Automatic hand buckle buckling and pressing equipment

An automatic buckle and hand buckle technology, which is applied to conveyor objects, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of time-consuming and labor-intensive, human resources increasing the production cost of enterprises, and low production efficiency of woven bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

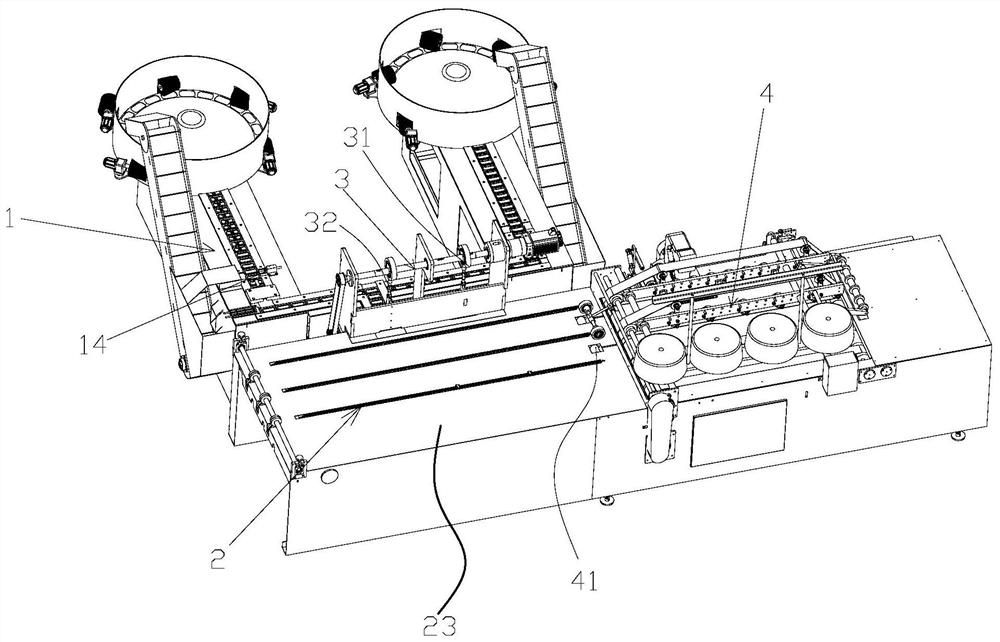

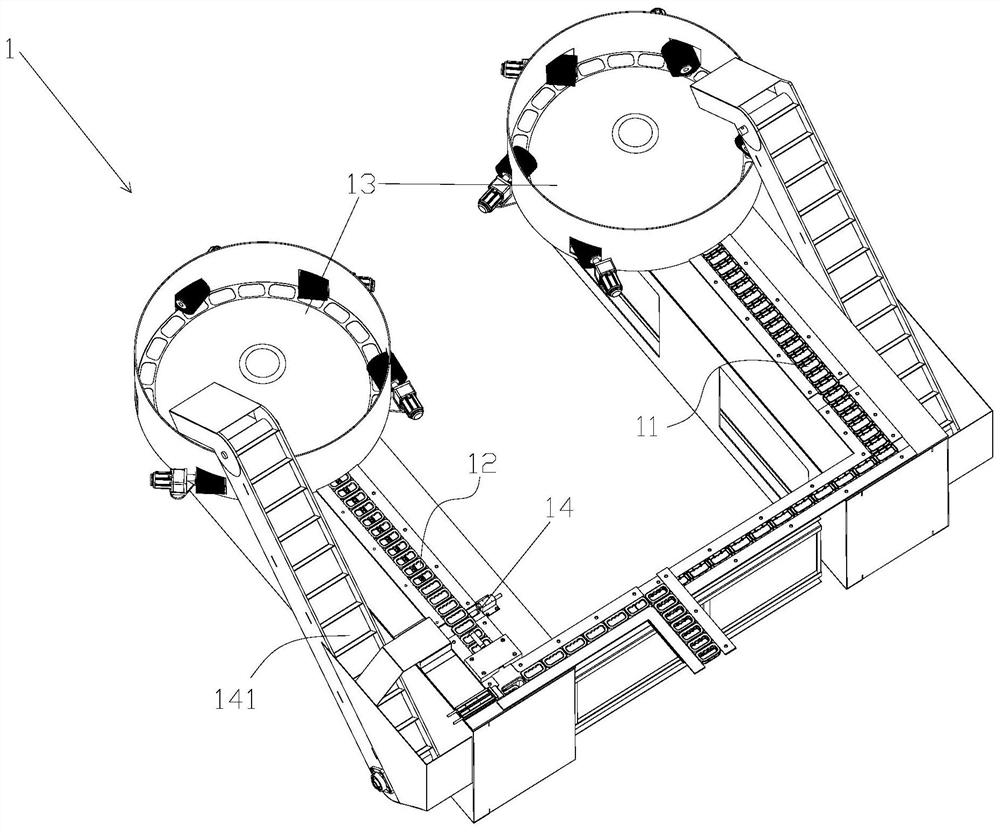

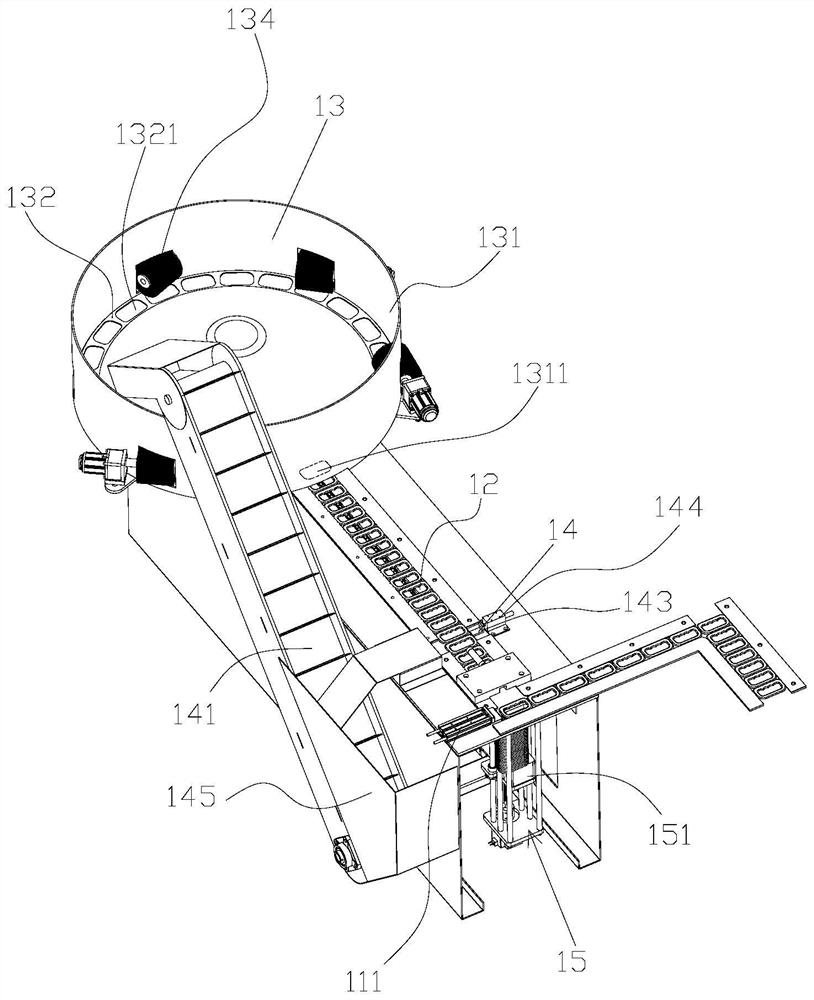

[0033] Specific embodiments of the present invention such as Figure 1-8 As shown, a portable buckle automatic crimping device includes a frame, and the frame is provided with a portable button feeding device 1, a woven bag feeding device 2 and a stamping device 3, and the punching device 3 is arranged along the The feeding direction of the woven bag is successively provided with a punching station 31 for punching holes in the woven bag and a crimping station 32 for crimping the female button and the sub-button. The portable button feeding device 1 corresponds to the crimping station 32 on the woven bag The end face and the lower end face are respectively provided with a female button feeding track 11 and a sub-button feeding track 12, and the female button feeding track 11 and the sub-button feeding track 12 are provided with a cylinder for driving the button material (comprising the female button and the sub-button) to slide. Under the push of the cylinder, the button materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com