An adjustable dynamic tracking bottle divider

A dynamic tracking and adjustable technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems affecting the normal transportation of the conveyor chain, bottle label damage, bottle congestion, etc., to achieve simple structure, strong applicability, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

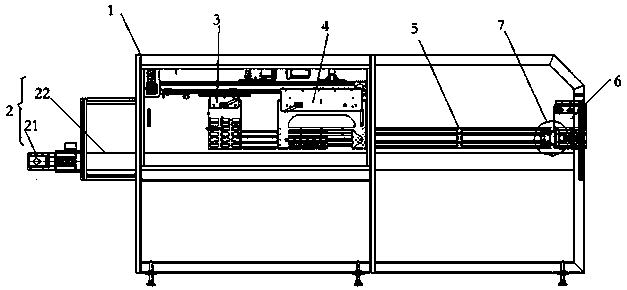

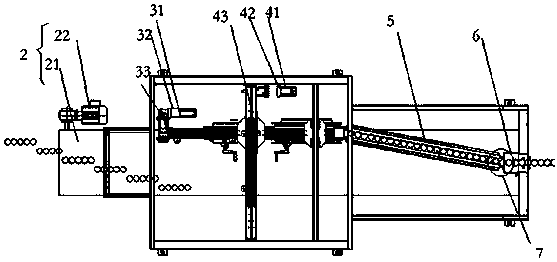

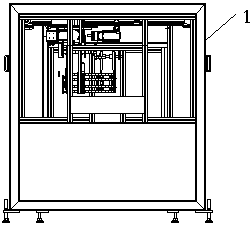

[0028] Such as Figure 1-7 The shown adjustable dynamic tracking bottle divider includes a frame 1, and the frame 1 includes a conveying device 2, a front and rear moving guardrail 3, a front and rear driving unit, a left and right moving guardrail 4 and a left and right driving unit, a swinging guardrail 5, Entrance width adjustment mechanism 6 and controller, described conveying device 2 comprises chain net conveyor belt 21 and conveying motor 22, and described controller controls conveying motor 22 operation, and described conveying motor 22 is provided with encoder, and described encoder The signal output terminal is electrically connected to the controller, the front and rear moving guardrail 3 is set on the left side of the left and right moving guardrail 4, the swinging guardrail 5 is set on the right side of the left and right moving guardrail 4, and the swinging guardrail 5 and the inlet width adjustment mechanism 6 pass through the rotary joint 7 connect.

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com