Graphene field emission cathode and preparation method thereof

A technology for emitting cathode and graphene, applied in the field of field emission, can solve the problems of poor emission stability, low emission current density, large emission turn-on electric field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The second aspect of the embodiments of the present invention provides a method for preparing a graphene field emission cathode, comprising the following steps:

[0034] S01. Provide a conductive substrate, prepare a graphene layer on a surface of the conductive substrate;

[0035] S02. Depositing metal nanoparticles on the surface of the graphene layer away from the conductive substrate, and vacuum annealing to prepare a graphene / nano-metal composite layer, wherein the work function of the metal nanoparticles is less than or equal to 4.5eV.

[0036] In the preparation method of the graphene field emission cathode provided by the embodiment of the present invention, metal nanoparticles with low work function are deposited on the surface of the graphene layer, and annealing treatment is further performed. During the annealing process, electronic interaction occurs between the graphene in the graphene layer and the nano-metal particles on its surface, and this electronic ...

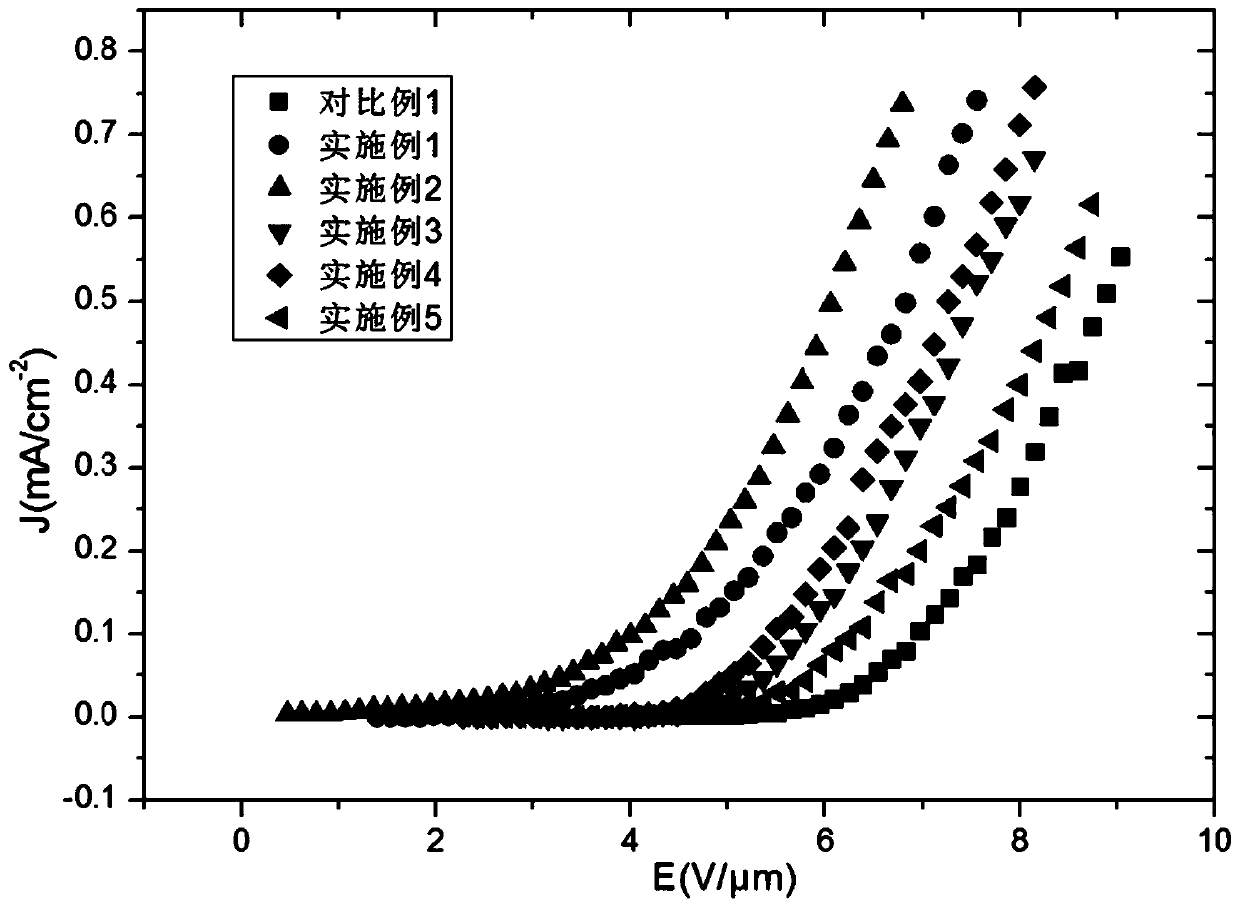

Embodiment 1

[0053] A graphene field emission cathode, its preparation method is as follows:

[0054] Provide iron-based conductive substrate;

[0055] Prepare a 0.2mg / ml graphene solution, and ultrasonicate at 200W for 1 hour to form a stable dispersion. Wherein, the graphene in the graphene solution is multilayer graphene with a size of 1-3 microns. The graphene solution is drop-coated on the iron-based conductive substrate to deposit a graphene film, and dried at a temperature of 90° C. to form a graphene cathode;

[0056] Titanium nanoparticles with a thickness of 3nm are deposited on the surface of the graphene thin film away from the iron-based conductive substrate by magnetron sputtering, annealed at a temperature of 500°C for 30 minutes to prepare titanium metal nanoparticles doped graphene cathode.

Embodiment 2

[0058] A graphene field emission cathode, its preparation method is as follows:

[0059] Provide iron-based conductive substrate;

[0060] Prepare a 0.2mg / ml graphene solution, and ultrasonicate at 200W for 1 hour to form a stable dispersion. Wherein, the graphene in the graphene solution is multilayer graphene with a size of 1-3 microns. The graphene solution is drop-coated on the iron-based conductive substrate to deposit a graphene film, and dried at a temperature of 90° C. to form a graphene cathode.

[0061] Using the magnetron sputtering method to deposit bismuth nanoparticles with a thickness of 3 nm on the surface of the graphene film away from the iron-based conductive substrate, annealing at a temperature of 500 ° C for 30 minutes to prepare bismuth metal nanoparticles doped graphene cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Work function | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com