Stress mitigation method for tc4 titanium alloy additive manufacturing components based on dual electron beams

An additive manufacturing, double electron beam technology, applied in the field of additive manufacturing, to achieve the effect of improving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

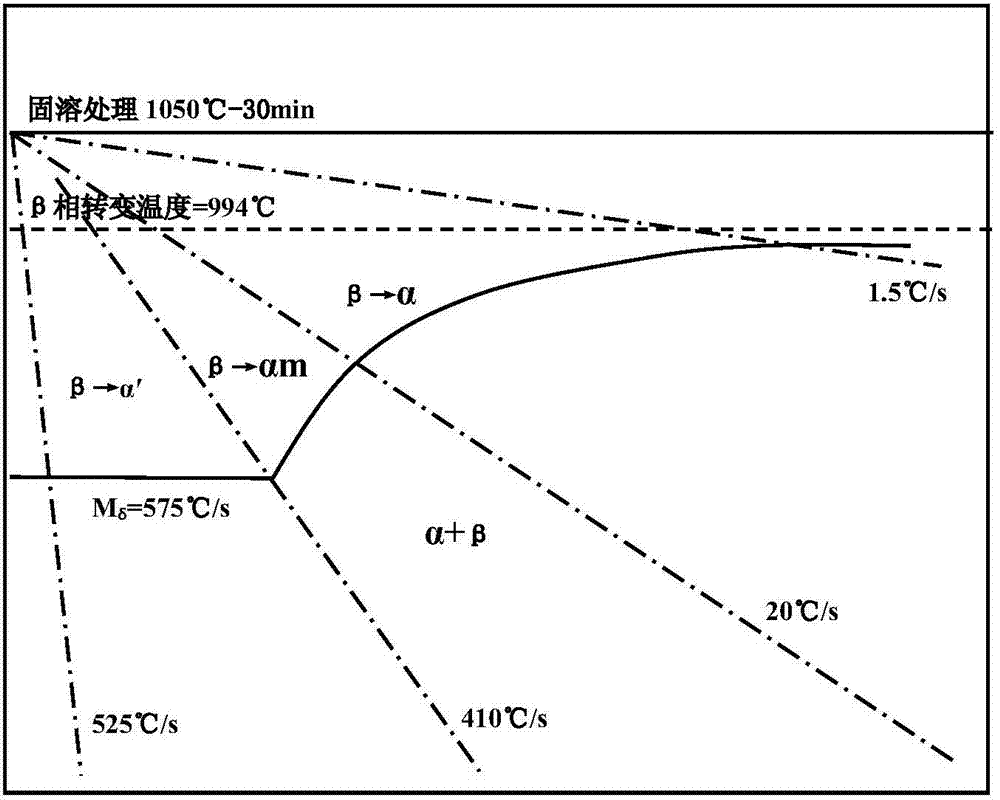

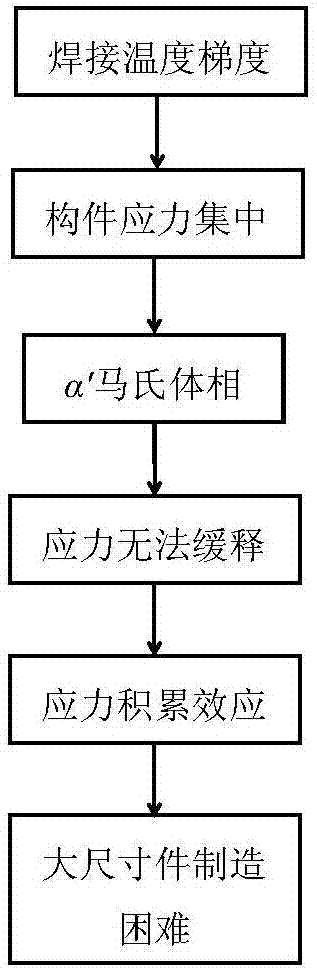

Problems solved by technology

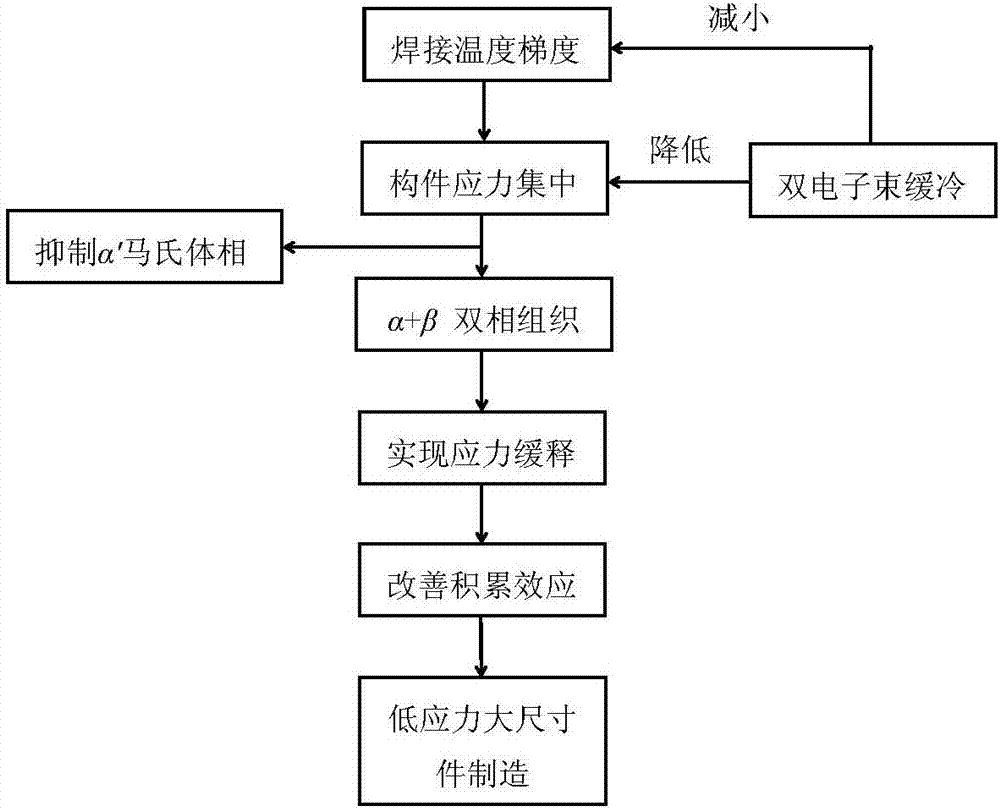

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0036] Embodiments of the invention (as attached Figure 4 , 5 shown)

[0037] 1. Establishment and correction of the dual electron beam temperature field model

[0038] Step 1. Before additive manufacturing, use the Marc finite element simulation software to establish a temperature field model for the dual electron beam additive manufacturing process by loading the thermophysical parameters, grid division, heat source, and boundary conditions of the TC4 titanium alloy.

[0039] Step 2. Weld the thermocouple 11 to the area near the cladding layer 7 on the TC4 base material substrate 8, and its output end is connected to the external temperature measuring device 13 through the plug of the flange 12 of the vacuum chamber 1, and then connected to the computer 14.

[0040]Step 3. Use the thermocouple 11 to collect the temperature of the additive manufacturing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com