High-anti-poisoning one-component pouring sealant for LED driving power supply and preparation method of high-anti-poisoning one-component pouring sealant

A technology of LED drive and potting glue, which is applied in the direction of circuits, adhesives, electrical components, etc. It can solve the problem of heat dissipation protection of internal components of LED drive power supply and cannot ensure the electromagnetic compatibility of potting glue and LED drive power supply. , Dielectric properties of potting glue and other issues, to achieve excellent anti-poisoning performance, good flow performance and operability, and good electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

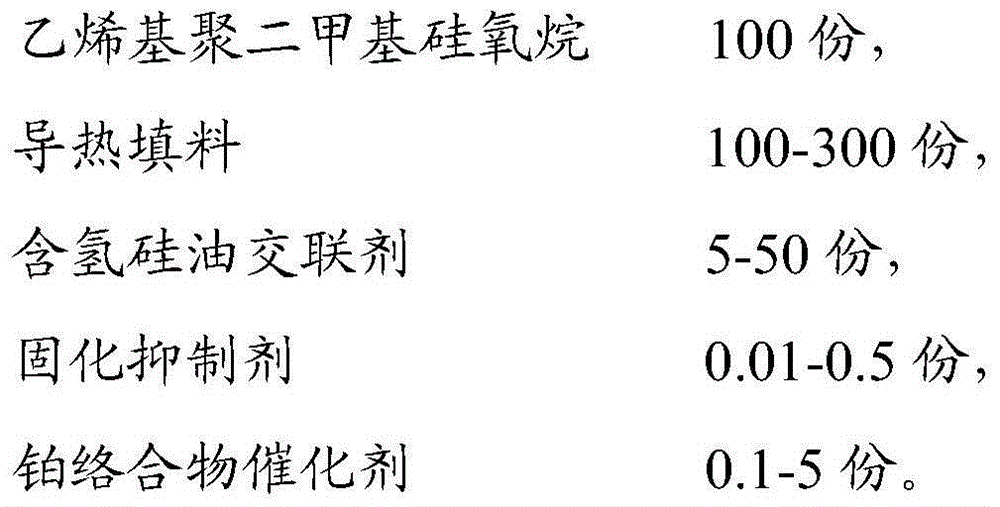

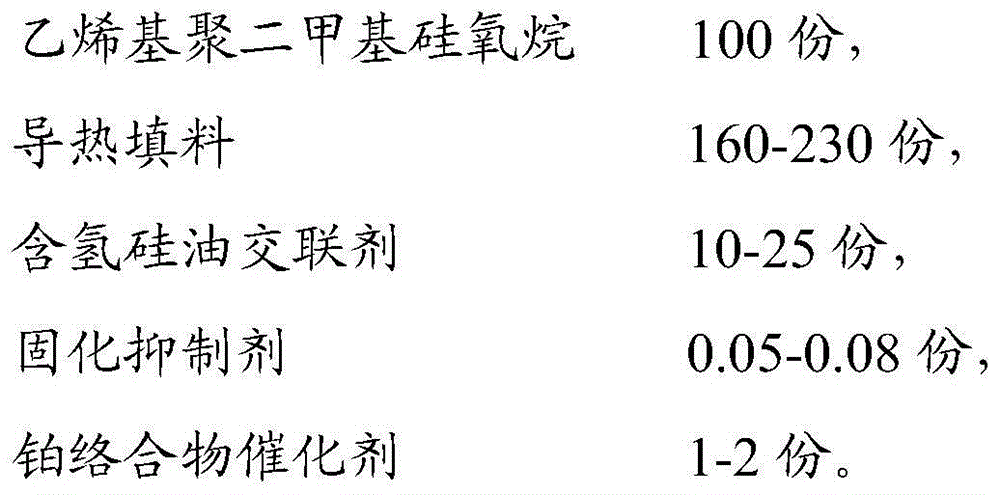

Method used

Image

Examples

Embodiment Construction

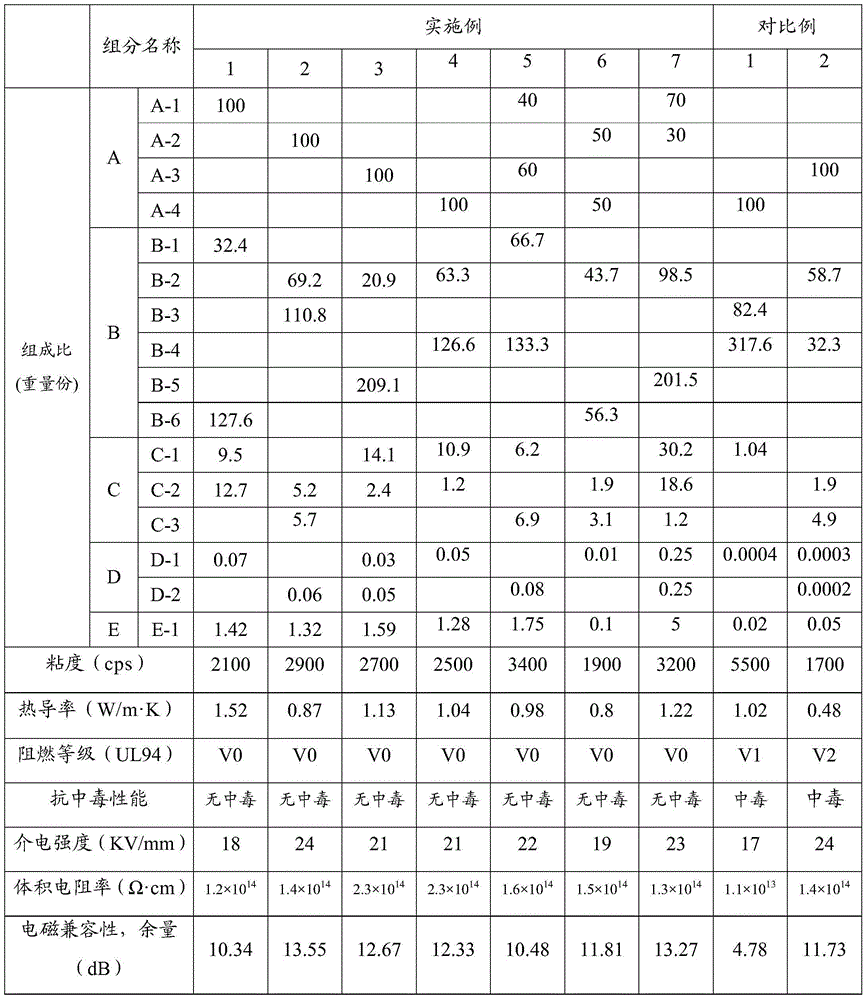

[0038] The present invention will be further described below in conjunction with specific examples.

[0039] Each component that following each embodiment is used is as follows:

[0040] (A) Vinyl polydimethylsiloxane:

[0041] (A-1) Linear vinyl polydimethylsiloxane, kinematic viscosity at 25°C is 250mm 2 / s, vinyl content 0.22mmol / g;

[0042] (A-2) Linear vinyl polydimethylsiloxane with a kinematic viscosity of 500mm at 25°C 2 / s, vinyl content 0.15mmol / g;

[0043] (A-3) Linear vinyl polydimethylsiloxane, kinematic viscosity at 25°C is 1000mm 2 / s, vinyl content 0.11mmol / g;

[0044] (A-4) Linear vinyl polydimethylsiloxane, kinematic viscosity at 25°C is 2000mm 2 / s, vinyl content 0.08mmol / g;

[0045] (B) Thermally conductive filler:

[0046](B-1) zinc oxide (average particle size 2 μm);

[0047] (B-2) silicon dioxide powder (average particle size 1 μm);

[0048] (B-3) silicon dioxide powder (average particle size 10 μm);

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com