Catalyst for catalyzing methyl alcohol, preparation method and chemically modified electrode of catalyst

A catalyst, methanol technology, applied in the field of polymers, can solve the problems of direct interaction obstruction, low methanol oxidation reaction kinetics, difficult to achieve mass transfer and electron transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

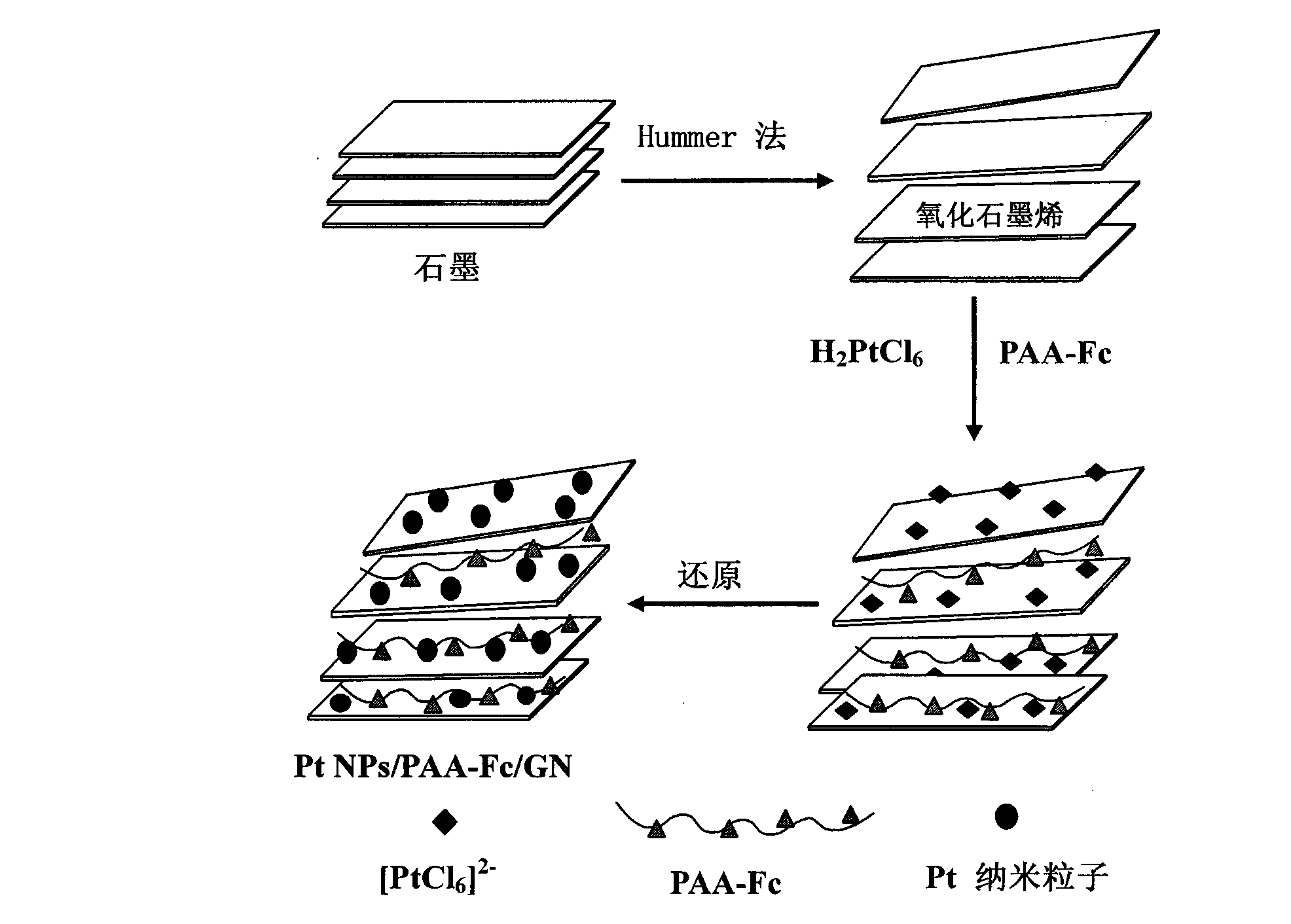

[0043] The invention provides a preparation method of a catalyst for methanol catalysis, comprising the following steps:

[0044] Provide a dispersion of graphene oxide;

[0045] The polyacrylic acid and ferrocene are mixed, and the polyacrylic acid-ferrocene compound is obtained after the reaction;

[0046] Mixing the graphene oxide dispersion with the polyacrylic acid-ferrocene composite and the metal nanoparticle precursor to obtain a mixed solution;

[0047] The mixed solution is mixed with a reducing agent, and a catalyst for methanol catalysis is obtained after a reduction reaction is performed.

[0048] The present invention provides a dispersion liquid of graphene oxide. The present invention has no special limitation on the source of the graphene oxide, and the graphene oxide well known to those skilled in the art can be used. In the present invention, the preparation method of the graphene oxide is the same as the preparation method of the graphene oxide described...

Embodiment 1

[0087] In a 500mL beaker, add 2.5g expanded graphite and 5g sodium nitrate, then add 120mL concentrated sulfuric acid with a mass concentration of 98%, and stir the obtained mixture under ice bath conditions for 120min;

[0088] Then, under the condition of strong stirring, slowly add 15g potassium permanganate to the obtained mixture to carry out the reaction, and the temperature of the reaction is controlled below 20°C;

[0089] After the addition of potassium permanganate was completed, the ice bath was removed, and the resulting reaction product was stirred at room temperature overnight. As the reaction progressed, the inventors observed that the mixture in the beaker gradually turned into a paste, and the color changed to bright brown;

[0090] Finally, 150 mL of secondary water was added dropwise to the beaker under vigorous stirring, the reaction temperature rose rapidly to 98°C, foam was observed, and the color of the reaction product in the beaker turned yellow;

[0...

Embodiment 2

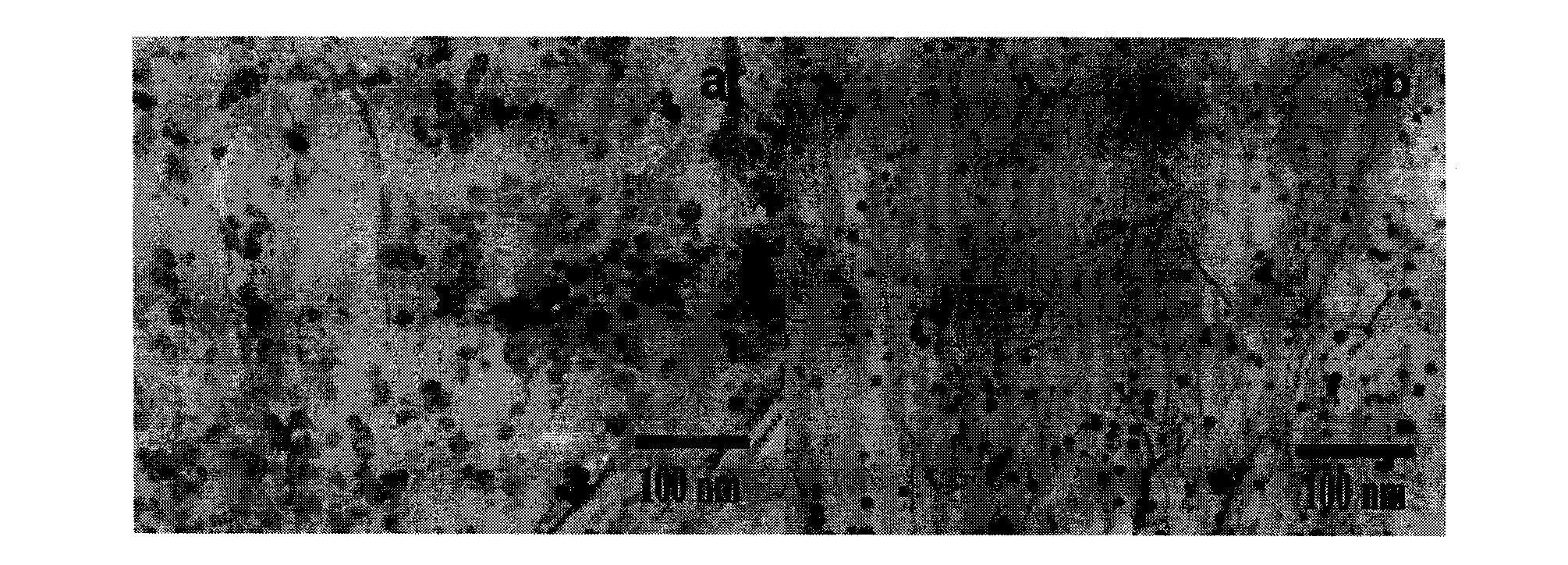

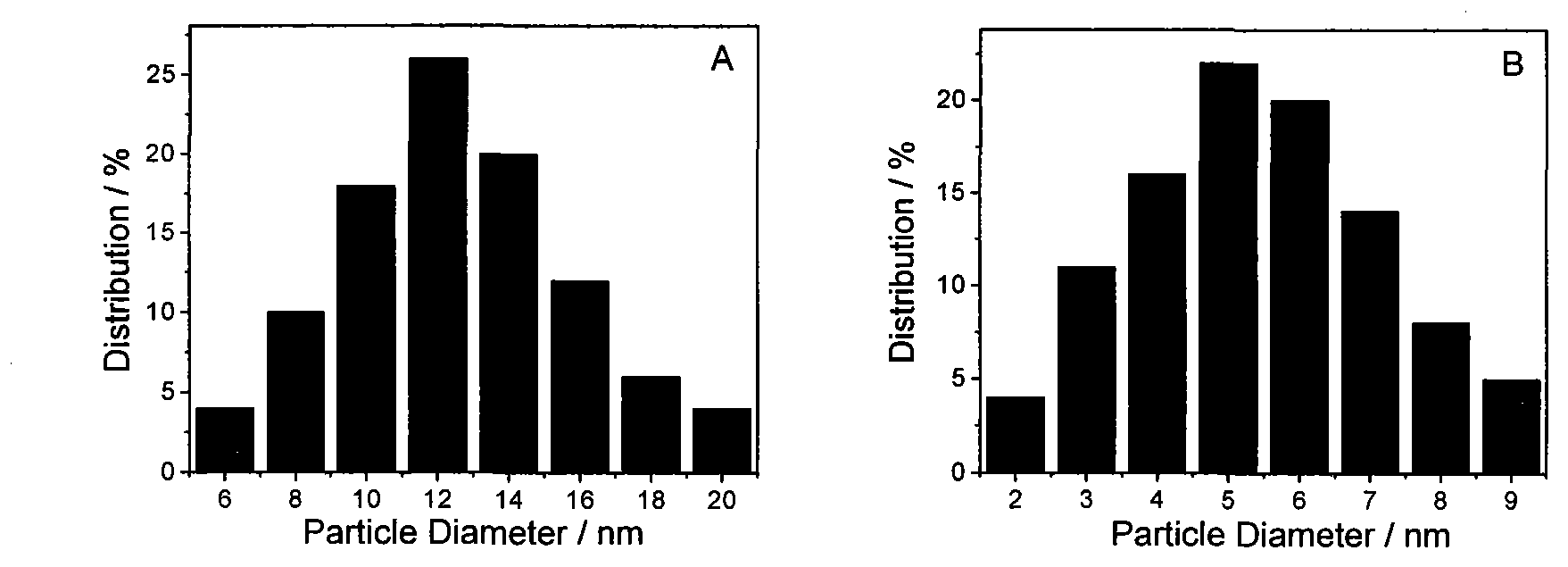

[0094] The graphene oxide obtained in 30 mg of Example 1 was dissolved in 45 mL of methanol aqueous solution, and the volume ratio of methanol to water in the methanol aqueous solution was 1: 1, and graphene oxide (GO) dispersion was obtained after ultrasonication for 30 min;

[0095] 2mL of polyacrylic acid-ferrocene solution was added to the above GO dispersion, wherein the molar concentration of polyacrylic acid was 1.2 mol / L, and the molar concentration of ferrocene was 0.1 mol / L. After ultrasonication for 60 min, under stirring Add 1 mL of H with a molar concentration of 0.038 mol / L to it. 2 PtCl 6 Aqueous solution, then, add dropwise a NaOH solution with a molar concentration of 0.5 mol / L to it, and adjust the pH value of the mixed solution to 11;

[0096] Then, 200 mg of NaBH was slowly added to the mixed solution with a pH value of 11 under stirring conditions. 4 Powder, continue stirring at room temperature for 24h. Finally, the obtained reaction product was subjec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com