A kind of preparation method of direct heating type anti-electron bombardment cathode

A technology of electron bombardment and direct heating, which is applied in the direction of cathode, cold cathode manufacturing, and electrode system manufacturing of time-of-flight electron tubes. It can solve the problems of the end of life of pure W wire cathode magnetron and achieve high resistance to electron bombardment. ability, high thermal emission current density, and the effect of reducing evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

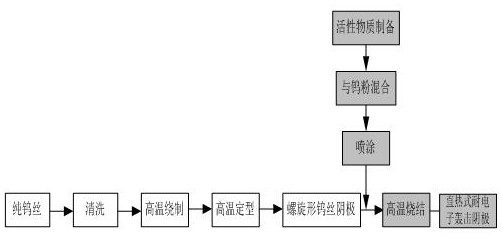

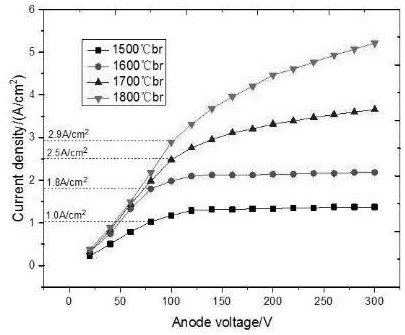

[0020] A kind of preparation method of direct heating type anti-electron bombardment cathode, such as Figure 1-5 shown, including steps:

[0021] a. Set Y 2 o 3 、Gd 2 o 3 , HfO 2 / ZrO 2 Y 2 o 3 、Gd 2 o 3 and HfO 2 / ZrO 2 mixed powder and pressed into blocks;

[0022] b. Put the block obtained in step a into a muffle furnace, and sinter at 1450±50° C. for 1 to 4 hours to synthesize Y-Gd-Hf / Zr-O refractory oxide active material;

[0023] c, grinding the refractory oxide block of Y-Gd-Hf / Zr-O obtained in step b for not less than 3 hours;

[0024] d. Mix the Y-Gd-Hf / Zr-O refractory oxide active material obtained in step c with metal tungsten powder, pour it into an agate bowl and grind it well, and obtain a uniformly mixed Y-Gd-Hf / Zr- O active substance powder;

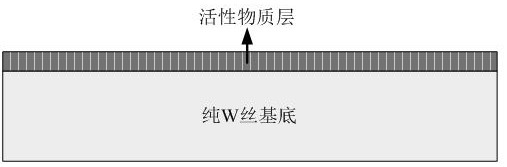

[0025] e. Evenly mix the Y-Gd-Hf / Zr-O active material powder obtained in step d with 1.5-3wt% nitrocellulose solution, apply the mixed solution to the surface of the tungsten wire cathode substrate, and pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com