A compact low magnetic compression ratio magnetron injection electron gun

A technology of magnetron injection and electron gun, which is applied in the direction of time-of-flight electron tubes, circuits, discharge tubes, etc., can solve the problems of large size of electron guns, achieve the effects of reducing area, overcoming the decrease of electron velocity ratio, and increasing the initial lateral velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

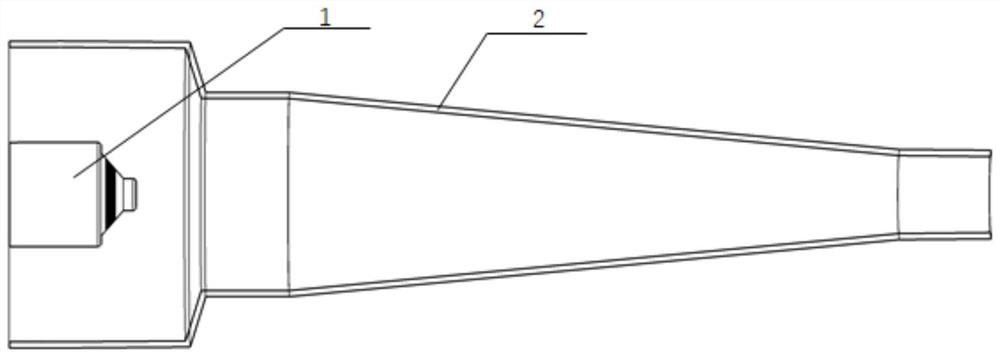

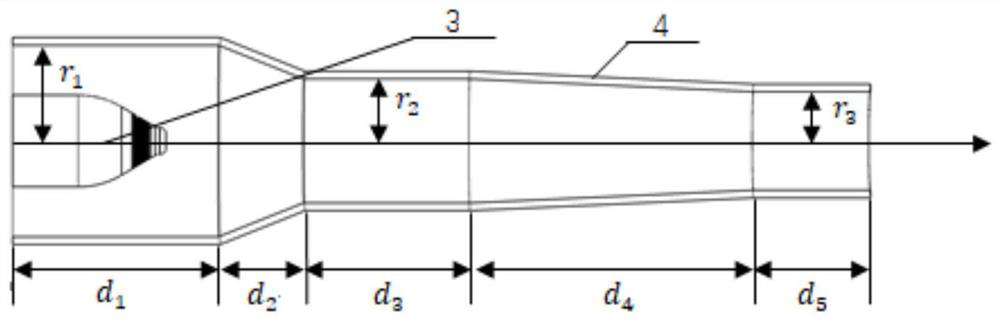

[0031] The invention provides a compact low magnetic compression ratio magnetron injection electron gun, such as figure 2 As shown, including the electron gun body as the anode and the cathode. The anode is a hollow metal shell with a traditional linear tapered structure. The cathode 3 and the anode are located inside the electron gun body and arranged coaxially with the anode.

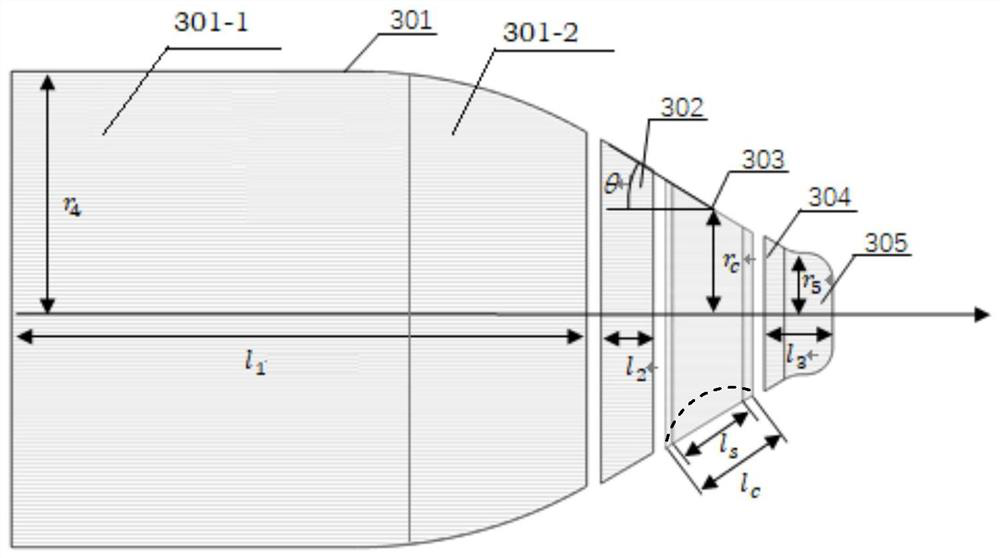

[0032] The cathode is a solid matrix with a structure such as image 3 As shown, the cathode includes a rear forming pole 301, an emitter band 303 and a front forming pole 305; the rear forming pole 301, the emitter segment 303 and the front forming pole 305 are smoothly connected in sequence along the electron emission direction to form a shaft-shaped whole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com