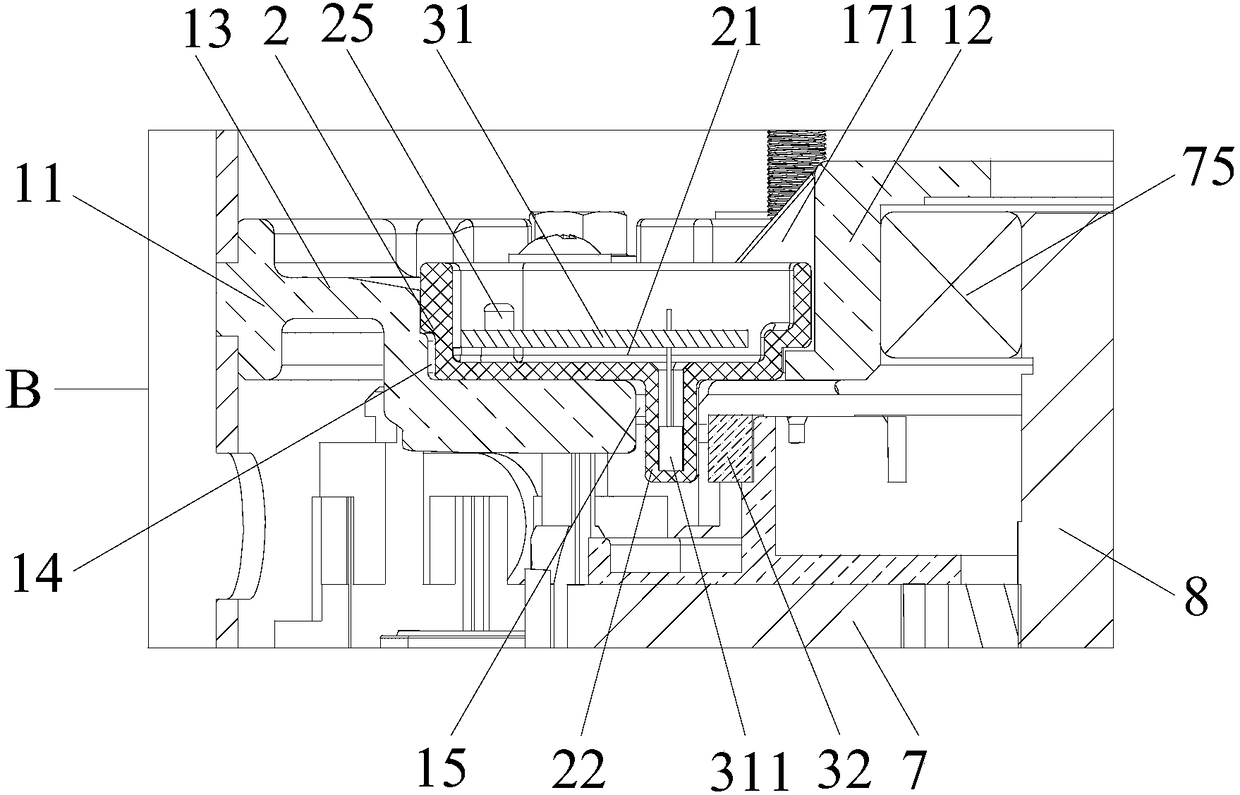

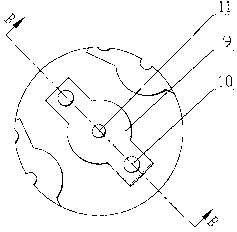

BLDC (brushless direct current) motor

PendingCN108233660AThe induction effect is stableImprove the induction effectStructural associationHall elementFixed frame

The invention discloses a BLDC (brushless direct current) motor. The BLDC motor comprises a motor body and a controller, wherein a rotating shaft extends out of the front end of the motor body, and the tail end of the motor body is connected with the controller; the motor body comprises a case, a front end cover, a back end cover, a stator assembly, a rotor assembly and a rotating shaft; the frontend cover and the back end cover are mounted at two ends of the case respectively; the stator assembly and the rotor assembly are mounted in a cavity of the case; a magnetic ring is mounted on the rotor assembly; the back end cover comprises a bottom plate, a bearing block bulging from the center of the bottom plate to the controller as well as an annular bulging edge arching on the outer edge ofthe bottom plate; an annular groove is formed between the annular bulging edge and the bearing block; a through hole is formed in the groove; a Hall fixing frame is mounted on the groove; a Hall circuit board is mounted on the Hall fixing frame; a Hall element on the Hall circuit board extends into the motor body via the through hole and is located beside the magnetic ring. The Hall circuit boardis convenient to mount, the back end cover and the Hall fixing frame are not easy to deform, and angle deviation of the Hall element is avoided.

Owner:ZHONGSHAN BROAD OCEAN

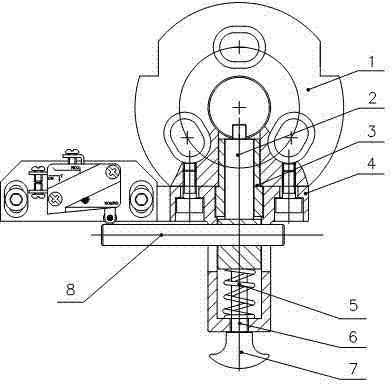

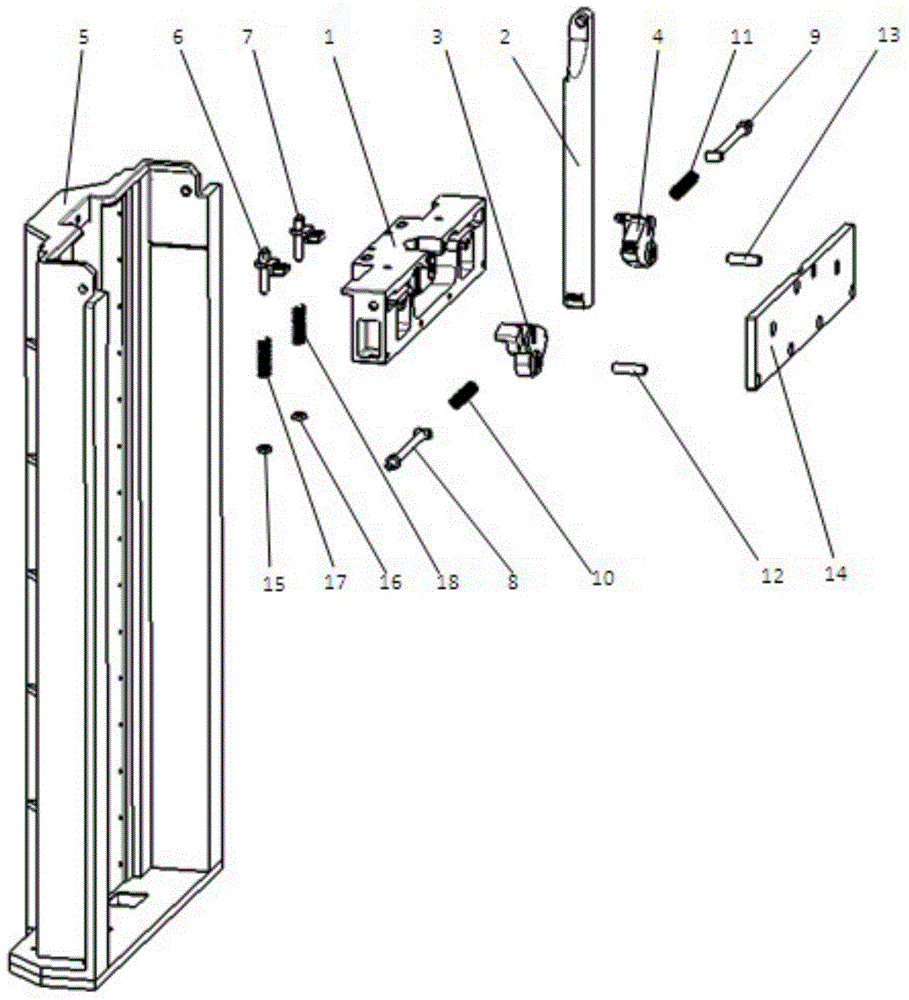

Tool for pressing signal wheel on camshaft

InactiveCN103770048APrecise positioningSimple structureWork holdersMetal-working hand toolsEngineeringCamshaft

The invention discloses a tool for pressing a signal wheel on a camshaft. The tool for pressing the signal wheel on the camshaft comprises a locating base, wherein a locating hole is formed in the middle of the locating base, a base plate is arranged at the lower end of the front side of the locating base, and an end cover is arranged at the upper end of the front side of the locating base; a locating shaft installing hole is formed in the locating base; an inner cavity is formed in the end cover, and is communicated with the locating shaft installing hole, a locating sleeve is arranged in the locating shaft installing hole, a locating shaft is arranged in the locating sleeve, a locating block is arranged at the end of the locating shaft, and extends into a locating hole, the front end of the locating shaft is fixedly connected with a stud, a handle is installed on the stud, and a reset spring is arranged at the periphery of the stud; a locating pin is arranged on the locating shaft, and can move in the direction of the center line of the locating shaft installing hole. The tool for pressing the signal wheel on the camshaft is simple in structure, accurate in locating and reliable in operation, angle deviation caused in the process of press mounting of the signal wheel can be avoided, the product percent of pass is improved, and the press mounting cost is reduced.

Owner:柳州瑞明威罗动力机械有限公司

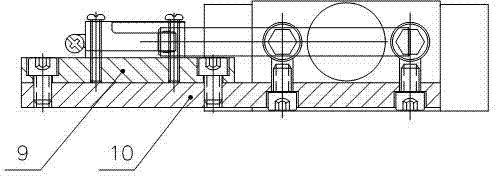

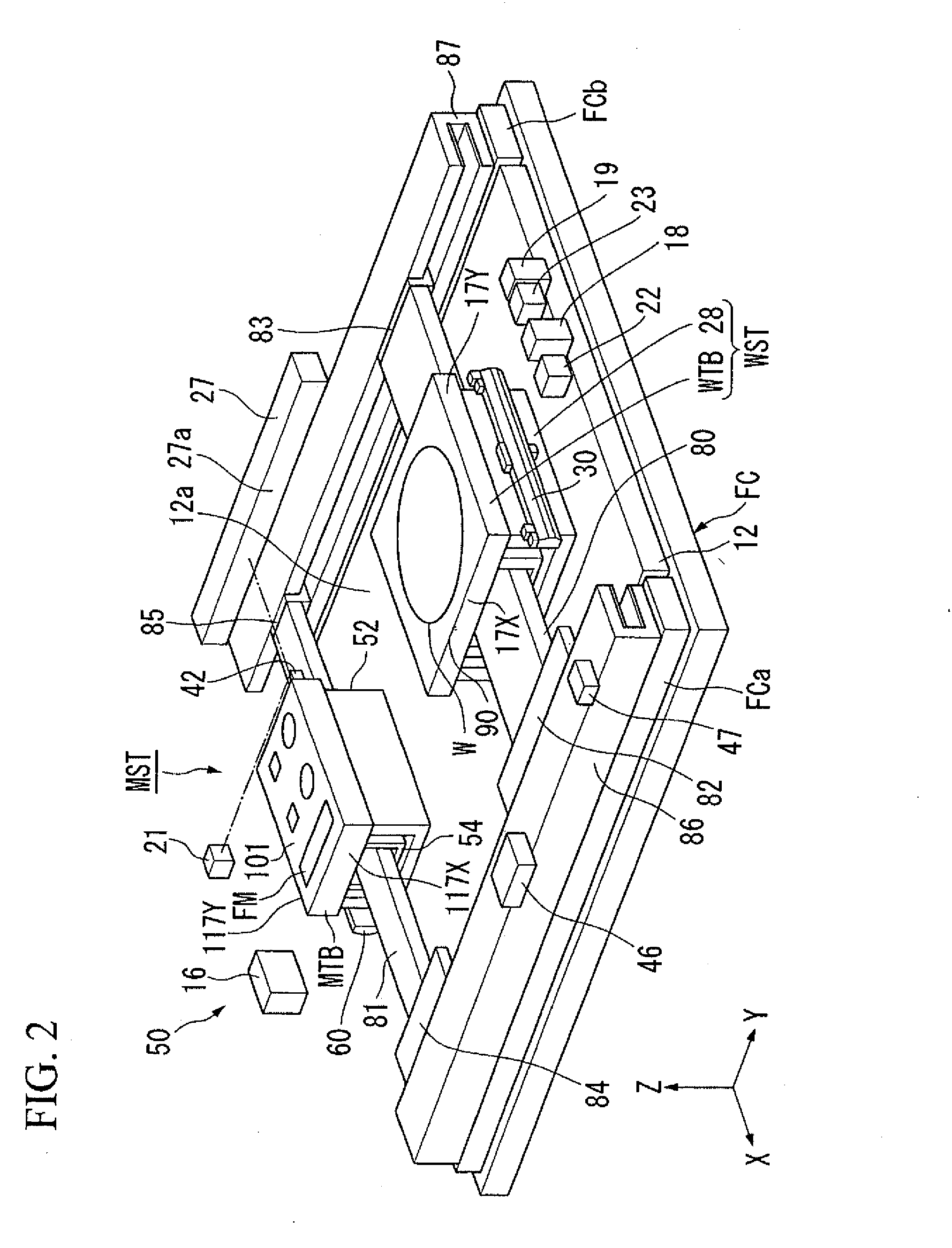

Reflector, optical element, interferometer system, stage device, exposure apparatus, and device fabricating method

InactiveUS20120127478A1Increase in sizeReduce morbidityMirrorsPhotomechanical apparatusExposureReflectron

Owner:NIKON CORP

Electrical signal connector

InactiveUS20140370748A1Much installation timeLabor moreElectrically conductive connectionsCoaxial cableBearing surface

An electrical signal connector for connecting a coaxial cable to a mating connector is disclosed to include a locknut, a metal central tube inserted through the locknut and defining a stop flange at one end, a barbed retaining portion at an opposite end, a locating groove around the periphery between the stop flange and barbed retaining portion and an annular bearing surface portion extending around the periphery between the stop flange and the locating groove, a chuck unit including a collar, which is press-fitted onto the annular bearing surface portion of the metal central tube and having longitudinal clamping strips suspending around the barbed retaining portion of the metal central tube, and a constraint shell surrounding the collar, and an actuation sleeve mounted within the constraint shell around the collar and manually axially movable relative to the chuck unit between two positions to compress or release the longitudinal clamping strips.

Owner:LEE CHUNG YU

Silicon carbide ceramic membrane filtering device

ActiveCN113368698AImprove filtering effectImprove filtration efficiencySemi-permeable membranesCarbide siliconCeramic membrane

The invention discloses a silicon carbide ceramic membrane filtering device, and belongs to the technical field of filtering equipment, wherein the silicon carbide ceramic membrane filtering device comprises a workbench, a filtering box, a first water pressure sensor, a second water pressure sensor, a silicon carbide ceramic membrane, impurity removal equipment and backflow equipment. When the device works, dead-end filtering is firstly carried out, if the pressure borne by the first water pressure sensor is far larger than that borne by the second water pressure sensor, it is indicated that impurities block the silicon carbide ceramic membrane after long-time filtering, and at the moment, the first water pressure sensor and the second water pressure sensor transmit signals to carry out cross-flow filtering; impurities in the silicon carbide ceramic membrane can be taken out through cross-flow filtration, then waste water carries the impurities to enter the impurity removal equipment, then the impurities are recycled by the impurity removal equipment, the remaining liquid returns to the filtering box again through the backflow equipment, and cleaning of the silicon carbide ceramic membrane is completed; and after cleaning of the silicon carbide ceramic membrane is completed, the whole device can continue to return to a dead-end filtering state, so that the filtering efficiency is improved.

Owner:山东浦创流体技术有限公司

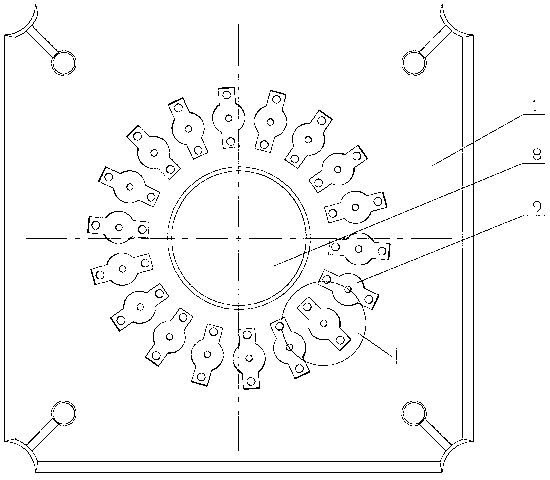

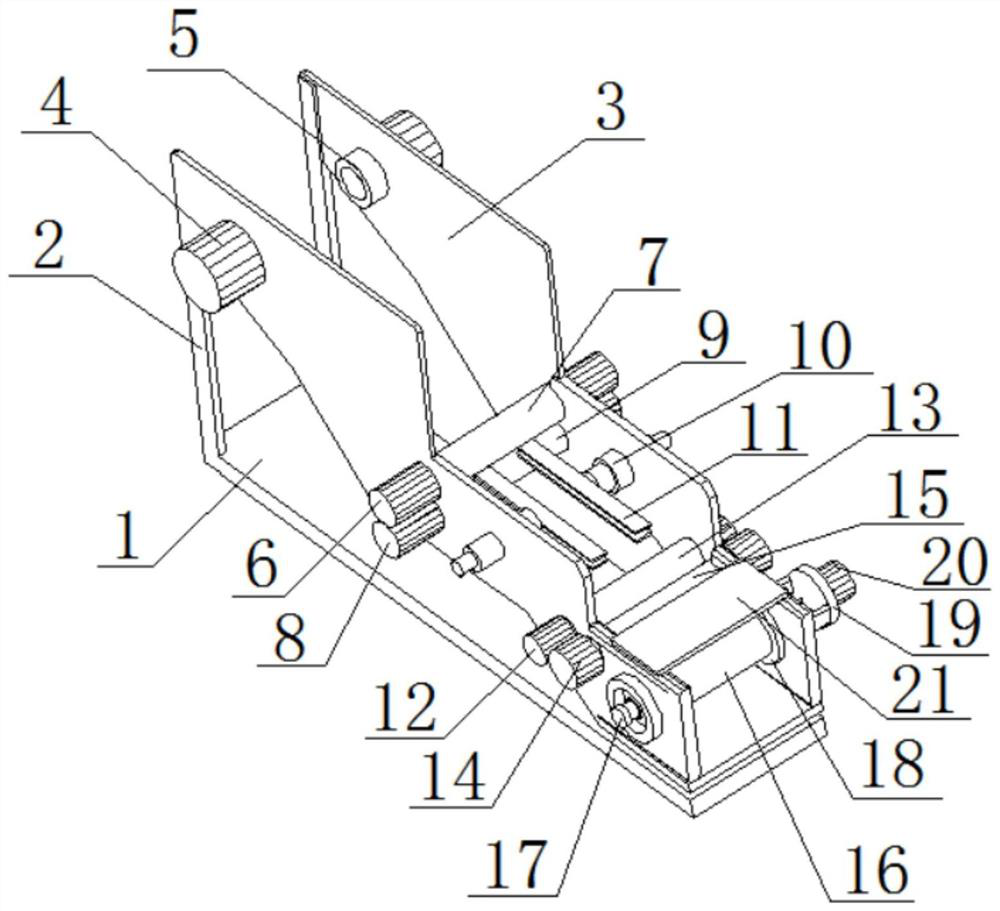

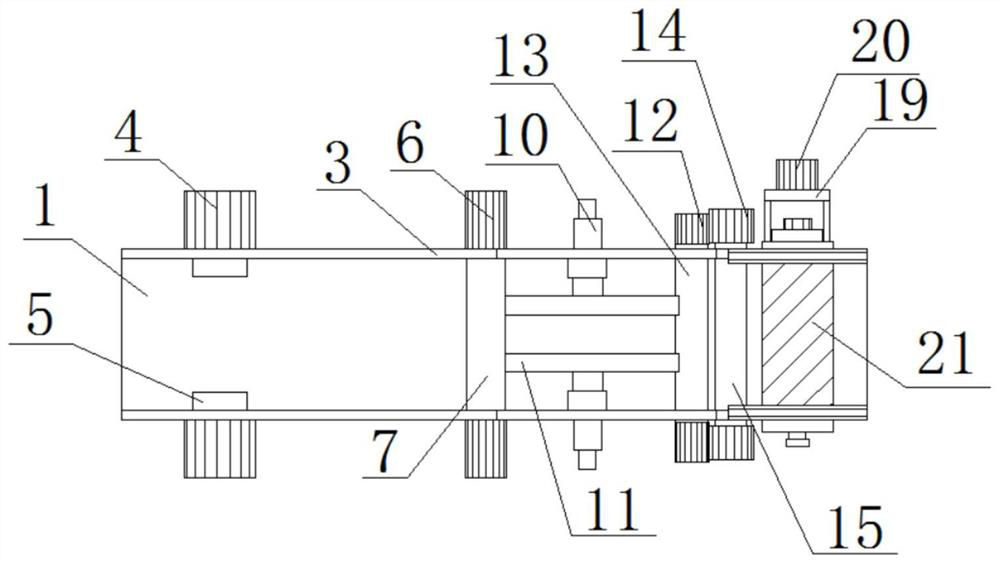

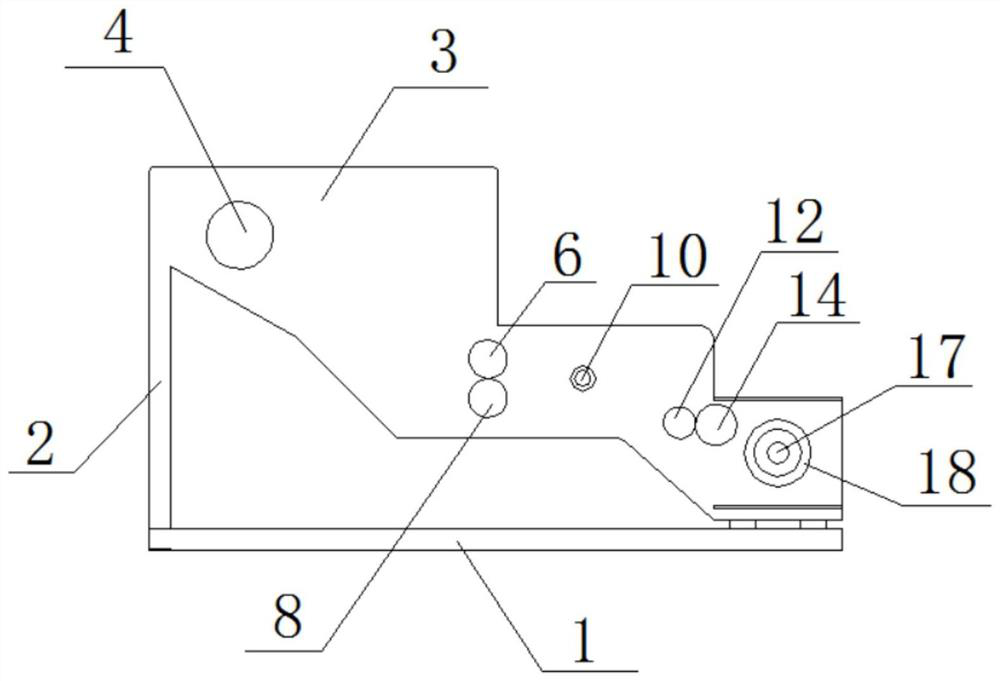

Special jig fixture for grinding non-standard optical fiber connectors

InactiveCN102848307APrecise positioningRapid positioningWork carriersEngineeringOptical communication

A special jig fixture for grinding non-standard optical fiber connectors comprises a chuck plate. A mounting hole is arranged in the chuck plate. The special jig fixture is characterized in that a plurality of mounting grooves arranged obliquely are arranged on the chuck and encircle the periphery of the mounting hole, pin through holes are arranged in the mounting grooves, a seat sleeve is mounted in each mounting groove by a screw, two axial guide grooves which are arranged symmetrically are arranged on side walls of each seat sleeve, positioning grooves which are rotatably arranged in the same direction are arranged at bottoms of the two guide grooves of each seat sleeve, a positioning sleeve is assembled in each seat sleeve, two axial guiding inner planes are arranged in an inner cavity of each positioning sleeve, springs and elastic chucks are mounted in the positioning sleeves, guiding sections are arranged on the elastic chucks, and guiding outer planes arranged on outer walls of the guiding sections are fittingly connected with the guiding inner planes in the positioning sleeves. The special jig fixture solves problems that the non-standard optical fiber connectors are difficult to grind and machine in the prior art, grinding angles are easy to deviate, production efficiency is low, and the like. The special jig fixture is mainly used for producing and machining the non-standard optical fiber connectors in optical communication.

Owner:黄石晨信光电股份有限公司

Clamp special for detection of feather of shuttlecock

The invention discloses a clamp special for detection of feather of a shuttlecock.According to the technical scheme, the clamp is characterized by comprising a fixed support, a first slideway and a second slideway are fixedly connected to the fixed support, a fixed plate is arranged on the fixed support, a lifter is arranged on the fixed plate, a lifting plate is arranged on the lifter, a clamper is arranged on the lifting plate, a pusher driven by the clamper is arranged on the lifting plate, and a pushing rod is arranged on the pusher; the clamper comprises a first clamp piece set and a second clamp piece set which abut against each other, the first slideway is located above the second slideway, the first clamp piece set is fixedly connected to the pushing rod, the second clamp piece set is fixedly connected to the lifting plate, the clamper is arranged on the bottom of the lifting plate, a supporting plate abuts against the bottom of the clamper, an expansion piece allowing the supporting plate to slide is arranged on the side, away from the clamper, of the lifting plate, a presser is arranged on the top of the lifting plate, a pressing plate is arranged on the presser, and a pressing rod abutting against the supporting plate is arranged on the pressing plate.

Owner:NANJING SHIPENG GOODS LTD

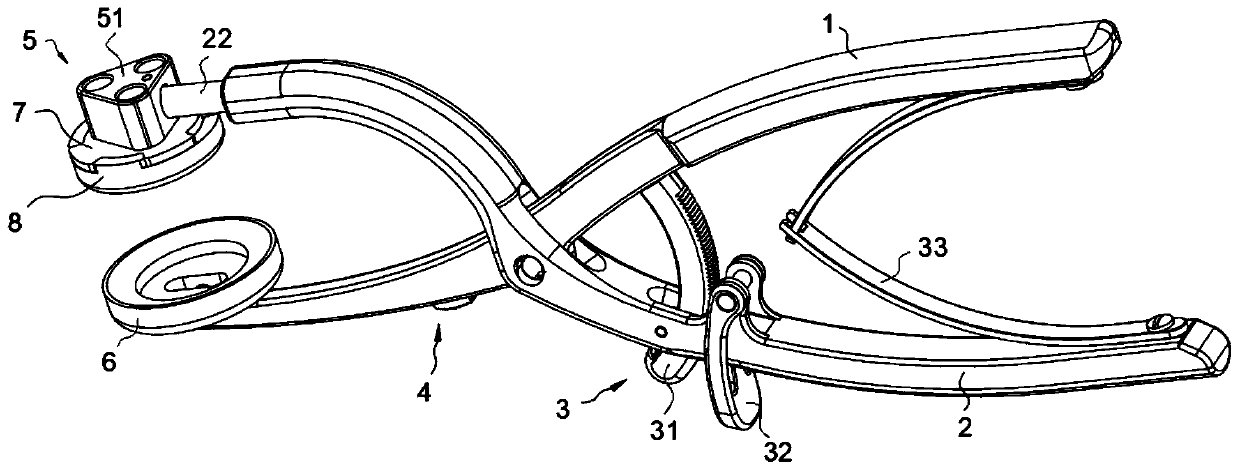

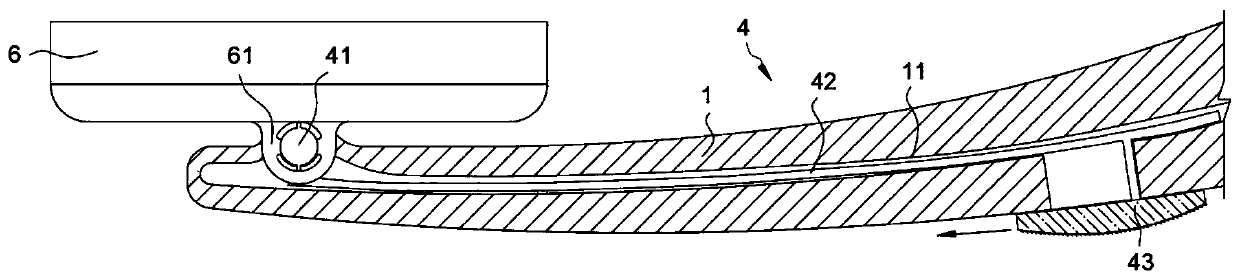

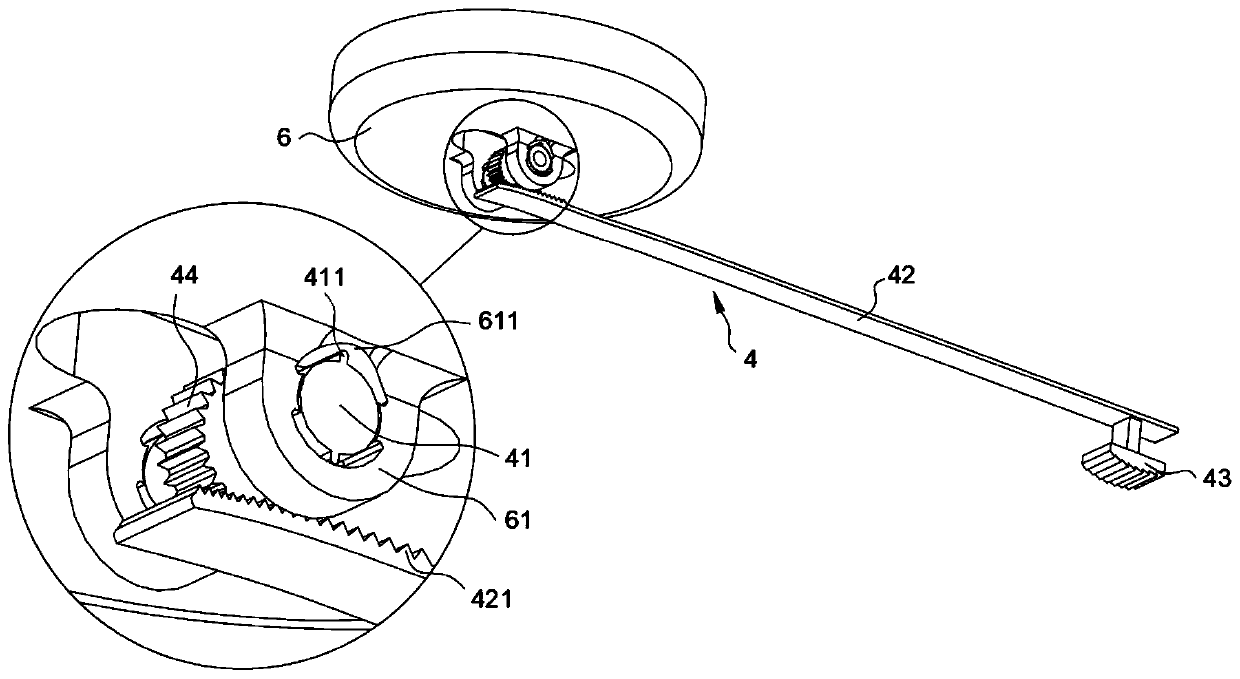

Patella driver

ActiveCN110711053AAvoid angular deviationHigh clamping accuracyJoint implantsKnee jointsPhysical medicine and rehabilitationEngineering

The invention discloses a patella driver. The patella driver comprises a first handle body and a second handle body hinged to each other, and a locking device is arranged between the first handle bodyand the second handle body; a patella pressing block is hinged to one end of the second handle body, installation parts are connected to one end of the second handle body, drill guide devices are arranged on one sides of the installation parts, patella end surface touch blocks are connected to the bottoms of the drill guide devices, and cambered surface clamping blocks are arranged at the bottomsof the patella end surface touch blocks; a direction adjusting device is arranged on the first handle body, and the direction adjusting device comprises a pushing block; and a sliding groove is formed in the first handle body, a slipping strip is slidably installed in the sliding groove, a rack is arranged on one side of the slipping strip, the installation parts are correspondingly arranged at the bottom of the patella pressing block, and a rotating shaft is rotatably connected between the two installation parts in an inserting mode. The patella driver has the characteristics of simple operation and being adapt to different implanting angles.

Owner:天衍医疗器材有限公司

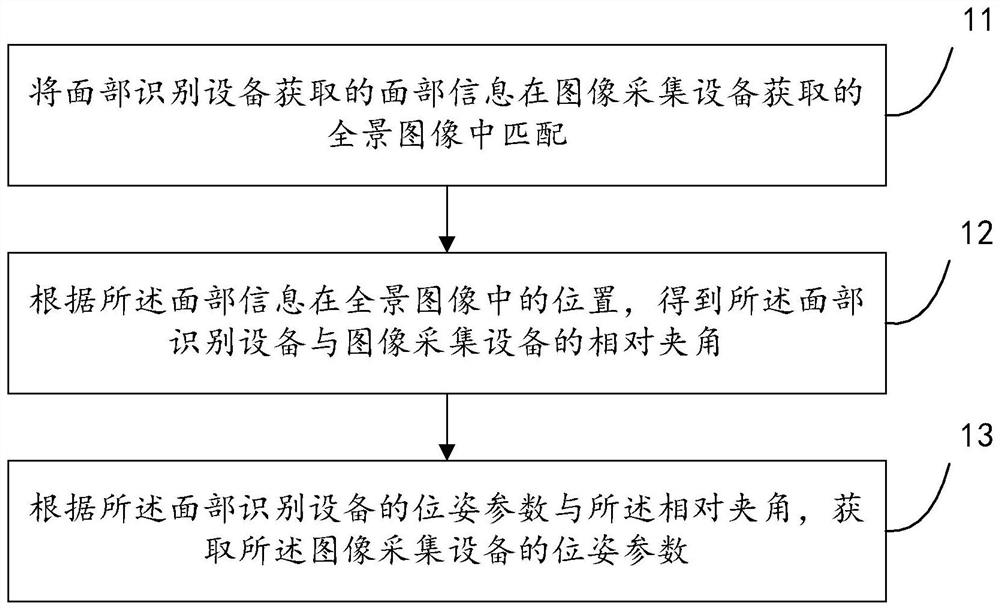

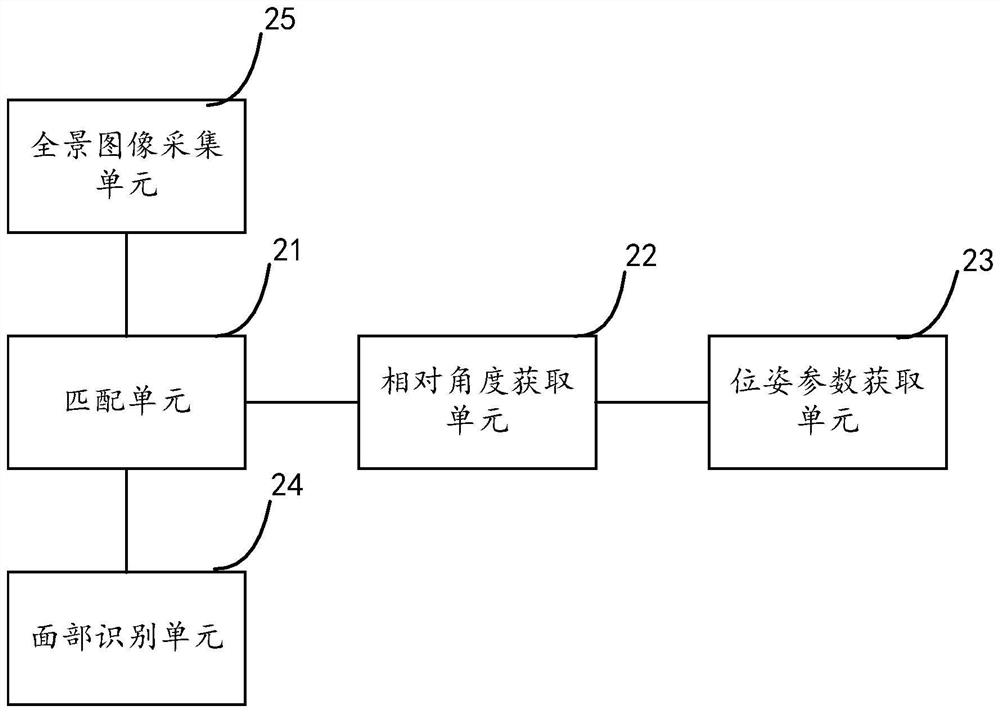

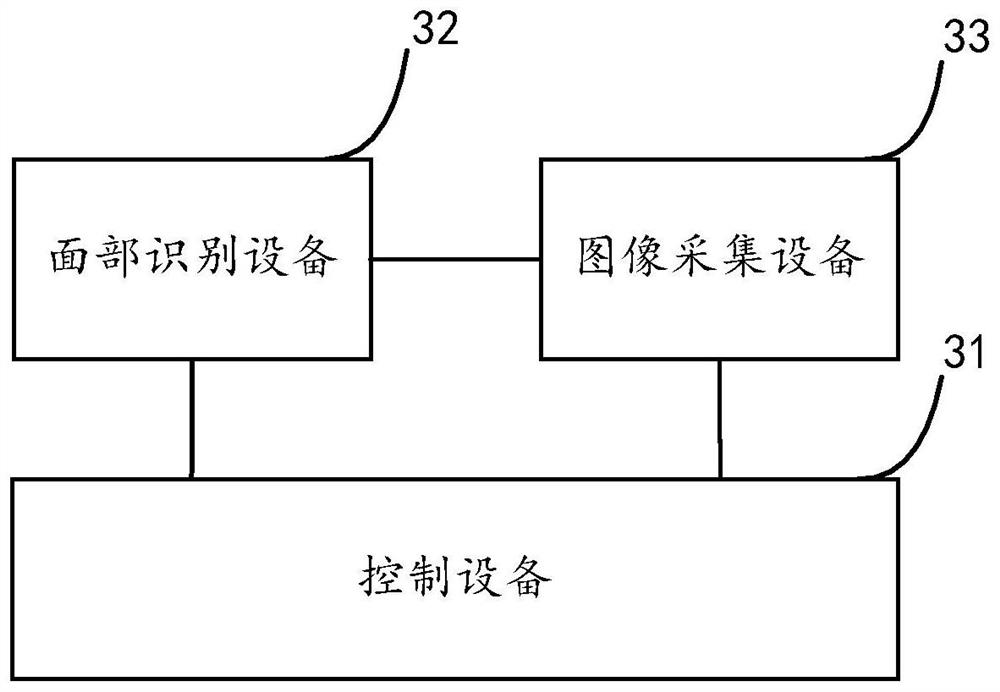

Panoramic information acquisition pose acquisition method, device and system

ActiveCN112073640AAvoid angular deviationConvenient automatic splicingTelevision system detailsColor television detailsNuclear medicineImage acquisition

The embodiment of the invention discloses a panoramic information acquisition pose acquisition method, device and system, and the method comprises the steps: employing the interaction between face recognition equipment and image collection equipment, comparing the face information collected by the face recognition equipment with a panoramic image collected by the image collection equipment, obtaining the position of the face information in the panoramic image, and determining the relative included angle between the face recognition device and the image acquisition device; after the face recognition equipment obtains the pose parameters of the face recognition equipment, acquiring the pose parameters of the image acquisition equipment according to the relative included angle. The pose parameters of the image acquisition equipment are acquired according to the pose parameters of the face recognition equipment in combination with the relative included angle, so the problem of angular deviation during splicing due to the fact that panoramic images acquired by the image acquisition equipment do not have the pose parameters is avoided.

Owner:BEIKE TECH CO LTD

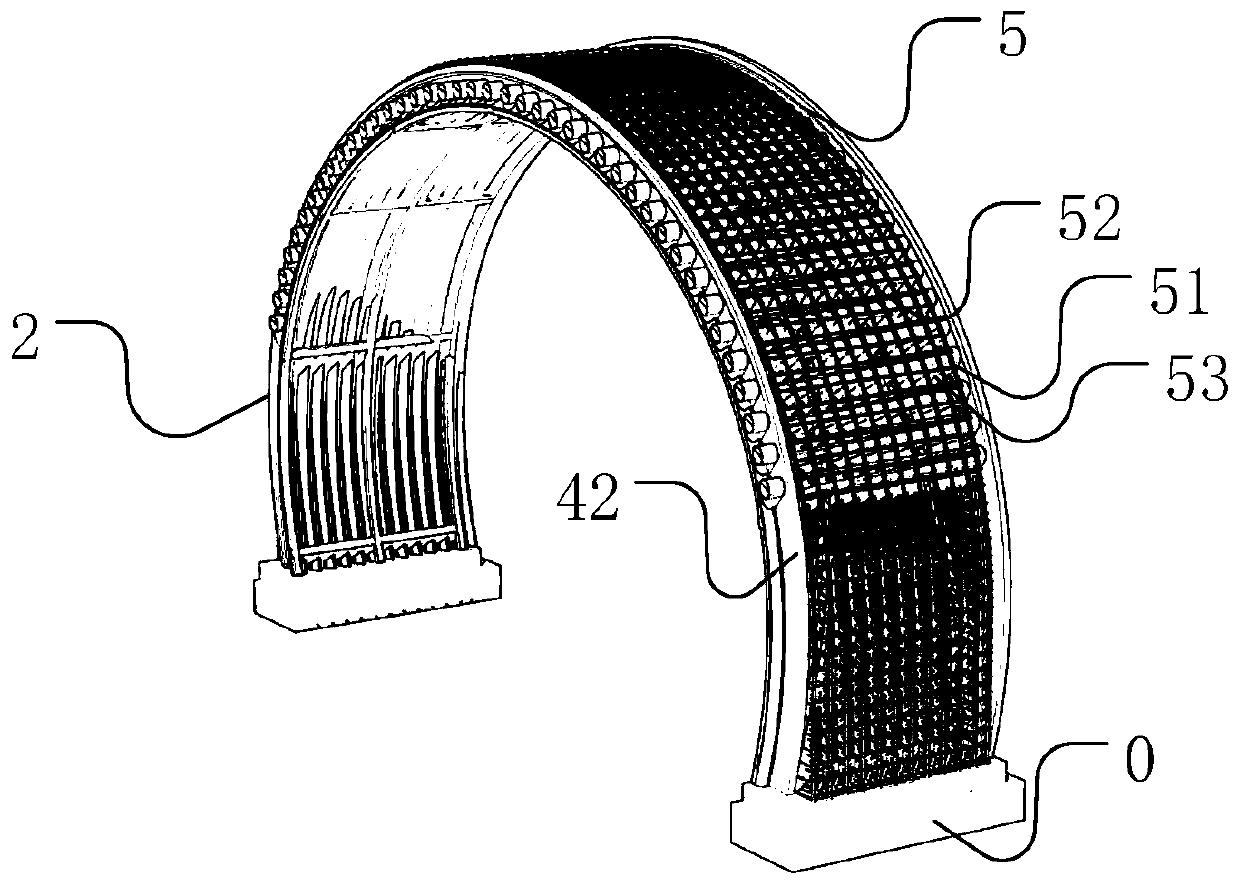

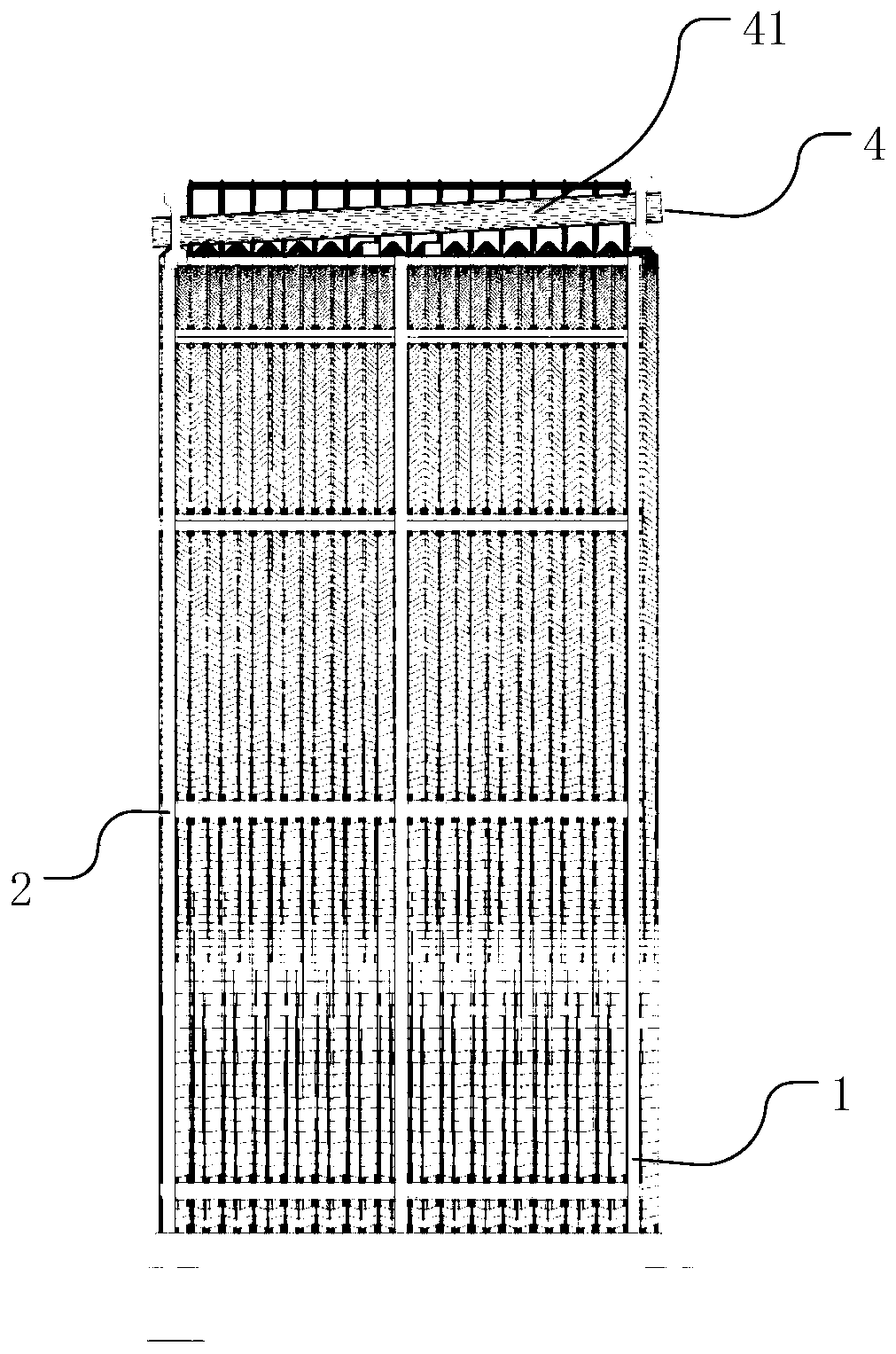

Zero-earthing corrugated plate holing structure

PendingCN109812278AAvoid progressAvoid quality problemsUnderground chambersTunnel liningMaterial resourcesRebar

The invention belongs to the field of structural assembly of soil engineering and relates to a zero-earthing corrugated plate holing structure. The holing structure comprises two bases and an arched corrugated plate structure spanning the two bases; a plane determined by one side, away from the arched corrugated plate structure, of each of the two bases is a first plane; the holing structure further comprises a corrugated plate reinforcing structure arranged on one side, facing the first plane, of the arched corrugated plate structure, an arched reinforcement structure surrounding the exteriorof the arched corrugated plate structure and a lead large pipe shed steel pipe limiting structure, the lead large pipe shed steel pipe limiting structure comprises front end I-steel, tail-end I-steeland one or more lead large pipe shed steel pipe sleeves spanning the front end I-steel and the tail-end I-steel, and the front end I-steel and the tail-end I-steel are arranged on the two sides of the arched corrugated plate structure. With the adoption of the holing structure, safety during tunnel holing is improved, working efficiency and construction accuracy are improved, and a large quantityof manpower and material resources are saved.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

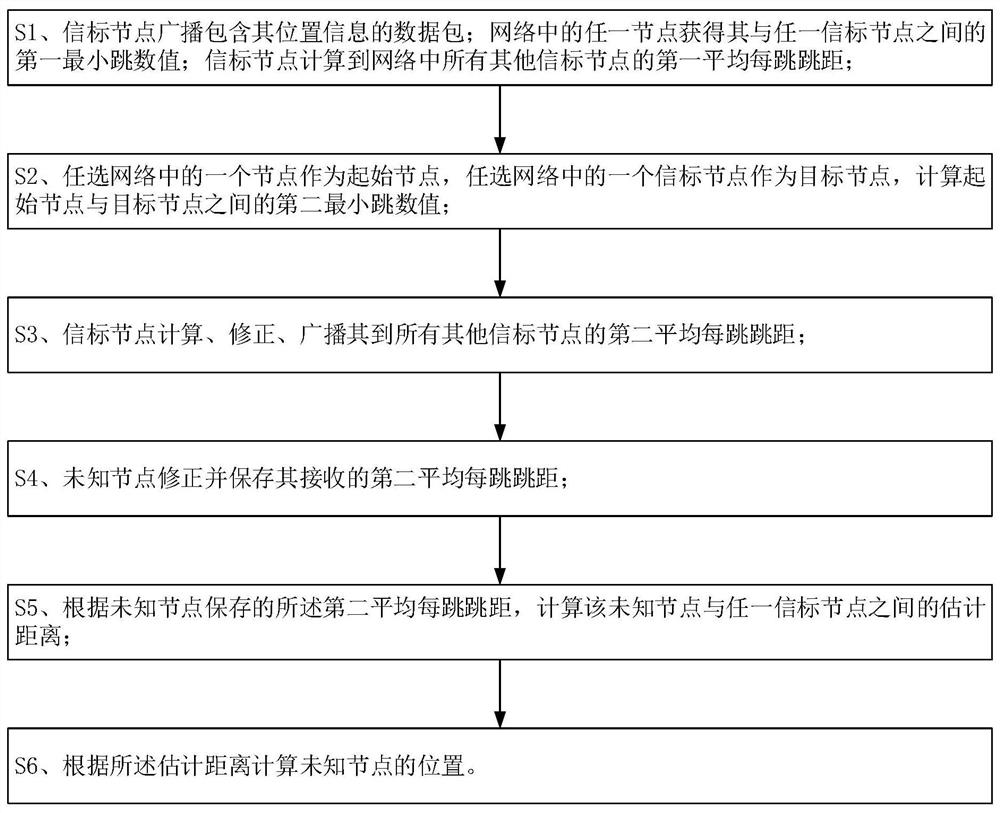

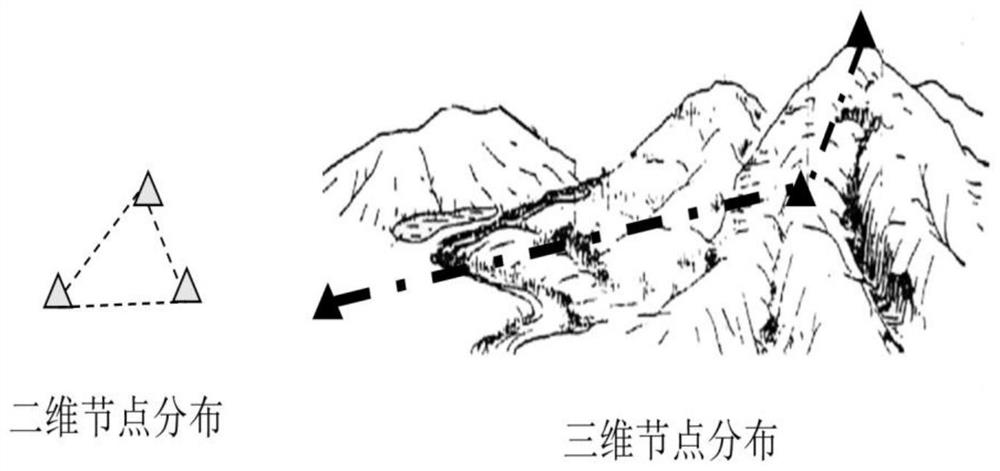

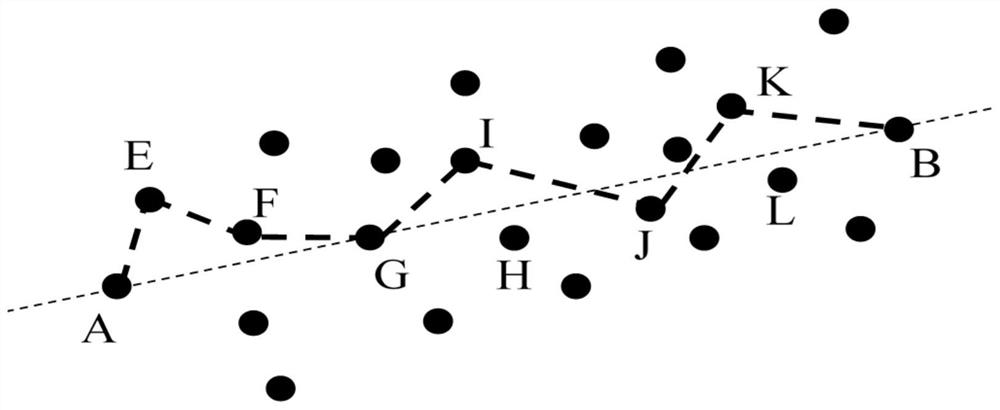

Wireless sensor network positioning method

ActiveCN112188615AGood application effectImprove compatibilityNetwork topologiesLine sensorEngineering

The invention provides a wireless sensor network positioning method. The wireless sensor network positioning method comprises the following steps: S1, a beacon node broadcasts a data packet containingposition information of the beacon node, any node in a network acquires a first minimum hop value between the node and any beacon node, and the beacon node calculates a first average hop distance perhop to all the other beacon nodes in the network; S2, one optional node in the network is selected as a starting node, one optional beacon node in the network is selected as a target node, and a second minimum hop value between the starting node and the target node is calculated; S3, the beacon node calculates, corrects and broadcasts a second average hop distance per hop from the beacon node toall the other beacon nodes; S4, an unknown node corrects and stores the received second average hop distance per hop; S5, an estimated distance between the unknown node and any beacon node is calculated according to the second average hop distance per hop stored by the unknown node; and S6, the position of the unknown node is calculated according to the estimated distance.

Owner:SHANGHAI MARITIME UNIVERSITY

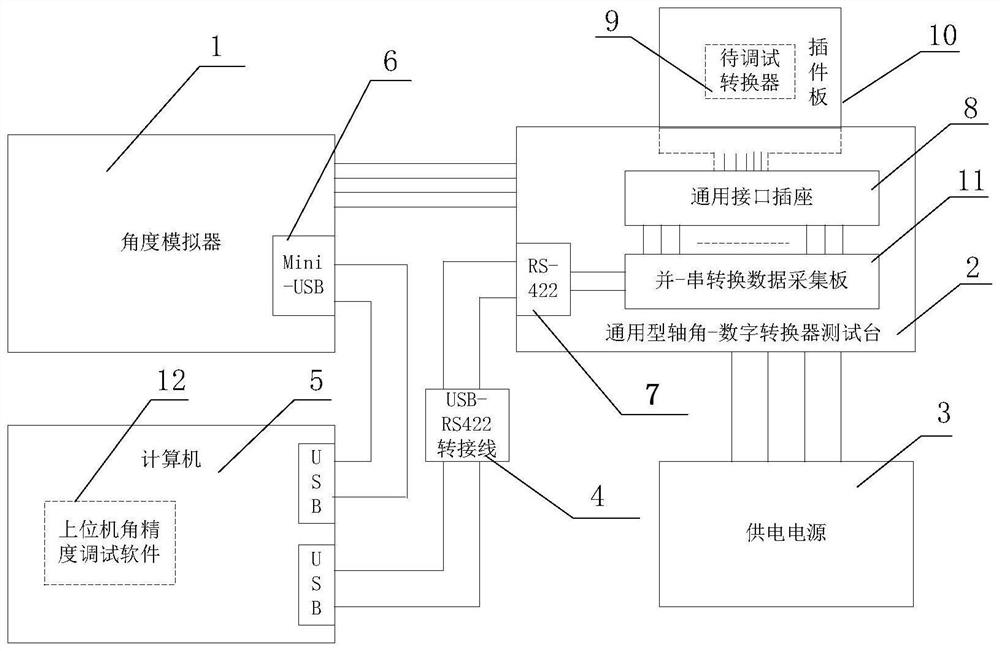

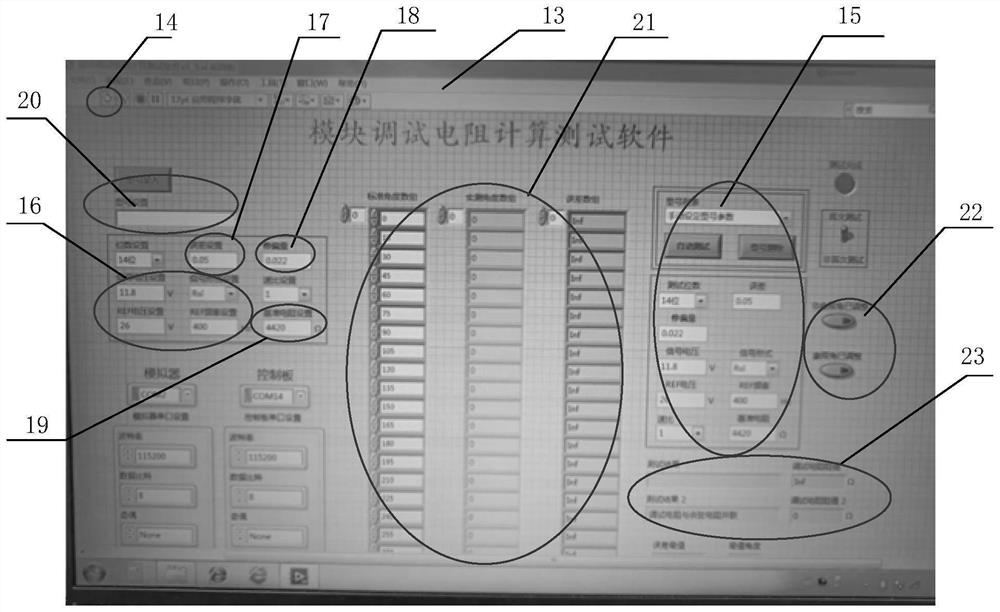

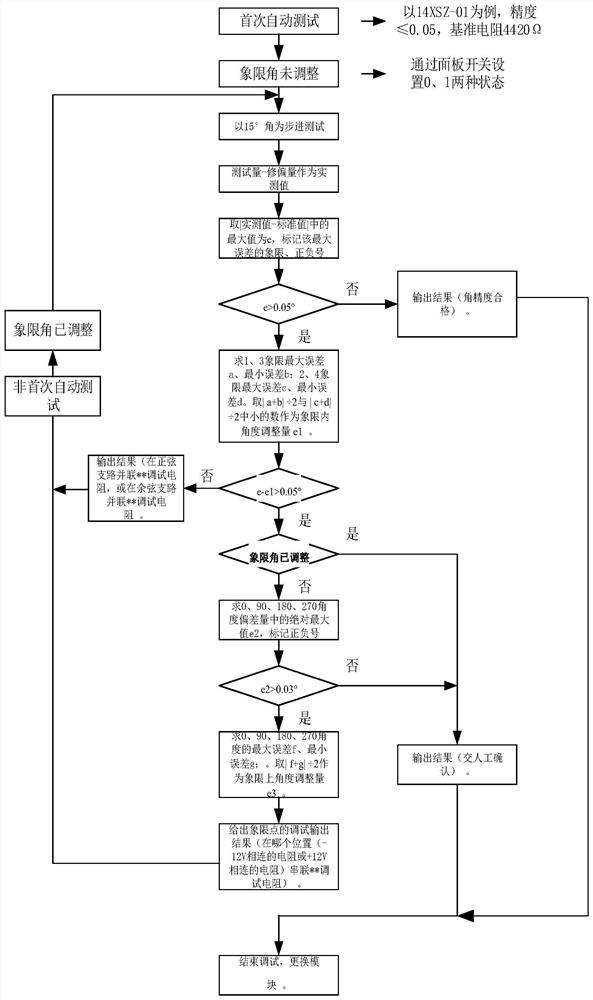

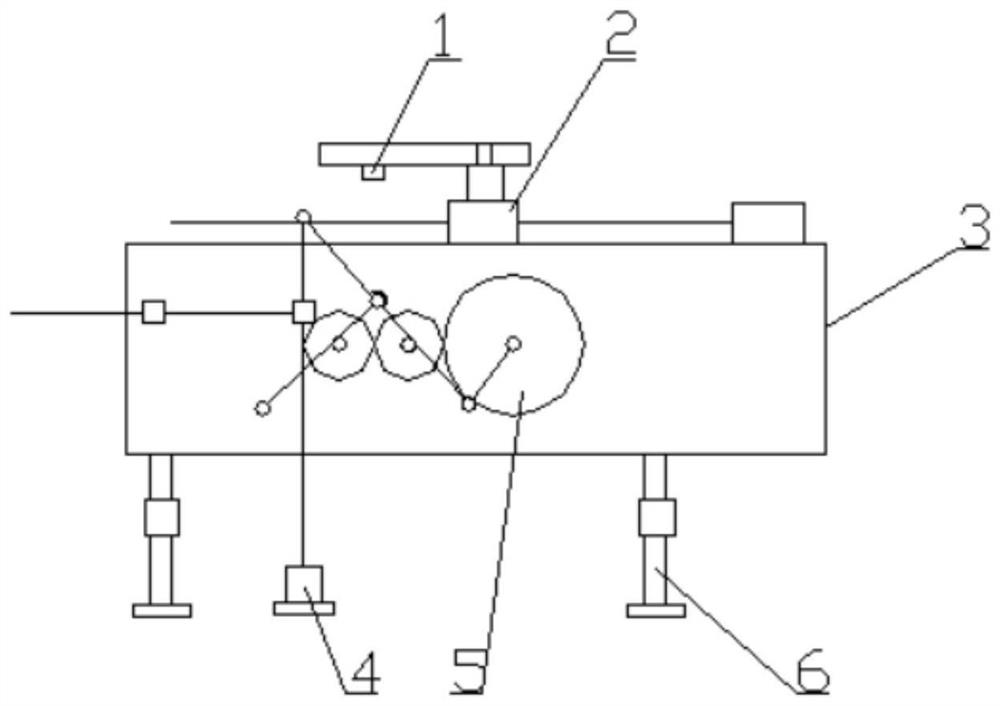

Automatic debugging platform and debugging method for angular precision of axial angle-digital converter

PendingCN113970679ARealize intelligenceAchieve efficiencyElectrical testingConvertersAutomatic control

The invention provides an automatic debugging platform and a debugging method for the angular accuracy of an axial angle-digital converter. The debugging platform comprises an angle simulator, an axial angle-digital converter test board, a power supply and an upper computer provided with automatic angular accuracy debugging software. According to the invention, automatic control of the output angle of a simulator, automatic collection of the output angle value of an axial angle-digital converter, calculation of the angle deviation value, and final display of the whole process of the debugging resistance value on the automatic debugging software can be realized. According to the invention, an angle simulator with independent property rights, a self-designed data acquisition board, and self-designed debugging software and debugging method are adopted, so that the debugging platform is completely independent. The test board is simple in structure, high in expandability, wide in application range of products to be debugged, easy to use and maintain, and capable of meeting the requirements of axial angle-digital converter batch production debugging environment construction and electronic conversion module military marking automation condition construction.

Owner:连云港杰瑞电子有限公司

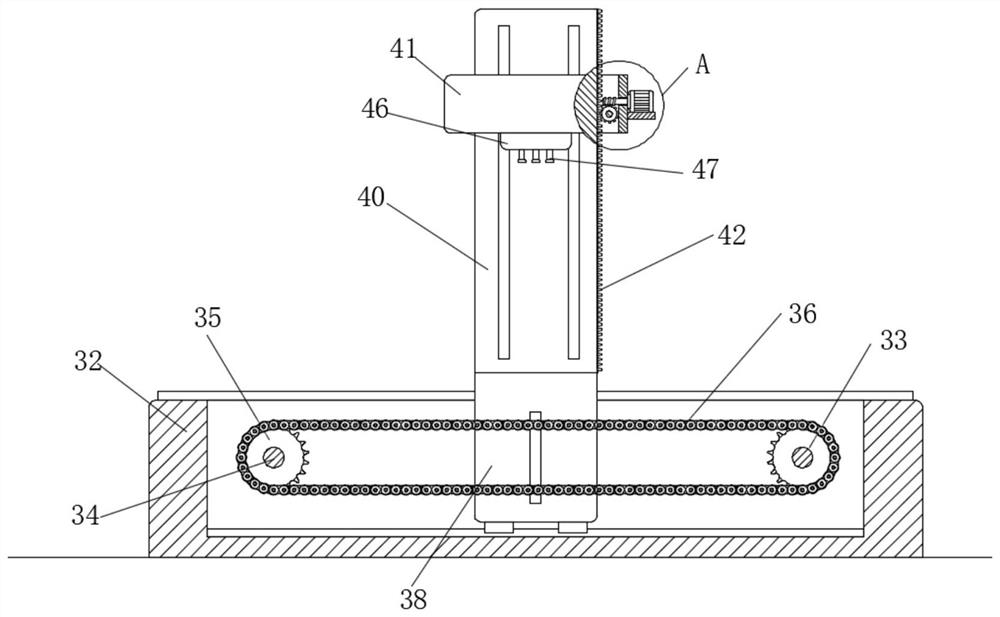

Building outer wall automatic crawling laser cleaning device

ActiveCN114016759AImprove accuracyAvoid angular deviationBuilding repairsEngineeringMechanical engineering

The invention provides a building outer wall automatic crawling laser cleaning device which comprises laser cleaning equipment, a moving device, a shell, a wall climbing device, a driving device and a wall suction device, and the laser cleaning equipment is installed at one end of the moving device and used for generating laser beams needed by cleaning; the moving device is installed on the upper portion of the shell, the wall climbing devices are installed on the two sides of the shell, and the driving device is installed in the shell and used for driving the wall climbing devices to move; a wall suction device is installed on the shell and used for being sucked to the wall face. The wall-climbing robot carrying the laser cleaning machine is used for conducting full-automatic cleaning on the building coating of the building outer wall, and therefore the function of cleaning the surface of the building outer wall is achieved.

Owner:JIANGSU UNIV

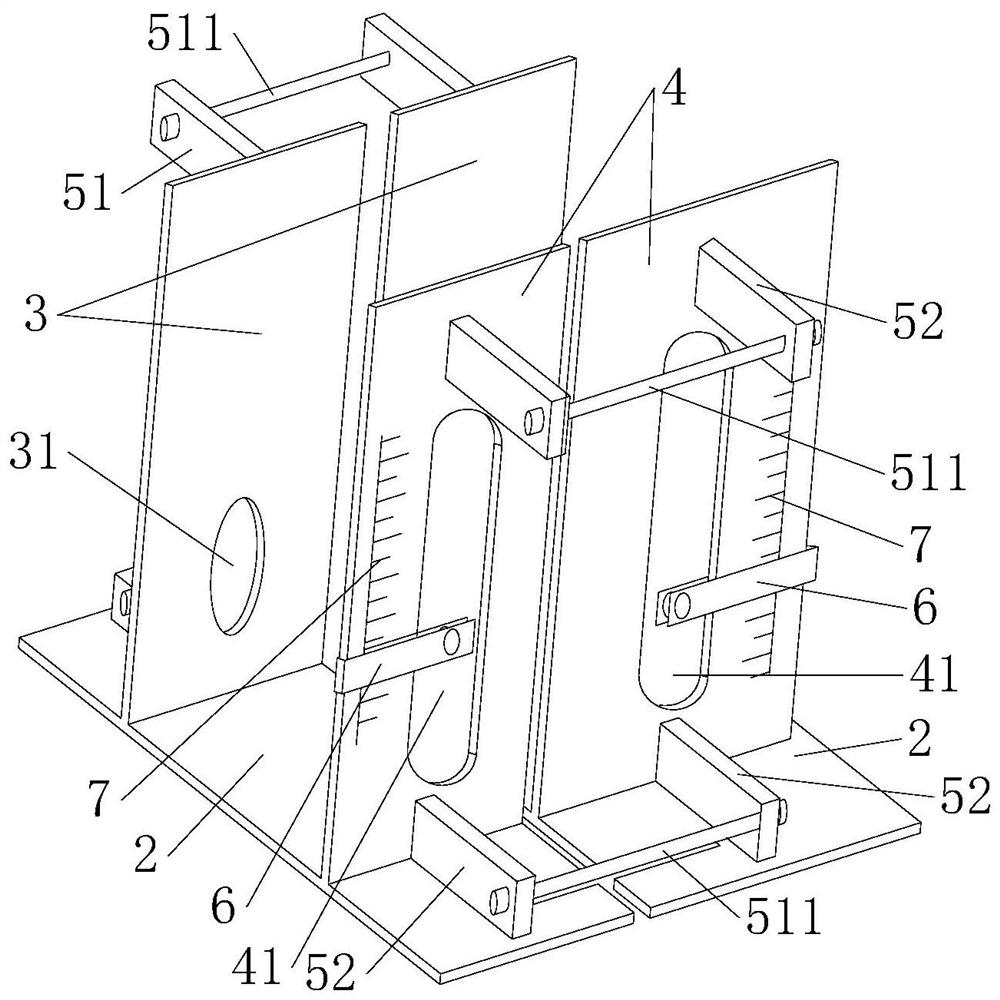

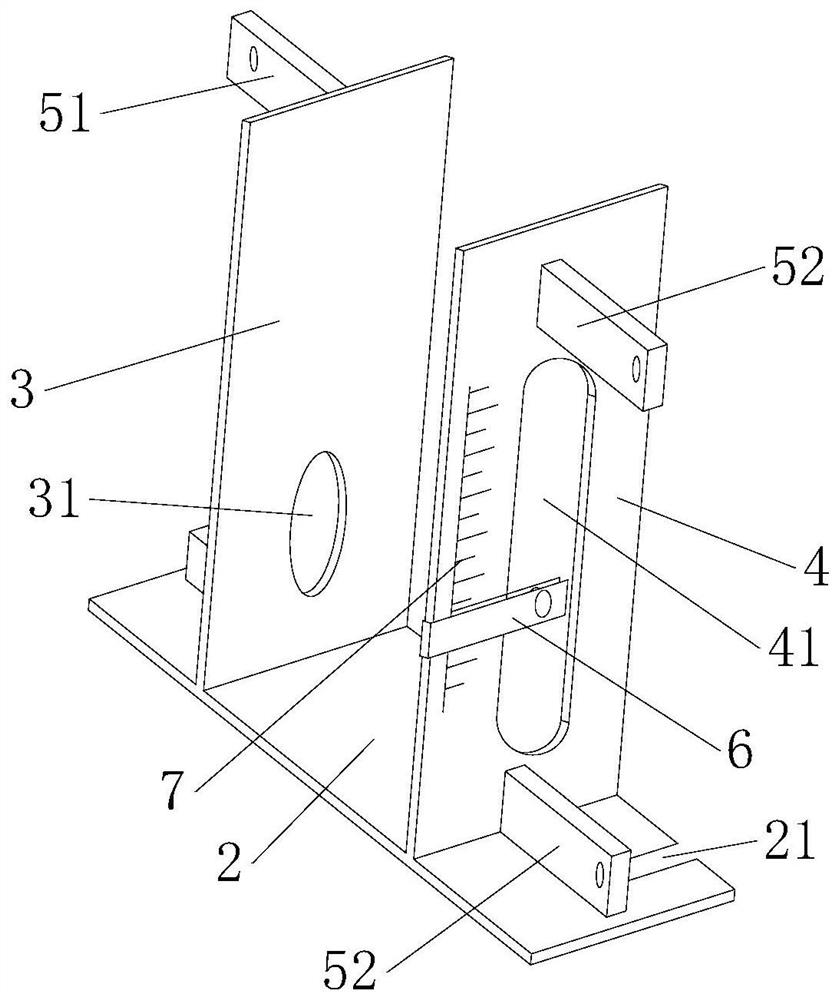

Orienting device for drilling of tunnel arch frame feet-lock bolt

PendingCN112360347AAvoid construction hazardsAvoid angular deviationSurveyDirectional drillingEngineeringRock bolt

The invention provides an orienting device for drilling of a tunnel arch frame feet-lock bolt. The orienting device comprises two orienting structures, wherein the two orienting structures are used for being oppositely arranged on the two sides of the foot part of an arch frame and are detachably connected to the arch frame, each orienting structure comprises a base, a first orienting plate and asecond orienting plate are arranged on each base, a first positioning hole is formed in each first orienting plate, a second positioning hole is formed in each second orienting plate, and the first positioning hole and the second positioning hole of the same orienting structure are used for allowing a drill rod to penetrate through and adjusting the angle of the drill rod. The drilling direction of the drill rod can be adjusted and controlled through the first positioning holes and the second positioning holes, then the direction of the feet-lock bolt is controlled, angle deviation existing inconstruction of the feet-lock bolt is avoided, the construction quality of the feet-lock bolt is guaranteed, then the supporting capacity of the feet-lock bolt is guaranteed, and tunnel constructiondangers are avoided. Meanwhile, the orienting device is detachably connected to the arch frame, can be repeatedly used and is convenient to construct.

Owner:中铁二十三局集团第四工程有限公司

Movable optical adjusting rack with lens ring adjusting function

The invention discloses a movable optical adjusting rack with a lens ring adjusting function. The movable optical adjusting rack comprises a fixing lens bracket, a movable plate and a fixing base. A lens ring is fixed in the middle of the fixing lens bracket and comprises an angle rotating shaft and a transmission rod, an optical lens is fixed in the middle of the lens ring, the movable plate is installed below the fixing lens bracket, and the fixing base is installed below the movable plate. Fixing holes are formed in the two ends in the fixing base, horizontal adjusting screws are fixed in the fixing holes, the upper ends of the horizontal adjusting screws are connected with the movable plate, and horizontal adjusting knobs are fixed to the lower ends of the horizontal adjusting screws. A case is fixed to the lower end of the middle of the fixing base, a wireless signal receiving and transmitting device is fixed in the case, and a storage battery is installed on one side of the wireless signal receiving and transmitting device. According to the movable optical adjusting rack, a movable lens ring adjusting mode is adopted, the angle of the optical lens can be adjusted through the angle rotating shaft and the transmission rod in the lens ring, and the movable optical adjusting rack is easy to use and convenient to control.

Owner:无锡信欧光电科技有限公司

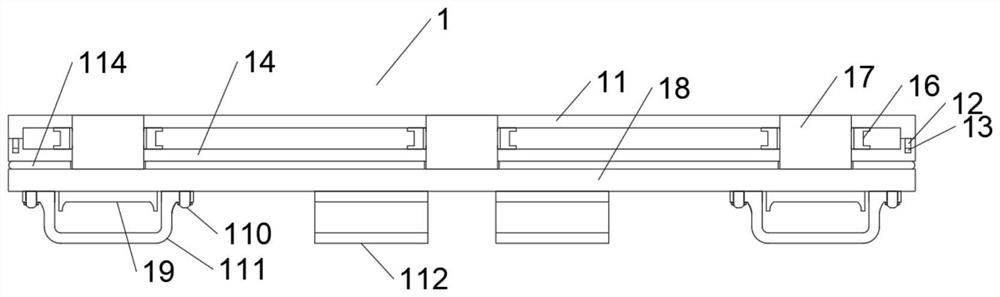

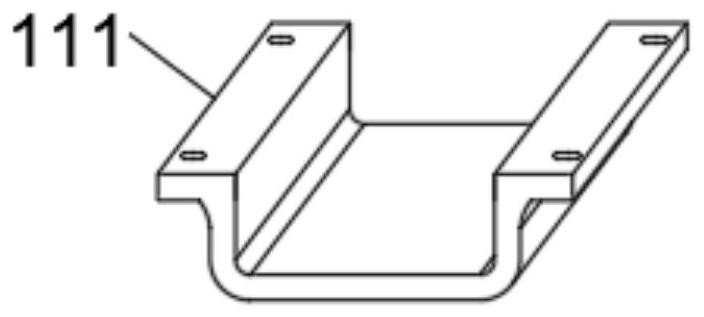

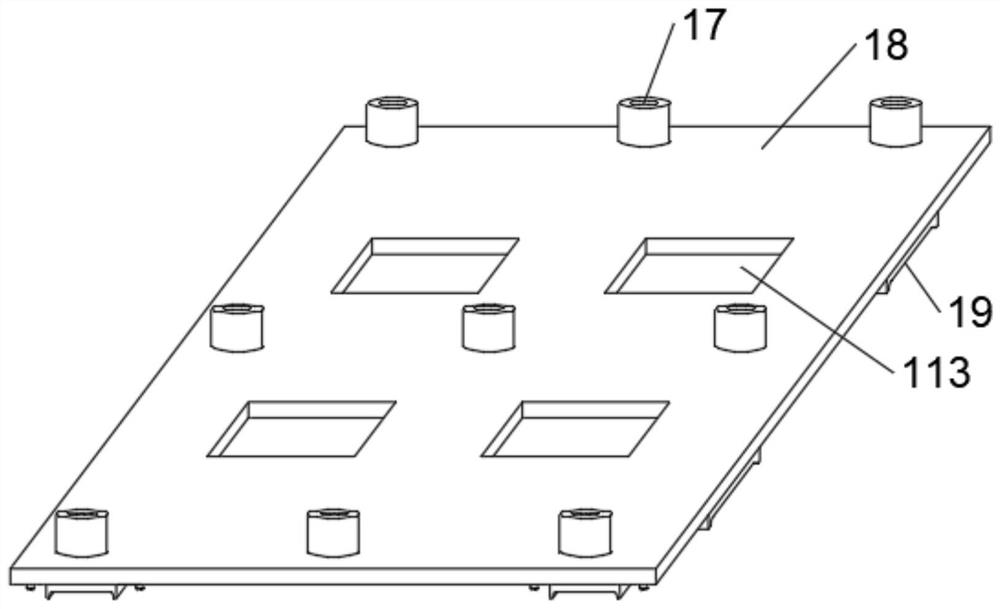

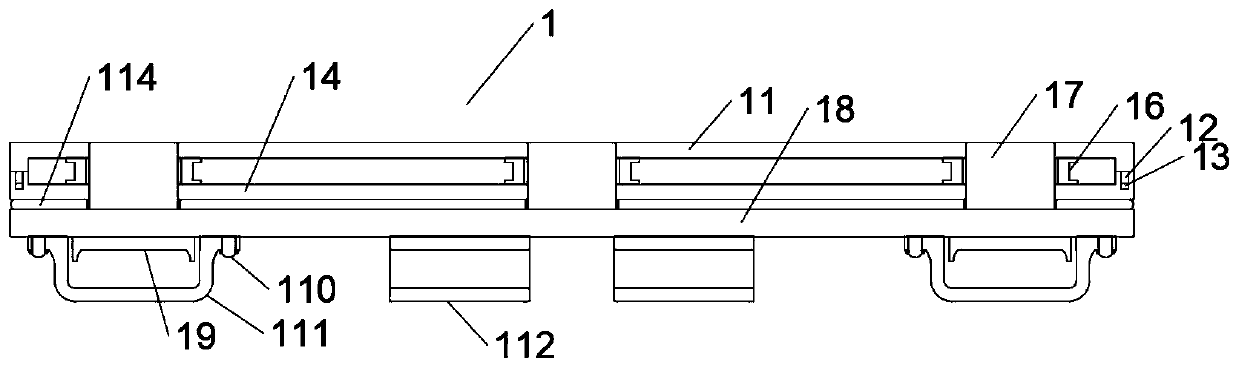

A transfer shelf for storage

ActiveCN111439508BPrevent disengagementReduce lossStorage devicesStructural engineeringUltimate tensile strength

The invention discloses a transfer shelf for storage and its processing equipment. The transfer shelf for storage includes a shelf body, the shelf body includes a storage board, a middle lining board and a metal plate, and the four sides of one side of the storage board are A number of pins are vertically provided on the sides. The shelf body designed by the present invention is mainly composed of a storage board, a middle lining board and a metal plate. They can be separated from each other, and when one of the above-mentioned three is damaged, the user can replace them separately, which reduces the waste of materials and makes the present invention more environmentally friendly in use, and the metal plate designed in the present invention greatly increases the cost The structural strength of the bottom of the invention, this design makes the invention not prone to defects such as breakage, and will not easily be damaged or dented when a forklift comes into contact with it, greatly prolonging the service life of the invention.

Owner:南京立为正仓储设备有限公司

Preparation of piezoelectric quartz unseeded acoustic surface wafer

InactiveCN101372758AEliminate Angle DeviationImprove the qualified rate of finished productsFrom normal temperature solutionsWire cuttingSurface wave

The invention provides a method for preparing a seed-crystal-free acoustic surface wafer of piezoelectric quartz, which belongs to a method for preparing the material for an acoustic surface wave device, and aims at solving the problems of long production period, low yield, low utilization rate of materials and high cost existing in the prior preparation method at home and abroad. The method comprises the following steps: seed crystal is placed in a high-pressure autoclave to culture crystal by hydrothermal temperature difference method; then, the crystal is cut into crystal wafers, wherein, the seed crystal is a seed crystal wafer in acoustic surface wave propagating angle with the dimension being 2 to 6 inches; sodium hydroxide aqueous alkali and sodium carbonate aqueous alkali are filled in the high-pressure autoclave, the seed crystal is placed on the upper part of the high-pressure autoclave, while raw materials for dissolving is arranged on the lower part of the high-pressure autoclave; the two kinds of solution convectively move upwards, so that the crystal is crystallized along the acoustic surface wave propagating angle to grow a crystal block according to the specification; according to the thicknesses of acoustic surface wafers required by different categories, cutting processing is carried out on the crystal block by wire cutting according to different thicknesses by taking a seed basal lamina as the standard of cutting angle, so as to obtain the seed-crystal-free acoustic surface wafer with the different thicknesses in the acoustic surface wave propagating angle.

Owner:SICHUAN SANTAI CRYSTAL ELECTRONICS

Transfer goods shelf for warehousing and processing equipment thereof

ActiveCN111439508APrevent disengagementReduce lossStorage devicesStructural engineeringUltimate tensile strength

The invention discloses a transfer goods shelf for storage and machining equipment thereof. The transferring goods shelf for storage comprises a goods shelf body. The goods shelf body comprises a storage plate, a middle lining plate and a metal plate. A plurality of insertion feet are vertically arranged at four side edges of one side surface of the storage plate; and the goods shelf body designedby the invention is mainly composed of the storage plate, the middle lining plate and the metal plate. The three parts are combined in an inserting manner; the stable connection is ensured; mutual separation can be realized; when one of the three parts is damaged, a user can carry out independent replacement, material waste is reduced, and therefore, the device is more environment-friendly in use; and the metal plate designed by the invention greatly enhances the structural strength of the bottom, due to the design, defects like breakage are not prone to appearing, and when a forklift truck makes contact with the shelf, conditions of damage or sinking are not prone to appearing, so that the service life of the transfer goods shelf is greatly prolonged.

Owner:南京立为正仓储设备有限公司

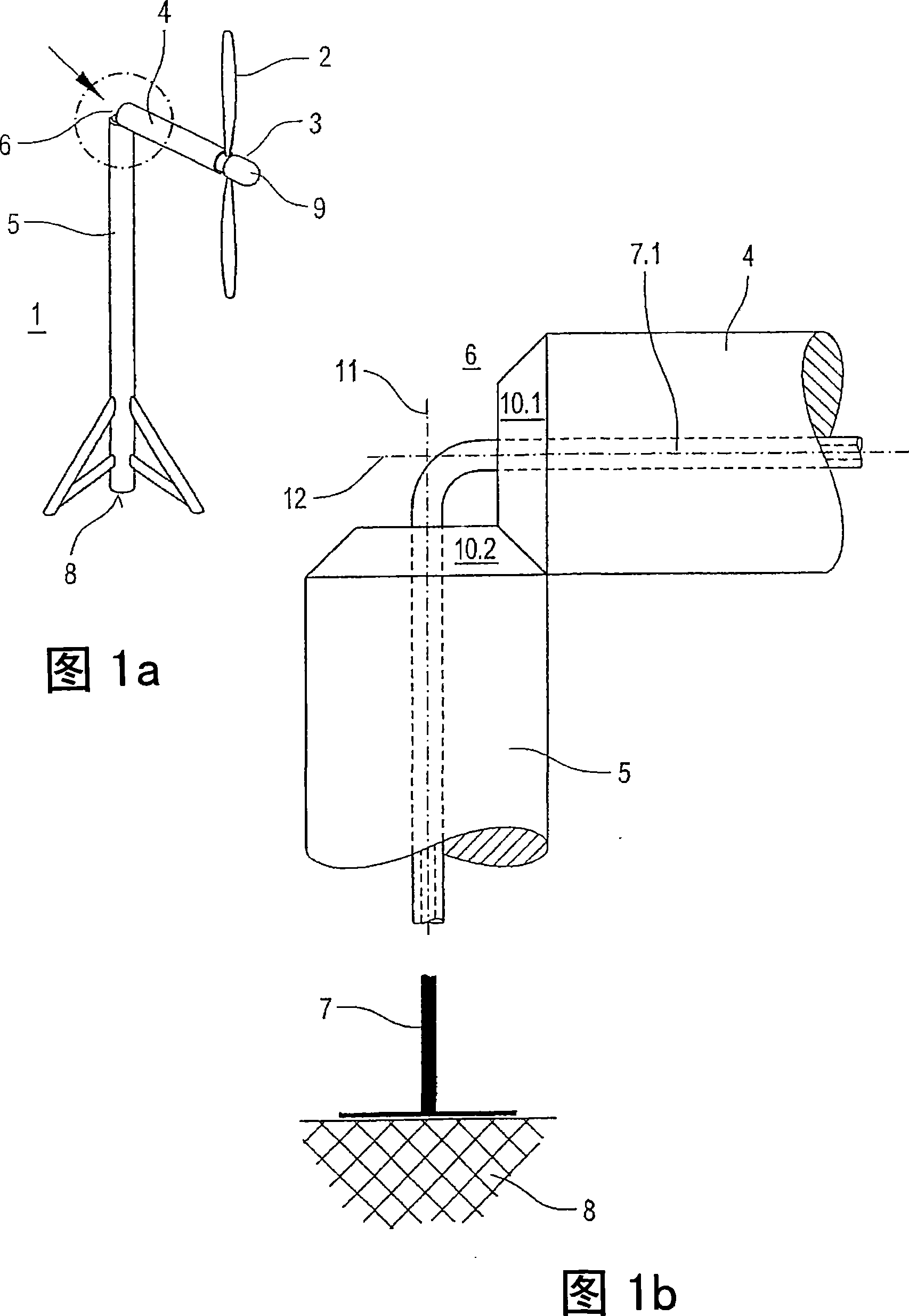

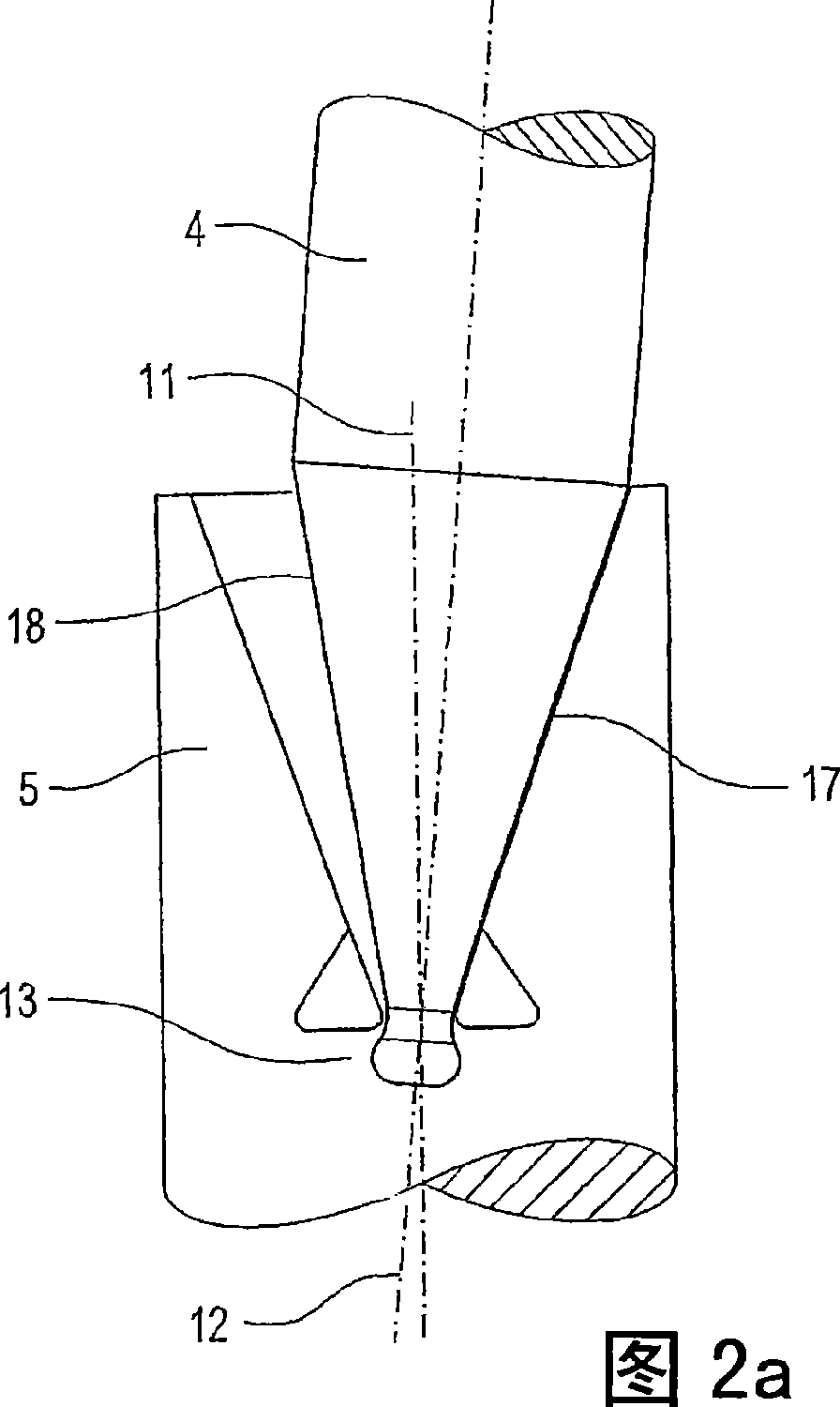

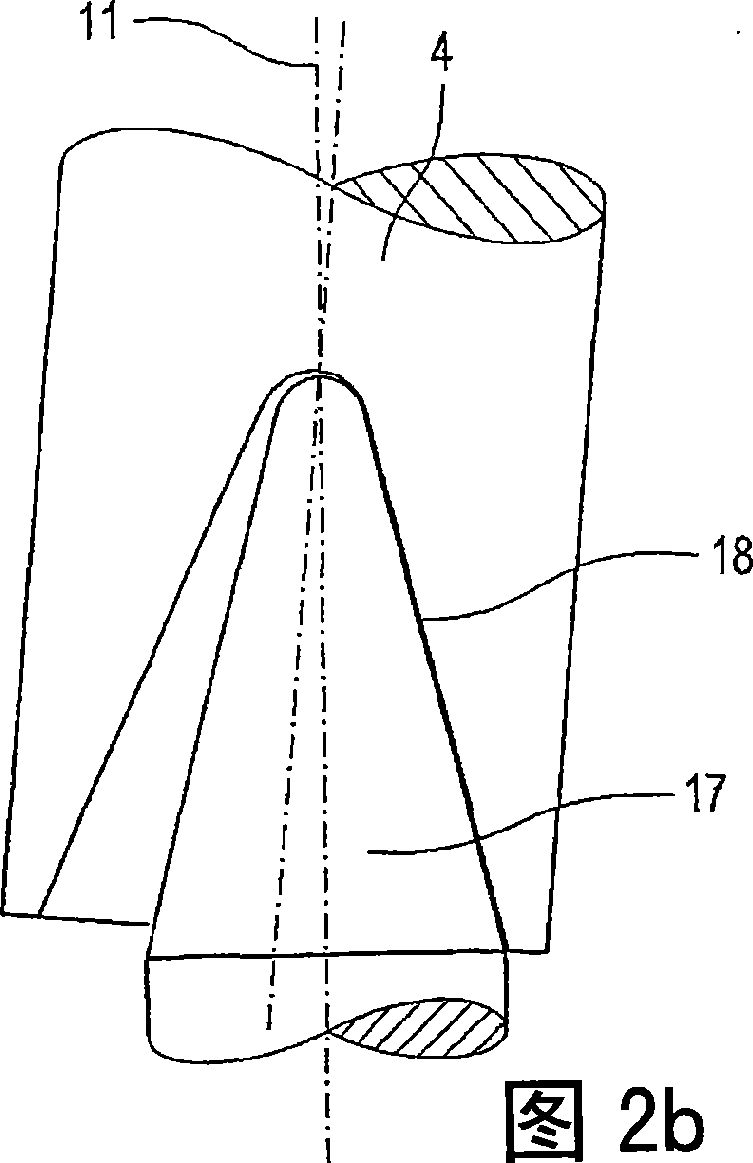

Rotatable power generating plant for producing electric power from water flow

The invention relates to a rotatable generation unit for generating electric energy from a water flow, comprising: a water turbine; an electric generator, driven by the water turbine; a carrier body, wherein a first axis is provided; a nacelle body, with which a second axis, which is angled toward the first axis, is provided and which is moveable relative to the carrier body; a connecting cable, extending from the electric generator through the nacelle body to the carrier body; a hinge connection device between the carrier body and the nacelle body ,possessing a device which transmits a rotational movement of the nacelle body about the first axis into a rotational movement of the nacelle body about the second axis assigned therewith, so that the twisting of the connecting cable is limited.

Owner:VOITH PATENT GMBH

Polyethylene film intelligent winding machine and polyethylene film production method

The invention discloses a polyethylene film intelligent winding machine and a polyethylene film production method. The polyethylene film intelligent winding machine comprises a bottom plate, wherein the upper end face of the bottom plate is connected with side plates through supporting legs, the side plates are made of stainless steel of a quasi-rectangular structure, the surface of each side plate is provided with a feeding motor, one end face of each feeding motor is in transmission connection with a feeding shaft, the portion, located below the front portion of the corresponding feeding motor, of the surface of each side plate is provided with a pressing motor, and a pressing roller is installed between the two pressing motors through bearings. According to the polyethylene film intelligent winding machine, by arranging deviation correcting devices, the position of film is monitored in real time, the problem that an existing device cannot sensitively sense the deviation of the film is solved, the coping capacity of the device to the deviation of the film is improved, and a stable deviation correcting effect is achieved; and by arranging rotating rings, a foundation is laid for overall matching work of the device, and the use experience is improved.

Owner:上海佰鑫新材料科技有限公司

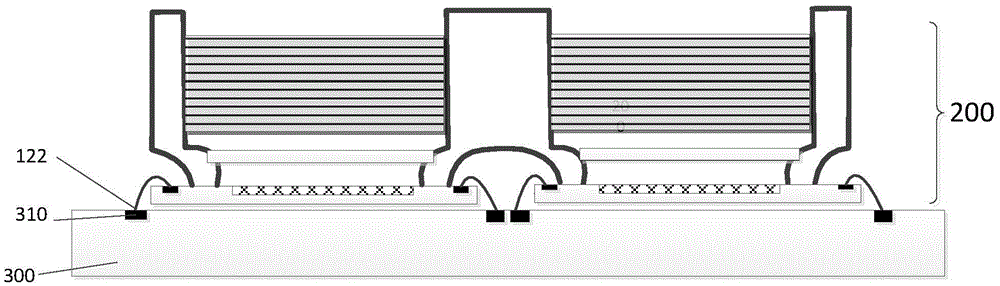

Method for forming multi-image sensor module

ActiveCN106856200BImaging performance degradationAvoid misalignmentSolid-state devicesRadiation controlled devicesMulti-imageWafer

The present invention provides a method for forming a multi-image sensor module, which is characterized in that the method includes: providing a wafer containing several image sensors; cutting the wafer to form: an integrated multi-image sensor; Reserving the dicing lane area respectively; assembling the integrated multi-image sensor to form a multi-image sensor module.

Owner:GALAXYCORE SHANGHAI

A lock mechanism for controlling action sequence and a vehicle-mounted tablet computer holder including the lock mechanism for controlling action sequence

InactiveCN103557416BControl motion sequenceOvercome the Risk of MisoperationStands/trestlesVehicle componentsMedial axisLocking mechanism

The invention provides a lock mechanism for controlling action sequences and a vehicle-mounted tablet personal computer support frame comprising the lock mechanism for controlling action sequences. The lock mechanism comprises a base, a lifting table, fish head wheels, a spring bolt, a top rod and a middle shaft, wherein the base is provided with a first-stage guide rail in vertical extending, the lifting table can move along the first-stage guide rail, the fish head wheels are symmetrically arranged on the lifting table at the left side and the right side, and the middle shaft is arranged in the center position of the lifting table and is matched with the fish head wheels. The lock mechanism has the advantages that the action sequences can be effectively controlled, the defect of risk of misoperation of mechanical parts is overcome, meanwhile, the structure is simple, the operation force is small, the noise is low, and the service life is long. The vehicle-mounted tablet personal computer support frame has the advantages that the integral operation is convenient, through the coil spring assistance, damping and friction hinge mechanisms are matched, the operation comfort is realized, the actions are smooth and coherent, the opening and the closing can be respectively completed within five seconds, a tablet personal computer can be in the most comfortable use position and angle, after the use completion, the tablet personal computer can be hidden into an interior trimming surface along with a support frame, and the appearance of the interior trimming is not influenced.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

An assembly device for processing an automobile fuel tank switch

ActiveCN111230480BEasy to get stuck inAdditional Actions Required to Lower RotationAssembly machinesFuel tankEngineering

The invention discloses an assembling device for machining a fuel tank switch. The assembling device comprises a conveying belt, a seal ring placing device, a handle placing device, a gasket placing device and a fixing device. The seal ring placing device comprises a feeding cylinder for putting a seal ring into a workpiece, a supplementing chamber for putting the seal ring into the feeding cylinder, a storing hopper arranged on the supplementing chamber, a screening part arranged on the feeding cylinder, and a discharging part. By arranging the seal ring placing device, the seal ring can be installed into the workpiece, the handle placing device is used for putting a handle onto the seal ring in the workpiece, the gasket placing device is used for installing a leaf spring on the handle, the fixing device is used for fixing a pressing piece and the handle placed on the handle, a pressing piece can rise or fall, a first spring can contract through a pressing plate and a pressing rod, the bottom end of an inner rod body is inserted into two holes in the workpiece, the seal ring is more accurately placed into the workpiece, and use is more convenient.

Owner:绍兴市上虞区敏敏汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com