Single-zone plate type high-temperature electrostatic dust collector

An electrostatic precipitator and plate-type technology, which is applied in the field of environmental protection dust removal equipment, can solve problems such as difficult to solve electrical insulation problems, difficult to maintain corona phenomenon, narrowed voltage range, etc., and achieve low surface work function, large emission current, and high operating voltage. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

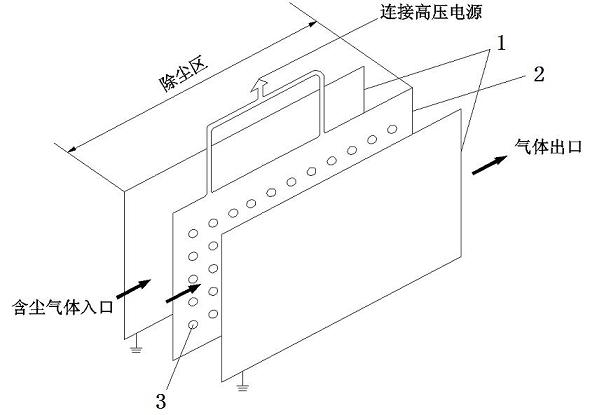

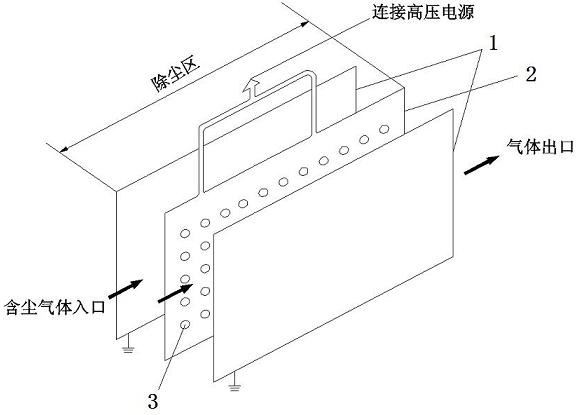

[0013] Such as figure 1 As shown, the single-zone plate high-temperature electrostatic precipitator is mainly composed of four parts: anode plate 1, cathode plate 2, emitter electrode 3 and high-voltage power supply. Two stainless steel plates are grounded and placed in parallel as the anode plate 1; a stainless steel plate with the same shape and size as the anode plate 1 is connected to the cathode of the high-voltage power supply as the cathode plate 2; the cathode plate 2 is suspended from the two anode plates 1 The center is parallel to the anode plate 1; the disc-shaped emitter electrode 3 is evenly inlaid on both sides of the cathode plate 2, and the emitter electrode 3 is made of barium-tungsten thermionic emission material doped with cerium oxide.

[0014] Among them, the barium tungsten thermionic emission material doped with cerium oxide is the addition of rare earth oxide CeO 2 The barium tungsten composite functional material, its composition is the CeO of mass p...

Embodiment 2

[0017] Basically the same as Example 1, the difference is: the doped rare earth oxide CeO 2 The barium tungsten composite functional material, its composition is the CeO of mass percent 1.1% 2 And 98.9% tungsten powder, the pores of the porous tungsten matrix doped with ceria are impregnated with aluminate. The single-zone plate-type high-temperature electrostatic precipitator of this embodiment has an actual measured dust removal efficiency of 95.1% under the conditions of a pressure of 0.1 MPa, a temperature of 690°C, and a voltage of 6000 V.

Embodiment 3

[0019] Basically the same as Example 1, the difference is: the doped rare earth oxide CeO 2 The barium tungsten composite functional material, its composition is the CeO of mass percent 1.2% 2 And 98.8% tungsten powder, the pores of the porous tungsten matrix doped with ceria are impregnated with aluminate. The single-zone plate-type high-temperature electrostatic precipitator of this embodiment has an actual measured dust removal efficiency of 78.2% under the conditions of a pressure of 0.1 MPa, a temperature of 566°C, and a voltage of 6000 V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com