A preparation method of a direct-heating type electron-bombardment-resistant cathode

An electron bombardment and direct heating technology, which is applied in the cathode, cold cathode manufacturing, and electrode system manufacturing of time-of-flight electron tubes, can solve the problems of the end of life of the pure W wire cathode magnetron, and achieve high resistance to electron bombardment ability, high thermal emission current density, and the effect of reducing evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

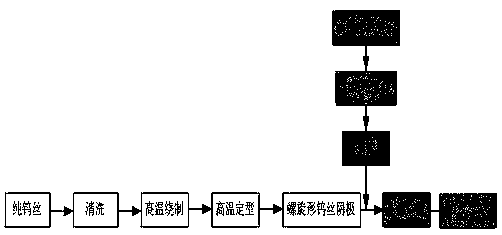

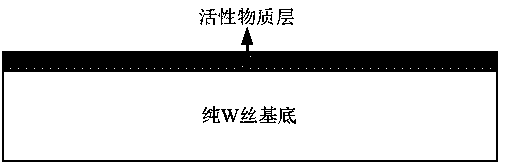

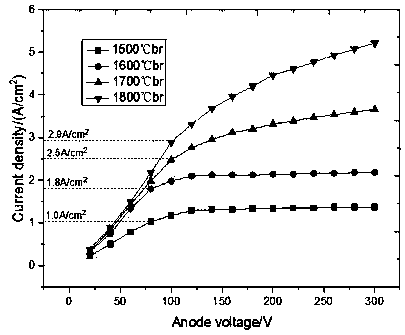

[0020] A kind of preparation method of direct heating type anti-electron bombardment cathode, such as Figure 1-5 shown, including steps:

[0021] a. Set Y 2 o 3 、Gd 2 o 3 , HfO 2 / ZrO 2 Y 2 o 3 、Gd 2 o 3 and HfO 2 / ZrO 2 mixed powder and pressed into blocks;

[0022] b. Put the block obtained in step a into a muffle furnace, and sinter at 1450±50° C. for 1 to 4 hours to synthesize Y-Gd-Hf / Zr-O refractory oxide active material;

[0023] c, grinding the refractory oxide block of Y-Gd-Hf / Zr-O obtained in step b for not less than 3 hours;

[0024] d. Mix the Y-Gd-Hf / Zr-O refractory oxide active material obtained in step c with metal tungsten powder, pour it into an agate bowl and grind it well, and obtain a uniformly mixed Y-Gd-Hf / Zr- O active substance powder;

[0025] e. Evenly mix the Y-Gd-Hf / Zr-O active material powder obtained in step d with 1.5-3wt% nitrocellulose solution, apply the mixed solution to the surface of the tungsten wire cathode substrate, and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com