A kind of preparation method of direct heating type high temperature tungsten-rhenium alloy cathode

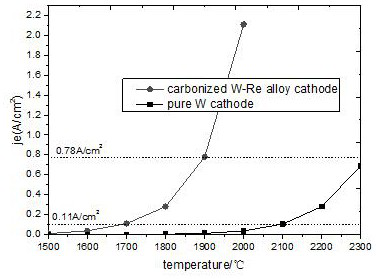

A tungsten-rhenium alloy, direct heating technology, applied in cathode manufacturing, cold cathode manufacturing, electrode system manufacturing, etc., can solve problems such as the end of the life of the magnetron, achieve strong ion bombardment ability, large thermal emission current density, reduce The effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

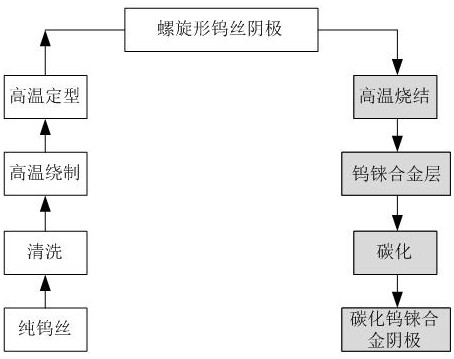

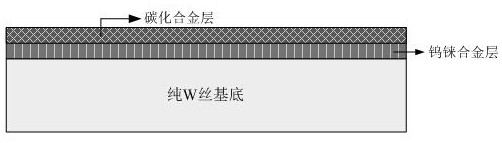

[0017] A kind of preparation method of direct heating type high temperature tungsten-rhenium alloy cathode, such as Figure 1-4 shown, including steps:

[0018] a. Mix metal tungsten powder and rhenium powder and pour them into an agate bowl to grind fully to obtain evenly mixed tungsten-rhenium alloy powder;

[0019] b. Evenly mix the tungsten-rhenium alloy powder with 1.5-3wt% nitrocellulose solution, apply the mixed solution to the surface of the tungsten wire cathode substrate, and bake it under an infrared lamp;

[0020] c. Put the tungsten wire with tungsten-rhenium alloy powder applied on the surface into a high-temperature hydrogen furnace, and keep it warm at 1500±50°C for 5-10 minutes to prepare the tungsten-rhenium alloy layer;

[0021] d. Place the tungsten wire with the tungsten-rhenium alloy layer sintered on the surface at an air pressure of 10 -3 ~10 -1 In the benzene atmosphere of Pa, the high-temperature chemical reaction is carried out at the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com