Morgan roller box assembling platform

An assembly platform and Morgan roller box technology, applied in the direction of assembly machines, workbenches, metal processing equipment, etc., can solve the problems of operator injury, time-consuming and labor-intensive, low efficiency, etc., to avoid injury, prevent displacement, and avoid assembly The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

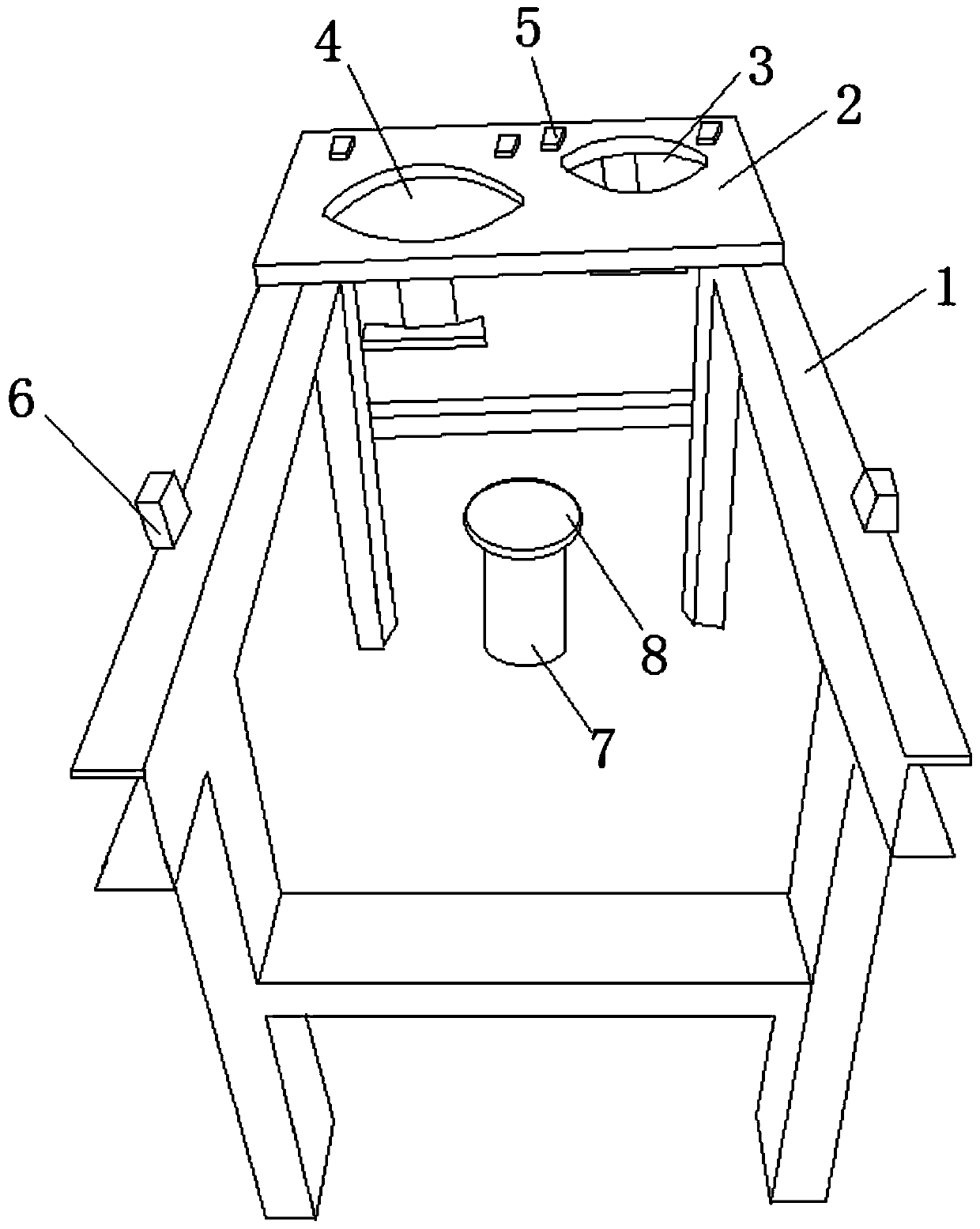

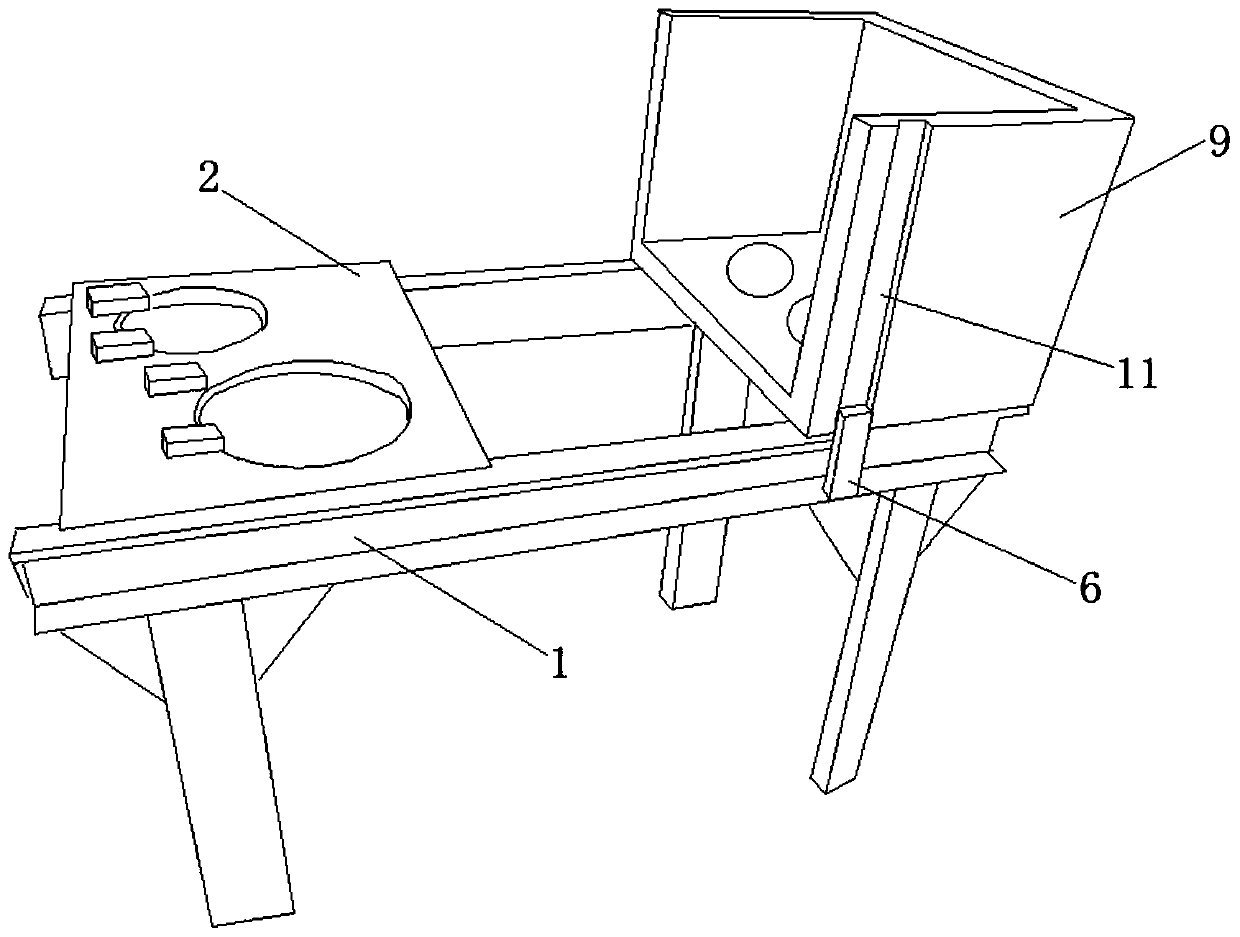

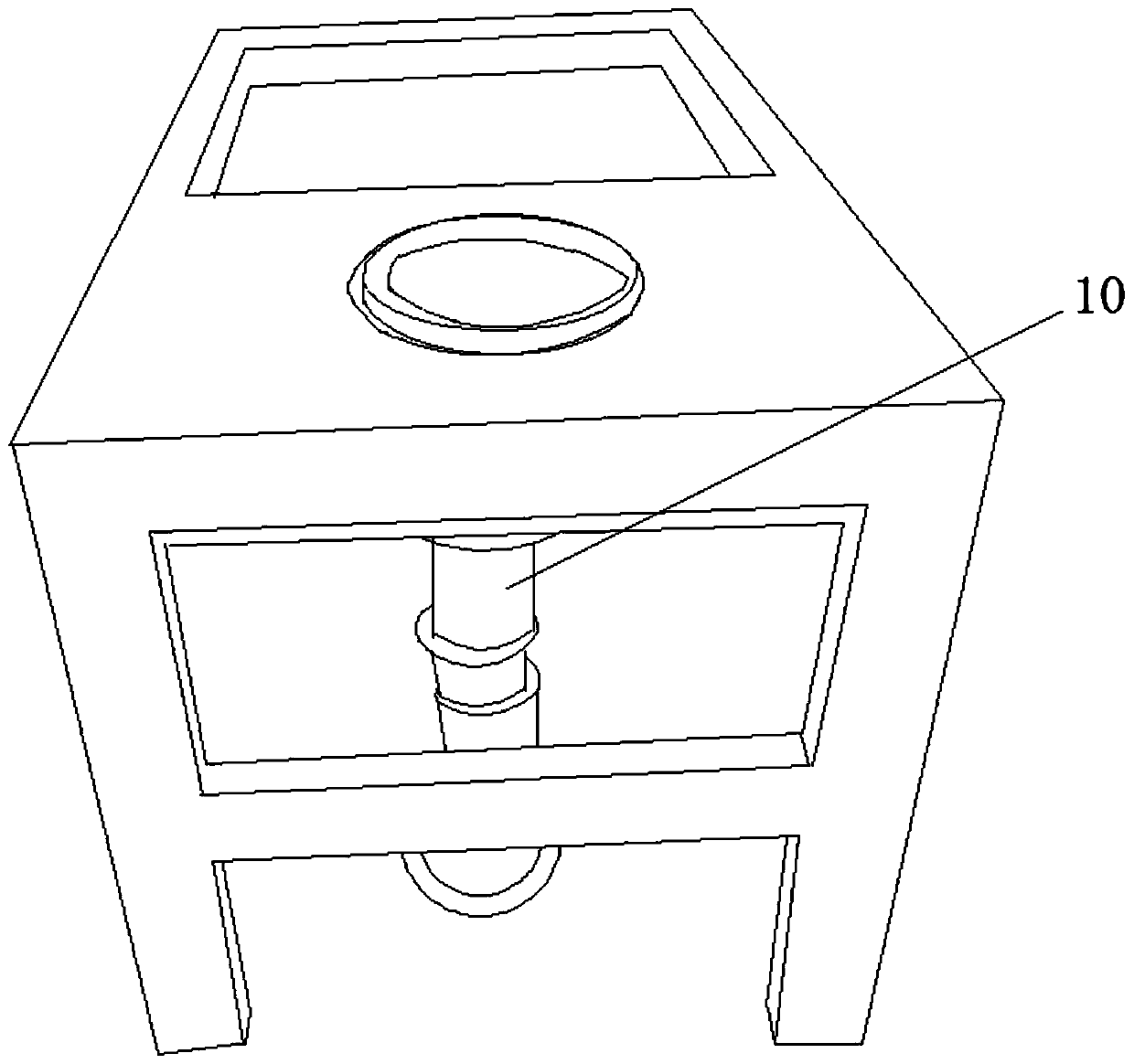

[0015] see Figure 1 to Figure 3 , the present invention relates to a Morgan roller box assembly platform, which includes a bracket 1, a bottom plate 2 is erected on the front end of the bracket 1, and a first through hole 3 and a second through hole 4 are opened on the bottom plate 2. A through hole 3 and a second through hole 4 are used to place an eccentric sleeve equipped with an oil film bearing. The diameters of the first through hole 3 and the second through hole 4 are different, which can be adapted to different types of eccentric sleeves; There is a movable support column 7, and a movable gasket 8 is arranged on the support column 7, and the gasket 8 is used to raise the roll shaft 10 when the roll shaft 10 is installed in the eccentric sleeve; the first through hole 3 and the Both sides of the front end of the second through hole 4 are provided with stoppers 5; both sides of the left and right sides of the rear end of the support 1 are provided with baffle plates 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com