Tungsten carbide/platinum composite material with core-shell structure as well as preparation and application thereof

A technology of composite materials and core-shell structure, applied in structural parts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as PtWC composite materials that have not been reported, and achieve cost reduction, good thermal stability, catalytic highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

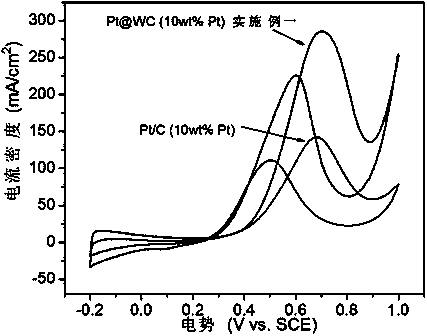

Embodiment 1

[0034] Mix ammonium metatungstate and copper nitrate at a mass ratio of 1:0.6, and add deionized water to prepare a 22wt% solution. In the present invention, the mixed solution of ammonium metatungstate and copper nitrate is preferably dispersed by ultrasonic treatment for 3 minutes, then spray-dried, and then dried by dual-flow spray drying (inlet temperature 210°C), and the obtained solid particles are Reduction carbonization, the carbonization atmosphere is: CO and H with a volume ratio of 1:2 2 The mixed atmosphere was raised to 800° C. for 4 hours by using the temperature programmed-gas-solid reaction method at a stepwise programmed temperature rise rate of 6° C. / min. The obtained particles are immersed in 5mmol / L chloroplatinic acid solution at a temperature of 50°C. The chloroplatinic acid solution is fed according to the mass of Pt in the solution being 10% of the mass of the prepared PtWC. After maintaining for 6 hours, filter After washing and drying, a PtWC sample ...

Embodiment 2

[0037] The process is similar to that of Example 1, but ammonium metatungstate and copper nitrate are mixed at a mass ratio of 1:0.5, and the rest of the steps are the same to obtain a PtWC sample. Figure 6 SEM image of the as-prepared PtWC material. From Figure 6 It can be seen that the sample particles are nanoparticles.

Embodiment 3

[0039] Similar to the process of Example 1, the ultrasonic dispersion time is 1 minute, and the rest of the steps are the same to obtain a PtWC sample, and the topography of the sample is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com