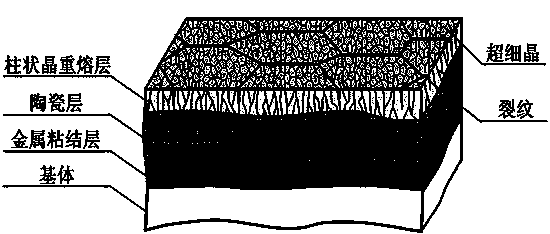

Thermal barrier coating material with closed surface layer and preparation method thereof

A technology of thermal barrier coating and surface layer, applied in coating, metal material coating process, melt spraying and other directions, which can solve problems such as loose and porous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] S1. Carry out pre-grinding, cleaning, and sandblasting roughening treatment on the superalloy substrate; according to the technical requirements of the sandblasting equipment, the sandblasting material is 60 mesh white corundum, the pressure is 0.4MPa, and the sandblasting distance is 120mm.

[0031] S2. Deposit a metal bonding layer Co23Cr13Al0.5Y on the surface of the roughened superalloy substrate by atmospheric plasma spraying to complete the preparation of the metal bonding layer. The thickness of the bonding layer is 160 μm; according to the requirements of atmospheric plasma spraying equipment, select The voltage is 38V, the current is 750A, the speed of the spray gun is 450mm / s, and the spraying distance is 85mm.

[0032] S3, using the method of atmospheric plasma spraying to deposit 8% Y on the surface of the metal bonding layer 2 o 3 Stable ZrO 2 For the ceramic surface layer, the preparation of the thermal barrier coating is completed, and the thickness of ...

Embodiment 2

[0038] Same as Example 1, only change the electron beam parameters in S4, select the electron beam energy as 27KeV according to the technical requirements of HCPEB equipment, and the energy density is 4J / cm 2 , the target-source distance is 15cm, and the sample is irradiated 5 times.

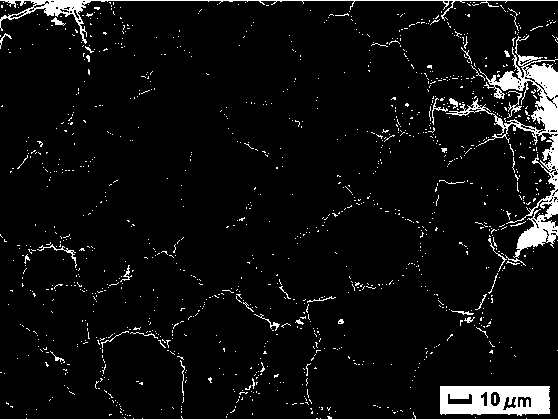

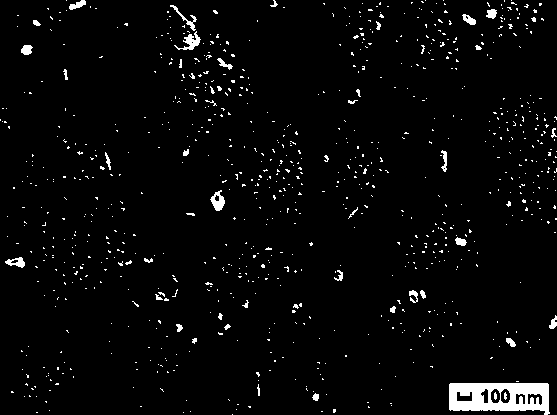

[0039] The surface and cross-section of the thermal barrier coating were observed by SEM; the results showed that after 5 irradiation treatments, the surface layer evaporated, and the grain grew, forming a larger grain structure with a size between 0.6 and 1.3 μm; A large number of gas-deposited particles can be observed in the fine-grained surface layer; in addition, only individual melting pits were observed after 5 bombardments; the number and width of network vertical cracks increased compared with 1 bombardment; the thickness of the remelted layer was between 2.5-4 μm between.

[0040] The surface roughness of the thermal barrier coating was analyzed by three-dimensional laser scanning mic...

Embodiment 3

[0043] Same as Example 1, only change the electron beam parameters in S4, select the electron beam energy as 27KeV according to the technical requirements of HCPEB equipment, and the energy density is 4J / cm 2 , the target-source distance is 15cm, and the sample is irradiated 10 times.

[0044] The surface and cross-section of the thermal barrier coating were observed by SEM; the results showed that after 10 times of irradiation treatment, the surface layer evaporated obviously, and the grain size was reduced compared with 5 times of bombardment, between 0.5 and 1.5 μm. A large number of gas deposition particles can be observed in the surface layer; in addition, the melting pit completely disappeared after 10 bombardments; the number and width of vertical cracks in the network increased compared with 5 times; the remelted layer is mainly composed of columnar grains, and the combination of columnar grains Tight; the thickness of the remelted layer is about 7~8μm.

[0045] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com