Patents

Literature

38 results about "Electron-beam technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Since the mid-20th century, electron-beam technology has provided the basis for a variety of novel and specialized applications in semiconductor manufacturing, microelectromechanical systems, nanoelectromechanical systems, and microscopy.

Process for making antimicrobial polymer articles

This invention relates to a process for making articles antimicrobial and odor inhibiting, which comprises using vacuum deposition and electron beam techniques to graft amino-reactive functional groups onto polymeric material which the article comprises, followed by contacting the polymeric material with a chitosan solution.

Owner:EI DU PONT DE NEMOURS & CO

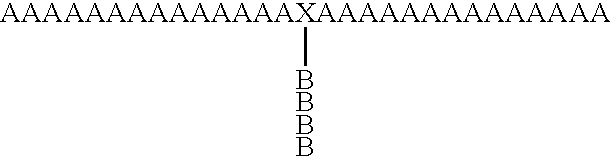

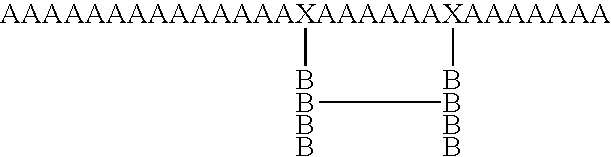

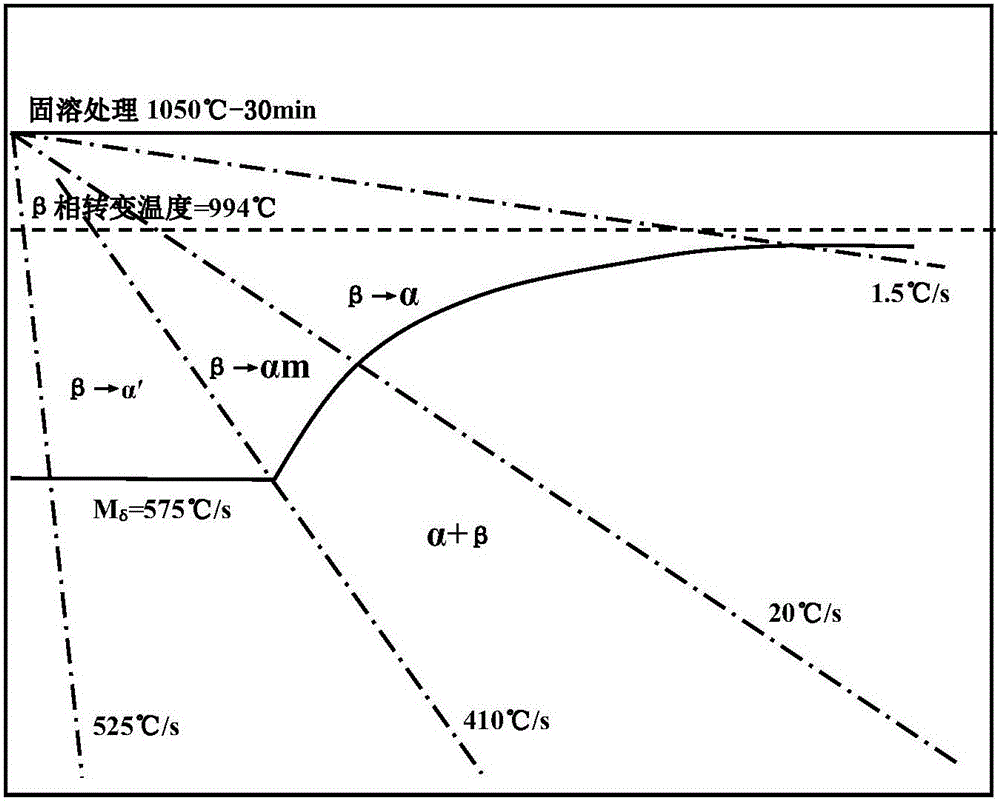

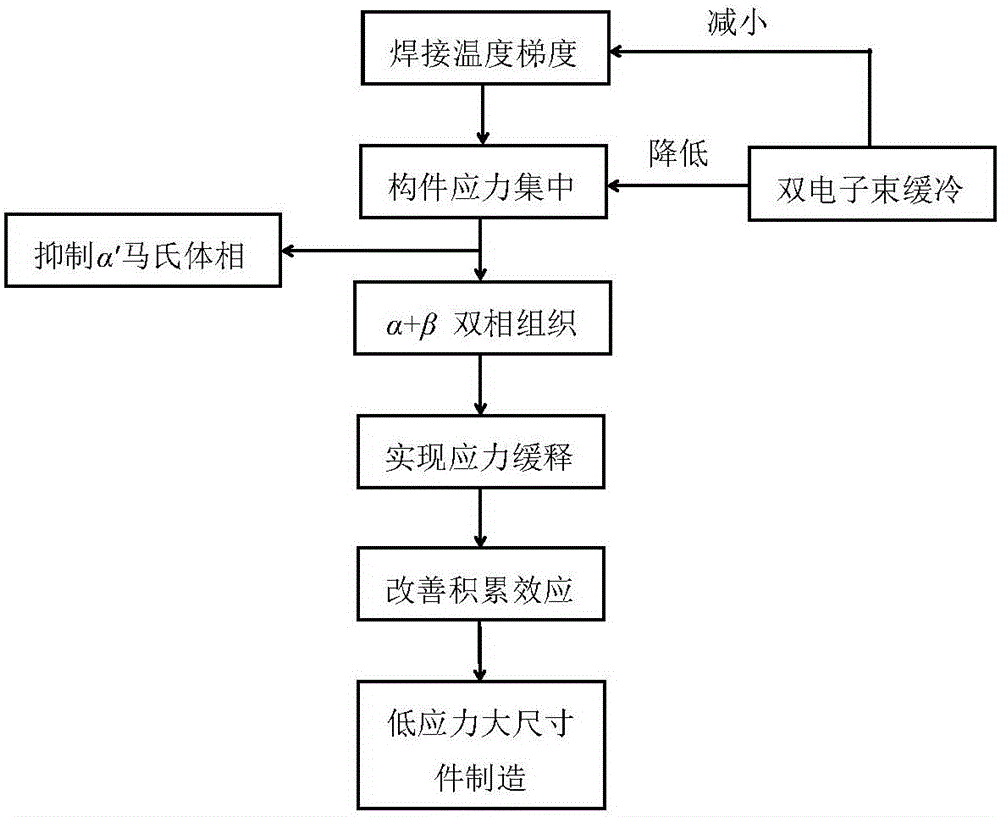

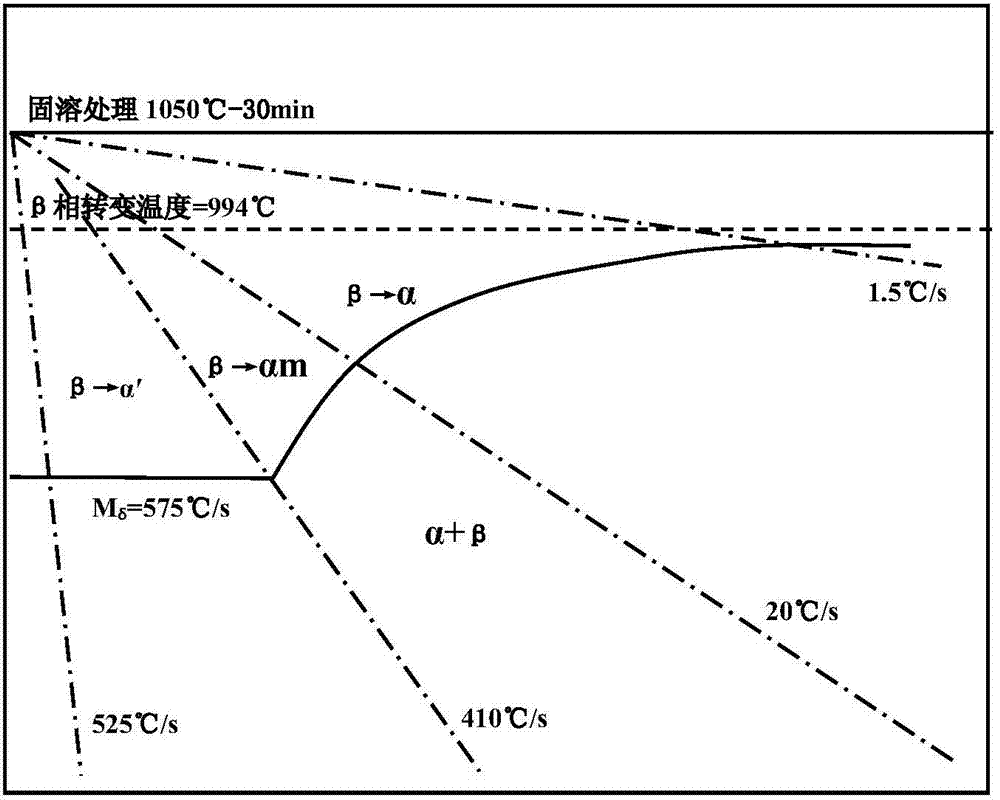

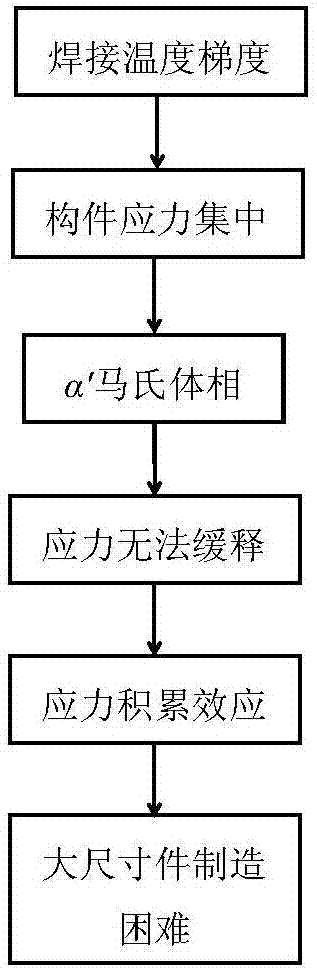

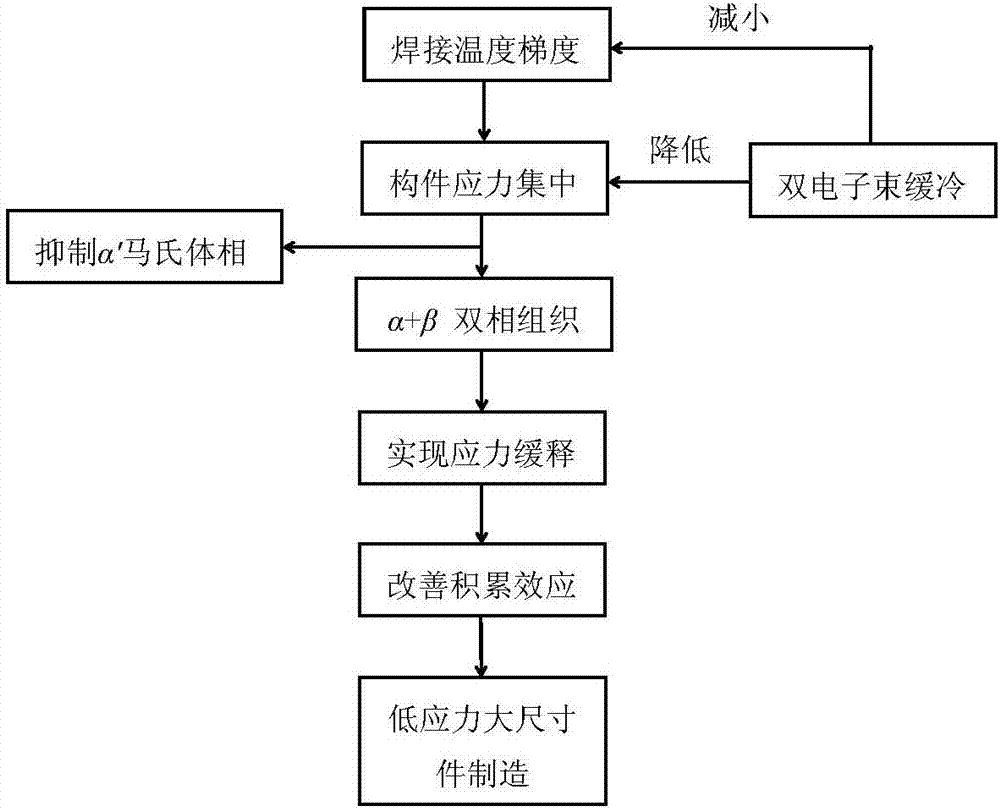

Stress slow release method for TC4 titanium alloy additive manufacturing component based on double electron beams

ActiveCN105798301AIncrease stressAdditive manufacturing apparatusIncreasing energy efficiencyAviationChemical industry

The invention discloses a stress slow release method for a TC4 titanium alloy additive manufacturing component based on double electron beams, particularly relates to a stress slow release control method for the large-size TC4 titanium alloy additive manufacturing component based on the double electron beams, and relates to the technical field of additive manufacturing. The method comprises the steps of A, establishing and correcting a temperature field model of the double electron beams; and B, carrying out filler wire additive manufacturing through the double electron beams. According to the method, the phase change is controlled in real time in the additive manufacturing process through the double electron beam technology, slow release of stress of the large-size TC4 titanium alloy additive manufacturing component is realized through the mode of improving the integral plasticity by controlling the phase change, a new method is provided for solving the key technological problem of manufacturing of the large-size TC4 titanium alloy additive manufacturing component, the utilization potentiality of the additive manufacturing technology in the field of aviation, aerospace, petroleum, the chemical industry and metallurgy is improved, and theoretical and technical guidance is provided for additive manufacturing of other metal material.

Owner:SHANGHAI UNIV OF ENG SCI

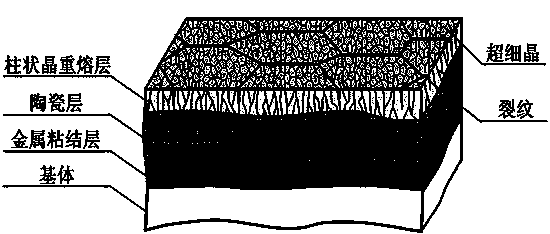

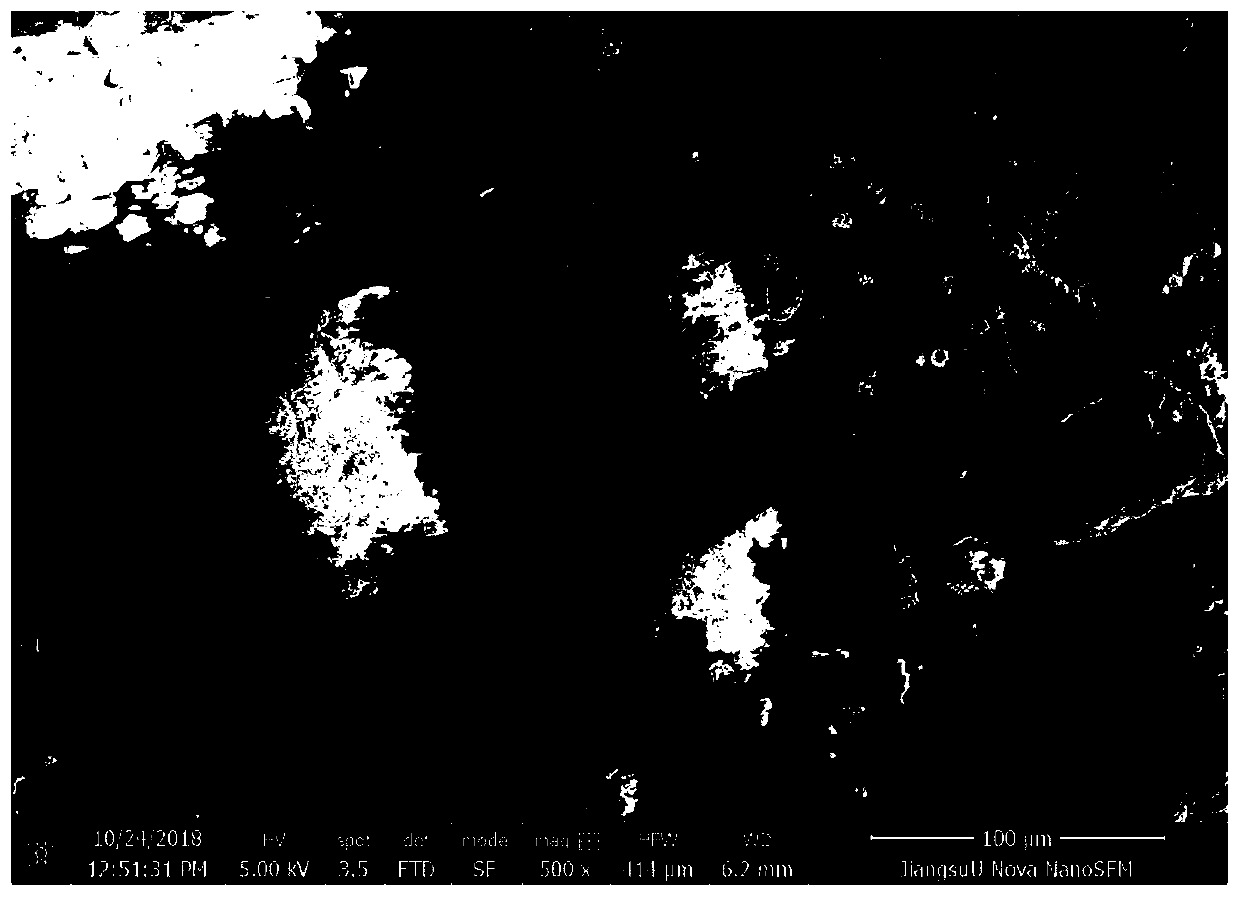

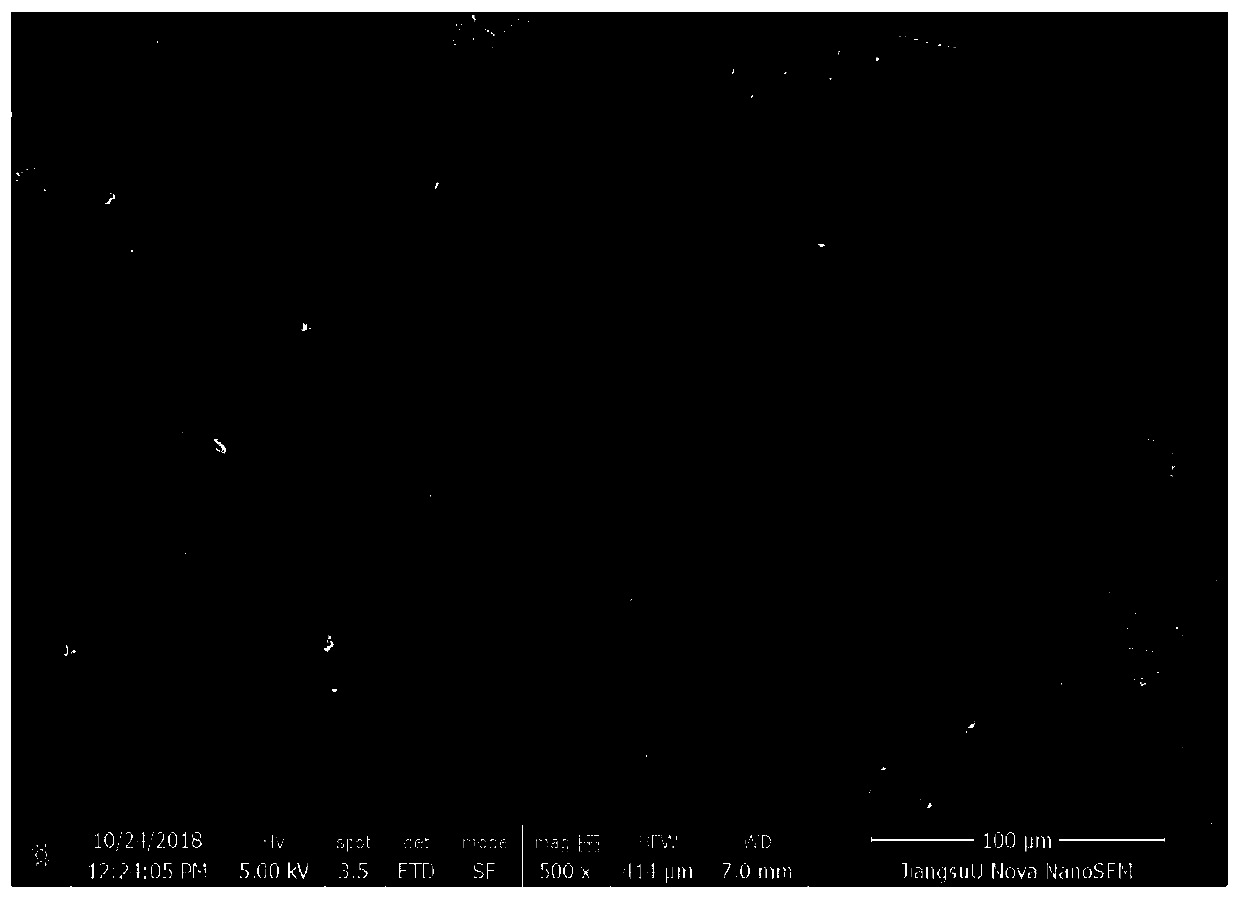

Thermal barrier coating material with closed surface layer and preparation method thereof

InactiveCN103993254AAvoid influenceGood high temperature service performanceMolten spray coatingAlloy substrateSuperalloy

Belonging to the technical field of thermal barrier coating surface treatment and modification, the invention in particular relates to a thermal barrier coating material with a closed surface layer and a preparation method thereof. The coating material comprises a metal bonding layer, a rough and porous ceramic surface layer and a cylindrical crystal remelted layer with a closed surface layer. The invention also discloses a preparation method of the thermal barrier coating material with a closed surface layer, and the method includes: depositing the metal bonding layer on the surface of a high temperature alloy substrate by plasma spraying, then depositing the ceramic layer on the surface of the bonding layer, and finally conducting irradiation treatment on the ceramic layer by a high current pulsed electron beam technology, thus forming the closed cylindrical crystal remelted layer. The thermal barrier coating material with a closed surface layer prepared by the composite technology can effectively block invasion of external harmful gas and improve the strain tolerance and thermal shock performance of the coating, and has good high temperature service performance, thus being an ideal thermal barrier coating.

Owner:JIANGSU UNIV

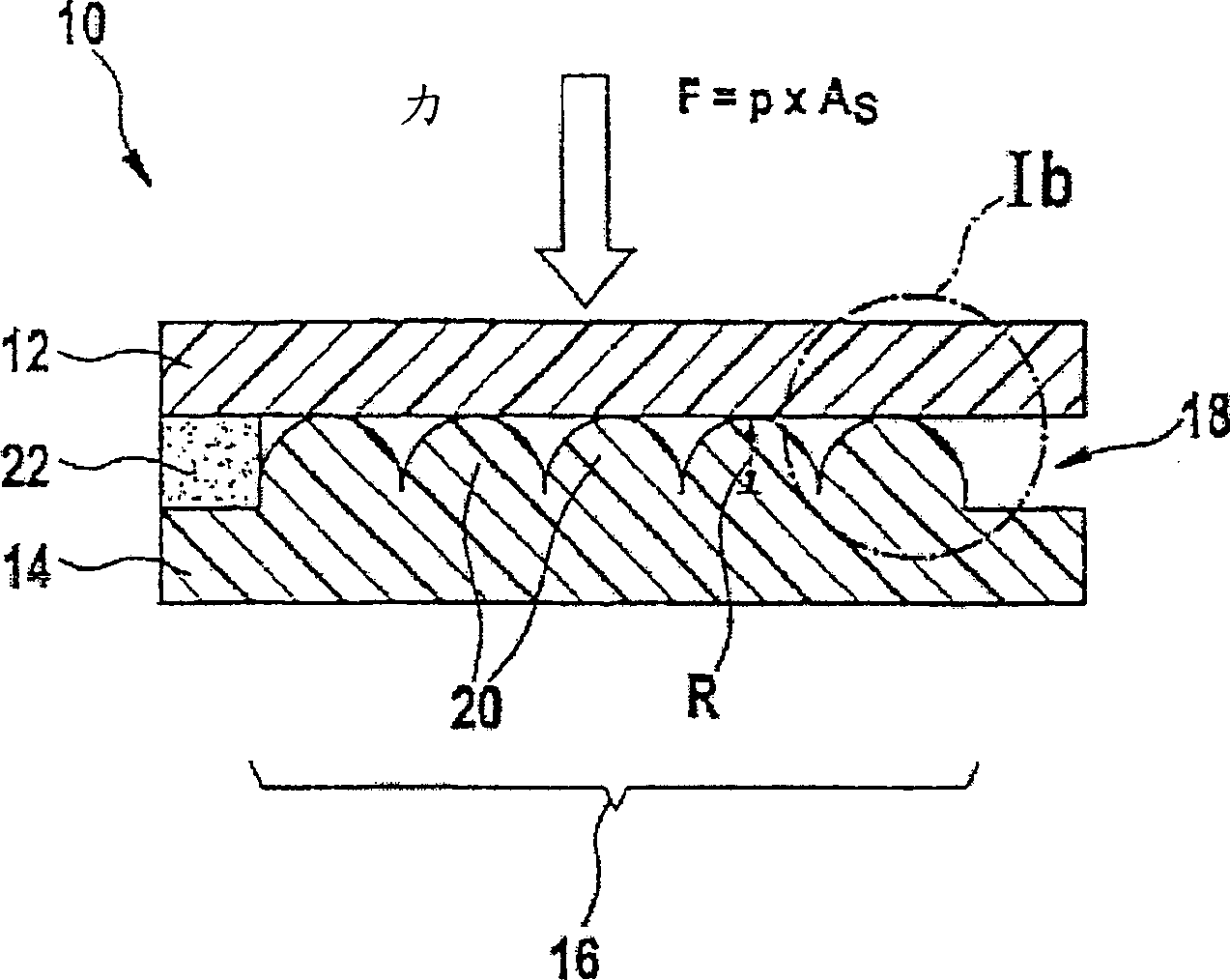

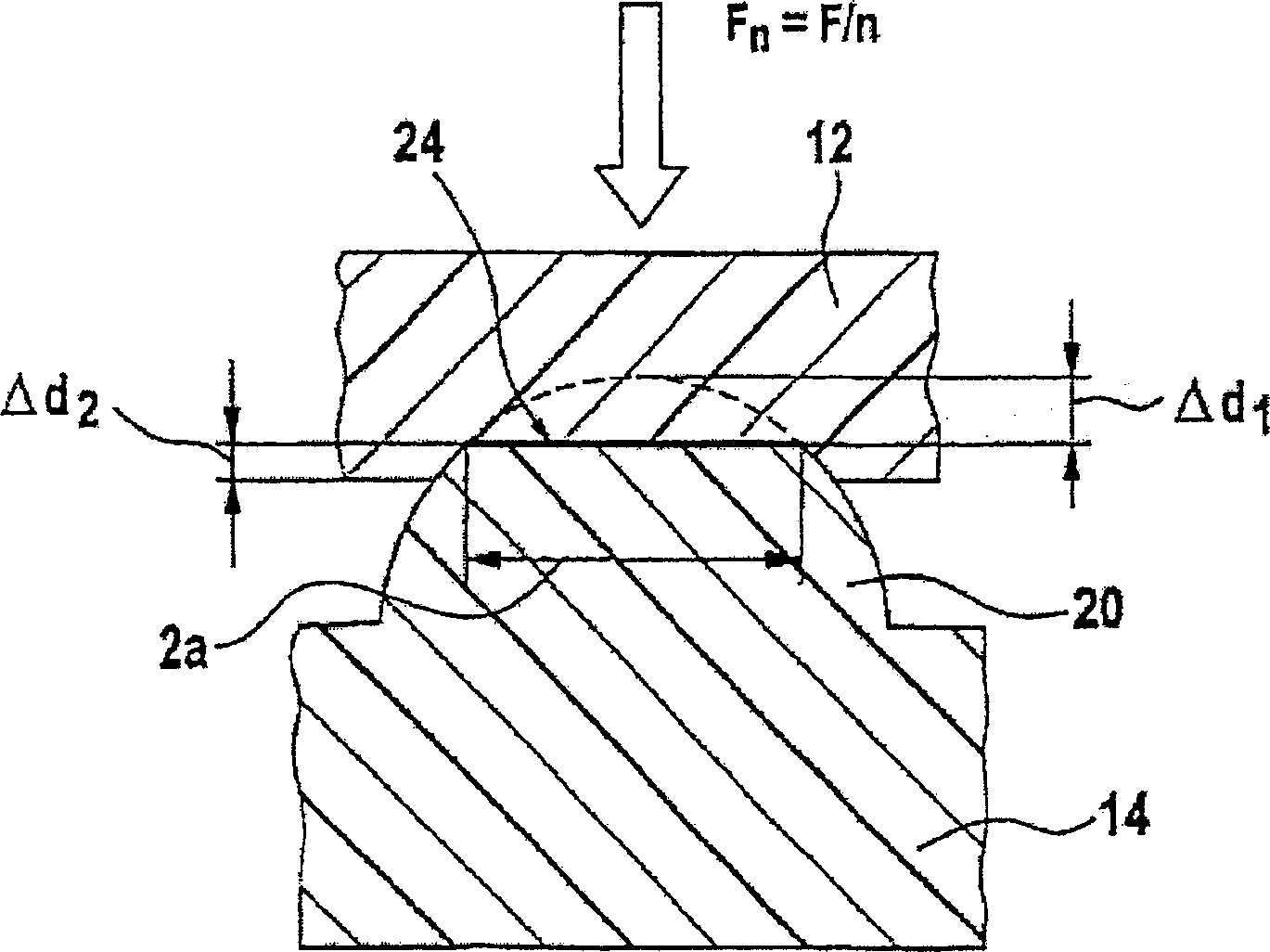

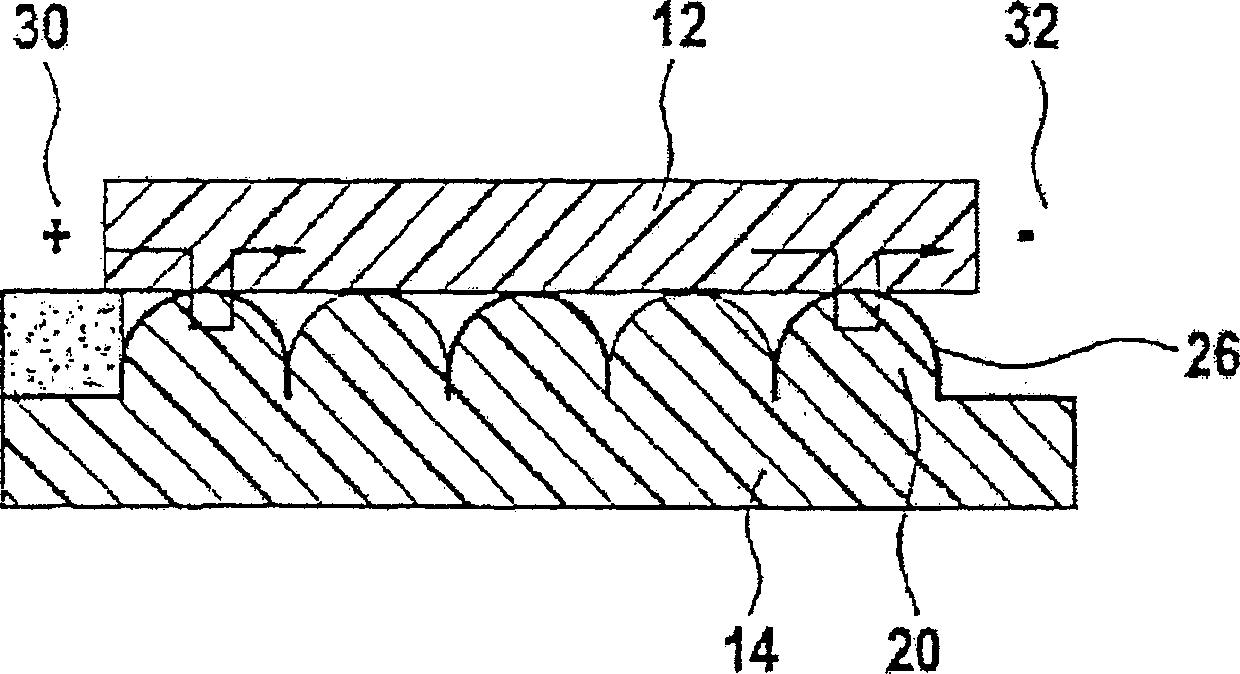

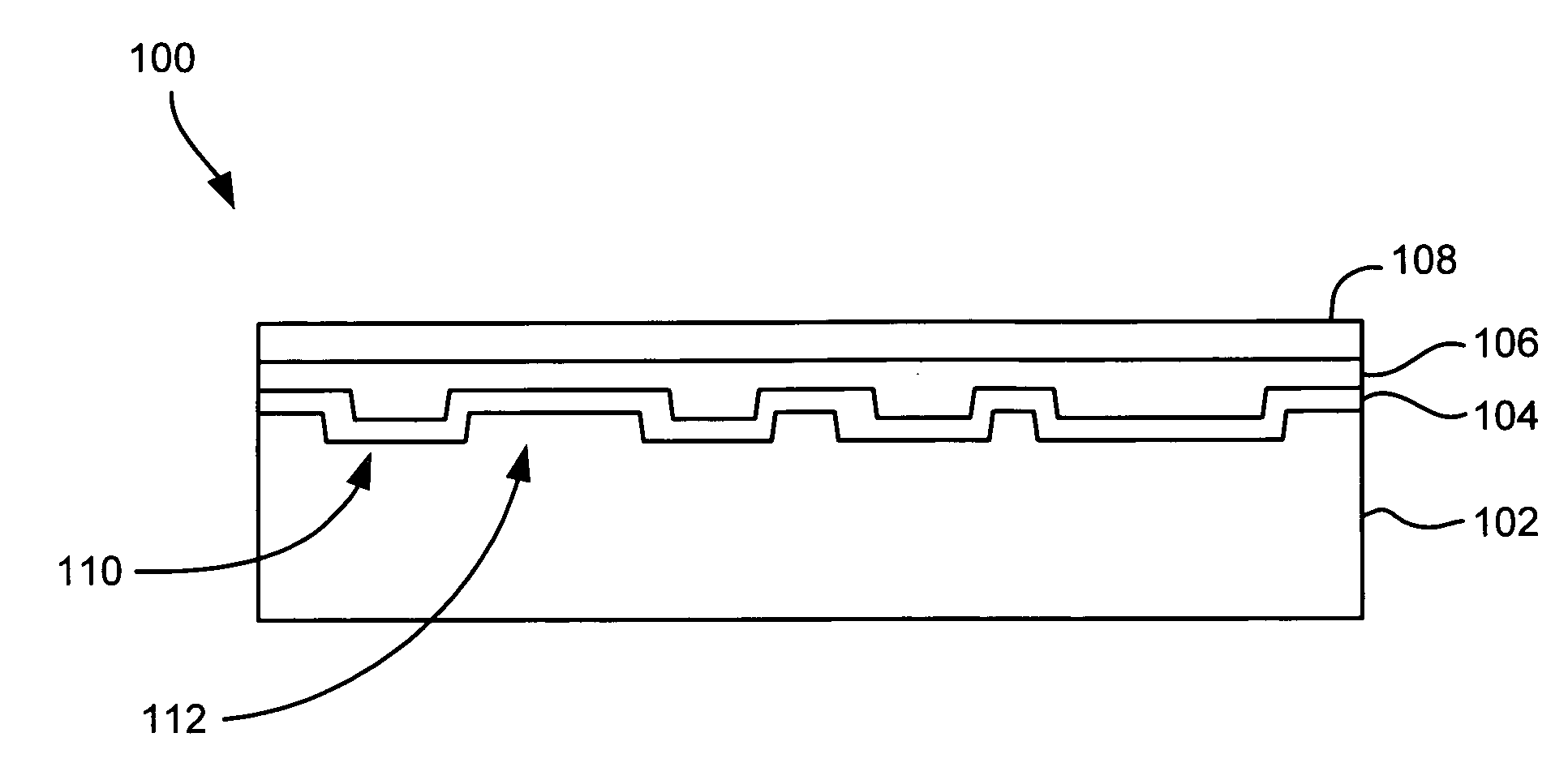

Pressure sensor comprising an elastic sensor layer with a microstructured surface

Disclosed is a pressure sensor comprising sensor layers ( 12, 14 ) which are made of an elastic, resistive material and are applied to a polymer film that is not represented. ( 22 ) embodies a spacer that is coated with an adhesive. One sensor layer ( 14 ) is provided with a microstructured surface encompassing spherical structures ( 20 ) within an active zone ( 16 ). The compression path amounts to 10 micrometers at an extension R of the structures of 50 micrometers. The structures ( 20 ) are large compared with a certain surface roughness. The inventive pressure sensor is produced by injection molding, etching, embossing, or by means of an electron beam technique or laser beam technique. Disclosed are variations thereof, which function differently.

Owner:IEE INT ELECTRONICS & ENG SA

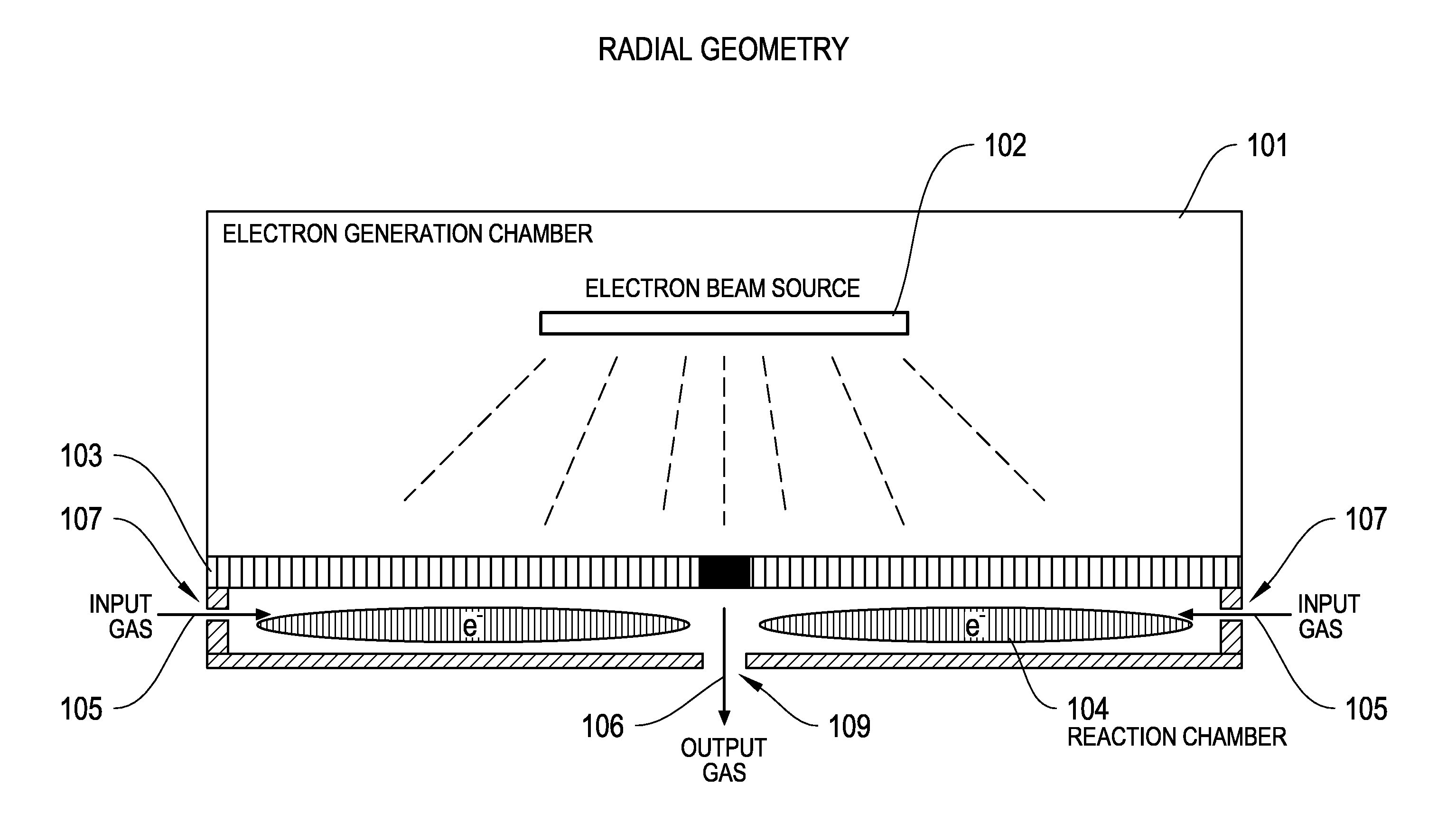

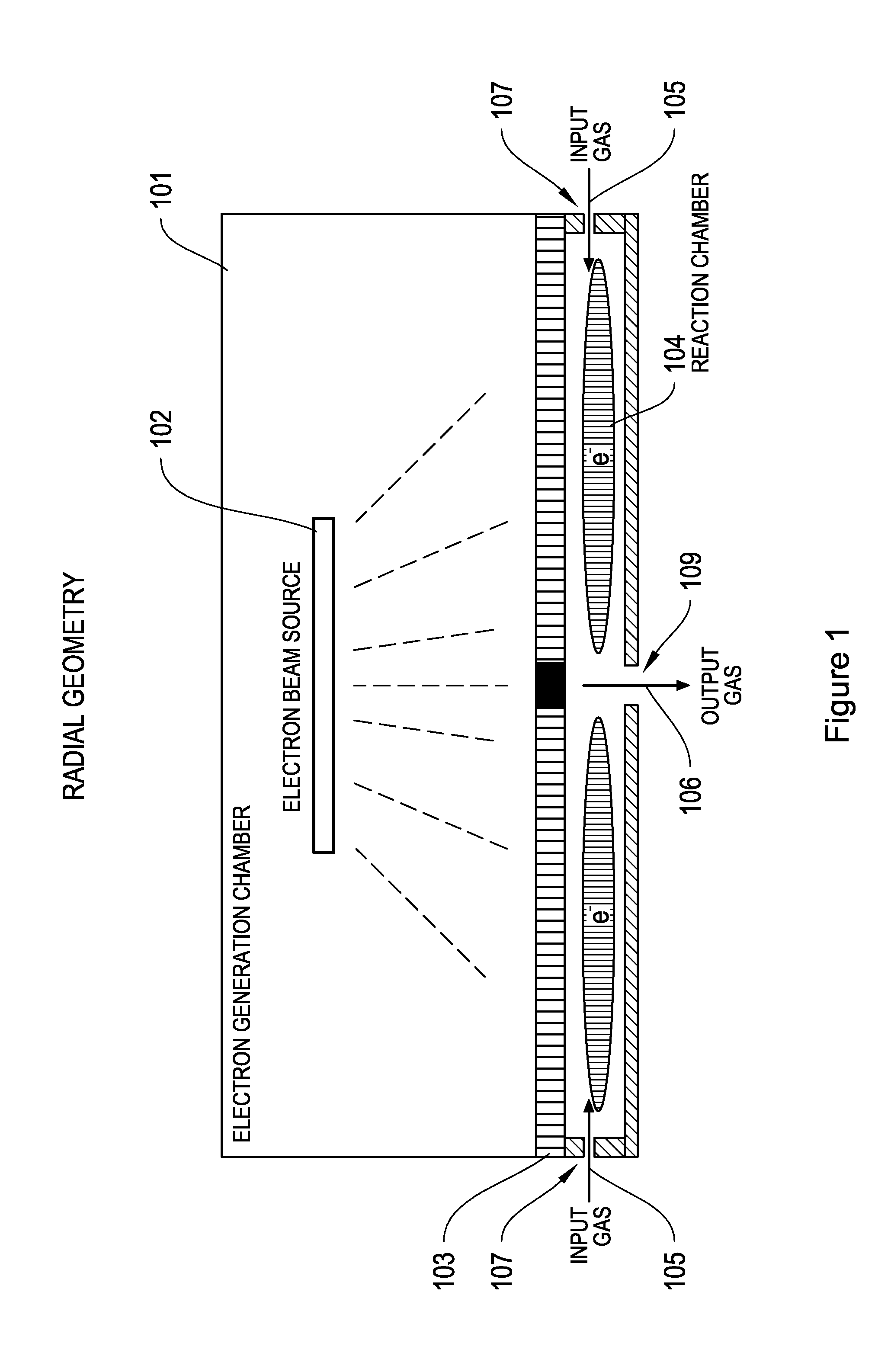

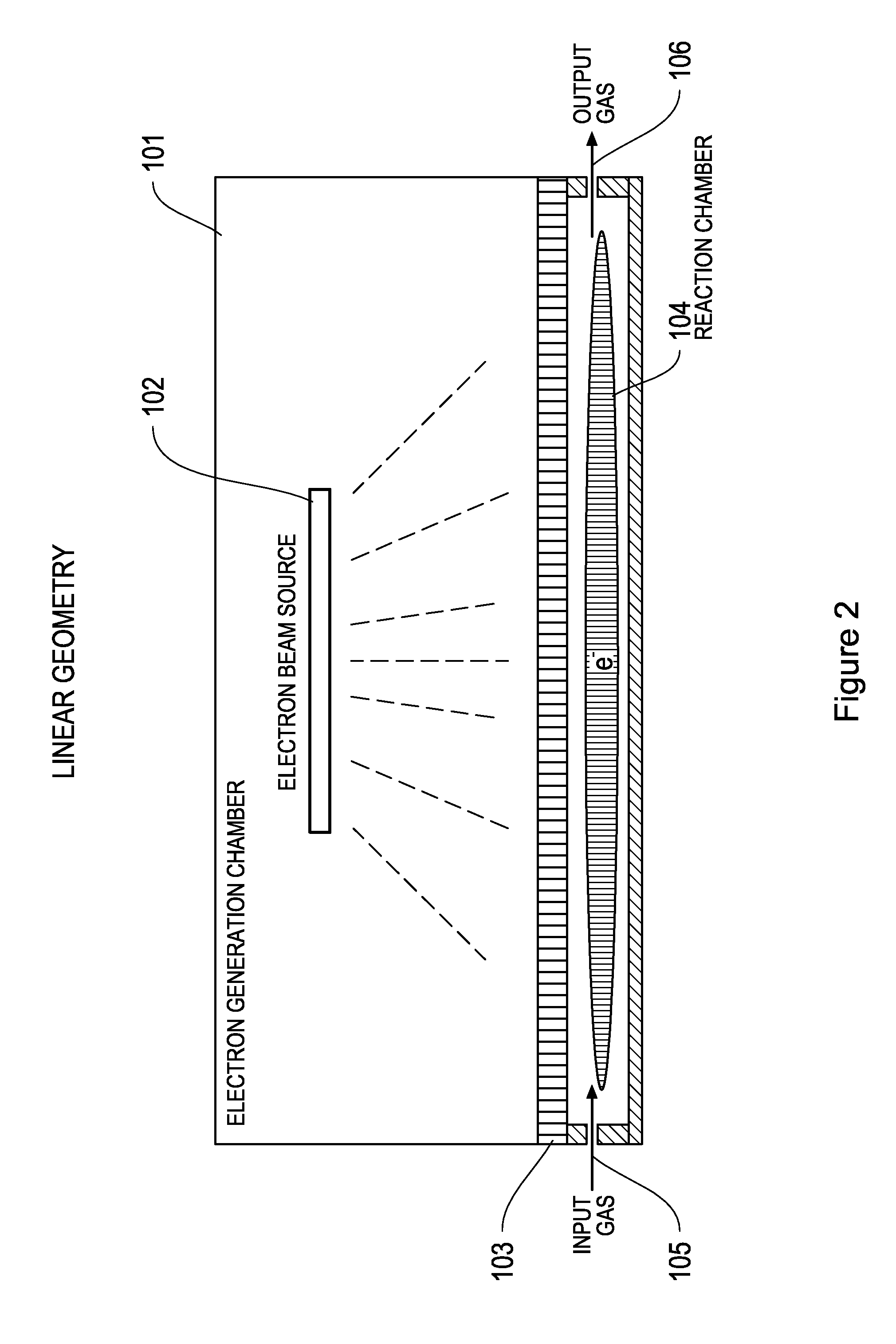

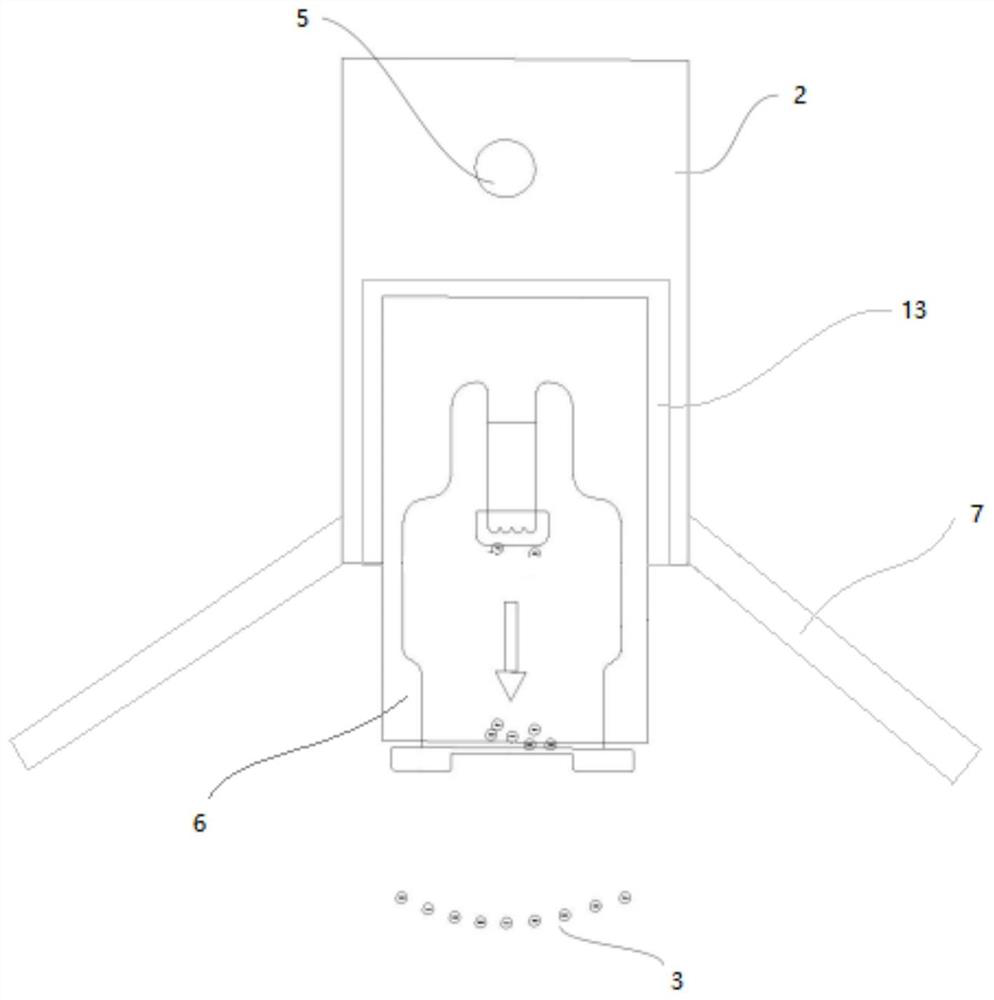

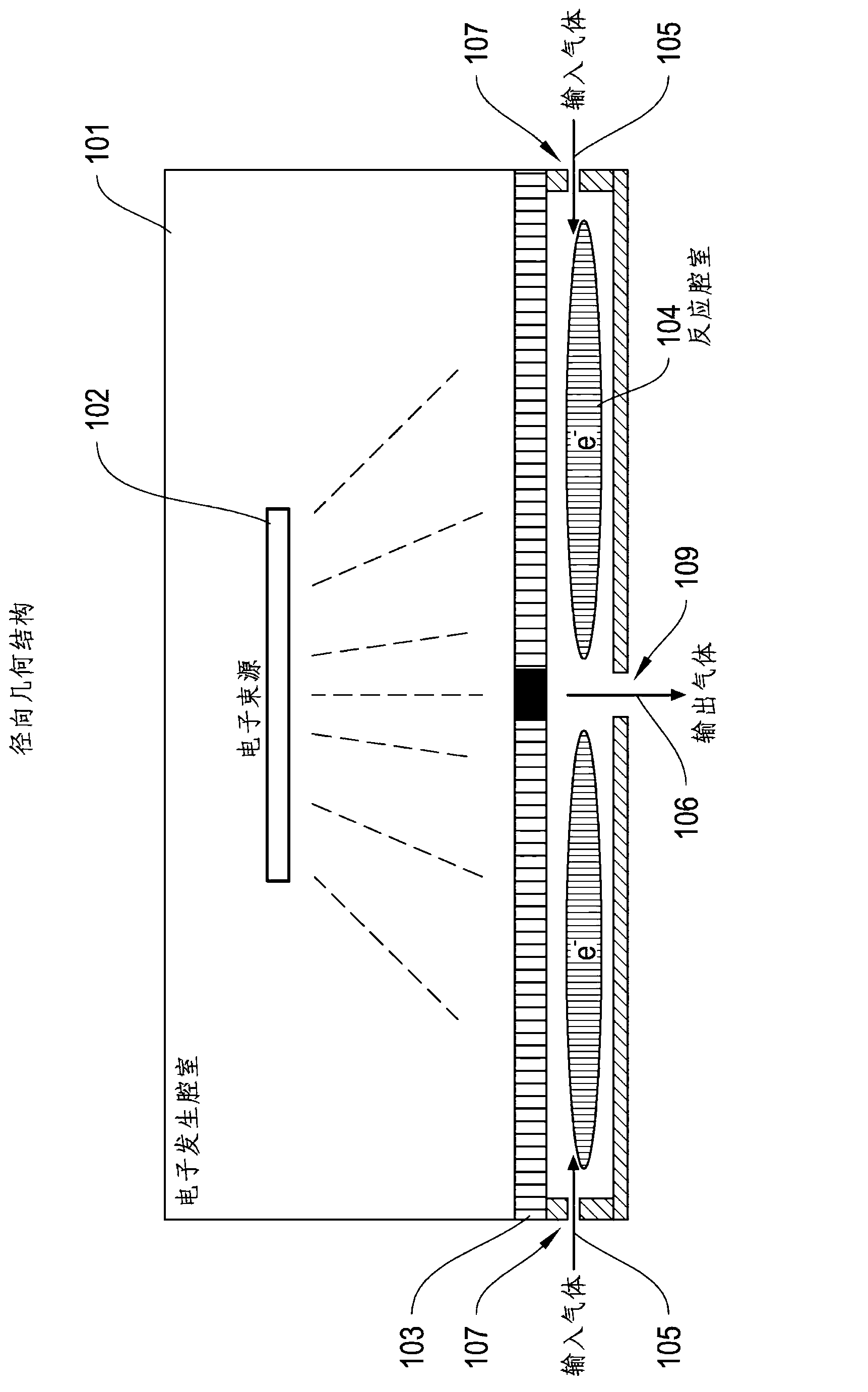

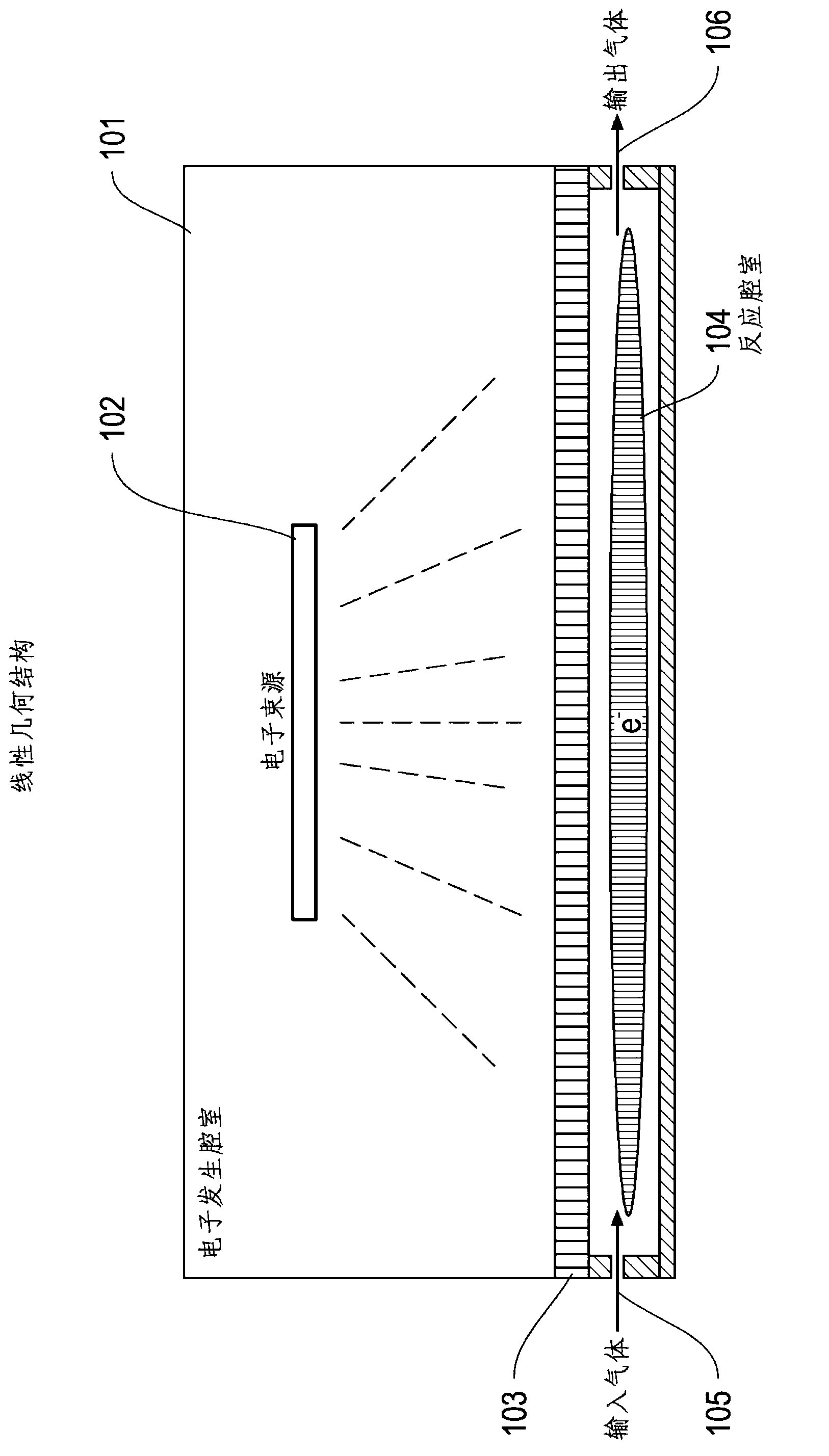

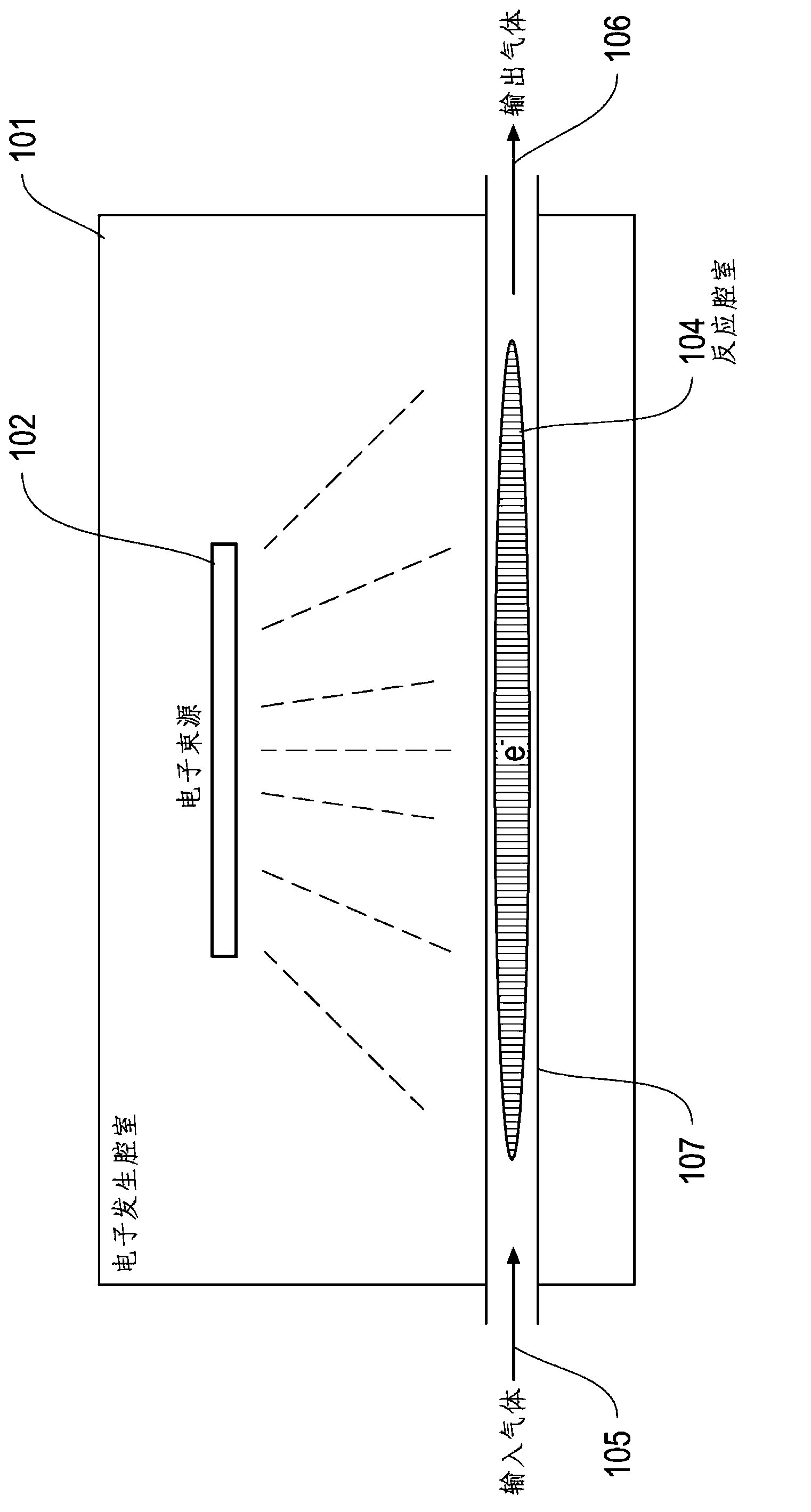

Ozone and plasma generation using electron beam technology

InactiveUS20130284587A1Electric discharge tubesDischarge tube electron gunsOzone generatorElectron-beam technology

This invention proposes, among other things, systems and methods for providing ozone generators or plasma generators that generate an electric field in an electron generation chamber that is separate from a reaction chamber. An electron beam emitter in an electron generation chamber is configured to emit a beam of electrons and is separated from the reaction chamber by an electron permeable barrier that provides a window through which the beam of electrons passes. The electrons are accelerated to the required energy in the electron generation chamber and transmitted through the barrier to the reaction chamber, where an input gas source introduces an input gas into the reaction chamber. The input gas may react with the beam of electrons inside the reaction chamber to form an output gas comprising a plasma or a concentration of ozone, and the output gas passes from the reaction chamber to a wafer processing chamber.

Owner:HITACHI ZOSEN CORP

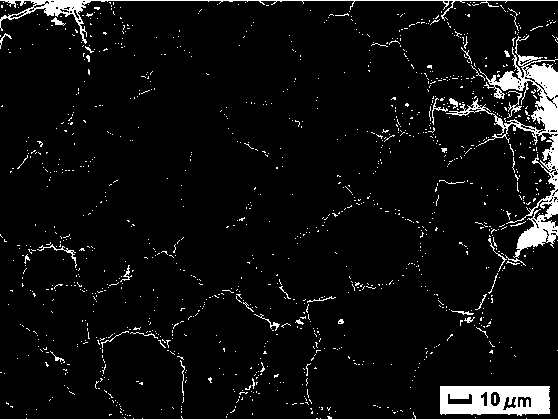

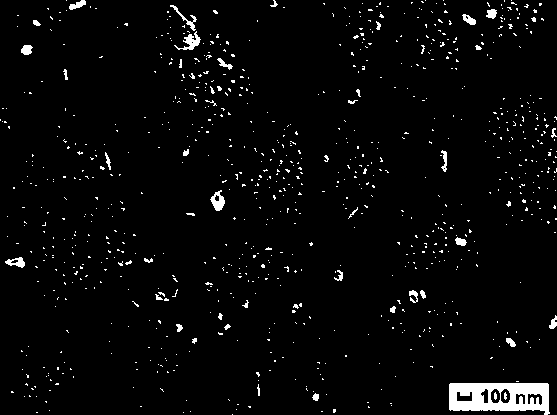

Laser cladding high-temperature protective coating surface polishing and purifying method based on pulsed electron beam technology

PendingCN110592592ASmall and dense tissueHigh bonding strengthMetallic material coating processesSuperalloyImpurity

The invention provides a laser cladding high-temperature protective coating surface polishing and purifying method based on a pulsed electron beam technology. The laser cladding high-temperature protective coating surface polishing and purifying method is characterized in that the pulsed electron beam technology is utilized to replace mechanical machining, pulsed electron beam polishing and purifying treatment is performed on a high-temperature protective coating prepared on the high-temperature alloy matrix surface by utilizing a laser cladding technology to remove a cladding layer surface oxide skin, machining defects are eliminated, and the laser cladding layer surface impurity, gap and dendritic segregation defects are further eliminated, cladding layer surface grains are refined, thepolished, purified and refined coating surface is obtained, and the cladding layer surface roughness is effectively reduced and the cladding layer high-temperature protective performance is improved.By means of the laser cladding high-temperature protective coating surface polishing and purifying method based on the pulsed electron beam technology, cladding layer surface grain ultrafining even nanoscale refining can be further realized, abundant deformation structures are generated, and then the cladding layer surface abrasive resistance, oxidation resistance and corrosion resistance are effectively improved.

Owner:JIANGSU UNIV

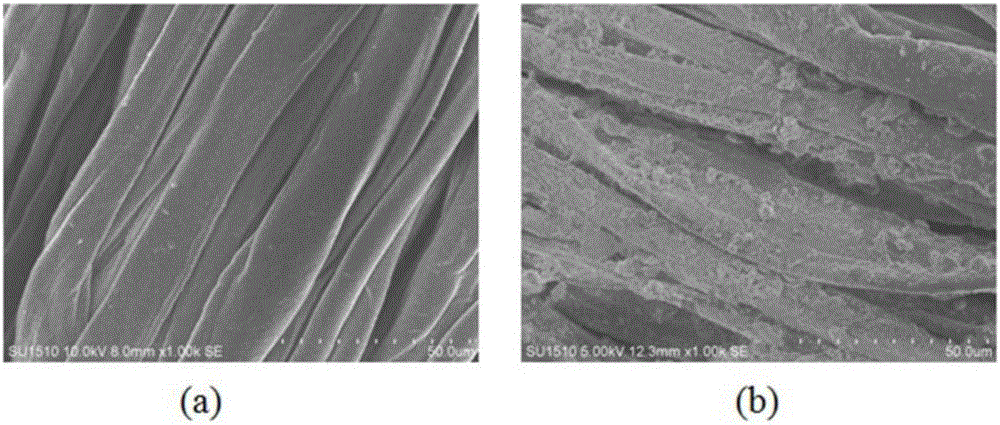

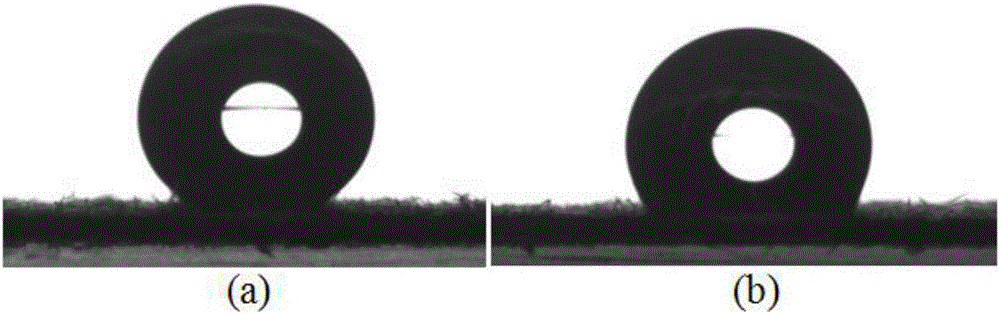

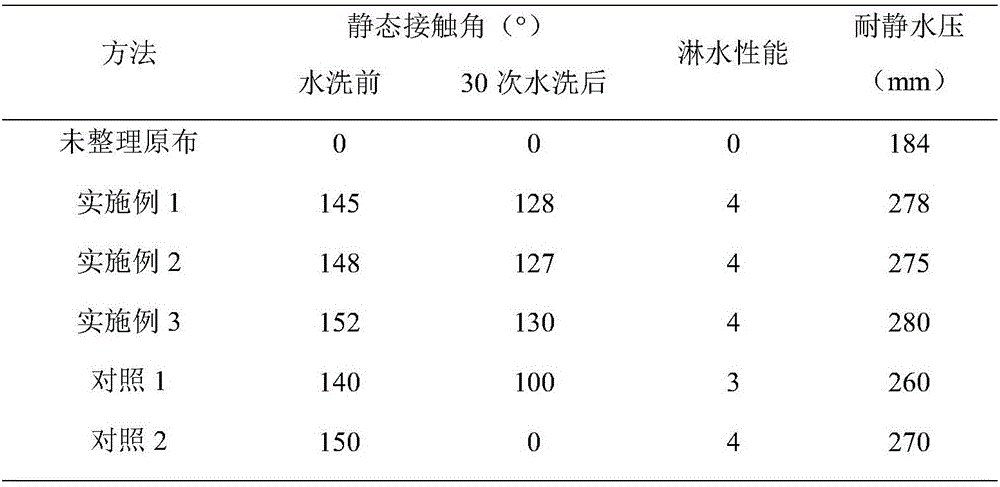

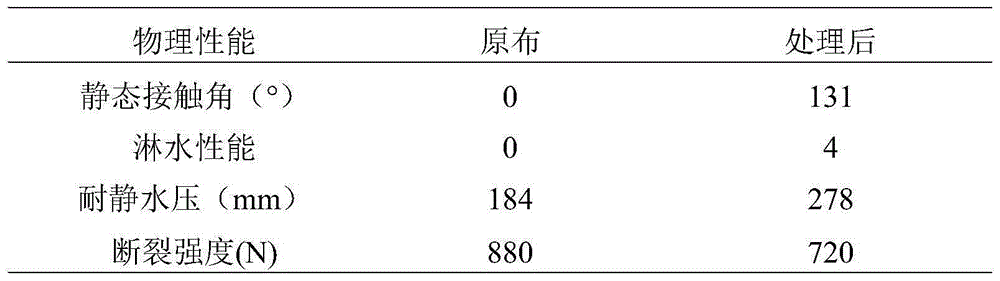

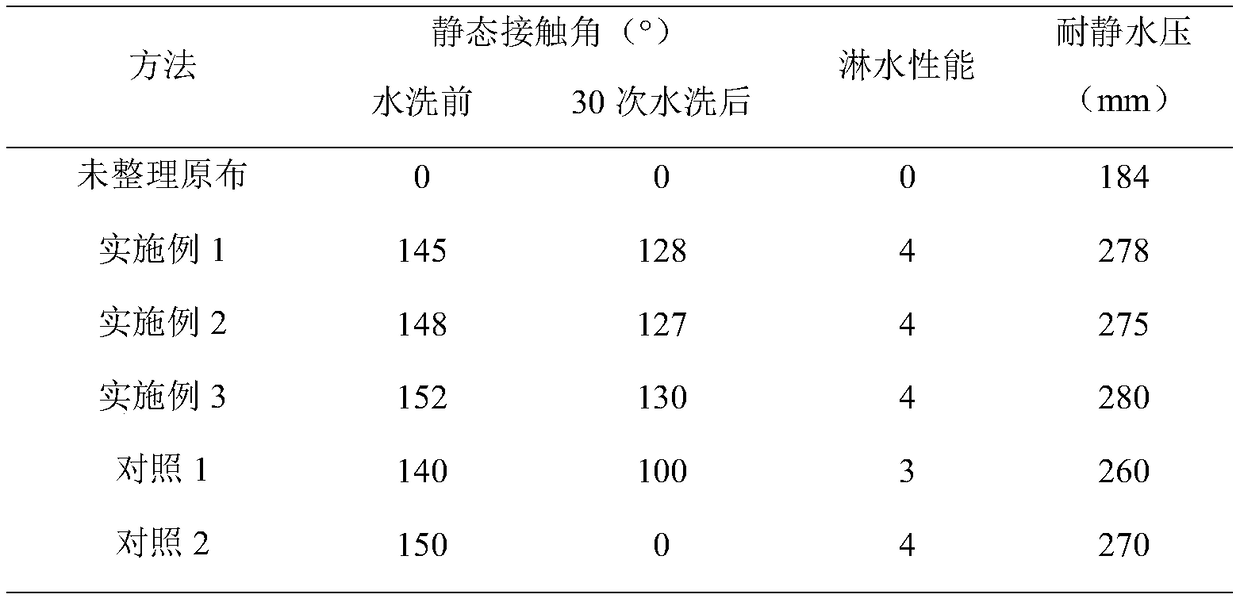

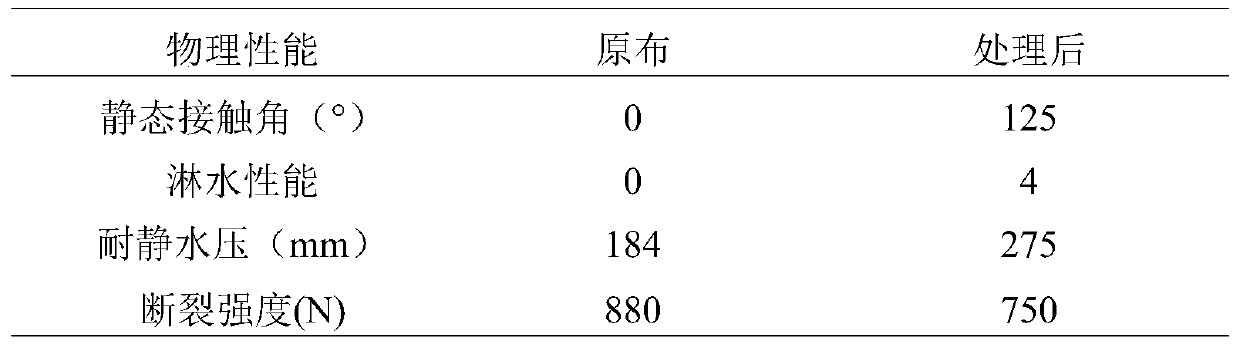

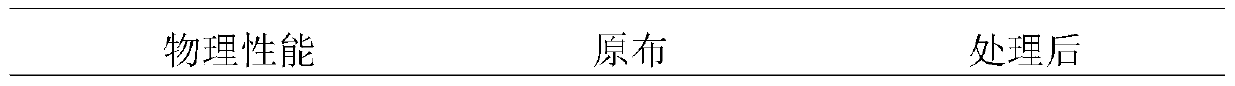

Cotton fabric hydrophobic finishing method based on acrylics-modified silicon ball-electron beam technology

ActiveCN106758215AReduce energy consumptionReduce pollutionFibre treatmentEngineeringSilicon dioxide

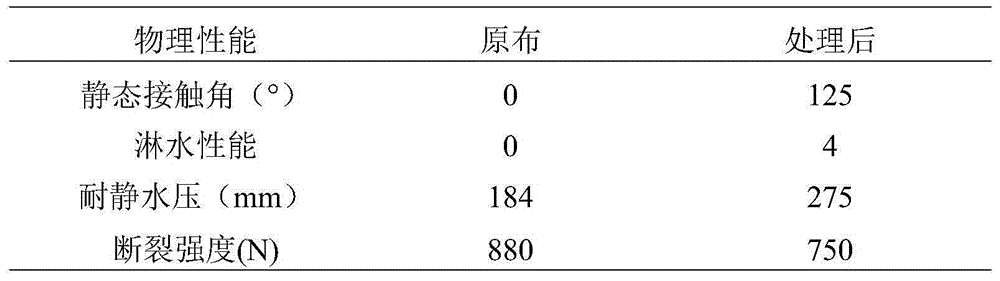

The invention discloses a cotton fabric hydrophobic finishing method based on an acrylics-modified silicon ball-electron beam technology, and belongs to the field of functional textiles. The method disclosed by the invention adopts an electron beam radiation technology, the method can react under room temperature, the energy consumption is low, an initiator does not need to be added, the reaction time is short, and the production cost can be obviously reduced; long-chain acrylic acid can be selected and used as monomers, so that the free energy of fabric surface can be obviously reduced, and meanwhile the environment-friendly problem easily generated by a fluorine-containing reagent is avoided; the roughness of the fabric surface can be improved through the addition of modified silicon dioxide, and meanwhile the problem, such as low adhesion caused by pure physical absorption, of silicon dioxide silicon balls is avoided. According to the method in which the lower surface energy is combined and the fabric surface roughness is improved, textiles with high hydrophobic performance are obtained through an electron beam one-step radiation graft polymerization technology.

Owner:高青如意纺织有限公司

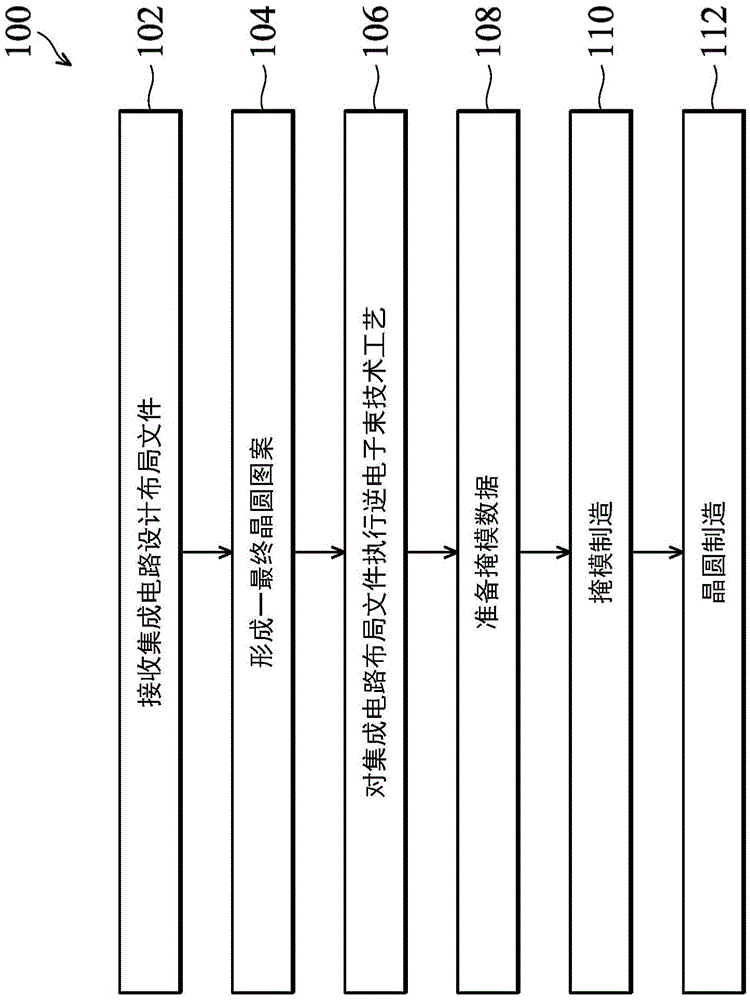

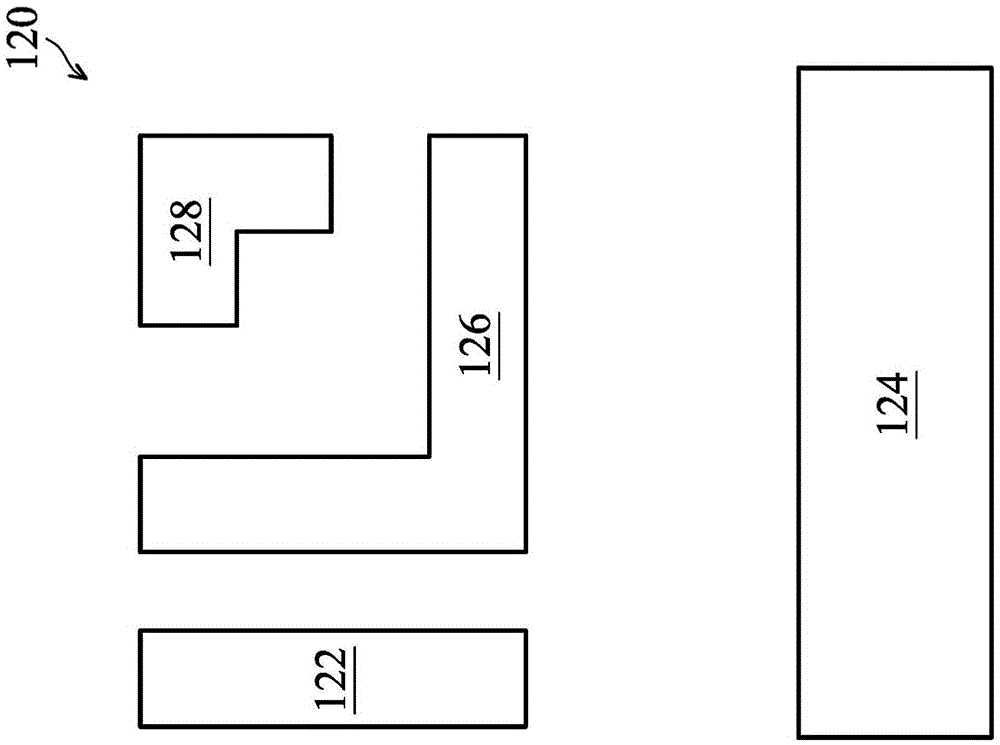

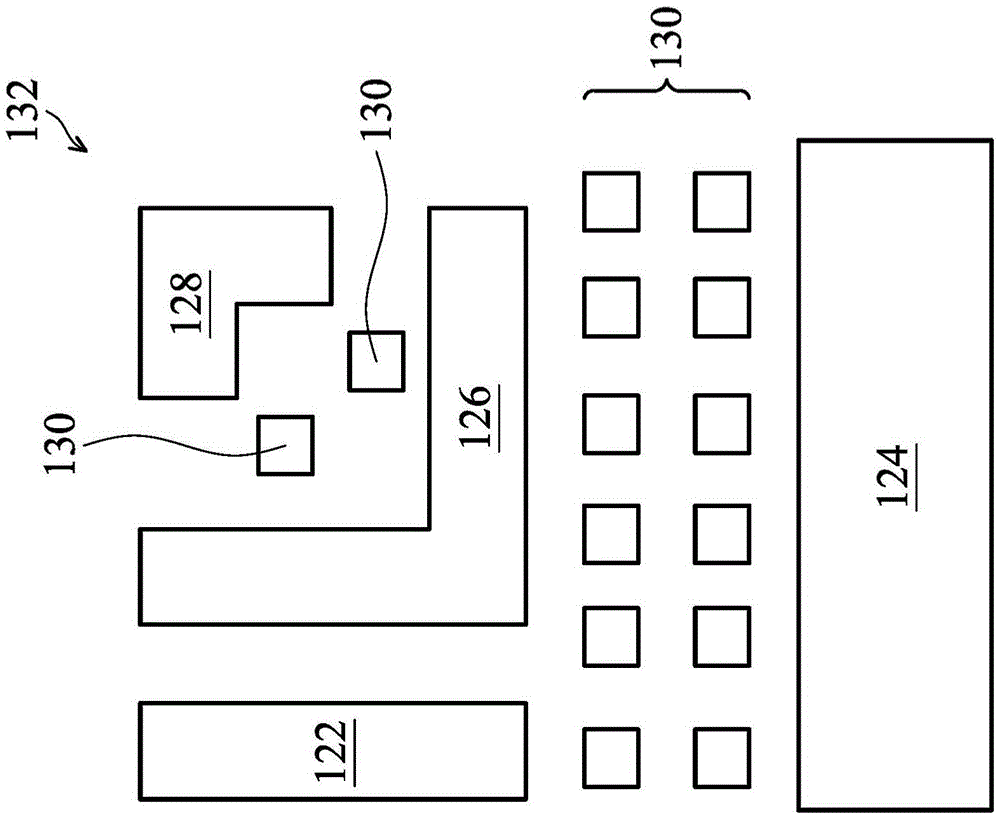

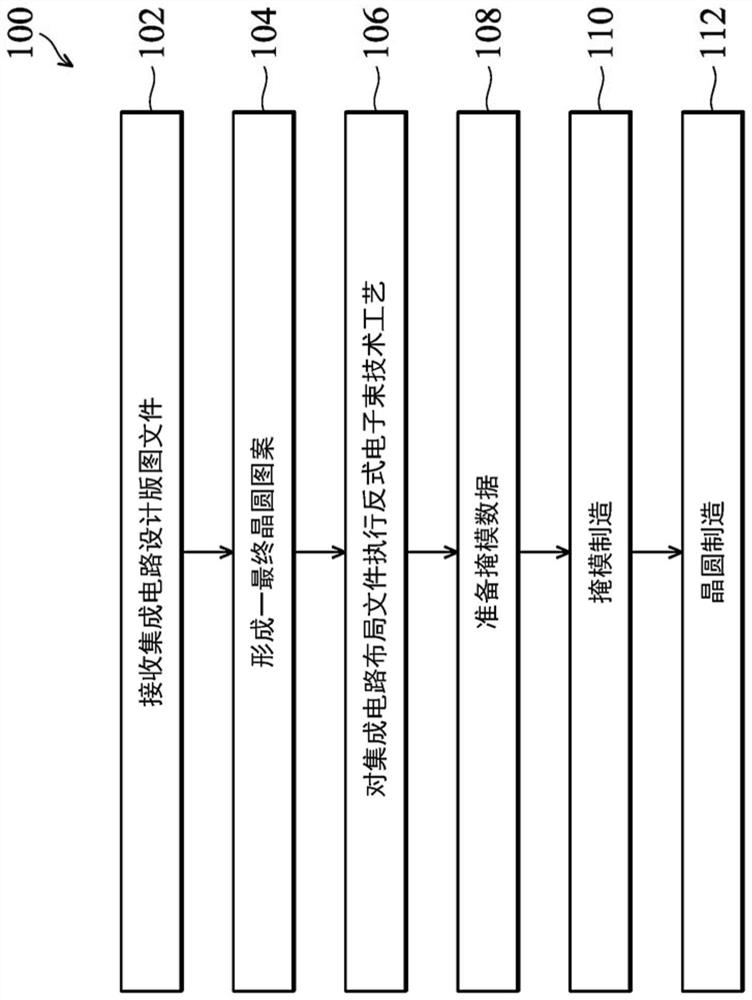

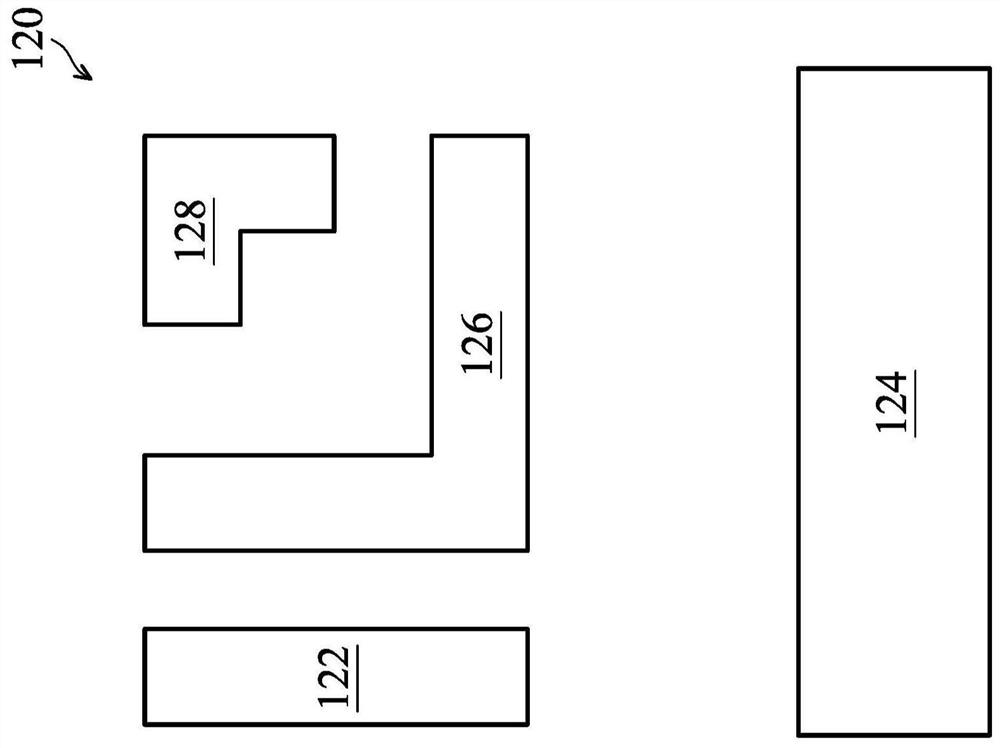

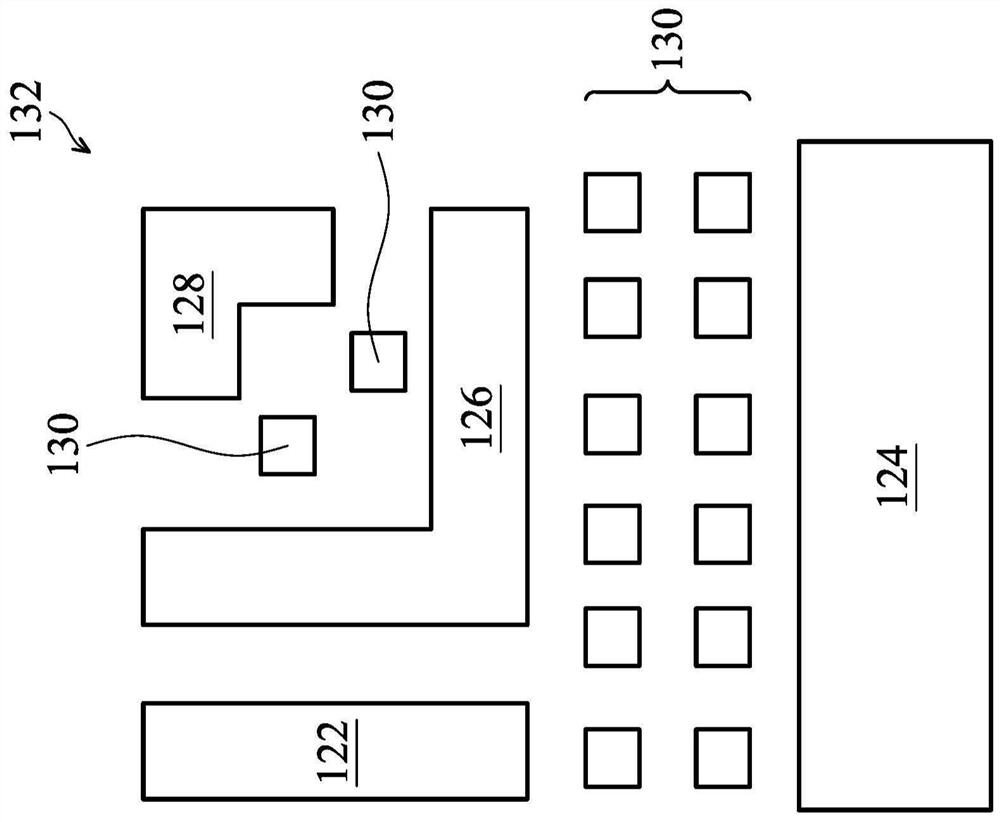

Integrated circuit method and integrated circuit design system

ActiveCN106469235APhotomechanical apparatusDesign optimisation/simulationElectron-beam technologyEngineering

The invention provides an integrated circuit method and an integrated circuit design system. The integrated circuit (IC) method includes receiving an IC design layout; and performing an inverse beam technology (IBT) process to the IC design layout, thereby generating a final mask pattern, wherein the IBT process uses a single IBT model to simulate both a mask making process and a wafer making process.

Owner:TAIWAN SEMICON MFG CO LTD

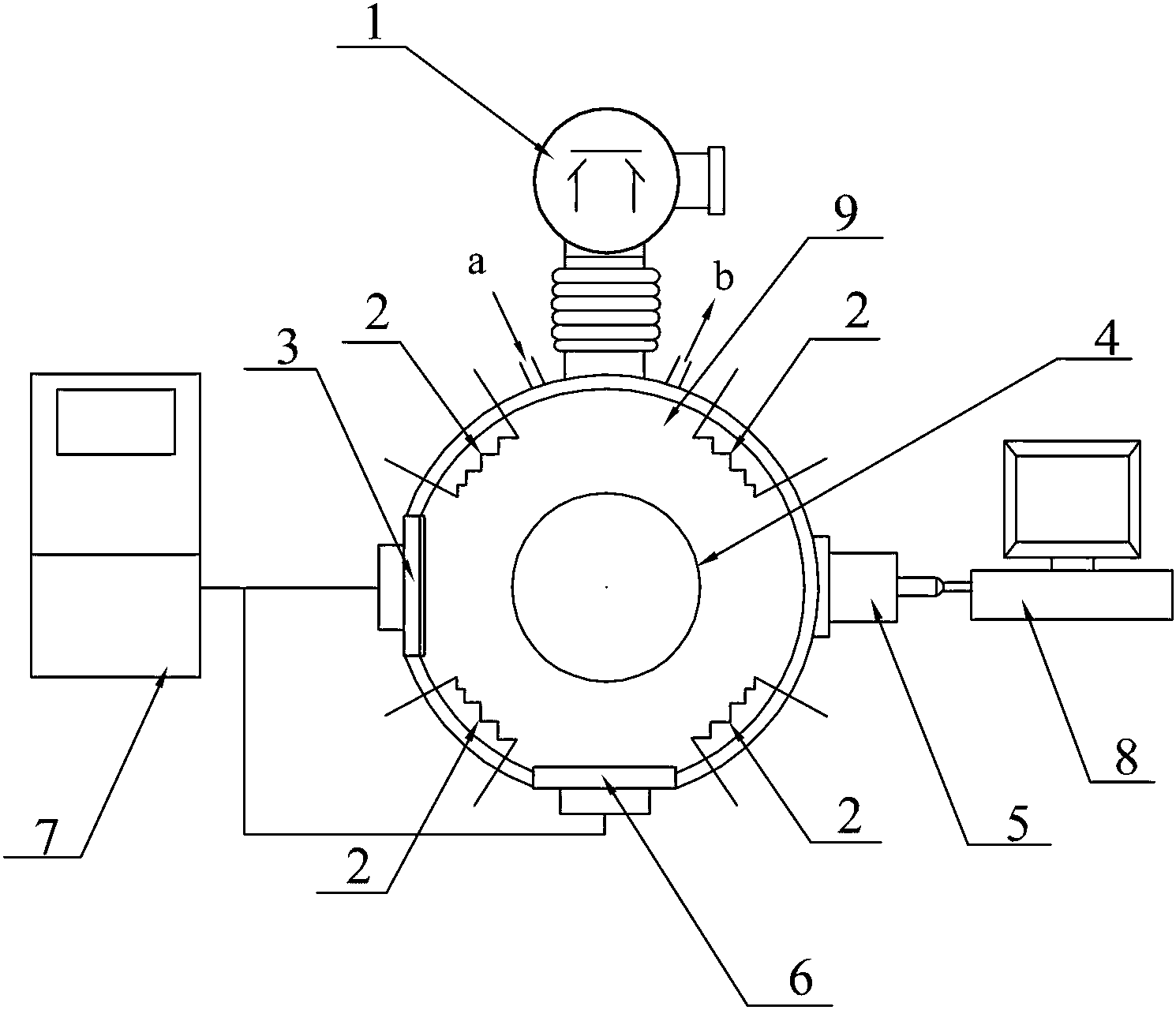

Device and method for preparing hard carbide ceramic coating based on composite treatment of large-area high-current pulsed electron beam

ActiveCN102936714ASolve binding problemsPrevent oxidationVacuum evaporation coatingSputtering coatingElectron-beam technologyCeramic coating

The invention provides a device and a method for preparing a hard carbide ceramic coating based on composite treatment of a large-area high-current pulsed electron beam, and relates to a device and a method for preparing the hard carbide ceramic coating, solving the problem that the conventional large-area high-current pulsed electron beam technology can not be used for ceramic coating treatment because the coating is subjected to arc discharge to be damaged due to charge accumulation effect when performing electronic beam irradiation treatment on the ceramic coating. The device is characterized in that a vacuum pump set is connected with a vacuum chamber; a rotary sample platform is placed in the vacuum chamber; a metal target is placed at one side opposite to the vacuum pump set; a graphite target and an electronic gun are correspondingly arranged; and four heaters are uniformly distributed on an inner wall of the vacuum chamber. The method comprises the following steps: placing a pre-processed component to be processed on the rotary sample platform to be opposite to the graphite target and the metal target; coating N layers of films, and then irradiating by the electronic gun; and heating by the heater to execute returns processing; and then maintaining the temperature and cooling, thus accomplishing the preparation. The device and method are applicable to the field of material surface treatment.

Owner:HARBIN INST OF TECH

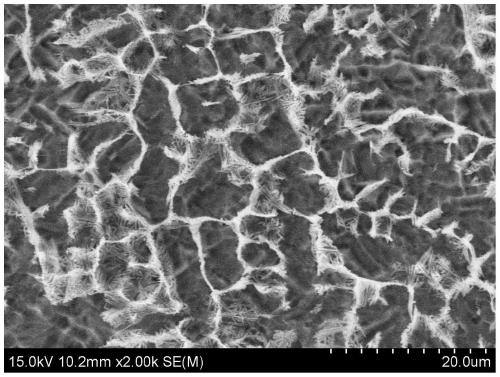

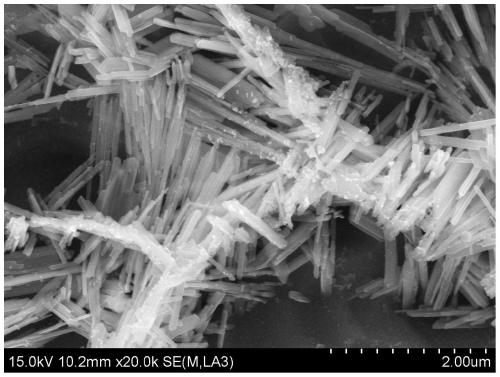

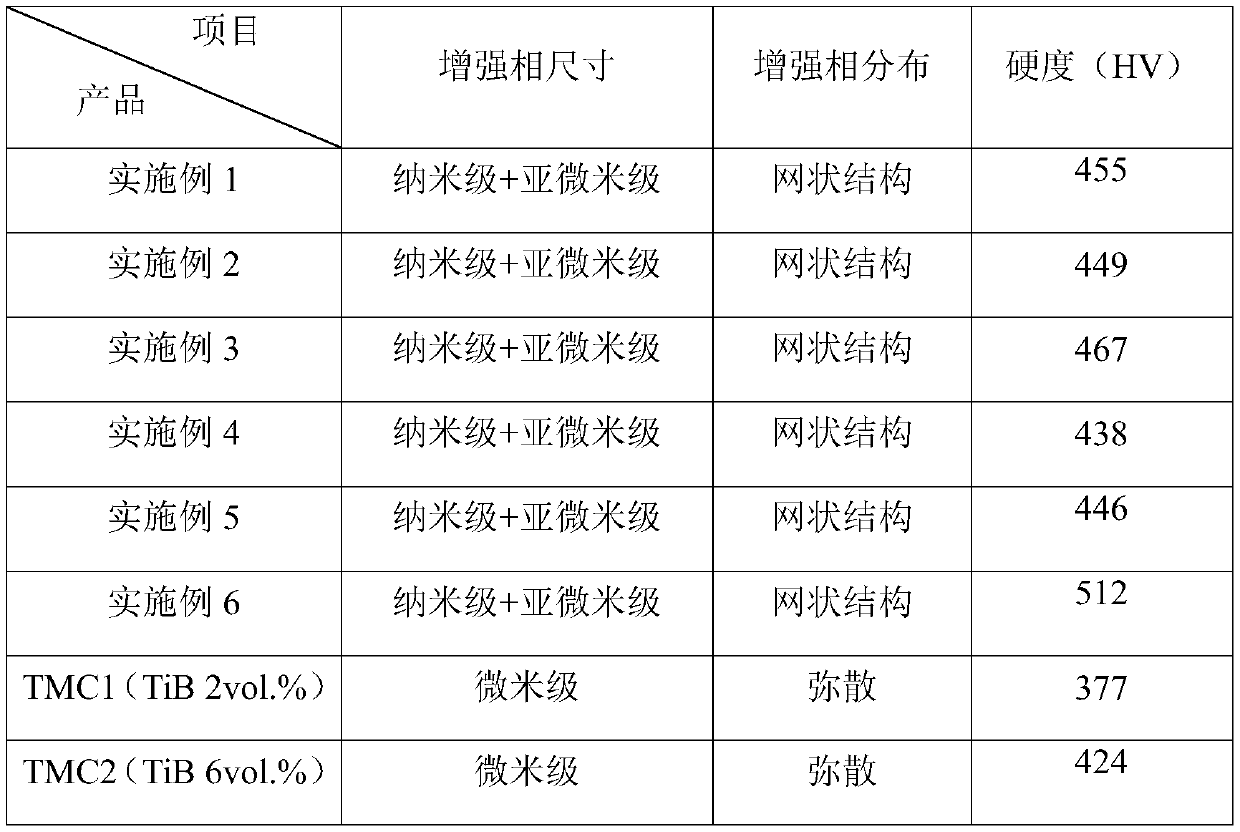

Reinforced phase regulation and control method for TiB reinforcing titanium-based composite

ActiveCN108531777AImprove mechanical propertiesFlexible processTitanium matrix compositesElectron-beam technology

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cotton fabric hydrophobic finishing method based on acetic anhydride-acrylics-electron beam technique

The invention discloses a cotton fabric hydrophobic finishing method based on acetic anhydride-acrylics-electron beam technique and belongs to the field of functional textiles. According to the method, cotton fiber is esterified with acetic anhydride firstly, and then cotton fabric is treated with an acrylic reagent dissolved in an alcohols solvent by means of electron beams, so that textiles with hydrophobic property are obtained. Compared with alkanes or olefin solvents, the alcohols solvent has the advantages of being low in toxicity, low in irritation, low in cost and the like. By the adoption of the method, environment problems caused by perfluorinated hydrophobic auxiliaries can be avoided, chemical bonding between fiber macromolecules and functional macromolecules can be achieved through electron beam irradiation, an obtained product is high in uniformity and repeatability and low in cost, and the degree of damage to fabric is low. The method can be used for hydrophobic finishing of cotton fabric.

Owner:高青如意纺织有限公司

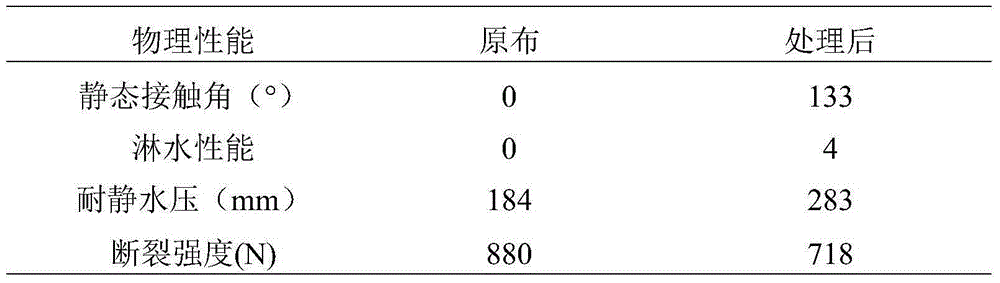

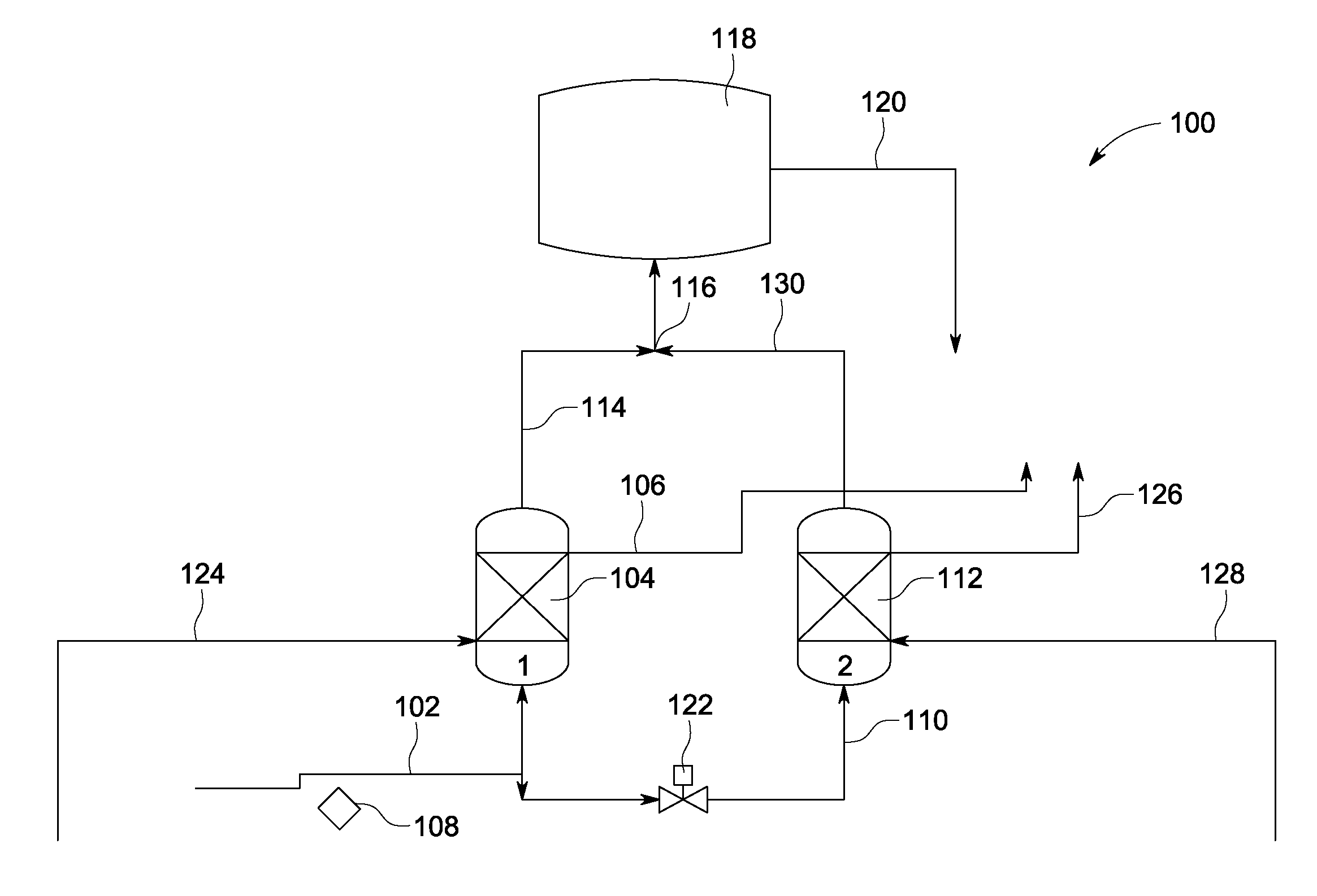

E-beam technology for water treatment

InactiveUS20120267310A1Water treatment parameter controlSpecific water treatment objectivesElectron-beam technologyOrganic matter

The present invention concerns a method of using Electron-beam technology to remove recalcitrant organic matter and / or volatile organic compounds from a target water sample or other fluid samples. A fluid is directed into a first vessel; and a beam of electrons from an electron beam generator is used to irradiate the fluid. Specifically, once the water is loaded into a first vessel and the organic contaminants are absorbed to saturation levels, a control sensor initiates influent water to be directed to a second vessel while the first vessel is isolated and desorbed using an energy means such as heat or microwave. The desorbed materials are directed through a common manifold containing an E-beam. The E-beam is then used to destroy organic matter desorbed from the first vessel. VOCs may be treated in this way as well, or they may be treated directly without first sorbing and desorbing prior to irradiation.

Owner:GENERAL ELECTRIC CO

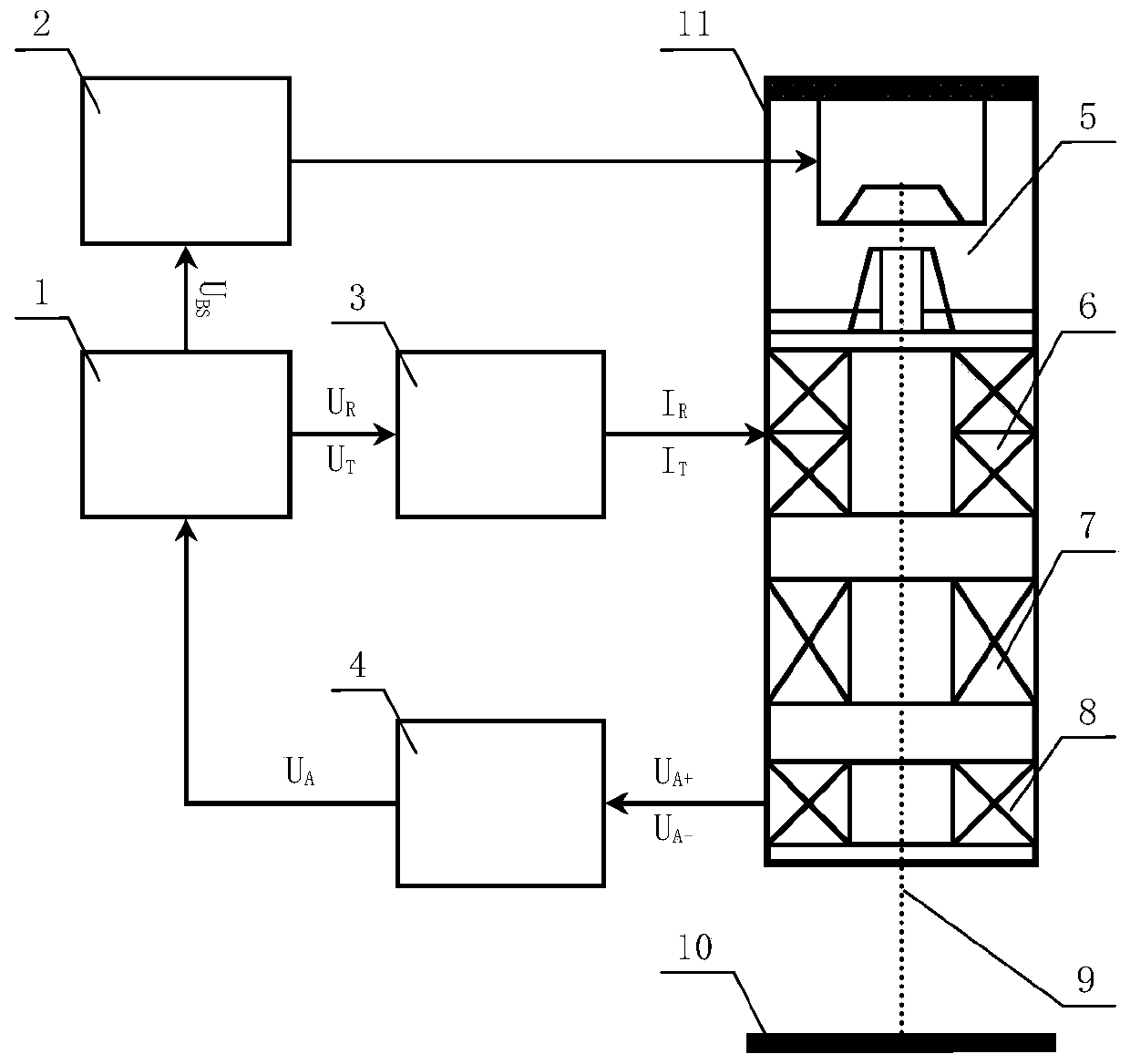

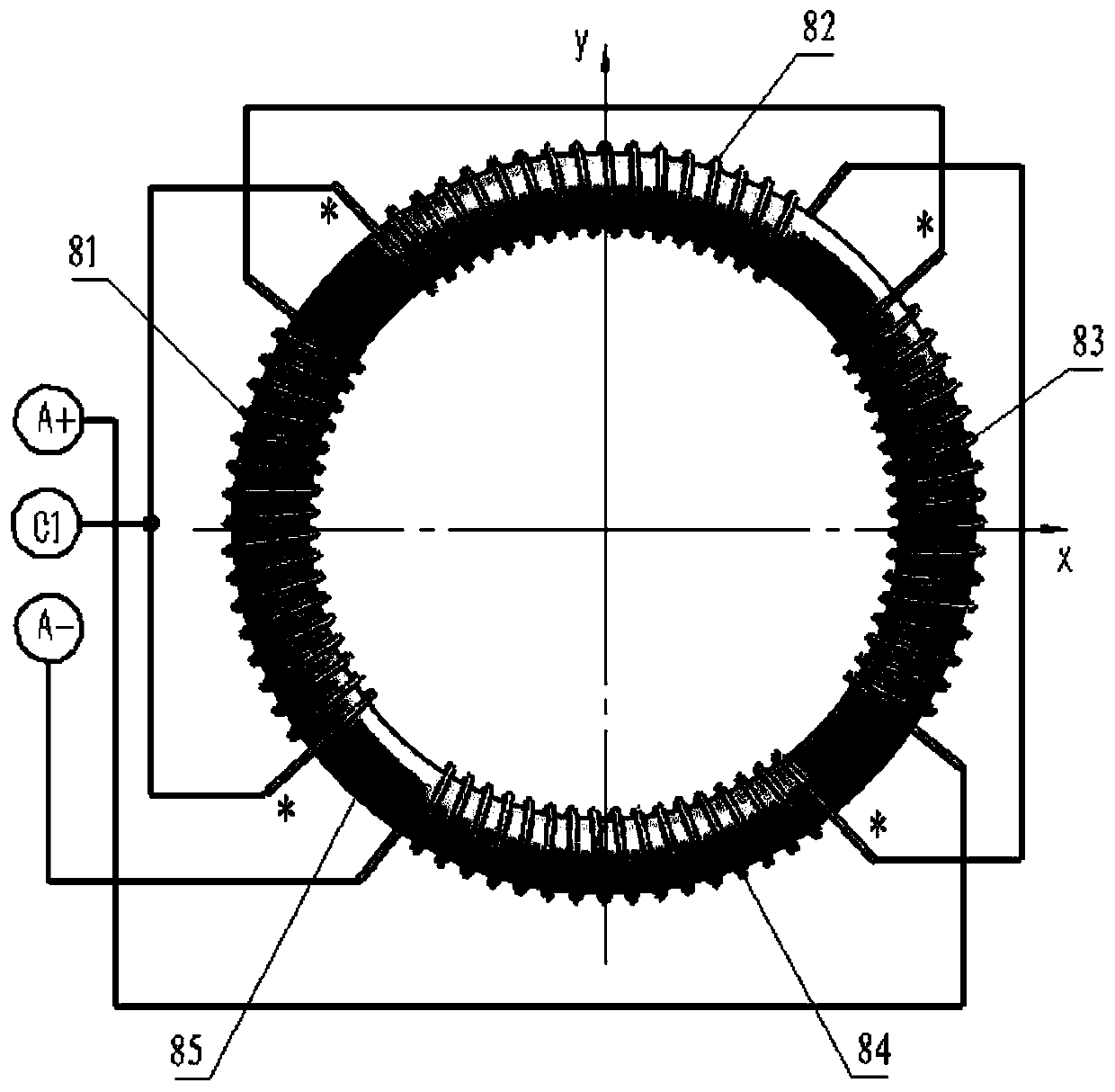

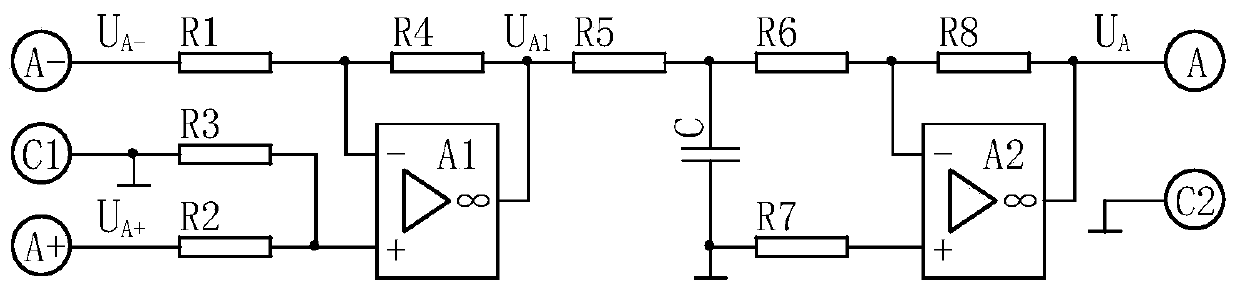

Automatic astigmatism eliminating electronic gun and automatic astigmatism eliminating method of electronic gun

PendingCN111477529AEasy to correctAdditive manufacturing apparatusElectrode and associated part arrangementsElectron-beam technologyExcitation current

The invention discloses an automatic astigmatism eliminating electronic gun and an automatic anastigmatism method of an electron gun, which adopt a split Rogowski coil as a detection element and combine a pulsed electron beam technology to realize the non-contact detection of the spot morphology of an electron beam. The split Rogowski coil outputs differential mode signals and takes the minimum value of detection signals as a correction target of the astigmatism elimination device, so that the processing mode of the detection signals is simplified, the influence of common-mode interference signals is eliminated, and the detection sensitivity and precision are improved. And the exciting current of the optimal astigmatism eliminating device is searched for in a split-axis mode, and rapid searching is achieved. The weighted value of the amplitude and the average value of the detection signal can fully reflect the difference of the electron beam spot morphology, the weighted value comprehensive data is used as the judgment basis, the optimal value is searched and confirmed for two rounds, the reliability is further improved, and the randomness is further reduced.

Owner:GUILIN THD TECH CO LTD

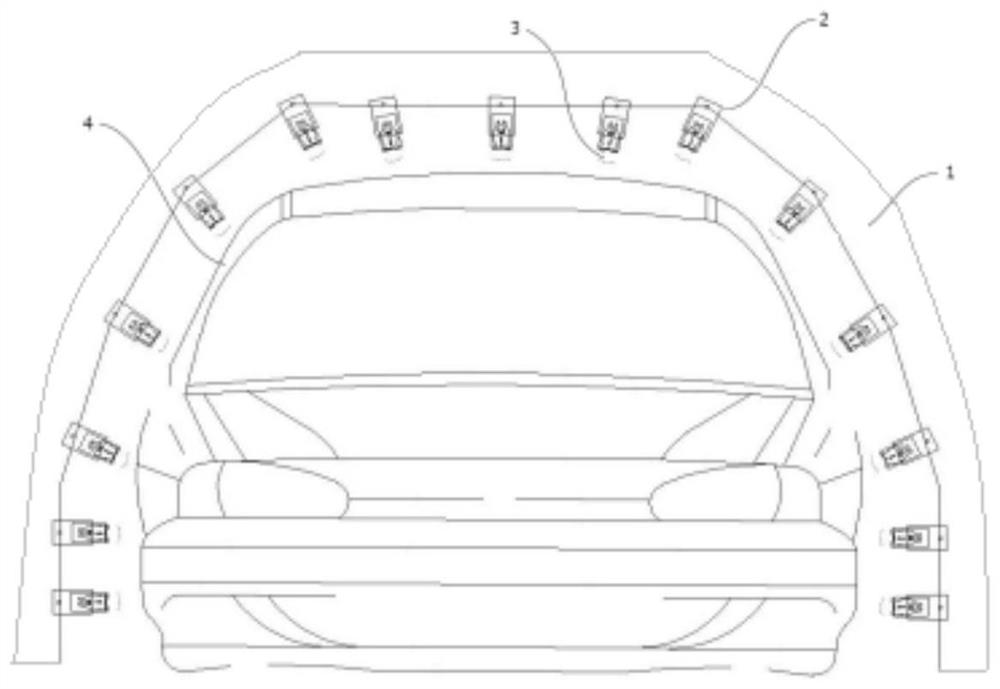

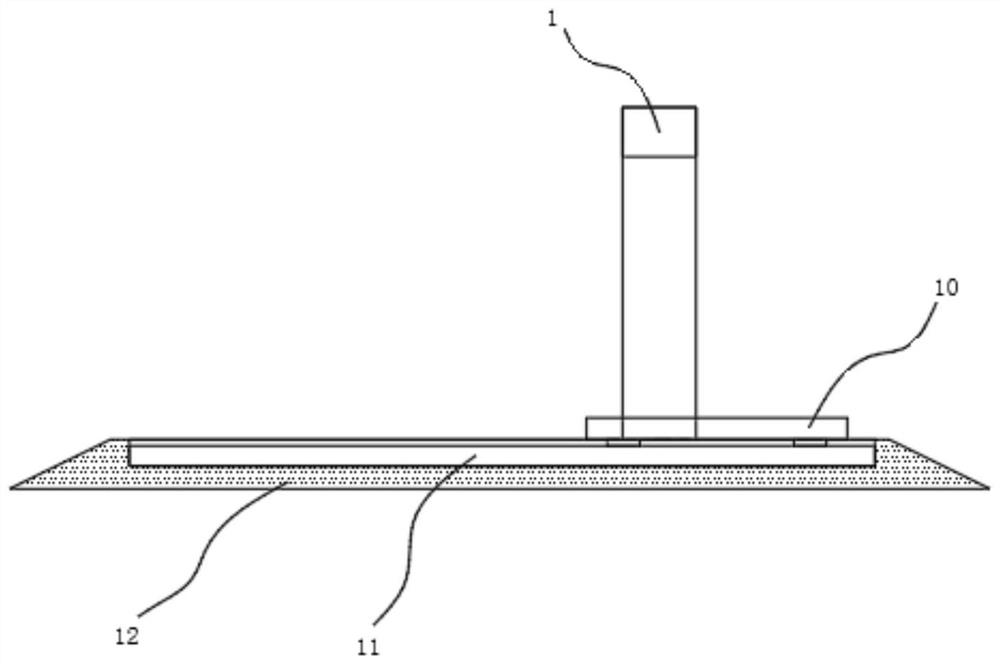

Electron beam paint quick-drying device and using method thereof

PendingCN114833051AImprove efficiencyStrong persistencePretreated surfacesCoatingsElectron-beam technologyUV curing

The invention belongs to the technical field of electron beams, particularly relates to an electron beam paint quick-drying device and a use method thereof, and provides the following scheme aiming at the problems of low paint curing efficiency and poor durability when paint is subjected to quick-drying treatment in an existing UV curing mode: the electron beam paint quick-drying device comprises a supporting base, and a gantry bracket is fixedly arranged at one end of the supporting base; a plurality of equidistant mounting grooves are formed in the inner wall of the gantry support, mounting shells are arranged on the inner walls of the mounting grooves, an automobile shell is arranged in an annular opening of the gantry support, electron beam sources are arranged on the inner walls of the adjacent ends of the mounting shells, and electron beams are reflected by the electron beam sources. According to the invention, when electron beams bombard the surface of the paint, a specific chemical reaction can be generated, so that the paint is rapidly cured, and compared with UV curing and electron beam curing in the current market, the method has the advantages of high efficiency, stronger durability and more environmental protection.

Owner:HUZHOU ADVANCED ELECTRONIC TECH CO LTD

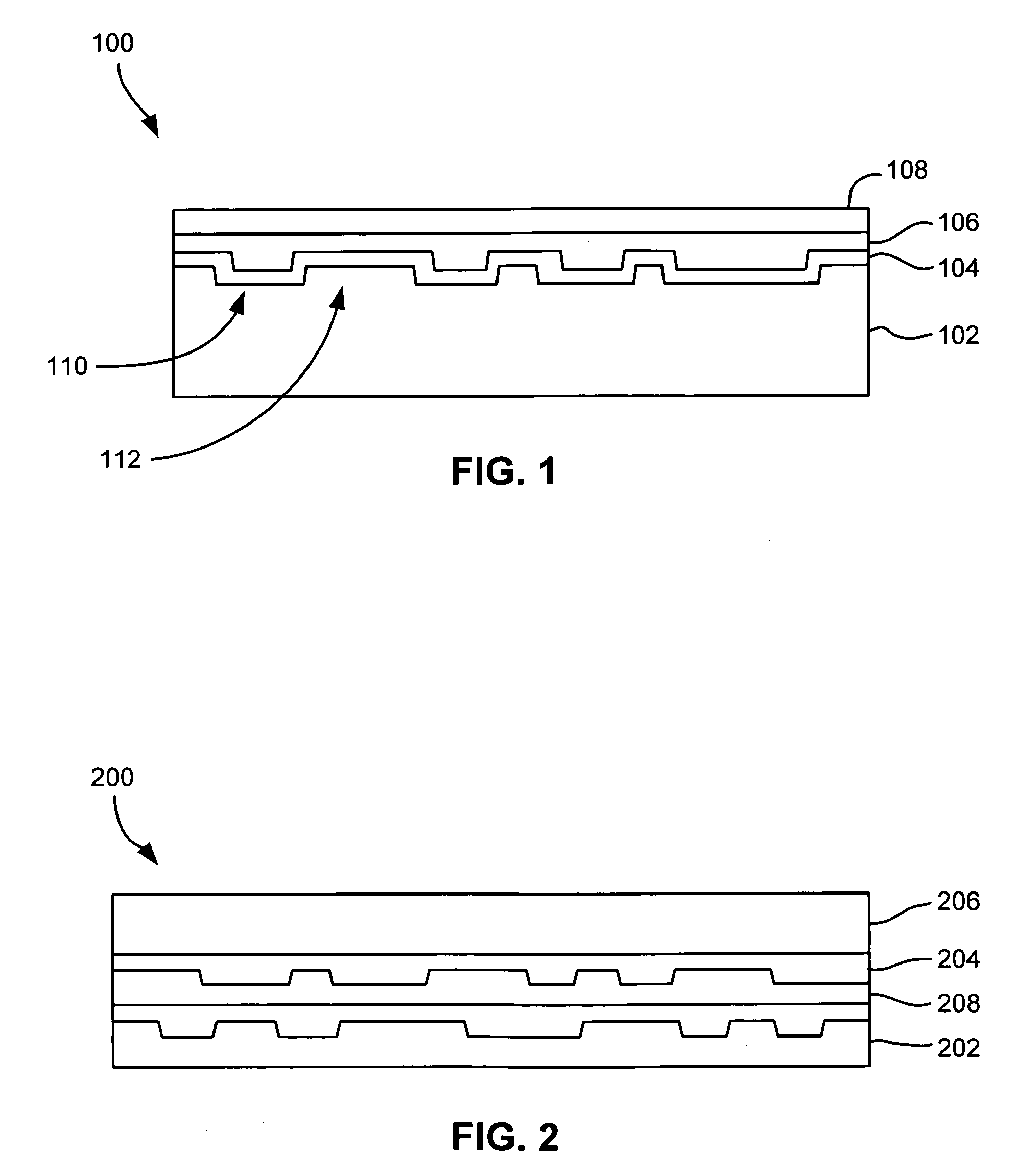

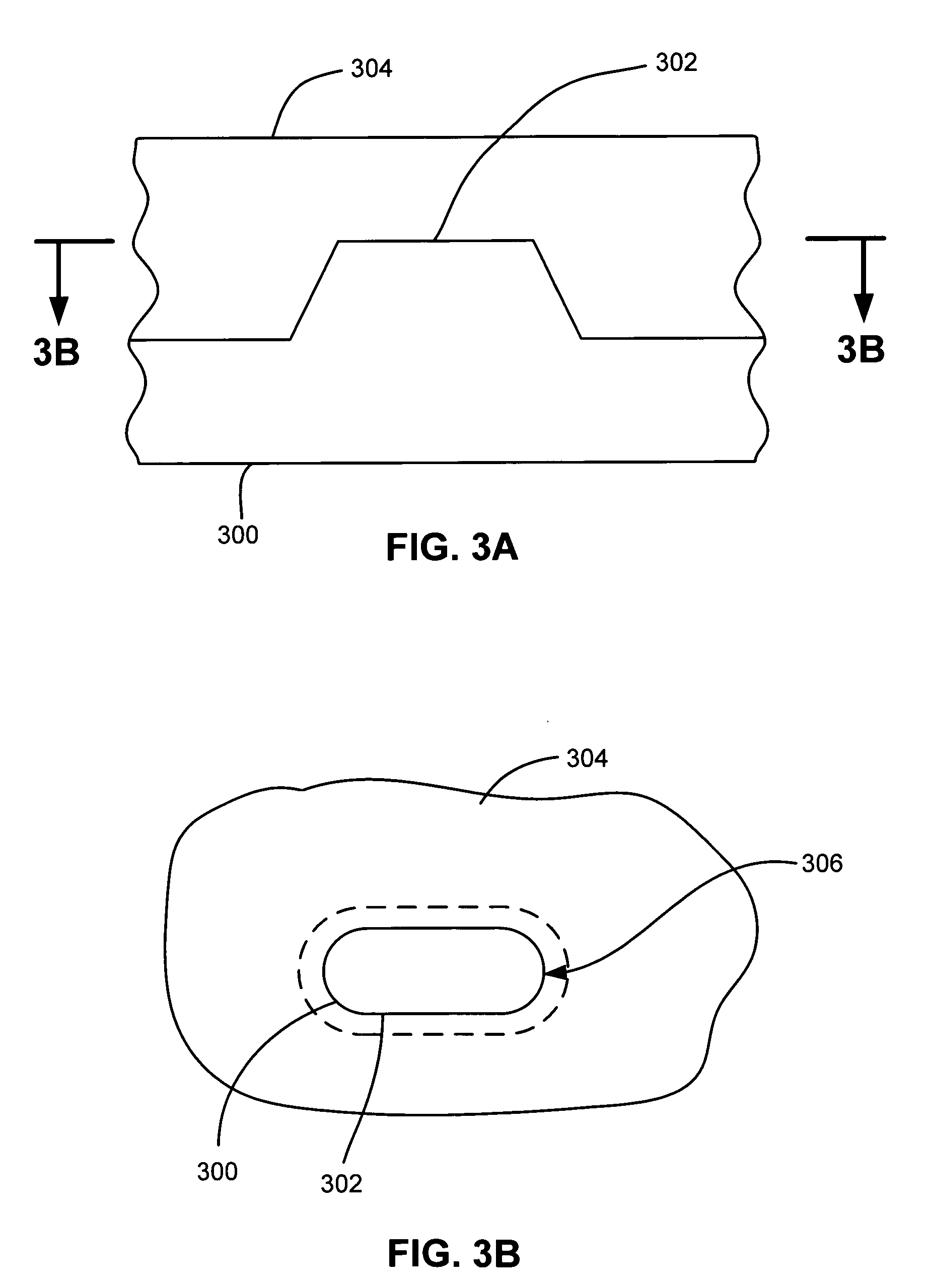

Fabrication of digital media using electron beam technology

InactiveUS20060018238A1Data storable can be greatly improveData augmentationElectron beam carrier recordingRecord information storageElectron-beam technologyElectron source

A method for writing data to an optical medium includes directing intermittent pulses of a beam of electrons from an electron source onto an optical medium in a controlled pattern for creating surface features on the optical medium, the surface features representing data. A system for performing this method, according to one embodiment, includes a medium receiving portion for holding an optical medium, an electron source for emitting a beam of electrons at the optical medium on the medium receiving portion, and a steering mechanism for directing the electron beam onto the optical medium in a controlled manner. The beam of electrons strikes the optical medium in intermittent pulses for creating surface features on the optical medium, the surface features representing data.

Owner:MARSHALL CHARLES

Stress mitigation method for tc4 titanium alloy additive manufacturing components based on dual electron beams

ActiveCN105798301BIncrease stressAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyMetallic materials

The invention discloses a method for stress slowing release of TC4 titanium alloy additive manufacturing components based on double electron beams, and specifically refers to a method for controlling stress slow release of large-sized TC4 titanium alloy additive manufacturing components based on double electron beams, which relates to additive manufacturing field of manufacturing technology. The invention consists of the establishment and correction of the double electron beam temperature field model in step A, and the wire filling additive manufacturing in step B by using the double electron beams. The invention uses dual electron beam technology to control the phase transition in real time during the additive manufacturing process, and realizes the slow release of the stress of the large-scale TC4 titanium alloy additive manufacturing component by controlling the phase transition to improve the overall plasticity of the component. It is a large-scale TC4 The key technical problems in the manufacture of titanium alloy additive manufacturing components provide a new method, which improves the application potential of additive manufacturing technology in aviation, aerospace, petroleum, chemical industry, metallurgy and other fields, and provides a new method for additive manufacturing of other metal materials. Theory and technical guidance.

Owner:SHANGHAI UNIV OF ENG SCI

Electron beam thermosetting resin 3D printing and application thereof

PendingCN110466150ARealize developmentImprove qualityManufacturing enclosuresManufacturing environment conditioningMicro nanoElectron-beam technology

The invention discloses a method for realizing 3D printing by using an electron beam thermosetting resin material. Resin is conventional thermosetting resin, a heat source is a fine micro-nano array electron beam source specially applied to rapid curing of the thermosetting resin; as for the resin fully paved with substrates, an electron beam heating source is controlled by adopting single fine electron beam quick scanning or large-area electron beam sources, switches or other mechanical means, thermal curing of the resin is achieved, and next-layer resin coating, full tiling and selective thermal curing are carried out, and a 3D printing process is achieved. A current thermosetting 3D printing technology cannot meet the high-precision 3D printing requirement; a high-precision 3D printinglight-curing 3D printing technology is achieved, photocurable resin or an optical system are expensive, and widespread application and popularization are difficult to achieve. The method achieves fine3D printing of the thermosetting resin, and the electron beam technology is applied to a 3D printing process of the resin material.

Owner:PERA

Ozone and plasma generation using electron beam technology

InactiveCN103262220AElectric discharge tubesSemiconductor/solid-state device manufacturingElectron-beam technologyPlasma generator

This invention proposes, among other things, systems and methods for providing ozone generators or plasma generators that generate an electric field in an electron generation chamber that is separate from a reaction chamber. An electron beam emitter in an electron generation chamber is configured to emit a beam of electrons and is separated from the reaction chamber by an electron permeable barrier that provides a window through which the beam of electrons passes. The electrons are accelerated to the required energy in the electron generation chamber and transmitted through the barrier to the reaction chamber, where an input gas source introduces an input gas into the reaction chamber. The input gas may react with the beam of electrons inside the reaction chamber to form an output gas comprising a plasma or a concentration of ozone, and the output gas passes from the reaction chamber to a wafer processing chamber.

Owner:HITACHI ZOSEN CORP

A method for regulating the reinforcement phase of tib-reinforced titanium-based composites

ActiveCN108531777BImprove mechanical propertiesFlexible processTitanium matrix compositesElectron-beam technology

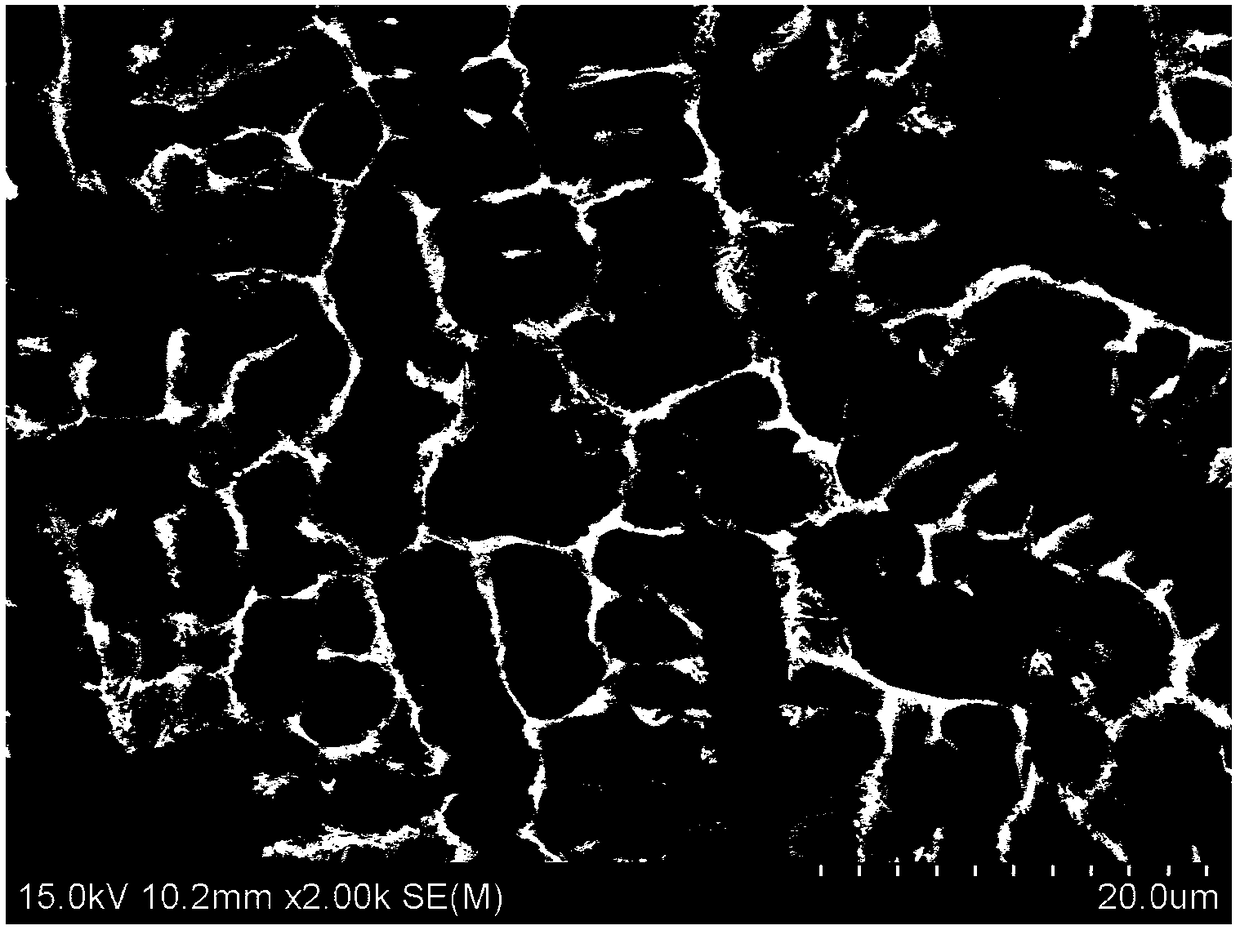

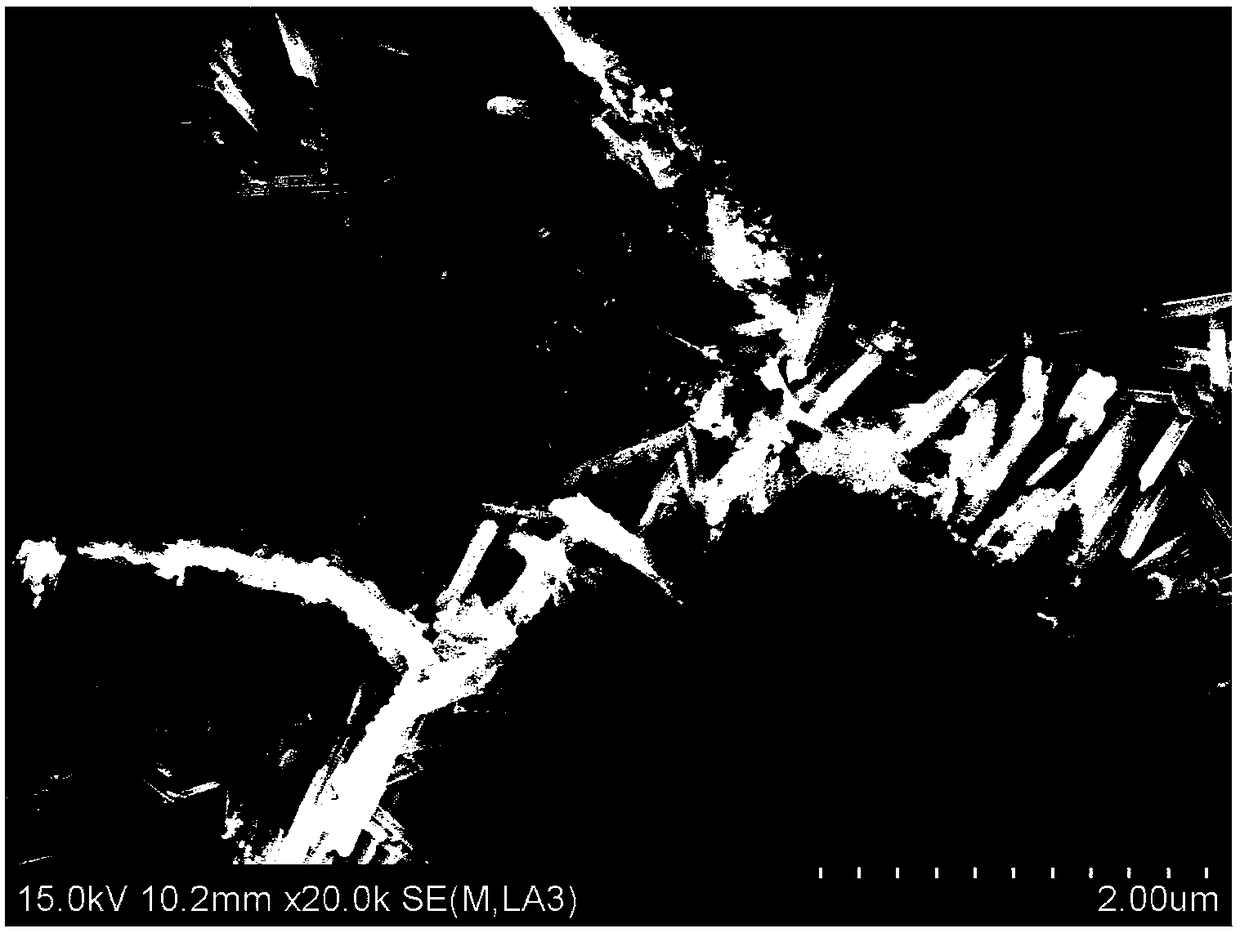

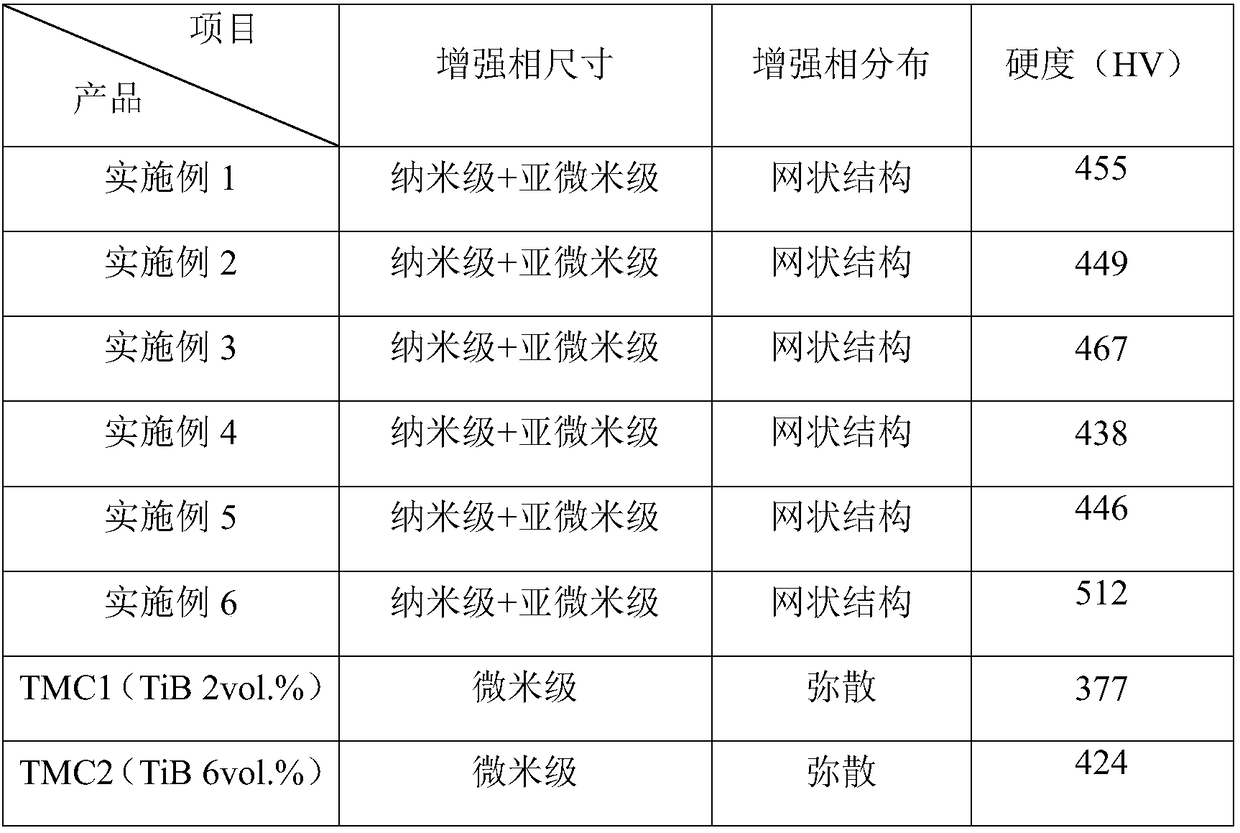

The invention relates to a reinforced phase regulation and control method for a TiB reinforcing titanium-based composite. The reinforced phase regulation and control method comprises the following steps that firstly, an electron beam technology is utilized to conduct melting treatment on the TiB reinforcing titanium-based composite; and then the melted composite is subjected to low-temperature aging treatment. According to the reinforced phase regulation and control method for the TiB reinforcing titanium-based composite, the nano-scale reinforced phase and the sub-micron TiB reinforced phasecan be obtained and distributed in a net structure, and the titanium-based composite has the excellent mechanical property.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

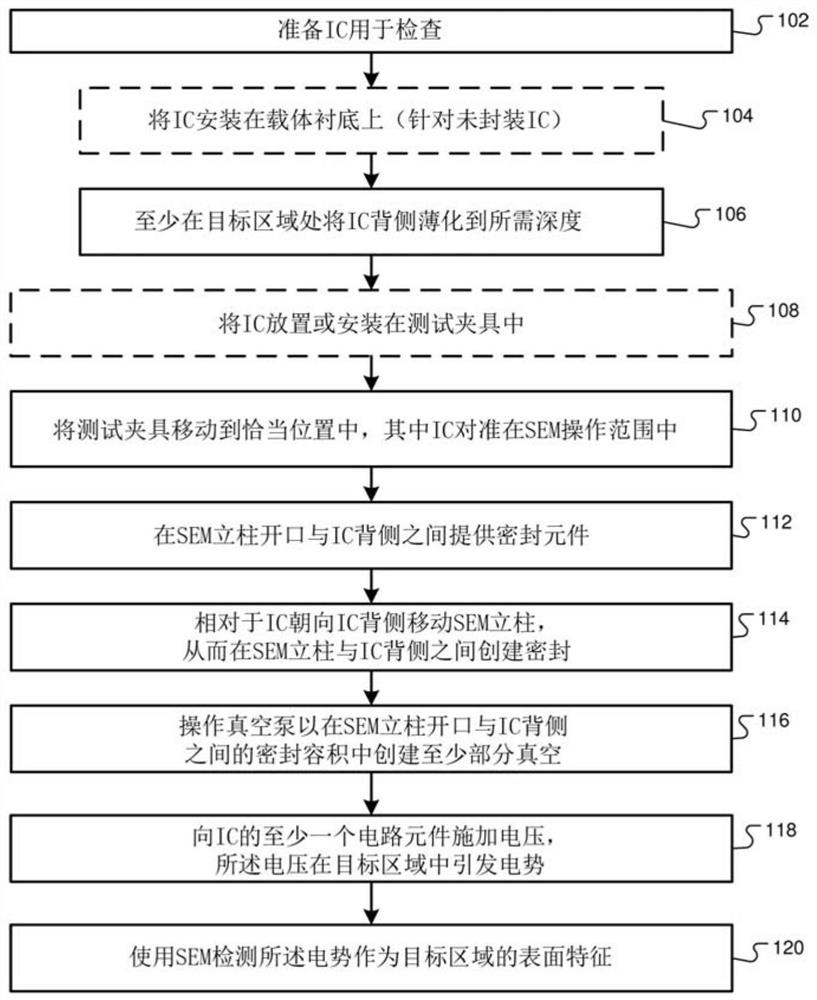

Integrated circuit analysis system and method with partially evacuated volume for electron beam manipulation

ActiveCN108226737BElectric discharge tubesIndividual semiconductor device testingElectron-beam technologyDevice material

The present invention provides new techniques for failure analysis in IC semiconductor devices, including methods for conducting electrical stimulation while a device under test (DUT) is being electrically stimulated or while the device is on its own or mounted in a circuit board or other module System design and methodology for implementing circuit probing using electron beam technology within an IC device under test (DUT) while simultaneously performing activities within a host system. The DUT may be a packaged IC or an IC in some unpackaged form. To create a localized evacuated volume immediately outside the electron beam tool, a sealing element is sealed against or around the DUT to obtain a localized seal. Such an arrangement eliminates the need for vacuum feedthroughs to the potentially thousands of signals required to operate and monitor the DUT, and further enables the DUT to be placed in its normal environment (such as mounted on a circuit board in its system) or The DUT is probed while operating on an error-free tester.

Owner:FEI CO

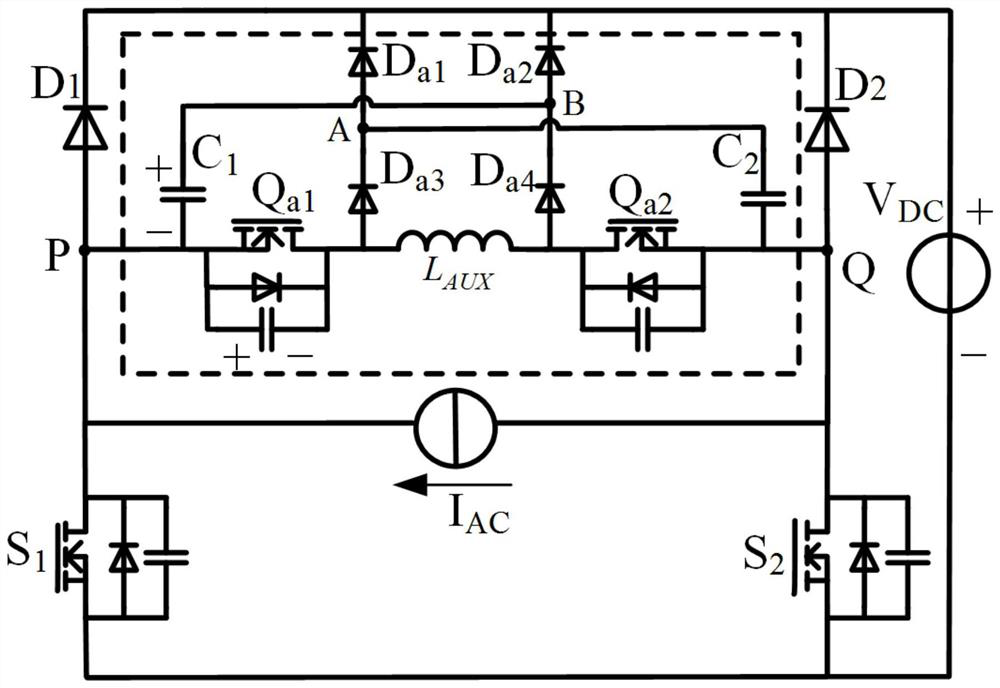

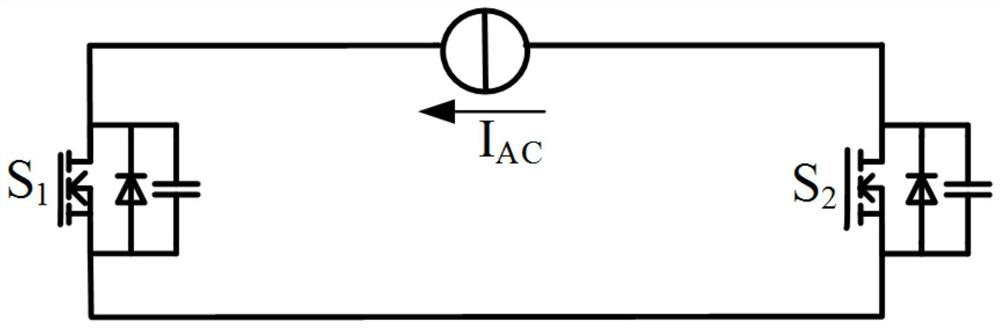

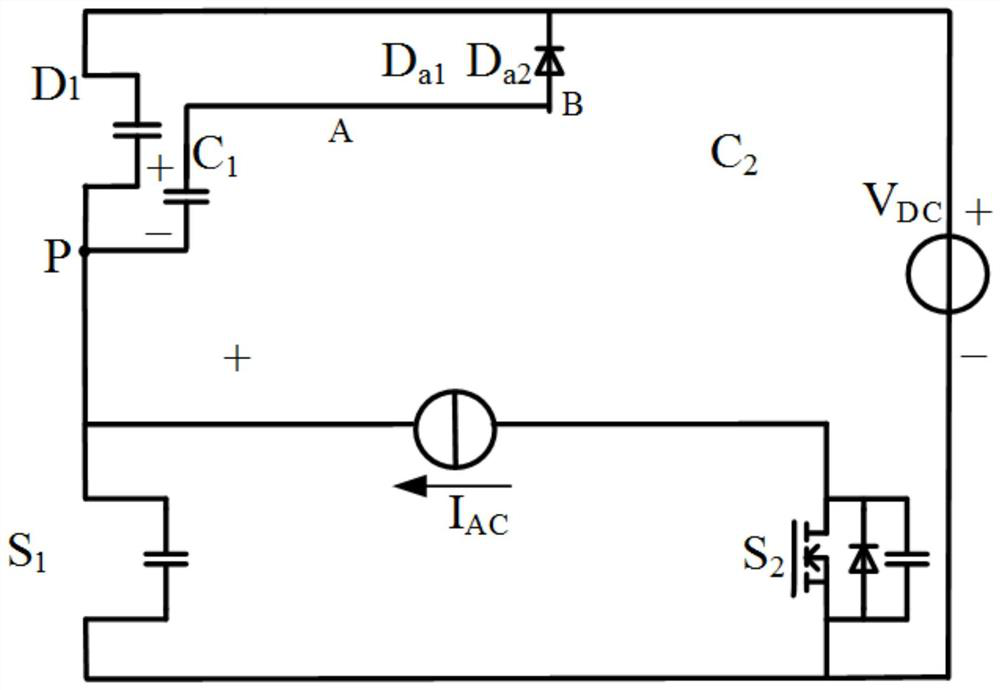

A bridgeless double-liter soft-switching rectifier with the lowest loss in the auxiliary circuit

ActiveCN111769754BImprove efficiencyReduced turn-off lossEfficient power electronics conversionAc-dc conversionCapacitanceSoft switching

The invention belongs to the technical field of power electronic conversion, and specifically relates to a bridgeless double-up soft-switching rectifier with the lowest loss in the auxiliary circuit, including a main circuit and an auxiliary circuit. The main circuit includes a first main switching tube and a first main rectifying diode , the drain of the first main switching tube and the anode of the first main rectifying diode are connected to point P to form the left bridge arm of the main circuit; the drain of the second main switching tube is connected to the anode of the second main rectifying diode The anodes are all connected to the Q point to form the right bridge arm of the main circuit; the source of the first main switching tube and the source of the second main switching tube are connected to the negative pole of the DC bus, and the first main rectifier diode Both the cathode and the cathode of the second main rectifier diode are connected to the anode of the DC bus. The invention realizes the zero-voltage turn-on of the main loop switch and the auxiliary loop switch, and the design of the absorbing capacitor reduces the turn-off loss and greatly improves the efficiency of the rectifier. The invention is used for rectification.

Owner:ZHONGBEI UNIV

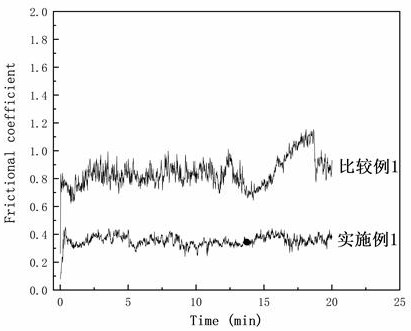

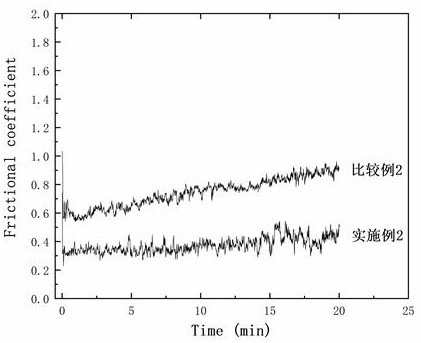

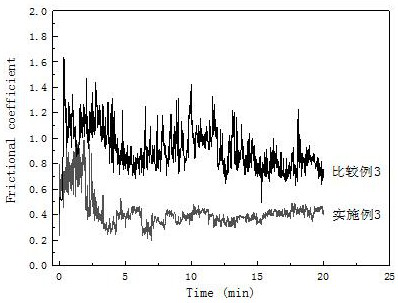

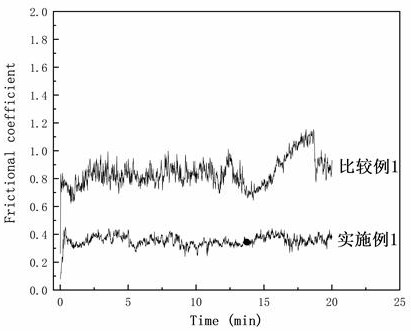

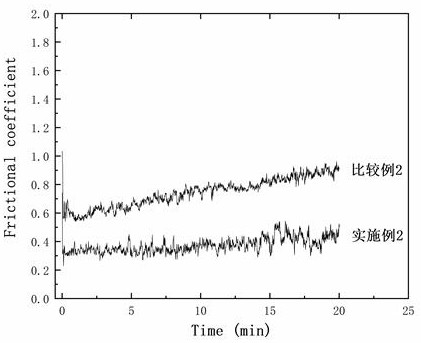

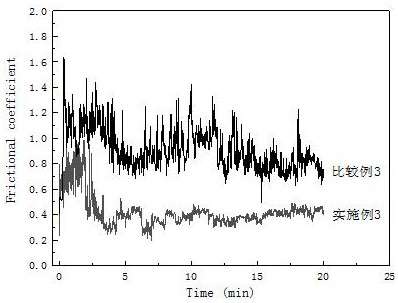

A method for preparing metal matrix composite coating on stainless steel surface

ActiveCN112779533BEasy to processImprove toughnessAnodisationMetallic material coating processesElectron-beam technologyElectron bunches

The invention discloses a method for preparing a metal-based composite coating on the surface of stainless steel. The method is to prepare a TiBCN coating on the surface of the stainless steel by means of synchronous powder feeding under the condition of an inert gas, and then use a strong current pulse to prepare a TiBCN coating. Electron beam technology uniformly polishes the laser cladding layer, and finally uses micro-arc oxidation technology to prepare an alumina ceramic layer with uniform thickness, so as to achieve high hardness and good wear resistance of the coating.

Owner:ZHONGBEI UNIV

A Hydrophobic Finishing Method of Cotton Fabric Based on Acrylate-Modified Silicon Ball-Electron Beam Technology

ActiveCN106758215BReduce energy consumptionReduce pollutionFibre treatmentEngineeringSilicon dioxide

Owner:高青如意纺织有限公司

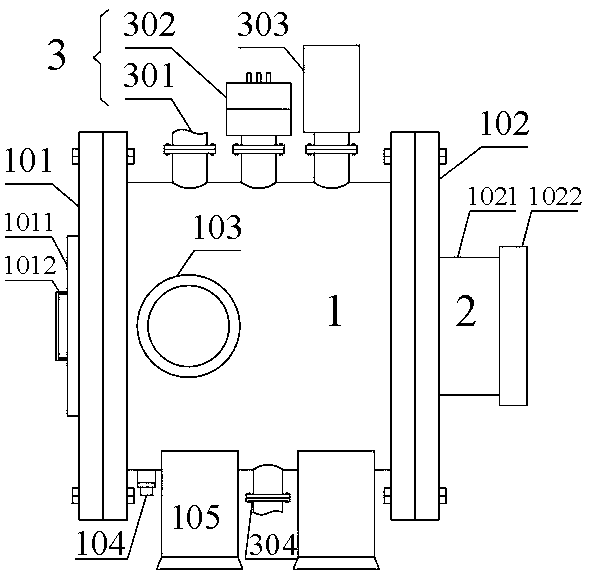

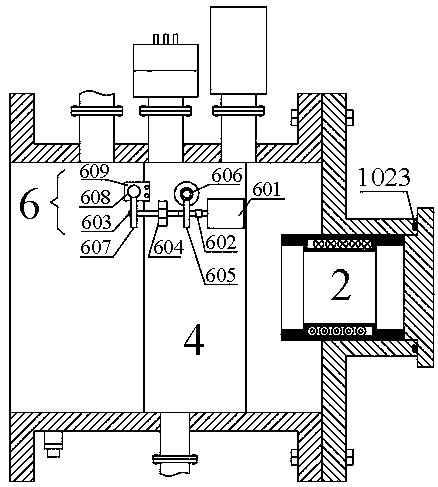

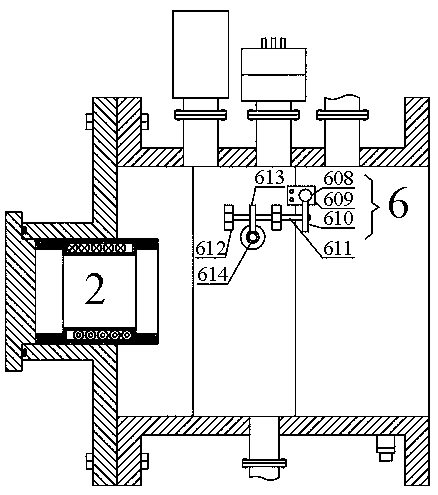

Metal plate surface treatment equipment

InactiveCN111394701AEasy to installEasy to assemble and disassembleVacuum evaporation coatingSputtering coatingElectron-beam technologyAlloy

The invention provides metal plate surface treatment equipment, and belongs to the field of metal non-cutting processing treatment. The metal plate surface treatment equipment comprises a sealing chamber, an electric spray gun, a vacuum device, an operating device, a carrier and a driving device. Based on mechanical automation and electron beam technology, the operating device, the carrier and thedriving device are used for driving a metal part to stably operate so as to fully receive electroplated particles to complete surface coating and surface alloying, and finally a stable alloy state isformed at the coating and the base of the metal part. The equipment can be widely applied to the fields of alloy sheets, metal precision machining and the like, and has the advantages of high automation degree, safety, reliability, no pollution and the like.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

Electron-beam physical vapor deposition process of preparing composite nano soft magnet and ceramic film

InactiveCN1265017CApplicable for evaporationHigh speed evaporation depositionVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionComposite film

In the electron-beam physical vapor deposition process, double evaporation source and double electron-beam are used to evaporate metal and ceramic rod and the rotation speed of the substrate and the evaporation rate of both metal and ceramic are regulated to obtain nano composite film with different components. Specially, the process includes setting N6 or W on ferro-silicon alloy and Fe-Ni alloy rod, setting alloy rod and ceramic rod in two crucibles separately, installing substrate, pumping to required vacuum rotating the substrate, heating the substrate, evaporating alloy rod and ceramic rod separately, opening the baffle to deposit and other steps.

Owner:BEIHANG UNIV

A method for hydrophobic finishing of cotton fabric based on acetic anhydride-acrylic ester-electron beam technology

ActiveCN105220475BLittle strengthSuitable for industrial productionVegetal fibresPolymer scienceAcetic anhydride

The invention discloses a cotton fabric hydrophobic finishing method based on acetic anhydride-acrylic ester-electron beam technology, belonging to the field of functional textiles. The method of the invention first adopts acetic anhydride to esterify cotton fibers, and then uses electron beams to treat cotton fabrics with acrylic ester reagents dissolved in alcohol solvents to obtain textiles with hydrophobic properties. Compared with alkanes and olefins solvents, the alcohol solvent used in the method of the present invention has the advantages of low toxicity, small irritation, and low cost. The method of the present invention can avoid environmental problems caused by perfluorinated hydrophobic additives, and electron beam irradiation can chemically combine fiber macromolecules and functional macromolecules, and the obtained product has good uniformity, repeatability, and low cost, and has no effect on fabrics. The damage is small, and this method can be used for the hydrophobic functional finishing of cotton fabrics.

Owner:高青如意纺织有限公司

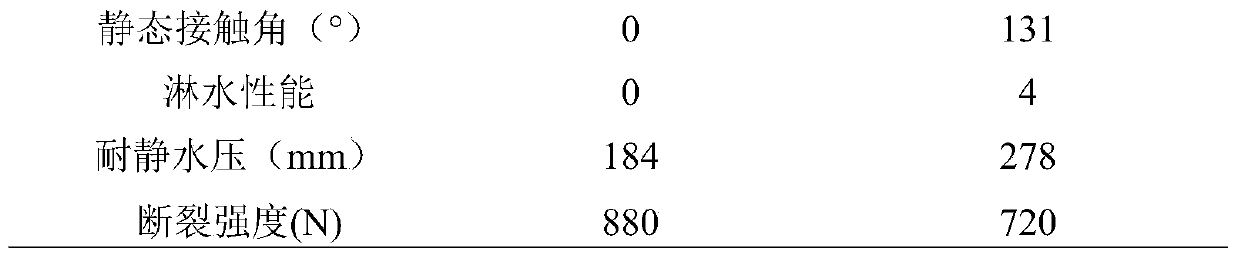

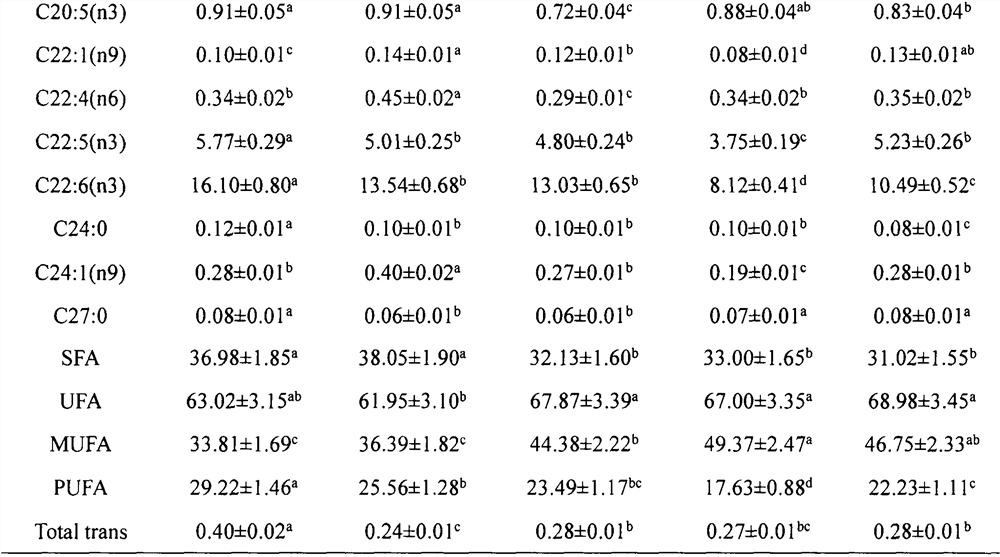

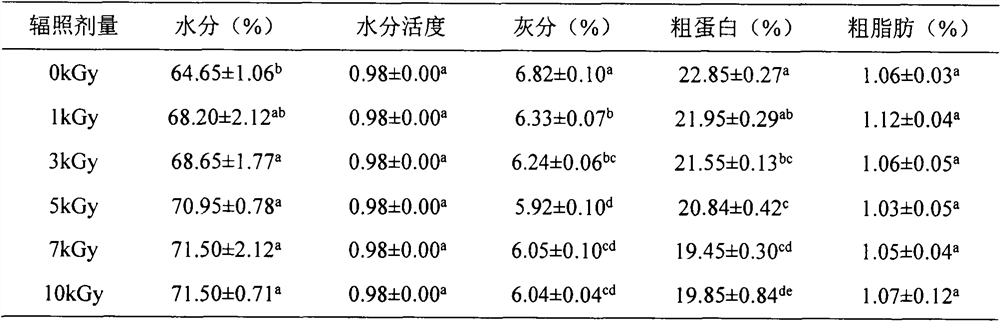

Method for improving fatty acid of frozen hairtail by using electron beam irradiation

PendingCN114304477AImprove fatty acid qualityHigh nutritional valueFood scienceNutritive valuesNutrition

The invention particularly relates to a method for improving fatty acid of frozen hairtail by using electron beam irradiation, which adopts a high-energy electron beam technology with the dosage of 1-7kGy to irradiate the frozen hairtail subjected to viscera removal, dicing and vacuum packaging, and finds that the irradiation effectively reduces the content of saturated fatty acid and trans fatty acid harmful to human health in the hairtail, and the content of fatty acid is reduced. And the content of unsaturated fatty acid beneficial to human health is increased. On one hand, the applied high-energy electron beam irradiation technology is an efficient, green and pollution-free processing technology, and the method is simple in process, environmentally friendly, free of residues and suitable for large-scale application; on the other hand, the technology can effectively improve the fatty acid quality of the hairtail, the nutritional value of the hairtail is improved to a certain extent, and a basis is provided for processing and application of related aquatic products. Considering from the aspects of energy conservation and nutritional quality, the optimal dosage of fatty acid suitable for improving frozen hairtail is 3kGy.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing metal-based composite coating on surface of stainless steel

ActiveCN112779533AEasy to processImprove toughnessAnodisationMetallic material coating processesOxide ceramicElectron-beam technology

The invention discloses a method for preparing a metal-based composite coating on the surface of stainless steel. The method comprises the steps that a TiBCN coating is prepared on the surface of stainless steel by a laser cladding technology in a synchronous powder feeding manner under the condition of inert gas, then, a laser cladding layer is uniformly polished by using a high-current pulsed electron beam technology, and finally, an aluminum oxide ceramic layer with uniform thickness is prepared by utilizing a micro-arc oxidation technology, so that high hardness and good wear resistance of the coating are realized.

Owner:ZHONGBEI UNIV

Integrated circuit design and manufacturing method and integrated circuit design system

ActiveCN106469235BPhotomechanical apparatusDesign optimisation/simulationElectron-beam technologyLayout

The invention provides an integrated circuit design and manufacture method and an integrated circuit design system. The integrated circuit design and manufacturing method includes: receiving an integrated circuit layout file; and performing a reverse electron beam technology process on the integrated circuit layout file to generate a final mask pattern, wherein the reverse electron beam technology process uses a single reverse electron Beam technology models to simulate a mask process as well as wafer process.

Owner:TAIWAN SEMICON MFG CO LTD

Method for guaranteeing quality of frozen hairtail by using electron beam irradiation

PendingCN114176112AMoisture unchangedConstant water activityFood freezingMeat/fish preservation by freezing/coolingElectron-beam technologyWater activity

The invention particularly relates to a method for guaranteeing the quality of frozen hairtail by utilizing electron beam irradiation, the method adopts a high-energy electron beam technology to irradiate the frozen hairtail which is subjected to viscera removal, dicing and vacuum packaging, and the preferable dosage suitable for the frozen hairtail is 1kGy from the aspects of energy conservation and shelf life prolonging. The dosage basically does not damage the nutritional ingredients of the hairtail, effectively inhibits the generation of trimethylamine in hairtail meat, inhibits the increase of volatile basic nitrogen in the storage process, and prolongs the storage period of the hairtail. On one hand, nutritional ingredients such as moisture, water activity and crude fat of the frozen hairtail are basically kept unchanged; on the other hand, the high-energy electron beam irradiation technology is utilized, so that the decay process of the hairtail can be efficiently slowed down in an energy-saving and pollution-free manner, and the shelf life of the frozen hairtail is prolonged to a certain extent. The method is simple in process, environmentally friendly, free of residues and suitable for large-scale application, the shelf life of the frozen hairtail can be effectively prolonged, and an application basis is provided for storage of related aquatic products.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com