Lanthanum-carbide-tungsten hot cathode material and preparation method thereof

A technology of lanthanum carbide and hot cathodes, which is applied in the manufacture of hot electron cathodes, electrical components, and parts of discharge tubes/lamps, etc., can solve problems such as complex procedures, non-hot cathode materials, serious brittleness, etc., and achieve simple preparation methods, The effect of good thermal electron emission capability and high emission stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

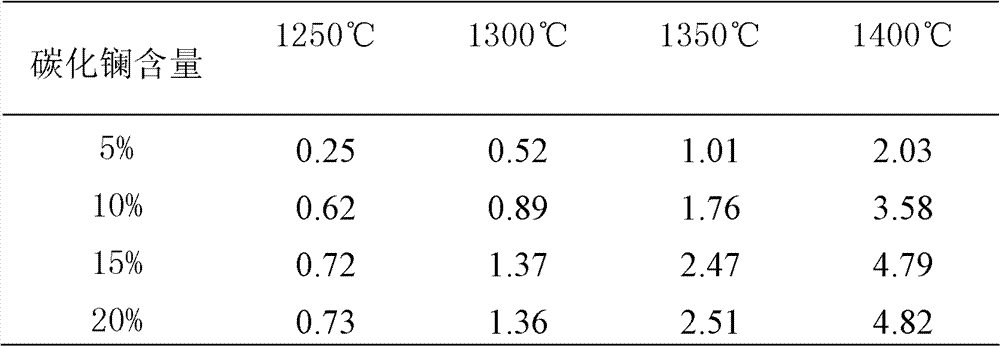

[0013] Example 1, put 16 grams of lanthanum hydride and 2 grams of graphite into a vacuum ball mill jar under the protection of an argon atmosphere, and then put the pellets in a ratio of 1:1. Put it on the ball mill and mill it for two hours at a speed of 800rpm. After the time is up, put it into a vacuum melting furnace and heat it to 1200°C for 30 minutes. Weigh 57 grams of tungsten powder, take 3 grams of lanthanum carbide and the weighed tungsten powder and put them into a ball mill jar, then put the ball material in a ratio of 1:1, and put it on the ball mill at a speed of 400rpm Ball mill for two hours. After the ball milling is completed, put the powder into a Φ20mm grinding tool, and sinter on a spark plasma sintering equipment with a pressure of 20MP and a temperature of 1000°C for 10 minutes. The sintered sample was machined into a cylinder with a diameter of 3 mm and a height of 2.8 mm by locomotive machining, and activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com