A method for hydrophobic finishing of cotton fabric based on acetic anhydride-acrylic ester-electron beam technology

A technology of acrylates and acetic anhydride pre-ester, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc. It can solve the problems that the hydrophobicity of fabrics cannot be improved, and low-surface substances cannot effectively cover fabrics, so as to avoid pollution and cost Issues, significant social and economic significance, reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

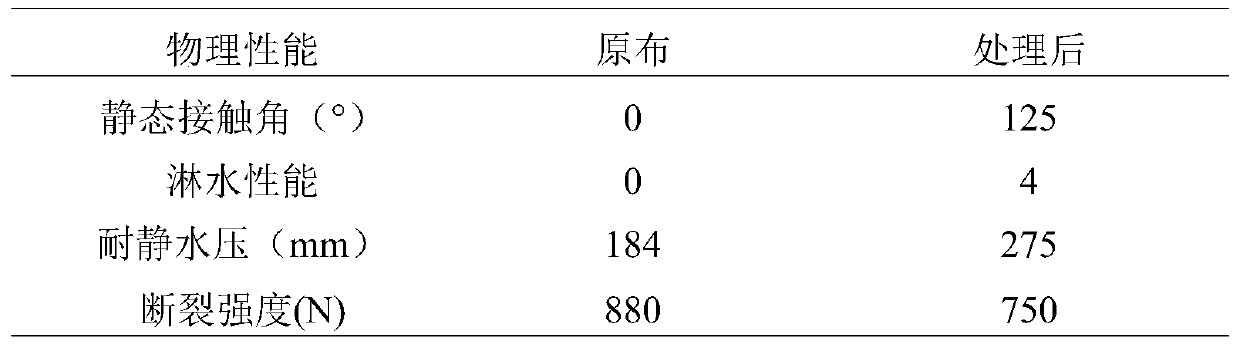

Embodiment 1

[0029] Fabric: pure cotton woven fabric (40S×40S / 133*72)

[0030] 1) Cotton fiber pre-esterified with acetic anhydride

[0031] Prescription: Acetic Anhydride

[0032] Iodine 2g / L

[0033] Bath ratio 1:25

[0034] Method: The cotton fabric is soaked in the above-mentioned acetic anhydride, and treated at room temperature for 2 hours. Reduction with saturated sodium thiosulfate until the dye solution is colorless, washed with water and dried for later use.

[0035] 2) After the cotton fabric is soaked in the organic solution containing acrylate compounds for 1 min, the excess solution is pressed by the paddle

[0036] Prescription: n-Hexyl Methacrylate: 20%

[0038] Method: The fabric is dipped and rolled in the reaction solution once, and the excess rate is about 60%.

[0039] 3) After electron beam irradiation, oven dry the fabric

[0040] Method: The irradiation dose is 33KGy, and the oven is dried at 105°C for 2 minutes after irradiation. ...

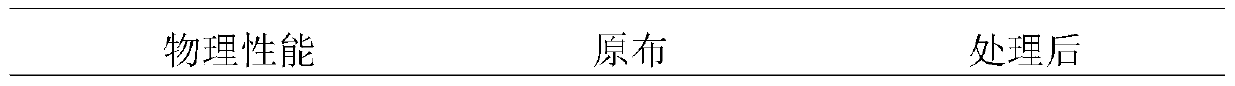

Embodiment 2

[0046] Fabric: pure cotton woven fabric (40S×40S / 133*72)

[0047] 1) Cotton fiber pre-esterified with acetic anhydride

[0048] Prescription: Acetic Anhydride

[0049] Iodine 1g / L

[0050] Bath ratio 1:25

[0051] Method: The cotton fabric is soaked in the above-mentioned acetic anhydride, and treated at room temperature for 3 hours. Reduction with saturated sodium thiosulfate until the dye solution is colorless, washed with water and dried for later use.

[0052] 2) After the cotton fabric is soaked in an organic solution containing acrylate compounds for 10 minutes, the excess solution is pressed by a paddle

[0053] Prescription: Stearyl Acrylate: 50%

[0055] Method: The fabric is dipped in the reaction solution once and rolled, and the rolling rate is about 100%.

[0056] 3) After electron beam irradiation, oven dry the fabric

[0057]Method: The irradiation dose is 45KGy, and the oven is dried at 60°C after irradiation.

[0058] Table 2...

Embodiment 3

[0064] Fabric: pure cotton woven fabric (40S×40S / 133*72)

[0065] 1) Cotton fiber pre-esterified with acetic anhydride

[0066] Prescription: Acetic Anhydride

[0067] Iodine 3g / L

[0068] Bath ratio 1:40

[0069] Method: The cotton fabric is soaked in the above-mentioned acetic anhydride, and treated at room temperature for 1 hour. Reduction with saturated sodium thiosulfate until the dye solution is colorless, washed with water and dried for later use.

[0070] 2) After the cotton fabric is soaked in an organic solution containing acrylate compounds, the excess solution is pressed by a paddle

[0071] Prescription: lauryl acrylate and n-octadecyl methacrylate (1:1g / g): 20%

[0072] Solvent: methanol + isopropanol + butanol (1:1:1)

[0073] Method: The fabric is dipped in the reaction solution once and rolled, and the rolling rate is about 100%.

[0074] 3) After electron beam irradiation, oven dry the fabric

[0075] Method: The irradiation dose is 65KGy, and the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com