Cotton fabric hydrophobic finishing method based on acrylics-modified silicon ball-electron beam technology

A technology of acrylic and cotton fabrics, which is applied in fiber processing, textiles and papermaking, etc. It can solve the problems of static contact angle of fabrics to be improved, achieve great social and economic significance, high energy utilization rate, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

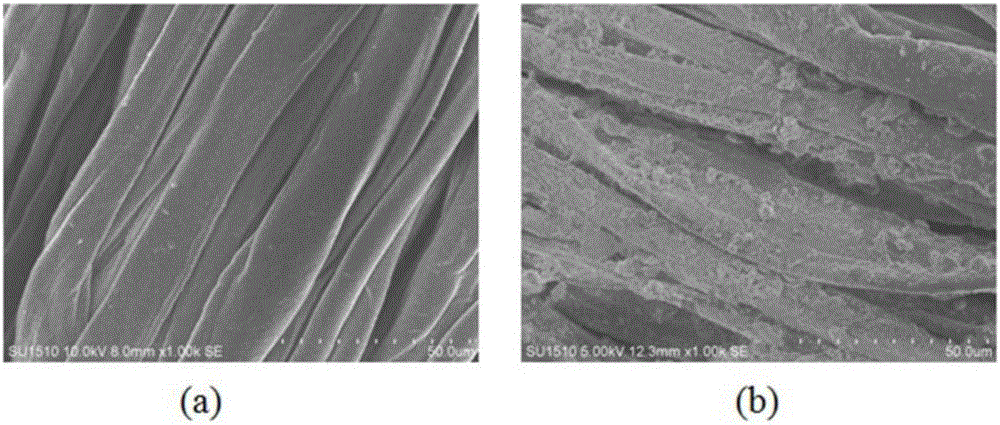

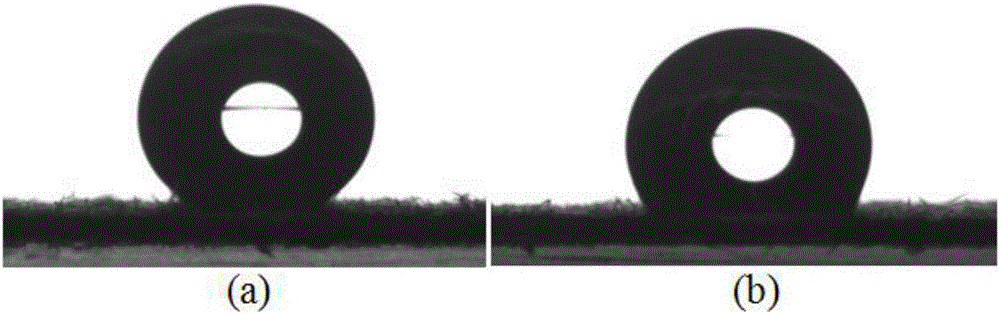

Method used

Image

Examples

Embodiment 1

[0028] Fabric: Cotton Woven (40 S ×40 S / 133*72)

[0029] prescription:

[0030] Octadecyl methacrylate (mass fraction): 5%

[0031] Modified silica balls: Vinyltrimethoxysilane modified silica balls

[0032] Modifier dosage: the mass ratio of modifier to silica balls is 6:1

[0033] Modified silicon sphere particle size: 100nm

[0034] Modified silica (mass fraction): 1%,

[0035] Solvent: The mass ratio of hexane to ethanol is 6:1

[0036] Dipping time: 5min

[0037] Surplus rate: 60%

[0038] Radiation: 16kGy

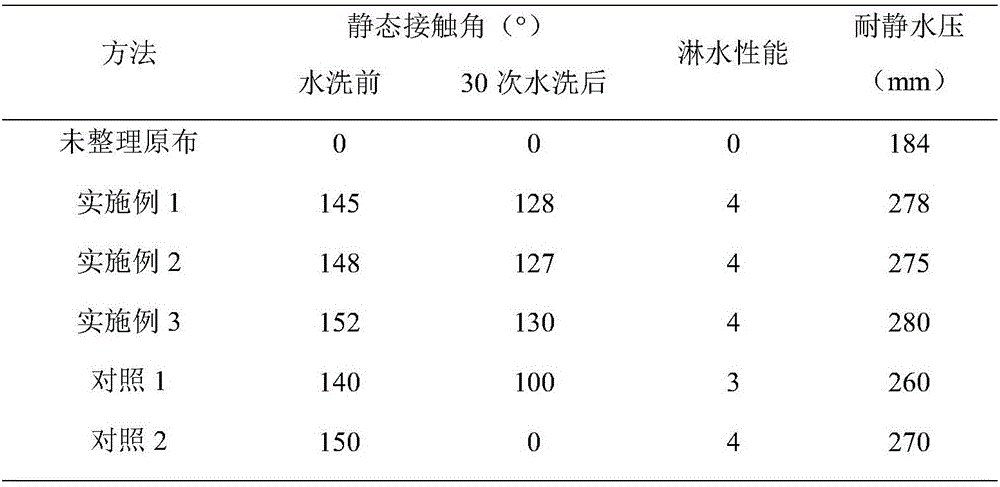

[0039] The properties of the treated fabric are shown in Table 1.

Embodiment 2

[0041] Fabric: Cotton Woven (40 S ×40 S / 133*72)

[0042] prescription:

[0043] Lauryl acrylate (mass fraction): 50%

[0044] Modified silica balls: vinyl triethoxysilane modified silica balls

[0045] Modifier dosage: The mass ratio of modifier to silica balls is 2:1

[0046] Modified silicon sphere particle size: 700nm

[0047] Modified silica (mass fraction): 5%,

[0048] Solvent: The mass ratio of hexene to ethanol is 1:1

[0049] Dipping time: 30min

[0050] Surplus rate: 200%

[0051] Radiation: 65kGy

[0052] The properties of the treated fabric are shown in Table 1.

Embodiment 3

[0054] Fabric: Cotton Woven (40 S×40 S / 133*72)

[0055] prescription:

[0056] Octadecyl acrylate (mass fraction): 30%

[0057] Modified silica balls: Vinyltrimethoxysilane modified silica balls

[0058] Modifier dosage: The mass ratio of modifier to silica balls is 4:1

[0059] Modified silicon sphere particle size: 200nm

[0060] Modified silica (mass fraction): 10%,

[0061] Solvent: The mass ratio of hexane to ethanol is 6:1

[0062] Dipping time: 5min

[0063] Surplus rate: 100%

[0064] Radiation: 43kGy

[0065] The properties of the treated fabric are shown in Table 1.

[0066] Control 1

[0067] Fabric: Cotton Woven (40 S ×40 S / 133*72)

[0068] prescription:

[0069] Octadecyl acrylate (mass fraction): 30%

[0070] Solvent: The mass ratio of hexane to ethanol is 6:1

[0071] Dipping time: 5min

[0072] Surplus rate: 100%

[0073] Radiation: 43kGy

[0074] The properties of the treated fabric are shown in Table 1.

[0075] Control 2

[0076] Fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com