Automatic assembly system and assembly process for electric power instrument production

A power meter and assembly system technology, applied in the field of automatic assembly system and assembly process for power meter production, can solve the problems of easy deflection of the meter, affecting the assembly accuracy of the power meter, affecting the assembly accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

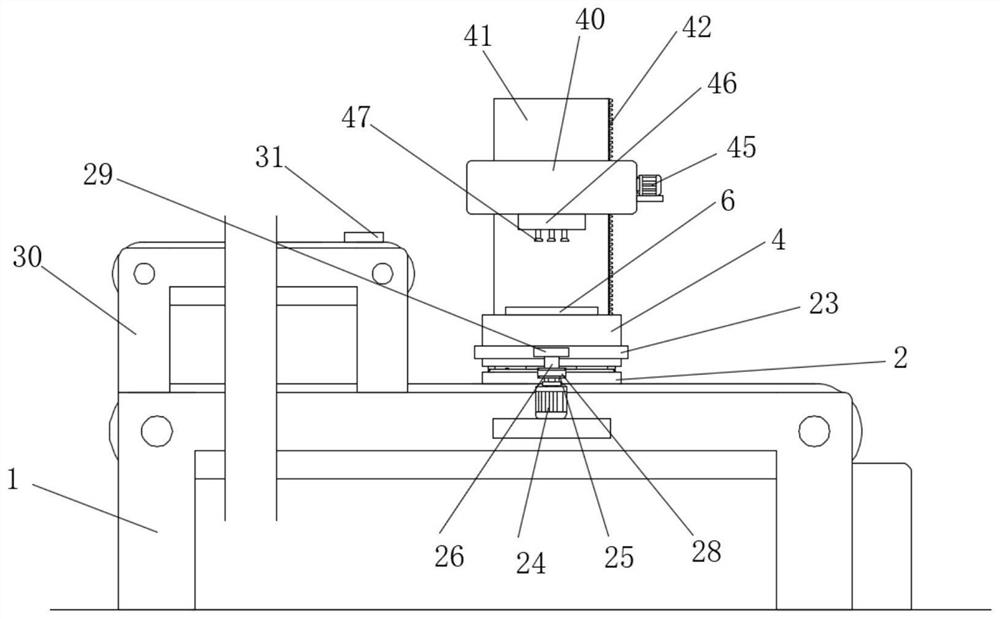

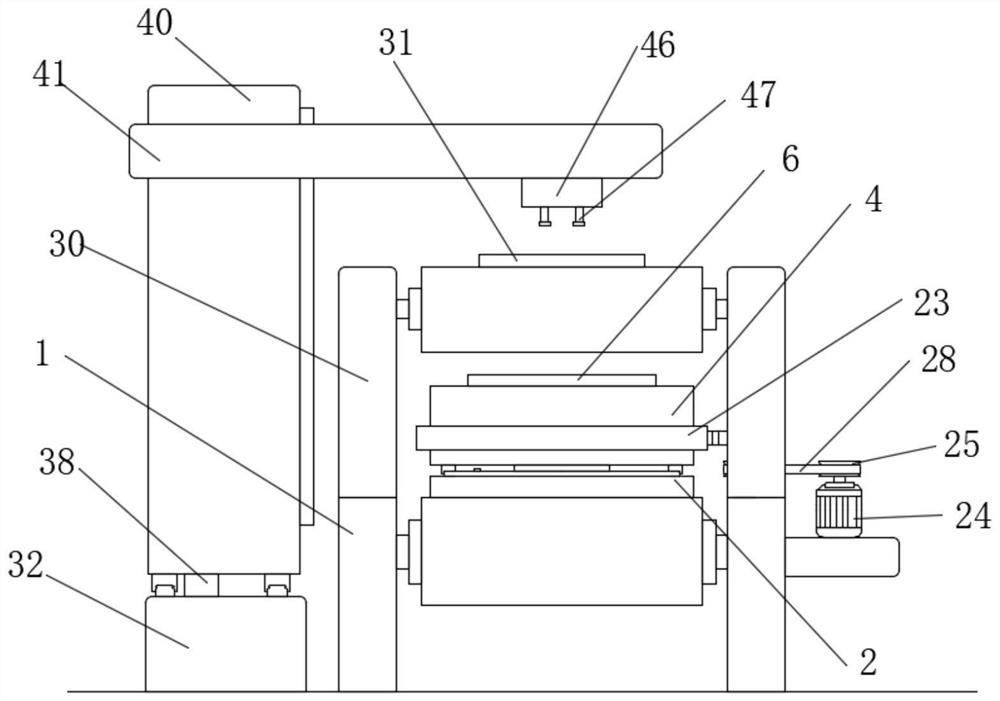

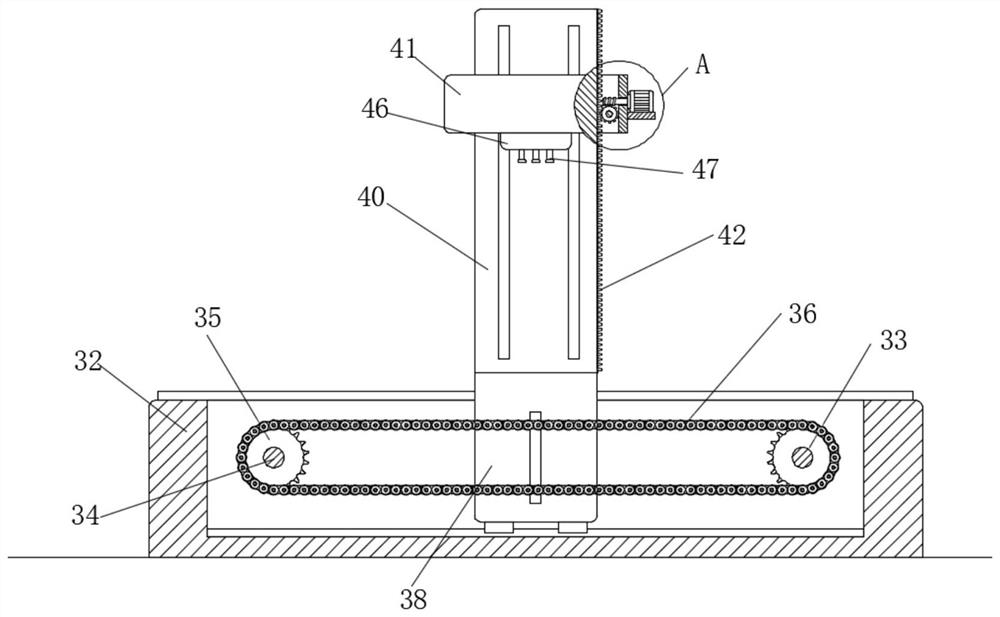

[0046] refer to Figure 1-13 , an automatic assembly system for electric meter production, comprising a first conveyor belt 1, the top of the first conveyor belt 1 is fixedly connected with a bottom plate 2, the top of the bottom plate 2 is rotatably connected with a rotating shaft 3, and the top of the rotating shaft 3 is fixedly connected with a Clamping platform 4, the bottom of clamping platform 4 is slidingly connected with the top of base plate 2, and the inner wall of both sides of clamping platform 4 is fixedly connected with placing plate 5, and instrument 6 is placed on the top of placing plate 5, and the internal setting of clamping platform 4 There is a clamping assembly for clamping the instrument 6, the top of the bottom plate 2 is provided with a brake assembly for braking the rotating shaft 3 and the clamping platform 4, and the outer wall of the clamping platform 4 is fixed with an external gear ring 23, The top side of the first conveyor belt 1 is provided wi...

Embodiment 2

[0059] Embodiment two: if Figure 14 As shown in -15, an automatic assembly system for electric meter production, the difference between this embodiment and Embodiment 1 is that the top of the beam 41 is slidably connected with a knocking rod 48, and the bottom end of the knocking rod 48 runs through the connecting platform 46 and is connected with The table 46 is slidingly connected, and the outer wall of the knocking bar 48 is covered with a spring 49. The bottom end of the spring 49 is fixedly connected to the top of the cross beam 41, and the top end of the spring 49 is fixedly connected to the outer wall of the knocking bar 48. One side of the cross beam 41 is fixedly connected with The second driving motor 50 , the output shaft of the second driving motor 50 is fixedly connected with a rotating disk 51 , and the side of the rotating disk 51 away from the second driving motor 50 is fixedly connected with a protrusion 52 .

[0060] In the present invention, the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com