Automatic debugging platform and debugging method for angular precision of axial angle-digital converter

A digital converter and automatic debugging technology, which is applied in the direction of instruments, measuring devices, and measuring electronics, can solve the problems of incomplete test points, low debugging efficiency, and low intelligence, and achieve accurate indication of the installation position of debugging resistors and avoid Repeated debugging operations, the effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

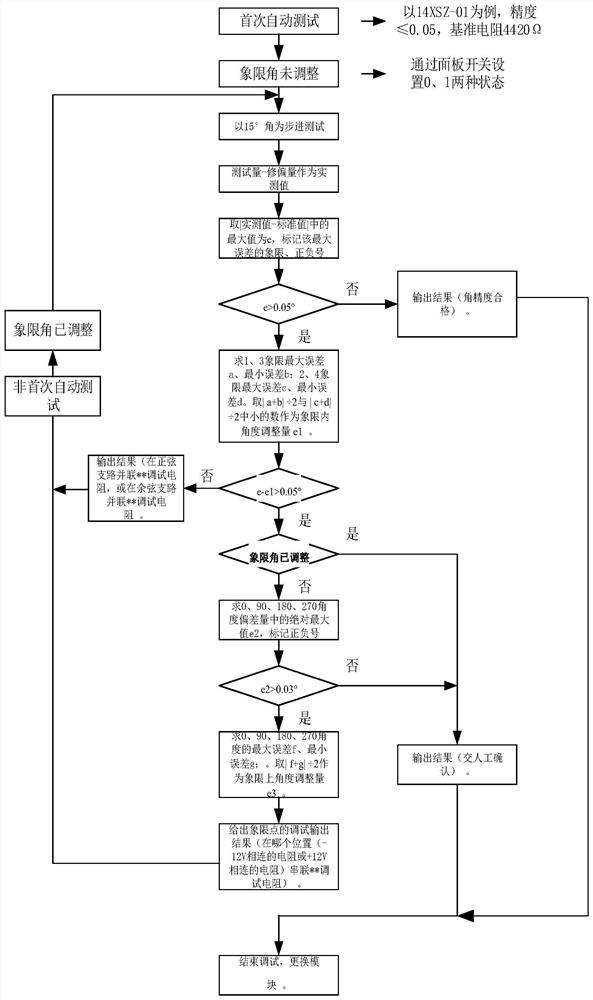

[0024] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

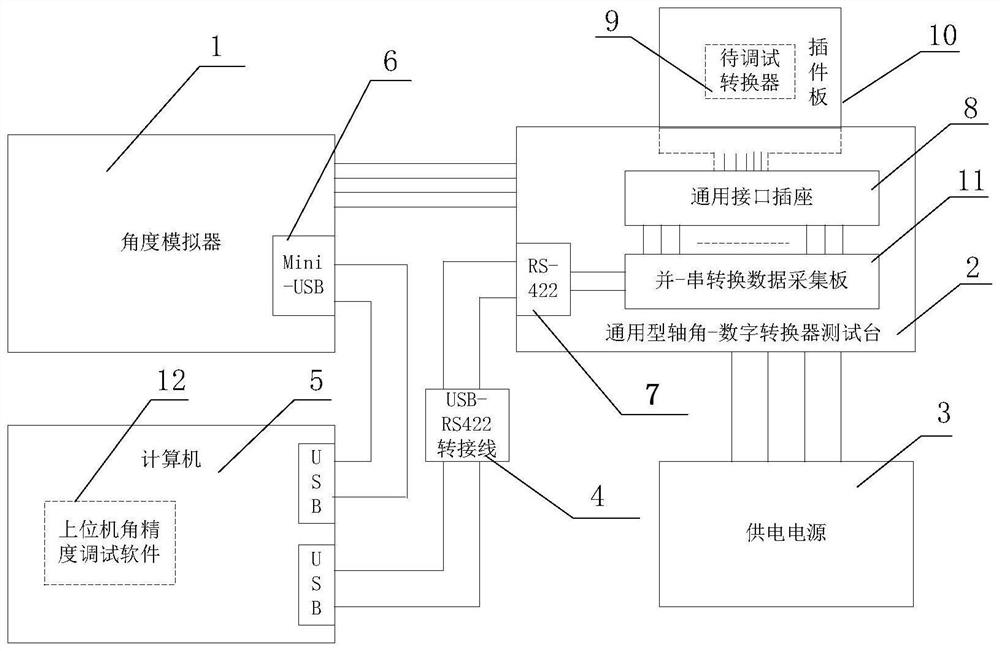

[0025] In one embodiment, a shaft angle-to-digital converter angular accuracy automatic debugging platform is provided, the automatic tuning platform includes a synchro / resolver angle simulator, a shaft angle-to-digital converter test bench, a power supply, And the upper computer with angular precision automatic debugging software installed;

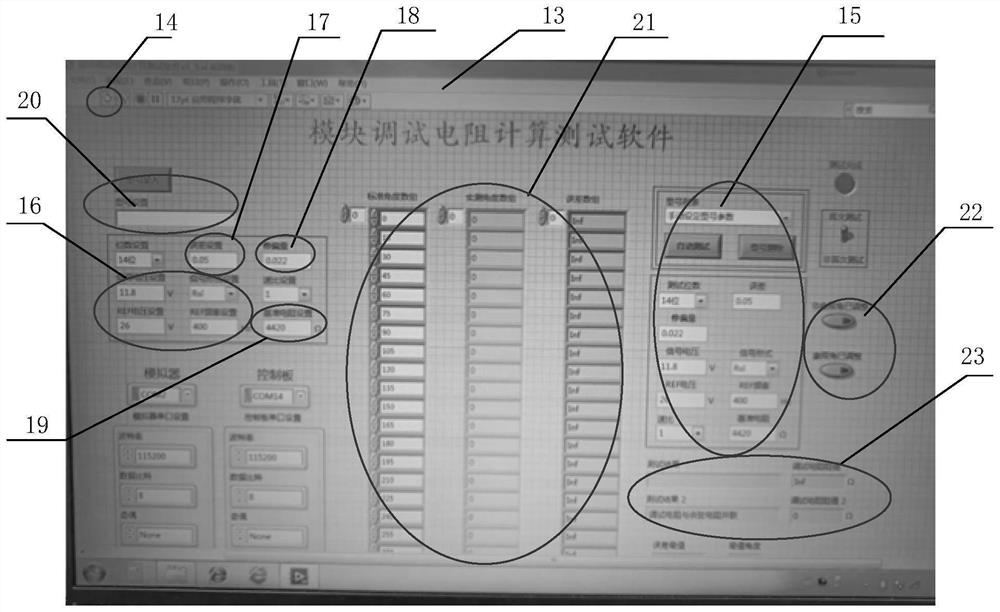

[0026] The host computer installed with angular precision automatic debugging software is used to realize the automatic control of the angle simulator output signal voltage, signal mode, and reference frequency, so that it is consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com